Professional Documents

Culture Documents

Qchesco

Uploaded by

prosperity_174Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qchesco

Uploaded by

prosperity_174Copyright:

Available Formats

PROFILE COMPANY & PROJECT QUALITY CONTROL

HESCO JSC VIETNAM

Milestone 10 Ha Noi - Ha Dong road Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

QUALITY CONTROL TEAMWORK

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Project Quality Plan

Project Name:

Department: Focus Area: Product-Process:

FLAP GATE VALVES AND STOPLOGS FOR TDC

ISO & QUALITY CONTROL PROJECT OF TDC IN HO CHI MINH CITY DESIGN-MANUFACTURING-DELIVERY-INSTALLATION

Prepared By:

M. Tech. LY THANH HA Mobile 0912336758

Project Quality Plan Version Control

Version

B 0

Date

B 1

Author

B 2

Change Description

B 3

1

B 8

10/09/08

B 9

M. Tech. LY THANH HA

B 0 1

N/A

B 1

Chapter 1

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

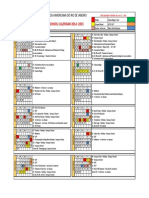

Chapter 1 LEGAL DOCUMENTS 1.1 GENERAL INFORMATION 1.2 FINANCIAL DATA 1.3 ORGANIZATION CHART 1.4 KEY PERSONNEL Chapter 2 PRODUCE PROCEDURES 2.2 FLAP GATE MANUFACTURING PROCEDURE 2.3 STOPLOG MANUFACTURING PROCEDURE Chapter 3 PROJECT QUALITY CONTROL 3.1 PROJECT QUALITY PLAN PURPOSE 3.2 QUALITY MANAGEMENT METHOD 3.3 PROJECT QUALITY ASSURANCE 3.4 PROJECT QUALITY CONTROL 3.5 PROJECT AUDITS & QUALITY REVIEWS 3.6 MANAGEMENT ESCALATION PLAN 3.7 QUALITY TEAM ROLES & RESPONSIBILITIES 3.8 QUALITY PLAN AUDIT LOG 3.9 QUALITY PLAN APPROVALS 3.10 DESIGNATION PROCEDURE Chapter 4 KEY PERSONELS FOR PROJECT Chapter 5 EQUIPMENT FOR PROJECT

5 5 6 9 10 12 14 14 16 17 18 18 19 19 24 27 29 30 31 31 32 33 34 34 36 36 Chapter 1 3

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

5.1 EQUIPMENT PROPOSED FOR THIS PROJECT 5.2 PICTURES Chapter 6 EXPERIENCES FOR PROJECT 6.1 LIST OF CONTRACTS EXECUTED FOR 5 LAST YEARS 6.2. PRODUCT PICTURES

38 40 43 43 44 49

Chapter 1

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Chapter 1

LEGAL DOCUMENTS

Chapter 1

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

1.1 GENERAL INFORMATION

1.1.1. Name of company: Hydraulic Equipment Joint Stock Company (HESCO) Address Tel No. Fax No. Email : : : : Milestone 10, Nguyen Trai Street, Ha Noi-Ha Dong 04.38544883 04.38544422 xnck2@yahoo.com

1.1.2. Period of development Hydraulic Equipment Joint Stock Company was established in 1963 under old name being Hydraulic Equipment Repair Plant. In 1996 it is changed into Hydraulic Equipment Repair & Manufacture Company according to the Decision 117/QD/TC-CB-LD of Minister of Ministry for Agriculture and Rural Development dated 16th July 1996. On 27th December 2002 it is changed into Hydraulic Equipment Joint Stock Company according to the Decision 5984/QD/TC-CB-LD of Minister of Ministry for Agriculture and Rural Development 1.1.3. Main lines of Business Repair, fabrication, renew, manufacture of hydraulic equipment; Repair of pump, motor, construction equipment;

1.1 GENERAL INFORMATION 6

Assembly, repair of electro-mechanical equipment of pumping station, hydropower station, overhead crane, penstock (pressure pipeline) for hydraulic, agriculture, processing of product of agriculture and forestry; Construction and installation of small & medium pumping stations and hydropower stations;

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Construction and installation of irrigation, agriculture & rural development Works; Construction of Works of supplying water, irrigation channels, dykes infrastructure development Works; Construction & installation low & medium voltage; Manufacture and installation of steel structure; workshop frame, microwave column, high tension column; Cast, zinc coating; Construction of hydropower works, rural infrastructure, civil works; Trade of house, hotel, tourist; hire of office, storing area, workshop; Local travel and tourist services; Consulting, design of mechanical equipment for hydraulic works, hydropower works Trade of materials as steel, industrial equipment, machines.

1.1.4. Charter capital: Charter capital : 12.000.000.000 VND

In which capital of the State is 5.520.000.000 VND 1.1.5. Main Managers Chairman Director : Le Van An : Nguyen Huy Quan

1.1 GENERAL INFORMATION 7

Deputy Director (Technical management): Do Cong Ba Deputy Director (Financial management) : Tran Van Thai Head of Technical Department : Nguyen Thi Dao

Head of Admistration & personnel dept : Nguyen Gia Cu

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

1.1.6. Time and experience of activities Item No. 1 Experience of activities Time

Repair, fabrication, renew, manufacture of hydro-mechanical From 1976 equipment for irrigation and rural works Assembly, repair of electro-mechanical equipment of From 1980 pumping station, hydro-power station, overhead crane, penstock (pressure pipeline) for hydraulic, agriculture, processing of product of agriculture and forestry Design, manufacture, installation of steel structure, hydro- From 1990 mechanical equipment such as sluice gates, spillway radial gates, automatic gates, trash rake machine, penstock, lifting mechanism devices such as hoist, overhead cranes, gantry cranes with capacity from 10-100T for agriculture, irrigation, hydropower works

Hanoi, dated 10th October, 2008 On behalf of Hesco

1.1 GENERAL INFORMATION

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

1.2 FINANCIAL DATA

1.2.1. Summarize actual assets and liabilities in VND for last three years

Unit: Vietnam dong

Item 1. Total Assets 2. Working Assets 3. Total Capital 4. Short Item liability 5. Total revenue 6. Profit before taxes 7. Profit after taxes

