Professional Documents

Culture Documents

New Connections

Uploaded by

Mahir MahmoodOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Connections

Uploaded by

Mahir MahmoodCopyright:

Available Formats

Applies to: Third party installers of new connections Prepared by: MJG Authorised by: SR

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed Issue Date: July 2010 Review Date: July 2015

SP-PS-313

Rev: 1.02 No of this copy:

INFORMATION PROVIDED TO ASSIST THE TENDERER FOR THE SUPPLY OF: ITEM: SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS

REFERRED TO IN EACH: HARMONISATION DOCUMENT / EUROPEAN STANDARD

I.E.C.

BRITISH STANDARD

7870, 4553-3, 7835

DEROGATIONS (IF ANY)

Page 1 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

SCOPE This specification is intended to be used by third parties installing new connections that will be adopted by SSE Power Distribution (SSEPD). Low smoke and fume sheathed cables should be used for installations with long cable runs within large buildings or when specified by the planner and/or developer.

REFERENCES Reference BS 4553-3 Title Specification for 600/1000 V single phase split concentric electric cables. Cables having thermosetting insulation and low emission of smoke and corrosive gases when affected by fire. Specification for armoured cables with extruded cross-linked polyethylene or ethylene propylene rubber insulation for rated voltages from 3.8/6.6 kV up to 19/33 kV having low emission of smoke and corrosive gases when affected by fire LV and MV polymeric insulated cables for use by distribution and generation utilities Energy Networks Association Standard for Outdoor meter cupboards Energy Networks Association Standard for Polythene protection tape for buried electricity supply cable Energy Networks Association Standard for Plastic ducts for buried electric cables Special backfill materials for cable installations SSE Procedure for over voltage testing of high voltage apparatus up to and including 275 kV

BS 7835

BS 7870 ENA TS 12-3 ENA TS 12-23 ENA TS 12-24 ENA TS 97-1 PR-PS-063

METER CUPBOARDS Small or slim outdoor meter cabinets shall be manufactured to ENA Technical Standard 12-3. (Advice should be sought before meter boxes are installed in corridors used as escape routes in communal buildings).

SERVICE TUBES AND DUCTS

4.1 Service Tubing

Where service tubing is installed to enable the service cable to be laid from the mains joint position to the meter box the 38 mm or 60 mm outer diameter black polyethylene tubing shall be manufactured to ENA Technical Standard 12-24.

4.2 Mains Cable Ducts

Black polyethylene or PVC ducting shall be manufactured to ENA Technical Standard 12 24. Standard sizes are 100 mm, 125 mm, & 150 mm. Both Rigi-duct and smooth wall ducts are approved and for 33kV cables where three single core cables are laid in a single duct then the installer may select the appropriate duct size to suit the cable size.

4.3 Sealing Ducts

All service tubes and ducts must be sealed against migration of gas when terminating in buildings or meter boxes.

Page 2 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

4.4 Duct Filling

If the cable is required to run at its maximum direct burial rating when it is installed in a duct for more than 15 metres, then the duct must be filled with Bentonite mixture. (100 parts of 10:1 Bentonite / water mix to 20 parts sand and 8 parts cement.) This mixture must be pumped into the duct so totally excludes the air and on completion of the filling be sealed to prevent any escape of Bentonite mixture.

LOW VOLTAGE SINGLE PHASE SERVICE CABLES

5.1 Concentric Cables

Low voltage single phase service cables shall be PVC sheathed 600/1000 V rated and comply with BS 7870 Section 3.10 or Section 3.11 Table 2. The conductors shall be PVC or XLPE insulated, single core solid aluminium phase and a copper stranded helical concentric combined neutral / earth with PVC oversheath. The aluminium phase conductors shall be either 25 mm or 35 mm cross sectional area with appropriately sized neutral/earth conductors.

