Professional Documents

Culture Documents

Hert-Kompressoren Marine Compressor Wave Series

Uploaded by

Mayur ChauhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hert-Kompressoren Marine Compressor Wave Series

Uploaded by

Mayur ChauhanCopyright:

Available Formats

MARINE COMPRESSORS

WAVE SERIES

RELIABILITY International shipping with its stringent requirements for quality and relibility is HERTZ KOMPRESSORENS traditional area of activity. Our starting and working air compressors have proven their reliability in this demanding market. They are among the most modern and most economic compressors available today. In particular the low maintenance 3 -stage air-cooled starting air compressors (compared with the traditionally used 2-stage water- cooled compressors) contribute significantly to modern ship operation concepts.

With these products, HERTZ KOMPRESSOREN has become one of the leading manufacturers of compressors for shipping and offshore technology worldwide. GENERAL ADVANTAGES Lowest compression temperatures. Better air quality due to mounted separator after each stage. Reduced installation costs for the yard per ship. Reduced maintenance costs for the ship owner. Corrosion and impact resistant composite canopy for acoustic

insulation and better cooling performance even in harsh conditions up to 60C. Operation of compressors independant from central CW system. High reliability due to not having a water cooling system. Maintenance intervals of at least 2000 operation hours for the compressor valves even when standard motor oil is used. Reliable and safe to operate also at an ambient temperature of up to 60 C. Directly assembled fan and oil pump to the crankshaft.

HERTZ KOMPRESSOREN GmbH 59227 Ahlen, In der Schlinge 6 Germany Phone: +49 2382 940 63 83 +49 2382 940 63 84 Fax : +49 2382 940 84 90 www.hertz-kompressoren.de info@hertz-kompressoren.de

HERTZ KOMPRESSOREN LTD. Unit 12-13 Peel Mills Industrial Estate Chamberhall Street Bury Manchester BL9 OLU United Kingdom Phone: +44 161 764 41 60 www.hertz-kompressoren.co.uk info@hertz-kompressoren.co.uk

High-speed concentric plate valvesin every stage. Additionally, specialcooling fins in the 1st an.d 2nd stage.Specially designed coolingsystem: 1st and 2ndstageintercoolers and oil cooler iscombined in plate/ bar typealuminum cooler. Cylinders,cylinder heads and final-stageafter cooler are also cooled bythis new cooling system.The new W-Tpye compressor design;Lower compression ratios and loeroutlet temperatures. Thus, lowerenergy consumption and longerservice intervals up to2000 hours. Specially designed coolingsystem: 1st and 2ndstageintercoolers and oil cooler iscombined in plate/ bar typealuminum cooler. Cylinders,cylinder heads and final-stageafter cooler are also cooled bythis new cooling system.

High performance, 2-stage air filter

High performancethree-phase A.C. motors,Diesel motor drive - Upon request

Standard, factory assembled, Control panel: Including electronic controller which monitors outlet temperature, air pressure and oil pressure. Additional temperature and pressure gauges for each stages. High pressure water seperatorfor compressed air outlet.Water is drained automaticly bythe electronic controller. High capacity oil filter whichcan be accessed from outsidefor easy service. Integrate flexible coupling, low-maintenance and safeoperation.

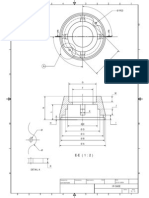

MARINE COMPRESSORS Wave Series W-166 Technical Data

NUMBER OF CYLINDERS NUMBER OF STAGES

MODEL

BAR

SPEED (rpm) 970 1170 1470 1770

FREQUENCY (hz) 50 60** 50 60**

M3/min. 110.0 132.7 166.7 200.7

L/min. 1833 2213 2778 3345

kW/Hp 16 19 25 31

L (mm)

W (mm)

H (mm)

Kg

W-166

40

1175

1580

1100

630

**Availability 50/60 hz, 132.7 m3/hour - 200.7 m3/hour. The specications and details are subject to change without prior notice

www.hertz-kompressoren.com

HR0185

You might also like

- CP 060 en Ceravac PDFDocument4 pagesCP 060 en Ceravac PDFMayur ChauhanNo ratings yet