Year 2004 38.814.761.493 34.661.413.974 32.126.502.310 31.477.351.310 27.971.394.177 1.099.385.677 1.099.385.677

Year 2005 60.669.679.051 33.879.000.121 53.176.901.077 52.966.901.077 39.251.965.284 1.552.242.119 1.334.928.222

Year 2006 80.804.094.781 57.450.543.907 59.254.970.203 46.620.417.320 53.662.985.053 2.332.457.615 1.679.369.483

1.2.2. Total credit amount and name of Bank providing credit 1. Name of Banks providing credit: Thanh Xuan Industrial & Commercial Branch of Vietnam Bank Address: 275 Nguyen Trai Street, Ha Noi City 2. Exchange of Bank for Investment & Development of Vietnam Viet Nam International Bank, Ha Dong Branch Total credit amount: 80.000.000.000 VND (Eighty billion Vietnam dong)

Hanoi, dated 10th October, 2008 On behalf of Hesco

1.2 FINANCIAL DATA

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

1.3 ORGANIZATION CHART

Organization apparatus of company includes: Five (05) departments: + Admistration & Personnel Department + Financial Department + Technical Planning Department + Business Department + ISO & Quality Control Department Five (05) factories + Mechnanical Factory No.1 + Mechnanical Factory No.2 + Mechnanical Factory No.3 + Mechnanical Factory No.4

1.3 ORGANIZATION CHART 10

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

+ Mechnanical Factory No.5 Total workforce of company is 234 persons. Professional staffs are 55 persons in which: Machine manufacture engineers Electrical engineers Construction, hydro-construction engineers Financial economic bachelors Economic middle-ranking executive Technical workers + Turner, miller, planer, grinder + Fitter, caster, painters, forgers + Welders + Installer, mechanical repairer + Workers of electrical construction + Workers of construction and installation of irrigation and hydropower project + Driver : 05 persons : 23 persons : 05 persons : 09 persons : 15 persons : 03 persons : 179 persons : 19 persons : 26 persons : 35 persons : 35 persons : 14 persons : 45 persons

Hanoi, dated 10th October, 2008 On behalf of Hesco

1.3 ORGANIZATION CHART 11

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

1.4 KEY PERSONNEL

Date of birth 1959

Years of experience in proposed position

Position 1. Managing Director 2. Deputy director 2.1. Head of Technical planning dept

Full name Nguyen Huy Quan Do Cong Ba Nguyen Thi Dao

Experience General management in business of company Being in charge of technique and production - Managing in design and designing supervise. - Manage and coordinate material and equipment for the works Manage directly in production

20

1953 1952

25 30

2.2. Production division Director of Machnanical Factory No.1 Nguyen Hong Phu 1953

Being in charge of manufacture and installation of lifting equipment such as hoist, overhead crane, gantry crane,etc Being in charge of manufacture and installation of types of gates as stoplog, spillway gates, automatic gates, flap gate, roller gates...etc Being in charge of manufacture and installation of penstock (pressure pipeline) Being in charge of manufacture and installation of electrical equipment as generator, lighting system, low and high voltage system for hydraulic works and hydropower works. Being in charge of manufacture

15

Director of Machnanical Factory No.2

Nguyen The Hieu

1973

10

Director of Machnanical Factory No.3 Director of Machnanical Factory No.4

Bui Van Hoa Nguyen Trong Lan

1956

20

1959

20

1.4 KEY PERSONNEL 12

Director of

Lai Quoc

1956

13

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Position Machnanical Factory No.5

Full name Sy

Date of birth

Experience and installation of equipment as trash rake machine, gates, agriculture equipment for food processing.

Years of experience in proposed position

3. Deputy director 4. Administration division

Tran Van Thai Nguyen Gia Cu

1949 1956

Being in charge of finance Being in charge of administration and personnel of company

25 30

Hanoi, dated 10th October, 2008 On behalf of Hesco

13

1.4 KEY PERSONNEL

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Chapter 2

PRODUCE PROCEDURES

14

Chapter 2

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

2.1 CAST IRON MOLDING PROCEDURE

15

PRODUCE PROCEDURES

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

2.2 FLAP GATE MANUFACTURING PROCEDURE

16

2.2 FLAP GATE MANUFACTURING PROCEDURE

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

2.3 STOPLOG MANUFACTURING PROCEDURE

17

2.3 STOPLOG MANUFACTURING PROCEDURE

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Chapter 3

PROJECT QUALITY CONTROL

18

Chapter 3

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

3.1 PROJECT QUALITY PLAN PURPOSE

The purpose of this Quality is: To provide the guidelines and methods necessary for planning, organizing, implementing, monitoring and auditing the Quality Program. To ensure that all activities for which HESCO and TDC is responsible are constructed, inspected, tested and maintained in compliance with the contractual scope of works and applicable documents. To achieve this objective, the methods and controls described in this Quality Assurance Manual are established. They are implemented at predetermined points, as necessary to prevent, detect and correct deficiencies and to document achieved quality. To discover and prevent unsatisfying points (flaws) in producing process, makr sure that all products which are supplied for the project to meet the quality according to the annouced standards.

3.2 QUALITY MANAGEMENT METHOD

Quality management method is the way to manage, operate labours, equipment, materials in our company to implement checking, making reports of product quality in the project according to the issued standards. Managing project quality requires an approved quality plan encompassing three major quality processes defined in Section 3.1. The quality plan is developed and approved during the project planning phase to confirm major deliverables/milestone acceptance criteria and manage approved project processes. 3.2.1. Quality Plan Processes

Quality Assurance Quality assurance activities focus on the processes being used to manage and deliver the solution to evaluate overall project performance on a regular basis. Quality assurance is a method to ensure the project will satisfy the quality standards and will define and record quality reviews, test performance, and customer acceptance. PROJECT QUALITY CONTROL 19

Quality Control

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Quality control activities are performed continually to verify that project management and project deliverables are of high quality and meet quality standards. Quality assurance also helps uncover causes of unsatisfactory results and establish lessons learned to avoid similar issues in this and other projects.

