Professional Documents

Culture Documents

Risk Assessment For HDB (14.12.12)

Uploaded by

Saravanan SKOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For HDB (14.12.12)

Uploaded by

Saravanan SKCopyright:

Available Formats

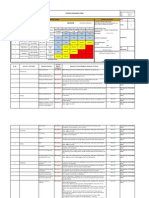

Shincon Industrial Pte Ltd Risk Assessment Form

Project : HDB CONTRACT Contractor: Shincon Industrial Pte Ltd Work Activity: Preparation of side formwork and steel work. Original Assessment date : 15 December 2012 Last review date Next review date :: 15 June 2013

Hazard Identification Possible Injury/ ill-health Bodily injury/ Fracture Physical injury

WHSO: RA leader : RA member 1 : RA member 2 : RA member 3 : RA member 4 : RA member 5 :

Francis Wong (Safety Officer) Rajmohan Vijay (Safety Supervisor) Shaiful Hamli Bin Moktar(Project Co-ordinator) Balasubramanian Karthikeyan (Site Engineer) Andrew Kiang (Site Supervisor) Thangavel Thangaraj (Foreman)

Risk Evaluation Likelihood

Approved by : Ref. No. HDB/12/2012/R1 Signature : Name : Designation : Date :

Risk Level

Koh Teck Lee Project Manager 15/12/2012

Risk Control Likelihood Risk Level

Rev. No. -

Severity

Severity

No

Work Activity

Hazard

Existing Control Measure

Additional Risk Control

Implementation Person Supervisor/ Foreman Supervisor/ Foreman Supervisor/ Foreman Supervisor/ Foreman Supervisor/ Foreman Supervisor/ Foreman Supervisor/ Foreman

Due Date

Remark

Preparation of side formwork

Slipped and fall on the Pallet table Hand hit by side formwork

Control of Oil application/ housekeeping/TBM/PPE proper arrangement of side formwork and provision of access/ housekeeping / /PPE removal / bending of nails and rebars / Illumination/ housekeeping/TBM/PPE Proper housekeeping/stacking, provision of adequate access/ TBM/PPE Use of proper Ppe - protective gloves Use of proper Ppe - protective gloves Guarding at all dangerous parts of machine must be provided Proper connection and distribution board shall be provided for tapping of electricity. Ensure that proper earthing is provided for the generator used on site.

Step on hazard (protruding nails/rabars) 2

Lower limbs injury

Erection and Tripped over reinforcement/ steel Physical injury fabrication of steel mesh reinforcement/ steel mesh Sharp cutting edges of rebar Minor cuts Caught in between bars minor fracture / laceration cuts

2 1 4

2 2 3

4 2 12

Use of proper Ppe - protective gloves Using industrial socket, avoid cable from moisture

2 1 3

2 2 2

4 2 6

Worker finger cut by bar bending Physical injury machine Electrical hazards Injury to person/property

Supervisor/ Safety Supervisor

Shincon Industrial Pte Ltd Risk Assessment Form

Project : HDB CONTRACT Contractor: Shincon Industrial Pte Ltd Work Activity: Concreting works Original Assessment date : 15 December 2012 Last review date Next review date :: 15 June 2013

Hazard Identification Possible Injury/ ill-health

WHSO: RA leader : RA member 1 : RA member 2 : RA member 3 : RA member 4 : RA member 5 :

Francis Wong (Safety Officer) Rajmohan Vijay (Safety Supervisor) Shaiful Hamli Bin Moktar(Project Co-ordinator) Balasubramanian Karthikeyan (Site Engineer) Andrew Kiang (Site Supervisor) Thangavel Thangaraj (Foreman)

Risk Evaluation Risk Level Likelihood

Approved by : Ref. No. HDB/12/2012/R1 Signature : Name : Designation : Date : Koh Teck Lee Project Manager 15/12/2012

Risk Control Likelihood Risk Level Severity Severity Implementati on Person Site Supervisor

Rev. No. -

No

Work Activity

Hazard

Existing Control Measure

Additional Risk Control

Due Date

Remark

Preparation works before concreting

Truck topping

Concreting works

Damage to property/ injury to people Poor coordination between truck Damage to property/ operator, signalman and injury to people workers. Hazard arising from unguarded Iinjury to people pull start disc. Accidental opening of concrete Injury to people bucket. Walking on steel reinforcement (tripping hazard) Hit against objects Falling/physical injury bodily injury

Ground condition check by engineer Use of qualified worker.