- CP 060 en ThermovacDocument14 pagesCP 060 en ThermovacMayur ChauhanNo ratings yet

- CP 060 en Ceravac PDFDocument4 pagesCP 060 en Ceravac PDFMayur ChauhanNo ratings yet

- CP 060 en PenningvacDocument8 pagesCP 060 en PenningvacMayur ChauhanNo ratings yet

- CP 060 en Ceravac PDFDocument4 pagesCP 060 en Ceravac PDFMayur ChauhanNo ratings yet

- TEFC VS ODP MOTOR ENCLOSURESDocument1 pageTEFC VS ODP MOTOR ENCLOSURESMayur Chauhan0% (1)

- Sunil - Borhade 12/21/2009: Designed by Checked by Approved by Date DateDocument1 pageSunil - Borhade 12/21/2009: Designed by Checked by Approved by Date DateMayur ChauhanNo ratings yet

- Cashew ProcessingDocument4 pagesCashew ProcessingDg CharpeNo ratings yet

- MayurDocument2 pagesMayurMayur ChauhanNo ratings yet

- Hert-Kompressoren Marine Compressor Wave SeriesDocument2 pagesHert-Kompressoren Marine Compressor Wave SeriesMayur ChauhanNo ratings yet

- Hertz-Kompressoren Double Stage-High Pressure-Reciprocating CompressorDocument4 pagesHertz-Kompressoren Double Stage-High Pressure-Reciprocating CompressorMayur ChauhanNo ratings yet

- Hertz Oil Convertors Remove Oil from Compressed AirDocument2 pagesHertz Oil Convertors Remove Oil from Compressed AirMayur ChauhanNo ratings yet

- Hertz-Kompressoren Oil Injected Rotary Screw Air Compressor HSC 45-315Document4 pagesHertz-Kompressoren Oil Injected Rotary Screw Air Compressor HSC 45-315Mayur ChauhanNo ratings yet

- Hertz-Kompressoren Oil Injected Direct Drive Rotary Screw Air Compressor HSC 22D-315DDocument4 pagesHertz-Kompressoren Oil Injected Direct Drive Rotary Screw Air Compressor HSC 22D-315DMayur ChauhanNo ratings yet

- Hertz-Kompressoren Double Stage-High Pressure-Reciprocating CompressorDocument4 pagesHertz-Kompressoren Double Stage-High Pressure-Reciprocating CompressorMayur ChauhanNo ratings yet

- Hertz Oil Convertors Remove Oil from Compressed AirDocument2 pagesHertz Oil Convertors Remove Oil from Compressed AirMayur ChauhanNo ratings yet

- Air CompresorDocument5 pagesAir CompresorMayur ChauhanNo ratings yet

- Brochure 302 en ScrewDocument48 pagesBrochure 302 en ScrewMayur ChauhanNo ratings yet

- Food Processing ContactsDocument5 pagesFood Processing ContactsMayur ChauhanNo ratings yet

- P 780 ED tcm8 6777Document5 pagesP 780 ED tcm8 6777Mayur ChauhanNo ratings yet

- Kaeser ASD SeriesDocument5 pagesKaeser ASD SeriesSachith VidanapathiranaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HE Series 02-2012Document2 pagesHE Series 02-2012Victor MoraesNo ratings yet

- Bank Management System Project ReportDocument19 pagesBank Management System Project ReportKharoudNo ratings yet

- Introduction To PythonDocument15 pagesIntroduction To PythonSamyak JainNo ratings yet

- Andrew Burrows Diagram Equipment Code ListDocument149 pagesAndrew Burrows Diagram Equipment Code ListВиктор Сабов100% (1)

- HubSpot Reporting Certification AnswersDocument23 pagesHubSpot Reporting Certification AnswersE KaynaklarNo ratings yet

- Comparison of ISO 17025Document4 pagesComparison of ISO 17025Susan CarterNo ratings yet