Project Deliverables and Processes Acceptance Criteria Project team members and key stakeholders agree at the project planning stage on formal project processes and major deliverable acceptance criteria that will be used to evaluate final deliverable results before the results are formally approved.

3.2.2. Project Overview Waste water treament project in Ho Chi Minh City, Thi Nghe sluice, includes 43 rectangular flap gates from 0,8m x 0,8m to 3,0m x 2,5m. The least weight of gate is 784,3kg and most weight is 7625, 5kg. The biggest overall dimension of valves is 3465 x 3514 x 830mm. Total weight of flap gate valve is 154.263kg. All flap gate valves are designed according to AWWA C501-80 standard. The project also includes stoplogs made from stainless steel ASTM A276 from 6 to 12mm thickness. All stoplogs is complexed from 2 to 5 logs with the maximum dimension is 3144x505, and the biggest weight of log is 389kg. Hesco will make a system for testing, checking all process from buying materials, machining, assemblying, installation at factories, and test according to the following flowchart:

20

3.2 QUALITY MANAGEMENT METHOD

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

21

3.2 QUALITY MANAGEMENT METHOD

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

3.2.3. Quality Standards Applied standard for flap gates: 1. ASTM A126 Standard Specifications of cast iron, class B 2. ASTM B21 C464 Standard Specifications of Neoprene and NBR seals 3. ASTM B584 C865 Standard Specifications of Copper Alloy Sand Castings For General Applications 4. ASTM A276 Standard Specifications of type 316 stainless steel, ANSI/AWWA C501-80 AWWA standard for gates a. Design standards b. Reference materials c. Equipment d. Paint e. Manufacture f. Checking, testing

g. Installation h. Transportation Applied standard for stoplogs: 5. ASTM B21 C464 Standard Specifications of Neoprene and NBR seals 6. ASTM A276 Standard Specifications of Stainless steel 7. ANSI/AWWA C501-80 AWWA standard for sluice gates 3.2 QUALITY MANAGEMENT METHOD 22 i. j. Design standards Reference materials

k. Equipment l. Paint

m. Manufacture n. Checking, testing o. Installation p. Transportation

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

3.2.4. Quality Tools To ensure quality for the project, we use the following tools: 1. Sonic tester for welding 2. Welding ruler 3. Stainless steel tape ruler 5m long 4. Calipper 0,02mm accuracy class 5. Palme 0,01mm accurecy class 6. Adjustment ruler 7. Leakage test bench for flap gates and stoplogs which are design for the project only 3.2.5. Quality Managers Responsibilities HESCO has adopted, and is committed to a quality system with the aims to conform to contractual requirement and providing consultant with confidence that the products and services provided are fit for their intended purpose. It is part of HESCOs consolidation and constant development to carry out and maintain quality to effect clients expectation of optimum price, timely delivery and fulfillment of contractual specification. The policies and guidelines described in this manual are mandatory. The Management is responsible for Quality Assurance irrespective of whether quality specialists of quality section are established. In arriving at decisions, the quality and personal integrity of staff are of fundamental importance and management shall ensure that each person: Everyone understands that quality assurance is important. Know how to assist in the achievement of adequate quality. Is stimulated and encourage doing so. This Quality Assurance Manual has been accepted and approved by the Management. The leader of Quality Control for the project is M. Tech. Lee Thanh Ha who have 15 experienced years in water hydraulic products. The leader of Manufacturing Control, Supervisor is The Chief of Engineer, Mr. Ta Khac Ap, who is 30 experienced years in manufacturing, machining, design, testingwater hydraulic product. A process of manufacturing will deliver to a team leader in factories who is a supervisor directly through the process, checking, testing for each part. 3.2 QUALITY MANAGEMENT METHOD 23

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

3.3 PROJECT QUALITY ASSURANCE

Quality assurance helps to establish if a deliverable is acceptable based on the processes used to create it. Quality assurance processes are used to evaluate overall project performance frequently and to determine that quality reviews were held, deliverables tested, and customer acceptance acquired. 3.3.1. Quality Assurance Procedures

24

3.3 PROJECT QUALITY ASSURANCE

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

3.3.2 Project Monitoring Processes After signing the contract with sub-contractor or supplier, project manager will set up a detail project quality control from buying materials, step-by-step, to machining, installation to each team. Each procedure will give responsibilities of team, personels and interlink together. Team of material for buying and pre-test materials, making plan to buy materials Team of pre-machining or welding for preparing raw foils, plates,sheets according detail drawing Team of machining to milling surfaces of cast iron pieces, pivotlugs, link arm Team of assemblying to assemble parts becomes complete products Team of test for testing leakage and making certificates, 3rd test certificates Team of quality control Team of logistics for transportation, insurance and delivery the goods

3.3.3. Project In-Process Quality Monitoring A store keeper will check input importing materials by tools with accurrecy 0, 05 for plates or sheets: o Width, length, thickness, certifacate of origin, certificate of content

by visual with/whitout ruler on surfaces for cast iron: o Surfaces of cast iron pieces, geometric telorances, clearances of contact surfaces

by supersonic tester for important pices from cast iron: o Internal structure of pivotlugs

by palme 0,02mm; calip up to 0,01mm for machining parts: o Surfaces of machined parts 3.3 PROJECT QUALITY ASSURANCE 25

by calibrator, lamp: o Clearances of seating faces and seats, seals and seats

by test bench with pumps, valves o Leakage of complete flap gates, stoplogs

by thickness tester:

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Painting layer thickness, adhension of painting by A-X cutting method

Acceptant test for input materials: 1. Stainless steel ASTM A276 For example: Engineer will check the equivalent code of stainless steel material baesd on certificates which are notarised by suppliers or contractor: AS2837-1986-316L; AISI TYPE 316L; BS970-316 S11 & S13; ASTM A276-316L W.Nr 1.4404 X2CrNiMo17 13 2; W.Nr 1.4435 X2CrNiMo 18 14 3 The contents are follows: Content Min (%) Max (%) C 0 0,03 Si 0 1 Mn 0 2 Ni 10 14 Cr 16 18 Mo 2 3 Ni 0 0,1 P 0 0,045 S 0 0,03