5.2 Split Concentric Cables

Low voltage single phase service cables shall be PVC sheathed 600/1000 V rated and comply with BS 7870 Section 3.20 or Section 3.21 Table 2. The conductors shall be PVC or XLPE insulated, single core solid aluminium phase and a copper stranded helical concentric combined neutral / earth with PVC oversheath. The aluminium phase conductors shall be either 25 mm or 35 mm cross sectional area with appropriately sized neutral and earth conductors.

5.3 Low Smoke and Fume Split Concentric Cables

Low voltage single phase service cables shall be LSF sheathed 600/1000 V rated and comply with BS 4553-3 Table 4. The conductors shall be XLPE insulated, single core solid aluminium phase and a copper stranded helical concentric combined neutral / earth with orange LSF oversheath. The aluminium phase conductors shall be 35 mm cross sectional area with appropriately sized neutral and earth conductors.

LOW VOLTAGE SINGLE PHASE STREET LIGHT SERVICE CABLES

6.1 Concentric Service Cables

Low voltage single phase street light service cables shall be 25 mm PVC sheathed, 600/1000 V rated and comply with BS 7870 Section 3.10 or Section 311 Table 1. The conductors shall be PVC or XLPE insulated, stranded copper phase and a copper stranded helical concentric combined neutral/earth with PVC oversheath.

6.2 Split Concentric Service Cables

Low voltage single phase street light service cables shall be 25 mm PVC sheathed, 600/1000 V rated and comply with BS 7870 Section 3.10 or Section 311 Table 1. The conductors shall be PVC or XLPE insulated, stranded copper phase and a copper stranded helical concentric combined neutral/earth with PVC oversheath.

Page 3 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

LOW VOLTAGE 3 PHASE SERVICE CABLES

7.1 Concentric Service Cables

Low voltage 3 phase service cables shall be PVC sheathed, 600/1000 V rated and comply with BS 7870 Section 3.10 or Section 3.11 Table 4. The conductors shall be PVC or cross linked polyethylene insulated, aluminium phase and a copper stranded helical concentric combined neutral / earth. The phase conductors shall be 35 mm cross sectional area with appropriately sized neutral / earth conductors.

7.2 Split concentric Service Cables

Low voltage 3 phase service cables shall be PVC sheathed, 600/1000 V rated and comply with BS 7870 Section 3.21 Table 4. The conductors shall be cross linked polyethylene insulated, aluminium phase and a copper stranded helical concentric combined neutral / earth. The phase conductors shall be 35 mm cross sectional area with appropriately sized neutral and earth conductors.

7.3 Low Smoke and Fume Split Concentric Cables

Low voltage three phase service cables shall be LSF sheathed 600/1000 V rated and comply generally with BS 7870 Section 3.21 Table 2. The conductors shall be XLPE insulated, solid aluminium phase conductors and a copper stranded helical concentric combined neutral / earth with orange LSF oversheath. The aluminium phase conductors shall be 35 mm cross sectional area with appropriately sized neutral and earth conductors.

LOW VOLTAGE DISTRIBUTION CABLES

8.1 3 Core Wavecon

Low voltage distribution cables shall be PVC sheathed 3 phase, 600/1000V rated and comply with BS 7870 Section 3.40 Table 1. The conductors shall be 3 core EPR or cross linked polyethylene insulated (XLPE), with solid aluminium phases and a copper stranded waveform concentric combined neutral / earth. The phase conductors shall be either 95 mm, 185 mm or 300 mm cross sectional area with appropriately sized copper neutral / earth conductor.

8.2 3 Core LSF Wavecon

Low voltage distribution cables shall be LSF sheathed 3 phase, 600/1000V rated and comply with BS 7870 Section 3.50 Table 1. The conductors shall be 3 core EPR or cross linked polyethylene insulated (XLPE), with solid aluminium phases and a copper stranded waveform concentric combined neutral / earth. The phase conductors shall be 185 mm cross sectional area with appropriately sized copper neutral / earth conductor with orange LSF oversheath.