- Commutation TechniquesDocument13 pagesCommutation TechniquesSantosh SinghNo ratings yet

- GTD Model QP 2Document3 pagesGTD Model QP 2Jeevan N BNo ratings yet

- Hi-Fog For Buildings: Technical IntroductionDocument16 pagesHi-Fog For Buildings: Technical IntroductionEsther TapiaNo ratings yet

- Automatic Dustbin Using Arduino: By-Yash Nawghare (PG18) Manav Walunj (PG21) Kaustubh Jagtap (PG24) Kundan Walunj (PG29)Document14 pagesAutomatic Dustbin Using Arduino: By-Yash Nawghare (PG18) Manav Walunj (PG21) Kaustubh Jagtap (PG24) Kundan Walunj (PG29)Manav WalunjNo ratings yet

- Physical Design and Sign OffDocument43 pagesPhysical Design and Sign OffAgnathavasiNo ratings yet

- Conceptual Framework Process ChartDocument2 pagesConceptual Framework Process ChartCarl Michael Robillos100% (6)

- Sony Klv-32v400a klv-32v400b Chassis Eg1l 987299403 Rev.3Document80 pagesSony Klv-32v400a klv-32v400b Chassis Eg1l 987299403 Rev.3بوند بوندNo ratings yet

- Matrix ActionsDocument8 pagesMatrix ActionsmaszerkNo ratings yet

- ICT Revision GuideDocument40 pagesICT Revision GuideIbad Rehman100% (1)

- Cluster DecDocument422 pagesCluster Decsts100No ratings yet

- Rayleigh vs Rician Fading Channels under Frequency Selective ConditionsDocument4 pagesRayleigh vs Rician Fading Channels under Frequency Selective Conditionssrikar01No ratings yet

- Guidance Document Verification For TMHS ManufacturersDocument25 pagesGuidance Document Verification For TMHS ManufacturersNurul amirahNo ratings yet

- Interface 3Document304 pagesInterface 3Gianluigi PetrosilloNo ratings yet

- Self Driving Car AI MethodsDocument5 pagesSelf Driving Car AI MethodsIndian e-commerce dealsNo ratings yet

- HYS0631 - C1L2P0 - Brochure Update Sept16 - Hyster J1.5-3.5GXDocument12 pagesHYS0631 - C1L2P0 - Brochure Update Sept16 - Hyster J1.5-3.5GXMickNo ratings yet

- JJ308 REPORT Layout and Piping of The Steam Power Plant SystemDocument9 pagesJJ308 REPORT Layout and Piping of The Steam Power Plant SystemAh Tiang86% (7)

- RWYL202 Remote Control Roller Explosive ViewDocument23 pagesRWYL202 Remote Control Roller Explosive ViewBrian EzequielNo ratings yet

- EasyLogic PM2000 Series - METSEPM2130Document4 pagesEasyLogic PM2000 Series - METSEPM2130ٍJordan SportNo ratings yet

- Telstrat EngageDocument4 pagesTelstrat EngageJesse MelloNo ratings yet

- Subaru Automatic Transmissions 4EAT Module 302 Technicians Reference BookletDocument37 pagesSubaru Automatic Transmissions 4EAT Module 302 Technicians Reference BookletFábio Silva de Oliveira100% (1)

- SOP DoconDocument38 pagesSOP DoconAcep GunawanNo ratings yet

- A-008559-1642179507704-119701-New Microsoft Word Document (2) DIKESHI WICKRAMASURIYADocument63 pagesA-008559-1642179507704-119701-New Microsoft Word Document (2) DIKESHI WICKRAMASURIYAelearn myNo ratings yet

- UK FireClass FC501 Data SheetDocument2 pagesUK FireClass FC501 Data SheetSanda Raluca-NicoletaNo ratings yet

- CSC099 Chapter 1 Introduction to Computer and Programming LanguagesDocument54 pagesCSC099 Chapter 1 Introduction to Computer and Programming LanguagesAbdul Ashraf RasidNo ratings yet