3 2

2 1

6 2

Sinnalman to communiate with driver

3 2

2 1

6 2

Equipment without guard must be kept in store Inspection on opening mechanism of concrete bucket before concreting. Designated access/ housekeeping/Toolbox meeting /PPE Use trained workers / TBM / PPE

3 3

1 3

3 9 Close supervision by experience supervisor/ Provide shoring system. Provide walking platform on the reinforcement

3 3

1 3

3 9

Site Supervisor Site Supervisor Supervisor Foreman

3 1

3 3

9 3

3 1

3 3

9 3

Shincon Industrial Pte Ltd Risk Assessment Form

Project : HDB CONTRACT Contractor: Shincon Industrial Pte Ltd Work Activity:Pre-cast Component Handling Original Assessment date : 15 December 2012 Last review date Next review date :: 15 June 2013

Hazard Identification Possible Injury/ ill-health Human body injury/ill-health

WHSO: RA leader : RA member 1 : RA member 2 : RA member 3 : RA member 4 : RA member 5 :

Francis Wong (Safety Officer) Rajmohan Vijay (Safety Supervisor) Shaiful Hamli Bin Moktar(Project Co-ordinator) Balasubramanian Karthikeyan (Site Engineer) Andrew Kiang (Site Supervisor) G Subani (Lifting Supervisor) Thangavel Thangaraj (Foreman)

Risk Evaluation Likelihood Risk Level

Approved by : Ref. No. HDB/12/2012/R1 Signature : Name : Designation : Date : Koh Teck Lee Project Manager 15/12/2012

Risk Control Likelihood Risk Level Severity Severity Implementation Person

Rev. No. -

No

Work Activity

Hazard

Existing Control Measure

Additional Risk Control

Due Date

Remark

Pre-cast Component Struck by dropped pre-cast Handling components due to failure of Lifting machines

Daily operator visual inspection on crane components - hoistrope, hook block, slings & lifting gears & operational checks on limit switches and various brakes. Periodic examination of the cranes lifting gears by authorised examiners Implement control over the lifting lug design & its fabrication

15

Conduct risk assessment to mitigate risks associated with the lifting operation

Crane Operator/ Lifting Supervisor

Struck by dropped pre-cast components due to defective lifting gears

Human body injury/ill-health

15

Plan for the lifting operations & document the plan and procedure Select suitable equipment which is properly maintained & in good working condition Clarify the roles/responsibility of personnel involved in the lifting operation Provide suitable training and select the appropriate and experienced lifting team

Crane Operator/ Lifting Supervisor Crane Operator/ Lifting Supervisor Crane Operator/ Lifting Supervisor Crane Operator/ Lifting Supervisor Crane Operator/ Lifting Supervisor

Struck by dropped pre-cast Human body injury/ill-health components due to failure of lifting lug of the pre-cast components Entanglement of slings with other Human body injury/ill-health materials

15

Adequate supervision by lifting supervisor & implement safe lifting procedures. Provide details of the pre-cast components in terms of weight, lifting locations, rigging method and concrete strength Adequate supervision by lifting supervisor & implement safe lifting procedures.

Struck by dropped pre-cast components due to overloading

Human body injury/ill-health

12

Trapped between suspended pre- Human body injury/ Damage to cast and other fixed structure or pre-cast elements other material

12

Shincon Industrial Pte Ltd Risk Assessment Form

Project : HDB CONTRACT Contractor: Shincon Industrial Pte Ltd Work Activity: Storage of Pre-cast Components Original Assessment date : 15 December 2012 Last review date Next review date :: 15 June 2013

Hazard Identification Possible Injury/ ill-health Damage to pre-cast elements

WHSO: RA leader : RA member 1 : RA member 2 : RA member 3 : RA member 4 : RA member 5 :

Francis Wong (Safety Officer) Rajmohan Vijay (Safety Supervisor) Shaiful Hamli Bin Moktar(Project Co-ordinator) Balasubramanian Karthikeyan (Site Engineer) Andrew Kiang (Site Supervisor) G Subani (Lifting Supervisor) Thangavel Thangaraj (Foreman)

Risk Evaluation Likelihood Risk Level

Approved by : Ref. No. HDB/12/2012/R1 Signature : Name : Designation : Date : Koh Teck Lee Project Manager 15/12/2012