Page 4 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

8.3 4 Core Wavecon

Low voltage distribution cables shall be PVC sheathed 3 phase, 600/1000V rated and comply with BS 7870 Section 3.40 Table 2. The conductors shall be 4 core EPR or cross linked polyethylene insulated (XLPE), with solid aluminium phases and a copper stranded waveform concentric earth. The phase conductors shall be either 95 mm, 185 mm or 300 mm cross sectional area with appropriately sized copper earth conductor.

8.4 4 Core LSF Wavecon

Low voltage distribution cables shall be LSF sheathed 3 phase, 600/1000V rated and comply with BS 7870 Section 3.50 Table 2. The conductors shall be 3 core EPR or cross linked polyethylene insulated (XLPE), with solid aluminium phases and a copper stranded waveform concentric combined neutral / earth. The phase conductors shall be either 95 mm, 185 mm or 300mm cross sectional area with appropriately sized copper neutral / earth conductor with orange LSF oversheath.

9 11kV POLYMERIC DISTRIBUTION CABLES 9.1 11kV Polymeric Cables with LLDPE Cable Sheath

Medium voltage distribution cables shall be 3 core 6350/11000V rated and comply generally to BS 7870 Section 420. The conductors shall be triple extruded tree retardent XLPE or EPR insulated with cold strippable insulation screen, with waterblocked stranded aluminium conductors, phase identification and copper wire screen. The oversheath shall be UV stable LLDPE coloured red. SSE standard and preferred sizes shall be either 70 mm, 150 mm or 240 mm cross sectional area with a copper wire screen with equalising wire suitable for an adiabatic earth fault rating of 5 kA for 3 seconds (60 mm). With the written agreement of SSE, 95 mm, 185 mm or 300 mm cross sectional area with a copper wire screen with equalising wire suitable for an adiabatic earth fault rating of 5 kA for 3 seconds (60 mm or 70 mm) may be supplied as an alternative to the preferred standard if the installer is unable to procure cable within a reasonable time period.

9.2 11kV Polymeric Cables with LSF Cable Sheath

Medium voltage distribution cables shall be 3 core 6350/11000V rated and comply generally to BS 7870 Section 420. The conductors shall be triple extruded tree retardent XLPE or EPR insulated with cold strippable insulation screen, with waterblocked stranded aluminium conductors, phase identification and copper wire screen. The oversheath shall be an extruded layer or compound type LTS 1 conforming to the requirements of BS 7655-6.1 and be coloured red. SSE standard and preferred sizes shall be either 70 mm, 150 mm or 240 mm cross sectional area with a copper wire screen with equalising wire suitable for an adiabatic earth fault rating of 5 kA for 3 seconds (60 mm). With the written agreement of SSE, 95 mm, 185 mm or 300 mm cross sectional area with a copper wire screen with equalising wire suitable for an adiabatic earth fault rating of 5 kA for 3 seconds (60 mm or 70 mm) may be supplied as an alternative to the preferred standard if the installer is unable to source cable within a reasonable time period.

Page 5 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

10 33kV POLYMERIC DISTRIBUTION CABLES

33kV single core distribution cables shall comply with BS 7870 Section 410 Table 3. The conductors shall be triple extruded tree retardent XLPE or EPR insulated with cold strippable insulation screen, with stranded copper conductors. The oversheath shall be black MDPE. The preferred conductor sizes are 185 mm, 240 mm and 500 mm copper or 300 mm, 400 mm 500 mm and 630mm aluminium with a 35 mm copper wire screen with equalising wire or tape and water blocking on the screen wires.

11 PILOT CABLES

19 pair 1/08 mm pilot cables to BS 7870 Section 8.2 Table 1 (5 kV) and cable to be filled with suitable compound to meet requirements of paragraph 7. (Note: 19 pair is SSEPD normal standard but different number of pairs may be specified for individual projects)

12 CABLE LAYING 12.1 General

Cables will be installed in accordance with best industry practices. The aim is to install the cable system without damage and to facilitate future operation / maintenance. It must not be fouled by or foul other Utilities plant. All excavations must be carried out in accordance with Regulations 12 & 13 of the Construction (Health, Safety and Welfare) Regulations 1996. The installer shall handle cables with care and install them correctly.