Every procedure will be the same for other materials and parts 2. ASTM A126 Standard Specifications of cast iron, class B 3. ASTM B21 C464 Standard Specifications of Neoprene and NBR seals 4. ASTM B584 C865 Standard Specifications of Copper Alloy Sand Castings For General Applications 5. ASTM A276 Standard Specifications of type 316 stainless steel, 6. ASTM B21 C464 Standard Specifications of Neoprene and NBR seals 7. ASTM A276 Standard Specifications of Stainless steel Acceptant test for welding: 1. ASME Acceptant test for leakage measurement: 8. ANSI/AWWA C501-80 AWWA standard for sluice gates 3.3 PROJECT QUALITY ASSURANCE 26

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

3.4 PROJECT QUALITY CONTROL

3.4.1. Project Deliverables Testing is includes test of materials, welding submerge and/or electrodes and/or wires, cast iron pieces, telorances, bolts, clearances, seals, leakages, surfaces quality, thickness of paint, adhension of painting according to the following table: Milestone Test of plates / sheets for a lot of container Deliverable Test of welding submerge, electrodes, wires Test of cast iron pieces Test of telorances, geometric parameters Checking namplates, sign, certificates of contents, origin. Checking thickness with symmetric telorances. Making test content to ASTM standards, a sample per a lot. Weight of welding electrodes to discover humidity content Codes of wires, electrodes. Status of welding material pakages. Quantitive analysys of content before refining cast iron. Checking flaws of cast iron pieces. Checking telorances to machine. Cheking thichness of covers, seat, seating faces with symmetric telorances. Checking roughness of seating faces, machined faces of coversnot under Rz80; bushes is not under Rz40, clearances of link arm and pivotlugs/link arms and cover holes up to 0,1mm accuracy, dimensions between bolt holes not up to 0,1mm. Checking the length of bolts, clearances bolts and screws, quantity, types for each product. Checking material certificates Checking co-linear of seals not bigger than 0,5..1mm/m depending on each length Checking leakage of complete flap gate valves or stoplogs+groove not exceed 0,02Lpm/m (0,1 gpm/ft) 3.4 PROJECT QUALITY CONTROL 27

Test of bolts

Test of seals

Test of leakage through welding line

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Milestone

Deliverable Checking dimension of width, length of welding line according to ASME section XIII Checking quality of surfaces after sand blasting spray process exceed Sa2.5; Checking by compararative method with sample according to BS7079 part A1 supplement 1: 1989. Checking the thickness of dryed paint layer according to SSPC-PA2 or ISO 2808 Checking by A-X cutting method and sticking-plater tape 30x75mm according to ASTM-D 3359-2

Test of blasting method

Test of paint thickness

Test of adhension of painting

3.4.2. Project Quality Control Procedures List the major quality control activities and processes that this project will include: Test procedures for materials Test procedures for welding Test procedures for sand blasting Test procedures for painting Test procedures for supersonic test of welding Test procedures for leakage Procedures for package or transportation Procedure for installation Procedure for test at side 3.4 PROJECT QUALITY CONTROL 28

3.4.3. Project Deliverables Test & Acceptance Process The planned test and acceptance processes that will be used to validate project deliverable quality, and these processes will verify deliverable quality. Test of materials: o Test stainless steel materials, welding rod/wires/flux, paint with certificates from suppliers or sub-contractor;

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

o -

Test certificates by Hesco for non-standard products buy from market.

Test of cast iron pieces: o o Test mechanical and/or chemical properties of cast iron; Quality certificates for all cast iron parts;

Test of dimensions: o o Internal test report of dimensions, telorances of mechanical parts after machining; Assembly test report of complete part units

Test of welding: o o Test report of ultrasonic result Final test report for mechanical properties of welding

Test of paint and/or sand blasting works: o o Test report of adhension of painting by A-X cutting method Report of cleaning result, final painting

3.4.4. Project Deliverables Acceptance Criteria The deliverable quality acceptance criteria based on quality standards for project deliverables as the criteria will be used in acceptance testing. The standards of criteria will be used to assess project quality: Test of steel mechanical properties according to ISO 6892-1998; Test of steel chemical properties according to ASTM E415-95; 3.5 PROJECT AUDITS & QUALITY REVIEWS 29 Mechanical test according to AWS D1.1.; Cleaness test of steel sheet according to ISO 8501-1-1988; Test for manufacturing and assemblying of stoplogs and flap gates according to AWWA C501-80; Ultrasonic test for welding according to ASTM section XIII; Leakage test according to AWWA C501-80 section 7;

3.5 PROJECT AUDITS & QUALITY REVIEWS

Identifying of the project quality audits and reviews that will be performed. The results of these audits and reviews will be factored into project planning and implementation. The process of lessons-learned reviews and those lessons can benefit the project team as the project continues.

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Project Quality Audit Review

B 4

Planned Date

B 5

Quality Review Auditor

B 6

Comments

B 7

Manufacturing flap valves and stoplogs from 0,8x0,8 to 1,2x1,2m

B 2 1

3 month ARO

B 8 1

Project manager

B 9 1

QC leader

B 0 2

Foundry

B 3 1

Head of Technical Department

B 1 2

Machining

B 4 1

Assemblying

B 5 1

Finishing

B 6 1

Test

B 7 1

Manufacturing flap valves and stoplogs from 1,5x1,5 to 3x2,5m

B 2

5 month ARO

B 8 2

Project manager

B 9 2

QC leader

B 0 3

Foundry

B 3 2

Head of Technical Department

B 1 3

Machining

B 4 2

Assemblying

B 5 2

Finishing

B 6 2

Test

B 7 2

3.6 MANAGEMENT ESCALATION PLAN

The plan for escalating unresolved quality noncompliance issues up the management chain. The standard initial level of escalation is from the project manager to their immediate manager. Escalation Level Mechanical engineer Metallurgy engineer Mechanical engineer Mechanical engineer Mechanical engineer Mechanical engineer Mechanical Management Title Ordering of raw materials,welding materials Test and receiving cast iron pieces from Minh Bach foundry company Machining parts of flap gates Forming parts of stoplogs Order of standard procducts: bolts, screws, seals Assemble of flap gate units and logs 3.6 MANAGEMENT ESCALATION PLAN 30 Name