Risk Control Likelihood Risk Level Severity Severity Implementation Person

Rev. No. -

No

Work Activity

Hazard

Existing Control Measure

Additional Risk Control

Due Date

Remark

Storage of Pre-cast Components

Lack of storage planning

Unstable pre-cast panels due to inadequate supports

Damage to pre-cast elements

Storage area should be large enough for pre-cast components to be stored properly with adequate room for lifting equipment and for manoeuvring trucks, cranes and other relevant vehicles. Pre-cast components should not be stored directly on the ground. Generally, two discrete support points should be provided. Timber supports raised above the ground or dedicated racking systems should be used in all cases

Supervisor

Overloading due to inadequate design of supporting structures for supporting racks/frames

Damage to pre-cast elements

The area should be reasonably level and hard surfaced with adequate drainage to ensure that a safe workplace can be maintained. Pre-cast components should be stored in such a manner that each component supports only its own weight without any load being imposed by other components.

Supervisor

Supervisor

Shincon Industrial Pte Ltd Risk Assessment Form

Project : HDB CONTRACT Contractor: Shincon Industrial Pte Ltd Work Activity: Unloading materials Original Assessment date : 15 December 2012 Last review date Next review date :: 15 June 2013

Hazard Identification Possible Injury/ ill-health Physical injury Physical injury

WHSO: RA leader : RA member 1 : RA member 2 : RA member 3 : RA member 4 : RA member 5 :

Francis Wong (Safety Officer) Rajmohan Vijay (Safety Supervisor) Shaiful Hamli Bin Moktar(Project Co-ordinator) Balasubramanian Karthikeyan (Site Engineer) Andrew Kiang (Site Supervisor) G Subani (Lifting Supervisor) Thangavel Thangaraj (Foreman)

Risk Evaluation Likelihood Risk Level Severity

Approved by : Ref. No. HDB/12/2012/R1 Signature : Name : Designation : Date : Koh Teck Lee Project Manager 15/12/2012

Risk Control Likelihood Risk Level Severity Implementati on Person Site Supervisor Site Supervisor Site Supervisor Site Supervisor/ Signalman Site Supervisor/ Signalman

Rev. No. -

No

Work Activity

Hazard

Existing Control Measure

Additional Risk Control

Due Date

Remark

Unloading materials Contact with sharp/ protruding parts Caught in-between materials

Wear Proper PPE Wear Proper PPE/ Protective gloves

1 2

2 2

2 4 Signalman to communiate with driver & use of tagline for bulky items

1 2

2 2

2 4

Inproper manual lifting 8

Vehicle using site Road accident while entering access, transporting site during loading & unloading of material in and out of excavator from trailer of site. Road accident while moving out Injury to people / of site Damage to property

Damage to property/ injury to people Injury to people

Use of proper PPE - protective gloves Drivers must brief to reduce speed and activate filter signal early to inform behind vehicles about his intention. Drivers must be briefed to give way to fast moving traffic and also to ensure its the right time for him to drive on.

3 3

1 2

3 6 Signalman to communiate with driver

3 3

1 2

3 6

Signalman to communiate with driver

Shincon Industrial Pte Ltd Risk Assessment Form

Project : HDB CONTRACT Contractor: Shincon Industrial Pte Ltd Work Activity: Liifting by Lorry crane/ Mobile crane Original Assessment date : 15 December 2012 Last review date Next review date :: 15 June 2013

Hazard Identification Possible Injury/ ill-health Damage to pre-cast culvert, drains, human body and property Damage to , pre-cast culvert, drains, human body and property

WHSO: RA leader : RA member 1 : RA member 2 : RA member 3 : RA member 4 : RA member 5 :

Francis Wong (Safety Officer) Rajmohan Vijay (Safety Supervisor) Shaiful Hamli Bin Moktar(Project Co-ordinator) Balasubramanian Karthikeyan (Site Engineer) Andrew Kiang (Site Supervisor) G Subani (Lifting Supervisor) Thangavel Thangaraj (Foreman)

Risk Evaluation Likelihood Risk Level Severity

Approved by : Ref. No. HDB/12/2012/R1 Signature : Name : Designation : Date : Koh Teck Lee Project Manager 15/12/2012

Risk Control Likelihood Risk Level Severity Implementation Person

Rev. No. -

No

Work Activity

Hazard

Existing Control Measure

Additional Risk Control

Due Date

Remark

Lorry / Mobile Crane

Collision of Lorry Crane

Ground Guides are deployed to guide vehicles in efficient manner with congested road Adhere vehicle travelling speed limit of 15 km/hr within site Qualified lifting supervisor, rigger and signaller for lifting operation must be certified by MOM and underwent proper lifting training Crane is parked at designated location in accordance to the site requirement Ground condition must be even surface and rigid. All outriggers are fully extended and rested fully on steel plates Crane is levelled after outrigger extension Crane is inspected by lifting supervisor prior to lifting Hoisting load is within SWL of the crane.