12.2 Position

Cables are always to be installed in footpaths, service strips or unmade ground where available as indicated on the layout drawings provided. Where these facilities are not available, routes need to be agreed in writing with SSE. Installation will be in accordance with the recommendations made by NJUG in their Publication Number 7. There will be times, e.g. when going around other Utilities inspection boxes, that variations will occur. These variations must be agreed with SSE in advance to ensure that vertical and horizontal separation is maintained between utilities. Where cable depth cannot be achieved due to other plant in the ground then variations in the route and / or extra protective measures must be agreed with SSE Power Distribution in advance.

12.3 Cable Examination

The installer shall examine and check the cable for damage during and immediately following cable installation. Any damage that occurs, no matter how small, must be rectified immediately. Any cables severely damaged during the installation process must be replaced.

12.4 Bending Radii

The installer shall ensure the cable bending radii used are not less than that specified by the manufacturer of the cable.

Page 6 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

12.5 Cold Weather

The installer should only lay PVC sheathed cables when the ambient temperature is above 0C and has been above this temperature for the previous 24 hours, or approved special precautions have been taken to maintain the cable above this temperature to avoid the risk of damage during handling.

12.6 Cable Pulling

Where the installer uses a winch it must have a swivel eye fitted. The swivel eye must be in good working order and freely rotate to prevent the cable twisting. The installer must only pull cable by winch where there is a serviceable and accurate dynamometer or an adjustable tension limiting switch fitted. The maximum pulling force must not exceed the values recommended by the manufacturer. The installer shall normally pull LV and 11kV cables by the nose. A cable stocking shall be fully pulled onto the cable to ensure a good grip. More difficult pulls may require the use of an American pulling eye or cable lug attached to the conductors. Rollers should always be used when pulling cables. All rollers used must be in serviceable condition moving easily on their spindle and with rolling surfaces free from damage. The rollers should be placed at approximately four-metre intervals. A leading roller shall be placed at the trench side at the pulling end, with slide rollers on bends and hoop rollers along straight sections. Inverted skid plates should be used to prevent the cable or pull wire rising into obstructions. At duct entries a bell mouth shall be attached at each end with rollers positioned to give central access into the bell mouth. Immediately following installation of cables, the ends of each cable should be inspected for damage and secured against the ingress of moisture by fitting heat shrink or cold shrink caps.

12.7 Separation between two or more circuits

Two or more cables running along the same route will be de-rated unless they are separated. They are also prone to double faults in the event of damage by third parties. LV and 11kV cables should have a minimum separation of 300 mm between cable centres and 33kV circuits 450 mm. Where more than 3 LV and / or 11kV cables run on the same route they will be at their normal respective depths and should have a minimum horizontal separation of 300 mm. Where more than 4 circuits are laid in the same trench the circuit configuration and spacing must be agreed in writing with SSE Power Distribution before work commences.

12.8 Backfill Surrounding Cable

12.8.1

LV & 11kV Cables Cables will be surrounded by a stone free, fine backfill material. This may be suitably graded excavated material or sand. A 50 mm layer will be placed on the bottom if the ground is rough or has sharp stones and further fine fill material placed the installed cable to a depth of 75 mm above the top of the cable To achieve this cables will be installed with the first 50 mm of compacted fine backfill in place.

12.8.2

33kV Cables Cables will be surrounded by material complying with ENA Technical Specification 97-1 with a backfill thermal resistivity of 2.7 or 1.2 as specified by SSE Power Distribution. This material will surround the cable or duct with a minimum depth of 100 mm of material above the top of the cable or duct. Cables laid direct will be installed with the first 50 mm of compacted fine backfill in place.