Finishing of flap gate valves and stoplogs Test

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Escalation Level engineer

Management Title

Name

3.7 QUALITY TEAM ROLES & RESPONSIBILITIES

Identifying of quality-related responsibilities of the project team and list specific task-related quality responsibilities, including responsibility for specific acceptance tests and project audits. Project Team Role QC Team QC Team QC Team QC Team QC Team QC Team leader QA Responsibilities QC Responsibilities Test of input raw materials Test of cast iron pieces Ultrasonic test Test of telorances Leakage test Finishing test

3.8 QUALITY PLAN AUDIT LOG

List all quality-related issues and resolutions resulting from quality plan audits and reviews. Quality Review Date

7-10 days after sign the contract/order/renew -order

B 2 3

Activity Reviewed

Checking materials: stainless steel, welding flux, wires, rods

B 3

Issue

Certificates for stainless steel, welding flux, wires, rods

B 4 3

Resolution

Checking certificates

B 7 3

Checking outside

B 8 3 B 9 3

Store reports for materials.

B 5 3

Test sample for a lot

B 0 4

Test report and results

B 6 3

Checking mechanical, chemical properties

B 1 4

11-15 days after sign the contract/order/renew -order

B 2 4

Checking cast iron pieces

B 3 4

Dimensions

B 4

Flaws

B 5 4

Checking by ruler, tape, palme

B 7 4

Test report for cast iron pieces

B 6 4

Ultrasonic checking

B 8 4

16-30 days after sign the contract/order/renew -order

B 9 4

Checking machined cast iron parts

B 0 5

Design dimensions

B 1 5

Telorances

B 2 5

Checking by palme 1:50 for outside dimension, holes

B 4 5

Roughness

B 3 5

31-40 days after sign the

B 5

Checking units after assemble

B 6 5

Assemblying dimensions

B 7 5

Checking by ruler class II, palme 1:50, samples,

B 9 5

31

3.7 QUALITY TEAM ROLES & RESPONSIBILITIES

Checking dimensions

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Quality Review Date

contract/order/renew -order

Activity Reviewed

Issue

Linear dimensions, colinear dimensions of faces, seating faces, covers, holes of covers

B 8 5

Resolution

calibation plates Rotating cover and seating faces

B 0 6

41-45 days after sign the contract/order/renew -order

B 1 6

Leakage test

B 2 6

AWWA standard

B 3 6

0,01 gpm/m seal

B 4 6

Test bench with pump, tank, valves

B 6

0,02 Lpm/m seal

B 5 6

Finising surface before painting

B 7 6

Sa 2.5

B 8 6

Test by compared samples

B 9 6

Protection layer

B 0 7

Adhension of painting up to 4A according to ASTM-D3359-2

B 1 7

Test by A-X cutting method and electromagnetic tester

B 3 7

Thickness 300 micron after drying

B 2 7

Packaging and handling before transportation

B 4 7

Covering all machined faces, seals, fixing plates

B 5 7

Checking tensions of packages

B 7

Making robust for all parts, units, valves, stoplogs before transportation

B 6 7

3.9 QUALITY PLAN APPROVALS

Prepared by Approved by ____________________________________________________ ___________________________________________________ ___________________________________________________

Project Manager Project Sponsor Executive Sponsor

_______________________________________________ Client Sponsor

32

3.9 QUALITY PLAN APPROVALS

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

3.10 DESIGNATION PROCEDURE

33

3.10 DESIGNATION PROCEDURE

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Chapter 4

KEY PERSONELS FOR PROJECT

34

Chapter 4

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

4.1 KEYPERSONEL FOR PROJECT

Position

Full name Do Cong Ba Ta Khac Ap

Date of birth 1953 1952

Main Duty

Years of experience in proposed position 25 30

Deputy director Chief of Engineer

- General management - Managing in design and designing supervise - Manage and coordinate material and equipment for the works - Machining production and supervisor - Cast iron production - Quality control for cast iron - Quality control leader - Quality control for machining, assemblying, testing, transportation, installation, erection at site - Welding management and materials for welding - Standardization - ISO expert

Cast Iron Expert

Nguyen Van Minh M. Tech. Lee Thanh Ha

1972

16

Design Leader

1973

15

Director of Mechanical Factory No.2 Senior Quality Control

Nguyen The Hieu Nguyen Van Luc

1973

15

1973

15

35

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Chapter 5

EQUIPMENT FOR PROJECT

36

Chapter 5

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

37

EQUIPMENT FOR PROJECT

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

5.1 EQUIPMENT PROPOSED FOR THIS PROJECT

Item No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. Name of equipment Vertical lathe 1516-2611 Bending machine WE67Y-600/6000 Shearing machine QC11Y-16x600 Lathe T6M20 Oil Country lathe Mazak 3000 Lathe 1D6 2M 2895 Lathe T6M12 CNC turning lathe 600x1300, A35N Lathe TUD-40-216 Horizontal milling machine 6M83 Milling machine FU315 Vertical milling machine X51 Horizontal milling machine 3x2m table Multi-function drilling machine 2A592 Vertical drilling machine Z525-261 Semi-automatic welding machine SAF 400 DC welding machine DC welding machine (One pliers) Welding generator EW190 Capacity 40kW 30kW 22kW 10kW 10kW 4,5kW 3,7kW 14kW 10kW 14,7kW 8kW 6,2kW 14,5kW 1,7kW 2,8kW 18,5kW 18kW 15kW 7KVA Qty 01 01 02 01 01 01 02 01 01 01 01 01 01 01 01 01 04 02 01 Manufactures country Poland China China Vietnam Japan China Vietnam Japan Poland Poland German China Poland Vietnam China Korea Vietnam America Japan

5.1 EQUIPMENT PROPOSED FOR THIS PROJECT 38

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Item No. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36.