12 Ground guide to warm vehicles or passersby of incoming lorry crane 12 All lifting related certificates (LM, LG & lifting personel) are inorder and within validity period

12

Ground Guide Crane Operator

10 Setting up of lorry crane

Toppling of crane

12 Crane Operator Lifting Supervisor -

Shincon Industrial Pte Ltd Risk Assessment Form

Project : HDB CONTRACT Contractor: Shincon Industrial Pte Ltd Work Activity: Liifting by Lorry crane/ Mobile crane Original Assessment date : 15 December 2012 Last review date Next review date :: 15 June 2013 WHSO: RA leader : RA member 1 : RA member 2 : RA member 3 : RA member 4 : RA member 5 :

Damage to pre-cast culvert, drains, human body and property

Francis Wong (Safety Officer) Rajmohan Vijay (Safety Supervisor) Shaiful Hamli Bin Moktar(Project Co-ordinator) Balasubramanian Karthikeyan (Site Engineer) Andrew Kiang (Supervisor) G Subani (Lifting Supervisor) Thangavel Thangaraj (Foreman)

Risk Evaluation Load is rigged by qualified rigger only Tag line with sufficient length (at least 6m) is tied on the load to better control during lifting All lifting signals to be instructed strictly by signaller during entire lifting operation No person are allowed to stand near or below suspended load All lifting crew and crane operator to stay within sight at all times during entire lifting operation All loads shall be predetermined to ascertain lifting capability of crane No person are allowed to stand below suspended load Safety latch of lifting block is in good condition and operational requirement Non operational personnel are to stay away from lifting zone at all time during entire lifting Area is clear from obstruction prior the lifting operation Proper and sufficient passage way in case of emergecy 3 3 9

Approved by : Ref. No. HDB/12/2012/R1 Signature : Name : Designation : Date :

Lifting supervisors is to overseees the lifting operation and empower to stop work shall there by any unsafe circumstances such as climate change

Koh Teck Lee Project Manager 15/12/2012

3 3 Risk Control 9 Lifting Supervisor

Rev. No. -

Hazard Identification 11 Lifting of Toppling of load commodities via lorry crane

Failure of lifting gears

Damage to pre-cast culvert, drains, and property

10 All lifting gears shall be physically checked prior the lifting operation to ensure consistency with valid certificates submitted and existing physical condition

10

Lifting Supervisor Crane Operator

Tripping over objects

Human body injury

Maintain proper housekeeping through the entire lifting operation

Severity scoring

Likelihood scoring

Recommended 5x5 Risk Matrix with numeric ratings

1-2 3-4 5-9

Very Low Risk Low Risk Medium Risk

10 - 16 High Risk 17 - 25 Very High Risk Note: The "Very Hight Risk" and "High Risk" must have additional control to bring below the "Medium Risk".

5x5 Risk Matrix with numeric ratings

Likelihood Rare (1) Severity Catastrophic (5) Major (4) Moderate (3) Minor (2) Negligible (1) 5 4 3 2 1 10 8 6 4 2 15 12 9 6 3 20 16 12 8 4 Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 25 20 15 10 5

Low Risk Medium Risk High Risk

(1 - 3) (4 - 14) (15 - 25)

- Acceptable - Tolerable - Not acceptable

Low Risk

Acceptable

Medium Risk

Acceptable

No additional risk control measures may be needed. Frequent review and monitoring of hazards are required to ensure that the risk level assigned is accurate and does not increase over time. No additional risk control measures may be needed. Frequent review and monitoring of hazards are required to ensure that the risk level assigned is accurate and does not increase over time.

You might also like

- Hazard Identification Risk Assessment and Risk ControlDocument7 pagesHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- 2 Risk Assessment Rev 00 EHS FormatDocument45 pages2 Risk Assessment Rev 00 EHS Formatkumar100% (1)

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- Welding, Cutting and GrindingDocument6 pagesWelding, Cutting and GrindingMohammed MinhajNo ratings yet

- Scaffolding Risk AssessmentDocument3 pagesScaffolding Risk AssessmentAlexandru Ghigea100% (1)

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument5 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez Tan100% (3)

- Risk Assessment: N C Tucker LTD Plastering 17/06/2019 NTDocument4 pagesRisk Assessment: N C Tucker LTD Plastering 17/06/2019 NTAngela DaveyNo ratings yet

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Document14 pagesRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee ChingNo ratings yet

- HSE TRA-04 Steel Reinforcement and Shuttering WorksDocument6 pagesHSE TRA-04 Steel Reinforcement and Shuttering WorksQusai Khalil Abu Awad100% (1)

- Site Activities Risk AssessmentDocument50 pagesSite Activities Risk Assessmentjamie542393% (41)

- Generic Risk AssessmentDocument8 pagesGeneric Risk Assessmentmorgojoyo100% (3)

- Concrete Pipe and Portal Culvert Installation Manual1Document28 pagesConcrete Pipe and Portal Culvert Installation Manual1ChristineNyambe100% (1)

- Environmental, Health and Safety Risk AssessmentDocument2 pagesEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- Risk Assesment For Formwork ActivityDocument8 pagesRisk Assesment For Formwork ActivityIbrahim Naguib85% (13)

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- RA.013 - Green Field Risk Assessment (Demolision Works For HMR & SR Ext of PL1&2) .Rev.02Document41 pagesRA.013 - Green Field Risk Assessment (Demolision Works For HMR & SR Ext of PL1&2) .Rev.02Venkadesh Periathambi100% (3)

- 25-Risk Assessment For Fabrication & NDT During Night ShiftDocument2 pages25-Risk Assessment For Fabrication & NDT During Night Shiftgulryz84100% (9)

- Risk Assessment For Tank BaseDocument5 pagesRisk Assessment For Tank Baseramod100% (2)

- Risk Assessment For CanopyDocument5 pagesRisk Assessment For CanopyJSN179100% (7)

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Risk Assessment For Scaffolding PDFDocument13 pagesRisk Assessment For Scaffolding PDFطارق رضوانNo ratings yet

- Job Safety Analysis Risk Assess Confined Spaces v2 250311 KPDocument9 pagesJob Safety Analysis Risk Assess Confined Spaces v2 250311 KPIkhwanul Hujiatna50% (2)

- Risk Assessment of Scaffolding Works - Rev. 1Document20 pagesRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- Risk Assessment in A Welding and Construction SiteDocument3 pagesRisk Assessment in A Welding and Construction SiteFad Tobi75% (8)

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Safe Work Method Statement - PlumbingDocument4 pagesSafe Work Method Statement - PlumbingJohn KurongNo ratings yet

- C 36 Engg Design Basis STR and Arch 1422532512Document40 pagesC 36 Engg Design Basis STR and Arch 1422532512Ramesh Subramani RamachandranNo ratings yet

- Risk Assisment For Fence WorkDocument2 pagesRisk Assisment For Fence Workashishakare100% (1)

- RA MEWP 0003 Dec 2011Document3 pagesRA MEWP 0003 Dec 2011Anup George Thomas100% (1)

- Lifting Operations Rev 3 (Mobile Crane)Document21 pagesLifting Operations Rev 3 (Mobile Crane)Rachel Flores100% (1)

- RA - 018 01 Scaffolding Erection and DismantlingDocument14 pagesRA - 018 01 Scaffolding Erection and DismantlingVuong Bui95% (63)

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- Hazard Analysis Structural SteelDocument3 pagesHazard Analysis Structural SteelRobbie Grose100% (3)

- Risk Assess Plastering 2006 Tcm17 26368Document2 pagesRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uNo ratings yet

- Various Types of Precast Concrete SlabsDocument33 pagesVarious Types of Precast Concrete SlabsLangit Pinagkait100% (14)

- 5-Risk Assessment For Excavation & Backfilling and Compaction WorksDocument15 pages5-Risk Assessment For Excavation & Backfilling and Compaction WorksAmran HossainNo ratings yet

- Chequered-Plate CALCULATIONDocument19 pagesChequered-Plate CALCULATIONRamuAlagappan100% (2)

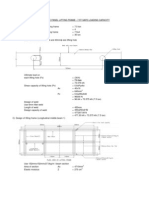

- Design Calculation Bus ShelterDocument36 pagesDesign Calculation Bus ShelterSaravanan SK0% (1)