Name of equipment Welding machine 23550 Welding generator - Japan Vertical lathe 3,5mHx3,7m dia. Compressor 2907 Compressor 100 HP2 - 163229 CNC plasma cut. machine 3000x12000mm Overhead crane 10T Overhead crane 5T CNC Milling machine H500xW700xL400 Manual overhead crane 3T Hoist 10T Heat treament equipment 5 tons/lot Electric foundry equipment 15 tons/lot Medium frequency foundry 0,5T/1T/1,5T Uninterrupted cast iron foundry 8T Spectrometer Fison ARL2460 Metal blasting line

Capacity 18kW 10KVA 4,5kW 3,5kW 7,5kW 4kW

Qty 01 01 02 01 01 01 01 03 01 01 02 01 01 03 01 01 01

Manufactures country Vietnam Japan Poland German Italy Japan Vietnam Vietnam Japan Vietnam Vietnam China China China

5.1 EQUIPMENT PROPOSED FOR THIS PROJECT 39

USA Swiss USA

Hanoi, dated 10th October, 2008 On behalf of Hesco

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

5.2 PICTURES

Pic 1. Hydraulic bending machine WE67Y-600/6000, China 2006

Pic 2. Hydraulic shearing machine QC11Y-16x600, China 2006

Pic 3. CNC plasma cutting machine 3000x12000mm, Maxigraph Japan 2006

40

5.2 PICTURES

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Pic 4. Vertical lathe 3,5mHx3,7m dia., Poland 1981

Pic 5. Horizontal milling machine 3x2m table, Poland 1981

Pic 6. CNC vertical milling machine H500xW700xL400 table

41

5.2 PICTURES

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Pic 7. Oil Country lathe Mazak 3000, Japan 1981

Pic 8. CNC turning lathe 600x1300, IKEGAI A35N, Japan 1981

42

5.2 PICTURES

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Chapter 6

EXPERIENCES FOR PROJECT

43

Chapter 6

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

6.1 LIST OF CONTRACTS EXECUTED FOR 5 LAST YEARS

Name of contract Manufacture, transport and installation of 06 sets of sluice gate for An Tho sluice and 04 sets of gate for Cau Cat sluice. Manufacture and installation of 01 set of radial gate BxH = (10x5,5)m for Thanh Lanh reservoir Vinh Phu Manufacture and installation of 03 sets of gate and hoisting equipment for Tan Lap sluice Design, manufacture and installation of gates for Huong rivers sluice Customer Bac Hung Hai Hydraulic Works Exploitation Company Completion time 8/2001 Place Hai Duong province

Hydraulic project Management Board 404

3/2001

Vinh Phu

PMB Thai Binh Agriculture & Rural development Dept. Thanh Ha Hydraulic Works Exploitation factory

10/2001

Thai Binh

2001

Hay Duong

Manufacture and installation of gates Nam Thai Binh Hydraulic for Lan sluice Works Exploitation Company Manufacture and installation of hydro-mechanical equipment including 03 sets of gate and electrical system for Long Tuu Bac Ha sluice Manufacture and installation of 01 set of radial gate and stop log lowering equipment for Phu Hoa reservoir Manufacture and installation of 01 set of radial gate and electrical system, transformer for Ai Tu reservoir Manufacture and installation of flat gates and 06 sets of 20VD2 screw Long Tuu PMB

2001

Thai Binh

2002

Ha Bac

PMB 408

2002

Quang Binh

EXPERIENCES FOR PROJECT 44

PMB 408

2002

Quang tri

Thai Binh Hydraulic Construction Company

2002

Thai Binh

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Name of contract hoist for Nhu Trac sluice Manufacture and installation of 03 sets of radial gate for Sao rivers sluice Supply and installation of equipment for Sa Vang sluice including 04 sets of radial gate. Construction of mechanical items of spillway under Dong Tron reservoir Phu Yen including 03 sets of radial gate and 03 sets of flat gate Manufacture and installation of 03 sets of radial gate and low and high voltage system for Bao Van sluice Manufacture and installation of gate and hoisting for Hoai rivers dam

Customer

Completion time

Place

Nghe An hydraulic Construction Electrical mechanical company PMB of Hydraulic Construction Works

5/2003

Nghe An

8/2002

Quang Binh

PMB 414

5/2003

Phu Yen

PMB 406

4/2003

Thanh Hoa

PMB Thai Binh Agriculture & Rural development Dept. PMB of repairing Nghi Quang sluice PMB of Ninh Thuan Rural Infrastructure branch

6/2003

Thai Binh

Manufacture and installation of gate and hoisting for Nghi Quang sluice Manufacture and installation of electro-mechanical equipment for Trau rivers reservoir: sets of radial gate, trash screen, pipe line, electric pulley + hoist Construction of Iaring Channel includes gates, 02 sets of screw hoist V1, pipelines, Manufacture and installation of intake basin, pressure pipelines, downstream discharge gate, hoist, crane 12T Manufacture of 06 sets of control

8/2003

Nghe an

PMB 412

6/2004

Gia Lai

Dong Son Investment & Construction JSC

12/2004

Son La

Construction &

12/2004

Ha Noi

45

6.1 LIST OF CONTRACTS EXECUTED FOR 5 LAST YEARS

8/2004

Ninh Thuan

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Name of contract gate under the routes from Lang Ha Thanh Xuan Ha Noi Manufacture and installation of hydro-mechanical equipment: Radial gates, automatic gates, generator, crane 40T for Do Diem Sluice Ha Tinh Manufacture, transport and installation of sluice gates, screw hoist (01 set screw hoist V5 + 01 set of screw hoist VD30) for Vinh Son hydropower project Manufacture and installation of mechanical equipment includes lock gates, 04 sets of screw hoist V3, and 04 sets of screw hoist V5 for Nhue river irrigation system. Manufacture and installation of hydro-mechanical equipment for Ho Ho hydropower project including gates and electrical hoist 45T, crane, hoist, electrical pulley, hydraulic control system Manufacture and installation of intake gates, discharge gates for Khe Dien hydropower Project Manufacture and installation electromechanical equipment for Hiep Thuan Intake sluice Day river key Works: Intake gates and electrical system Manufacture of 02 sets of radial gate BxH=(15 x 16,82) for Ba Ha river hydro-power Project Phu Yen