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONDocument6 pagesRisk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONnsadnanNo ratings yet

- Art of Precast ConcreteDocument80 pagesArt of Precast ConcreteShrinivas HansanpalliNo ratings yet

- Project Work Break Down System - GeneralDocument6 pagesProject Work Break Down System - GeneralAnthony Agner100% (2)

- Lifting FrameDocument8 pagesLifting FrameSaravanan SKNo ratings yet

- Method Statement For Painting of All Metallic Piping: Form 000.653.F0100Document9 pagesMethod Statement For Painting of All Metallic Piping: Form 000.653.F0100narmathaNo ratings yet

- Risk Assessment For Hot WorksDocument4 pagesRisk Assessment For Hot Workseldho100% (1)

- Risk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Document4 pagesRisk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Yam Balaoing100% (1)

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works JsaNazir Hussain67% (12)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Risk Assessment - Facade WorkDocument12 pagesRisk Assessment - Facade WorkCui KunchiNo ratings yet

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Activity Risk Assessment Internal Concrete WallsA WFDocument6 pagesActivity Risk Assessment Internal Concrete WallsA WFChoubi ChoubacaNo ratings yet

- Prestressing Record SheetDocument1 pagePrestressing Record SheetSaravanan SKNo ratings yet

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Example Risk Assessment For ExcavationsDocument3 pagesExample Risk Assessment For ExcavationsYaser A. Al-Bustanji72% (18)

- Master List of Drgs of B&S Dte.Document50 pagesMaster List of Drgs of B&S Dte.Hs Chopra0% (1)

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamNo ratings yet

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDocument6 pagesSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiNo ratings yet

- (GEOSS) - Guidelines On Good Practices For Pile Load TestDocument10 pages(GEOSS) - Guidelines On Good Practices For Pile Load TestPeter KyawNo ratings yet

- JSA GC-5 Mobile ScaffoldingDocument6 pagesJSA GC-5 Mobile Scaffoldinggrande100% (2)

- Method Statement and Risk Assessment - KFM 016 16 - Rev 0Document12 pagesMethod Statement and Risk Assessment - KFM 016 16 - Rev 0trija_mrNo ratings yet

- Jsa For Steel Structure For Off PlotDocument13 pagesJsa For Steel Structure For Off PlotKhuda BukshNo ratings yet

- Uncle Sam Parking Garage Condition Assessment ReportDocument96 pagesUncle Sam Parking Garage Condition Assessment ReportWNYT NewsChannel 13No ratings yet

- Behaviour of Precast Connections Subjected To Shock LoadingDocument13 pagesBehaviour of Precast Connections Subjected To Shock LoadingJitendra PatelNo ratings yet

- FC-WCJ-18016-CSW6ST101-001 Cal - PDFDocument205 pagesFC-WCJ-18016-CSW6ST101-001 Cal - PDFSaravanan SKNo ratings yet

- Installation of Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersDocument4 pagesInstallation of Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersEligio Antonio CerdaNo ratings yet

- MS-CVL-009 Erection of Hollowcore Slabs 1Document12 pagesMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanNo ratings yet

- Corporate Circular: Bridge Technical Direction Btd2013/01Document2 pagesCorporate Circular: Bridge Technical Direction Btd2013/01scribdarell100% (1)

- JACK IN Piling WorkDocument9 pagesJACK IN Piling WorkShaheed AzharNo ratings yet

- Risk Assessments For ACTIVITY BASEDDocument4 pagesRisk Assessments For ACTIVITY BASEDhello3232No ratings yet

- VT DDR - Main Report (EN) HTHDocument142 pagesVT DDR - Main Report (EN) HTHMr_TitanNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- JSA NO 2-Piling WorkDocument3 pagesJSA NO 2-Piling WorkKarthik GanesanNo ratings yet

- Health, Safety and Environment: Lifting Permit Cherrywood Construction of 188 Townhouses Permit NoDocument3 pagesHealth, Safety and Environment: Lifting Permit Cherrywood Construction of 188 Townhouses Permit NoSajid ShahNo ratings yet

- Alodie Vargas PfraDocument6 pagesAlodie Vargas Pfraapi-320187848No ratings yet

- Certificate of Equippotential Testing (BS 63319)Document1 pageCertificate of Equippotential Testing (BS 63319)Saravanan SKNo ratings yet

- Sdre14-14 Bol 1-5-1dec17Document6 pagesSdre14-14 Bol 1-5-1dec17Yam BalaoingNo ratings yet

- Transmittal Form: S/N Drawing / Ref. No. Title / Description QTY SizeDocument1 pageTransmittal Form: S/N Drawing / Ref. No. Title / Description QTY SizeSaravanan SKNo ratings yet

- Preface: Guide Drawings and Schedules of FinishesDocument6 pagesPreface: Guide Drawings and Schedules of FinishesSaravanan SKNo ratings yet

- C - Users - Cadstation - Documents - 016 Malaysia PC Plant - 002 Design and Cals - Silo Foundation ModelDocument1 pageC - Users - Cadstation - Documents - 016 Malaysia PC Plant - 002 Design and Cals - Silo Foundation ModelSaravanan SKNo ratings yet

- D1121 BM Amendment1Document75 pagesD1121 BM Amendment1Saravanan SKNo ratings yet

- Silo FoundationDocument1 pageSilo FoundationSaravanan SKNo ratings yet

- Silo FoundationDocument1 pageSilo FoundationSaravanan SKNo ratings yet

- ER 349 - POB 3 - Secondary Beam Design (200x100x12mm Thick RHS)Document1 pageER 349 - POB 3 - Secondary Beam Design (200x100x12mm Thick RHS)Saravanan SKNo ratings yet

- Loadtest-Setup Steelct BMP (4) - ModelDocument1 pageLoadtest-Setup Steelct BMP (4) - ModelSaravanan SKNo ratings yet

- Latest Amendments in IRC Codes 2Document24 pagesLatest Amendments in IRC Codes 2Pravin GundeliNo ratings yet

- DSFSDFSDF Advanced Construction TechnologiesDocument3 pagesDSFSDFSDF Advanced Construction Technologiessarveshfdk48No ratings yet

- Wall Cladding & PanelsDocument18 pagesWall Cladding & PanelsSubrata DeyNo ratings yet

- Construction Method Statement FOR RCC Boundry Wall With Precast Panel & ColumnDocument8 pagesConstruction Method Statement FOR RCC Boundry Wall With Precast Panel & Columnkhurshidoman123No ratings yet

- Traffic Barriers PDFDocument27 pagesTraffic Barriers PDFjunaid112No ratings yet

- E91437 15 A3 Urban Context Report and Architectural Drawings Part BDocument12 pagesE91437 15 A3 Urban Context Report and Architectural Drawings Part Bjanani1990No ratings yet

- Concrete Work Pour ReleaseDocument1 pageConcrete Work Pour Releaseyasir khanNo ratings yet

- IPC - Fabrication of ATM CabinsDocument8 pagesIPC - Fabrication of ATM CabinsAwaisZahidOrakzaiNo ratings yet

- Newsletter PrintDocument8 pagesNewsletter Printapi-314836990No ratings yet

- Precast Construction Methodology in Construction Industry & Ashwin M JoshiDocument8 pagesPrecast Construction Methodology in Construction Industry & Ashwin M JoshigmontesroyNo ratings yet

- Brosur Wika BetonDocument23 pagesBrosur Wika BetonBrantas AbiprayaNo ratings yet

- Input File For MXDocument31 pagesInput File For MXJithesh GowdaNo ratings yet

- Title: Construction Technology Ii Course Work Report: Siti Nadiah Binti Mokhtar Noor Safika Faezan Binti AzahariDocument107 pagesTitle: Construction Technology Ii Course Work Report: Siti Nadiah Binti Mokhtar Noor Safika Faezan Binti AzahariSeid HodzicNo ratings yet

- Reid Safe Lifting Guide v9Document16 pagesReid Safe Lifting Guide v9kevin_au18No ratings yet

- Hollow Core SpecificationsDocument8 pagesHollow Core SpecificationsJohn Carpenter100% (1)

- LGSDocument2 pagesLGSVigneshwarNo ratings yet

- MB Concrete Footbridges July2012Document8 pagesMB Concrete Footbridges July2012gorgika papand0% (1)

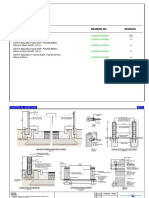

- Plan View: North Side Boundary Wall ElevationDocument2 pagesPlan View: North Side Boundary Wall ElevationKrishnan JayaramanNo ratings yet