Customer Mechanical Factory No.3

Completion time

Place

5/2006

Ha Tinh

Lung Lo Construction JSC

11/2005

Phu Yen

Nhue river Hydraulic Works Exploitation Company

4/2005

Ha Tay

North Electrical development & Investment Jsc

4/2007

Quang Binh

Ba river Electrical development & Investment Jsc PMB 401

11/2005

Da nang

3/2006

Ha Tay

Ba Ha river hydro-power Jsc

10/2006

Phu yen

46

6.1 LIST OF CONTRACTS EXECUTED FOR 5 LAST YEARS

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Name of contract Repair and improvement of key works of Minh Cam reservoir: Gates and screw hoist Manufacture and installation of hydro-mechanical equipment: gates, trash rake machine, hoist for Phu Mau hydro-power Project Supply and installation of hydromechanical equipment for Coc Dam Hydropower Project: Gates and lifting equipment Construction of mechanical equipment for spillway Rao Da reservoir: gates, trash screen, hoist Manufacture, installation of gates, hoist for Ha Dong regulator Nhue river irrigation system Supply, manufacture and installation of mechanical equipment for sluice, spillway and electrical system for lighting, operation Buk Ha reservoir Supply and installation of hydromechanical equipment for Phu Mau 1 Hydro-power Project: Gates, pressure basin, penstock Manufacture and installation of 04 sets of flat gate, 04 sets of hoist 10T for Phu Sa irrigation Works Manufacture and installation of lock gates and low voltage for Cau Hoi irrigation Sub-project

Customer Quang Binh PMB of Hydraulic Construction Works Tan An Co.Ltd

Completion time 7/2006

Place Quang Binh

1/2007

Lao Cai

Hoang Son Construction Co.Ltd

9/2007

Lao cai

Hydraulic construction & Investment Management Project Board No.5 Ha Dong PMB of Regulator Construction

6/2008

Quang Binh

8/2007

Ha Tay

Hong river Construction Corporation

8/2007

Dak Lak

Tan An Co. Ltd

11/2007

Lao Cai

Son Tay Phu Sa Hydraulic Company

5/2008

Son tay

Ninh Binh PMB of Flood protection

4/2008

Ninh Binh

47

6.1 LIST OF CONTRACTS EXECUTED FOR 5 LAST YEARS

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Name of contract Supply and installation of hydromechanical equipment for Muong Sang Hydro-power Project: Repaired gates, flat gates, trash screen, crane 30T

Customer Muong Sang Hydropower Jsc

Completion time 9/2007

Place Lao cai

Supply and installation of hydro- Ba river Hydro-power Jsc mechanical equipment for Krong Hnang Hydro-power Project: Intake gates, flow gates, hydraulic control equipment Manufacture and installation of hydro-mechanical equipment for spillway No.1 and intake sluice under Da Ban irrigation system: Radial gates, repair gates, cranes Hydraulic construction & Investment Management Project Board No.7

7/2008

Da nang

1/2008

Khanh Hoa

Hanoi, dated 10th October, 2008 On behalf of Hesco

48

6.1 LIST OF CONTRACTS EXECUTED FOR 5 LAST YEARS

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

6.2. PRODUCT PICTURES

Pic 1. Radial gates for reservoir

Pic 2. Stoplogs for hydropower

Pic 3. Flap gates for waste water treatment 6.2. PRODUCT PICTURES 49

HYDRAULIC EQUIPMENT JOINT STOCK COMPANY (HESCO) Address: Milestone 10 (Ha Noi - Ha Dong) Nguyen Trai street Tel: 84-4-38544883 E-mail: xnck2@yahoo.com

Pic 4. Round flap gate 3D-model

Pic 5. Rectangular flap gate 3D-model

Pic 6. Stoplog gate 3D-model

Pic 7. Stoplog guide 3D-model

50

6.2. PRODUCT PICTURES

You might also like

- Check Ielts EssaysDocument3 pagesCheck Ielts Essaysprosperity_174No ratings yet

- Check Ielts EssaysDocument3 pagesCheck Ielts Essaysprosperity_174No ratings yet

- Check Ielts EssaysDocument3 pagesCheck Ielts Essaysprosperity_174No ratings yet

- Claims Management HandoutsDocument6 pagesClaims Management Handoutsprosperity_174No ratings yet

- Chen and LinDocument14 pagesChen and Linprosperity_174No ratings yet

- Constructionmanual 022708Document169 pagesConstructionmanual 022708prosperity_174No ratings yet

- Constructionmanual 022708Document169 pagesConstructionmanual 022708prosperity_174No ratings yet

- Claims Management HandoutsDocument6 pagesClaims Management Handoutsprosperity_174No ratings yet

- Claims Management HandoutsDocument6 pagesClaims Management Handoutsprosperity_174No ratings yet

- CII - Quality Performance Measurement of The EPC Process The BlueprintDocument71 pagesCII - Quality Performance Measurement of The EPC Process The Blueprintprosperity_174No ratings yet

- 20.orchid Molecular BreedingDocument23 pages20.orchid Molecular Breedingprosperity_174No ratings yet

- CII - Quality Performance Measurement of The EPC Process The BlueprintDocument71 pagesCII - Quality Performance Measurement of The EPC Process The Blueprintprosperity_174No ratings yet

- People and Organizational Management in ConstructionDocument157 pagesPeople and Organizational Management in Constructionhai103014983% (6)

- 84Document49 pages84prosperity_174No ratings yet

- 20.orchid Molecular BreedingDocument23 pages20.orchid Molecular Breedingprosperity_174No ratings yet

- Scheduling For High-Rise Building ConstructionDocument7 pagesScheduling For High-Rise Building Constructionalila06No ratings yet

- Standard Form of Bidding Documents Procurement of Works For Smaller ContractsDocument74 pagesStandard Form of Bidding Documents Procurement of Works For Smaller Contractseuthan100% (3)

- New Safety Plan 2010Document192 pagesNew Safety Plan 2010prosperity_174No ratings yet

- Quality Manual Laboratories 2Document110 pagesQuality Manual Laboratories 2prosperity_174No ratings yet

- Example of Procedure 2Document9 pagesExample of Procedure 2Ronny AndalasNo ratings yet

- QchescoDocument50 pagesQchescoprosperity_174No ratings yet

- Fidic Brussels 20120607Document4 pagesFidic Brussels 20120607prosperity_174No ratings yet

- CIRRUS Logic Quality Manual 2Document8 pagesCIRRUS Logic Quality Manual 2prosperity_174No ratings yet

- 150 Contractual Problems & Their Solutions - Roger KnowlesDocument321 pages150 Contractual Problems & Their Solutions - Roger Knowlesprosperity_174No ratings yet

- Calculating Home Office Overhead in Construction Delay ClaimsDocument17 pagesCalculating Home Office Overhead in Construction Delay Claimsprosperity_174No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Anders LassenDocument12 pagesAnders LassenClaus Jørgen PetersenNo ratings yet

- Dyesebel 3Document7 pagesDyesebel 3Leachez Bbdear BarbaNo ratings yet

- Benno Przybylski Righteousness in Matthew and His World of Thought Society For New Testament Studies Monograph Series 1981Document198 pagesBenno Przybylski Righteousness in Matthew and His World of Thought Society For New Testament Studies Monograph Series 1981alenin1No ratings yet

- Our Common Future, Chapter 2 Towards Sustainable Development - A42427 Annex, CHDocument17 pagesOur Common Future, Chapter 2 Towards Sustainable Development - A42427 Annex, CHShakila PathiranaNo ratings yet

- Ancient Egypt - Basic NeedsDocument3 pagesAncient Egypt - Basic NeedsSteven Zhao67% (9)

- Office 365 - Information Security Management System (ISMS) ManualDocument18 pagesOffice 365 - Information Security Management System (ISMS) ManualahmedNo ratings yet

- The Paradox ChurchDocument15 pagesThe Paradox ChurchThe Paradox Church - Ft. WorthNo ratings yet

- VA-25 Grammar 5 With SolutionsDocument11 pagesVA-25 Grammar 5 With SolutionsSOURAV LOHIANo ratings yet

- Human Resources ManagementDocument18 pagesHuman Resources ManagementztrinhNo ratings yet

- Magsaysay v. NLRCDocument17 pagesMagsaysay v. NLRCJohn BernalNo ratings yet

- Base Rates, Base Lending/Financing Rates and Indicative Effective Lending RatesDocument3 pagesBase Rates, Base Lending/Financing Rates and Indicative Effective Lending Ratespiscesguy78No ratings yet

- Financial Reporting Standards SummaryDocument5 pagesFinancial Reporting Standards SummaryKsenia DroNo ratings yet

- 3 Macondray - Co. - Inc. - v. - Sellner20170131-898-N79m2kDocument8 pages3 Macondray - Co. - Inc. - v. - Sellner20170131-898-N79m2kKobe Lawrence VeneracionNo ratings yet

- P&WC S.B. No. A1427R3Document16 pagesP&WC S.B. No. A1427R3Elmer Villegas100% (1)

- UntitledDocument1,422 pagesUntitledKarinNo ratings yet

- Da Vinci CodeDocument2 pagesDa Vinci CodeUnmay Lad0% (2)

- In Re: Grand Prix Fixed Lessee LLC, Case No. 10-13825, (Jointly Administered Under Case No 10-13800)Document3 pagesIn Re: Grand Prix Fixed Lessee LLC, Case No. 10-13825, (Jointly Administered Under Case No 10-13800)Chapter 11 DocketsNo ratings yet

- Boundary computation detailsDocument6 pagesBoundary computation detailsJomar FrogosoNo ratings yet

- 1-C 2-D3-E4-A5-B6-E7-D8-A9-D10-BDocument36 pages1-C 2-D3-E4-A5-B6-E7-D8-A9-D10-BJewel Emerald100% (4)

- EH2741 HT16 Lecture 5 PDFDocument25 pagesEH2741 HT16 Lecture 5 PDFNiels Romanovich RomanovNo ratings yet

- St. Edward The Confessor Catholic Church: San Felipe de Jesús ChapelDocument16 pagesSt. Edward The Confessor Catholic Church: San Felipe de Jesús ChapelSt. Edward the Confessor Catholic ChurchNo ratings yet

- Skanda Purana 05 (AITM)Document280 pagesSkanda Purana 05 (AITM)SubalNo ratings yet

- CalendarDocument1 pageCalendarapi-277854872No ratings yet

- 79 Fair Empl - Prac.cas. (Bna) 1446, 75 Empl. Prac. Dec. P 45,771, 12 Fla. L. Weekly Fed. C 540 Mashell C. Dees v. Johnson Controls World Services, Inc., 168 F.3d 417, 11th Cir. (1999)Document9 pages79 Fair Empl - Prac.cas. (Bna) 1446, 75 Empl. Prac. Dec. P 45,771, 12 Fla. L. Weekly Fed. C 540 Mashell C. Dees v. Johnson Controls World Services, Inc., 168 F.3d 417, 11th Cir. (1999)Scribd Government DocsNo ratings yet

- Annex D Initial Evaluation Results IER 2Document6 pagesAnnex D Initial Evaluation Results IER 2ruffaNo ratings yet

- Preventive MaintenanceDocument2 pagesPreventive Maintenancedoctor_mumairkNo ratings yet

- Writ of Execution - U.S. DISTRICT COURT, NJ - Cv-Writ2Document2 pagesWrit of Execution - U.S. DISTRICT COURT, NJ - Cv-Writ2Judicial_FraudNo ratings yet

- EXIDEIND Stock AnalysisDocument9 pagesEXIDEIND Stock AnalysisAadith RamanNo ratings yet

- Case No. 23 - Maderada Vs MediodeaDocument3 pagesCase No. 23 - Maderada Vs MediodeaAbbyAlvarezNo ratings yet

- Research TitleDocument5 pagesResearch TitleAthena HasinNo ratings yet