Page 7 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

13 Cable Warning Marker 13.1 LV and 11kV Warning Tape

Marker tape manufactured to ENA TS 12-23 will be installed over all mains cables, service cables, ducts and service tubes. The tape will be placed 150 mm directly above the cable or duct.

13.2 33kV Plastic Cable Tiles

Plastic marker tiles with minimum dimension of 1000 mm long, 244 mm wide and 12 mm thick with plastic marker tape manufactured to ENA TS 12-23 bonded to the upper surface of the tile. The tiles will pegged or secured together and will be placed centrally 150 mm above every circuit for its entire length.

13.3 Trench Cross Sections

The trench sections below show the depths to the top of the cable, duct or service tube and minimum widths for various cable combinations. The bottom of the trench must be free of sharp stones and other materials that might damage the cable. In rough ground it may be necessary to excavate another 50 mm depth and lay a bedding of sand or other suitable fine backfill material. The trench edge nearest the kerb edge must be positioned a minimum of 1200 mm from the kerb edge to allow for separation from other utility plant.

13.4 Trench Reinstatement

All reinstatement in footways or highways must comply with New Roads and Street Works Act 1991, Specification for the Reinstatement of Openings in Highways.

a) LV Service cable or service tube b) Single LV main

Fig 1 M 150 300 A 150

2 LV Mains Fig. 2

a) (1LV) + (111kV) b) (2LV) + (211kV) Fig. 3

A M B

300 450 300

450 TRENCH CROSS SECTIONS - LV & 11kV CABLES Cable Type Unmade Ground, Roadway Agricultural Trench Depths Grassland or Depth mm Land Depth Footway mm Depth mm A -LV Services 450 800 1000 and Mains B - 11kV Mains 600 800 1000 M Position of cable marker tape/s

Page 8 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

A T T 150 Ducted cable & pilot cable 450 700 min. Direct burial bound in trefoil or triplex & pilot cable

TRENCH CROSS SECTIONS 33kV AND PILOT CABLES Cable Type Unmade Ground, Roadway Agricultural Trench Depth Grassland or Depth mm Land Footway Depth mm Depth mm A 33kV Single 800 900 1150 Core Polymeric Cable and Pilot Cable T Plastic Cables Tile/s

13.5 Testing Low Voltage Cables.

13.5.1 SSE Power Distribution requires mains and service cables to be tested and the

results recorded. For mains cables a 500 volt insulation resistance test is required between all phase cores and between all cores and earth. An insulation test is also required between the cable earth screen and an independent earth matt or rod where the cable installation was not witnessed and / or commissioning is delayed over 7 days from installation. The minimum acceptable insulation resistance value shall be 50 megohms. A continuity test on all cores is also required.

13.5.2 For service cables the same tests in par. 10.8.2 above. In addition an earth loop

impedance test (035 ohms for PME (Protective Multiple Earthing) single phase services and 08 ohms for SNE (Separate Neutral Earthing)) and correct polarity confirmed.

13.5.3 All results must be recorded on Declaration of Test Results for LV New Cable

Installations & Declaration of Test Results for New Substation equipment.

13.5.4 Testing of 11kV and 33kV Cables.

Page 9 of 10

Applies to: Third party installers of new connections Prepared by: MJG

SPECIFICATION FOR ELECTRICITY SERVICE AND DISTRIBUTION CABLES FOR USE DURING THE INSTALLATION OF NEW CONNECTIONS Uncontrolled if printed

SP-PS-313

Rev: 1.02

13.5.5 Testing to be carried out in accordance with SSE procedure PR-PS-063 and

include a 5 kV sheath test to prove the integrity of the cable sheath.

13.5.6 All results must be recorded on Declaration of Test Results for HV New Cable

Installations & Declaration of Test Results for New Substation Equipment

14 APPLICABLE STANDARDS 14.1 Third Parties will obtain copies on non SSE Standards from the issuing organisations at

their own expense.

14.2 Third Parties will obtain copies of SSE Standards from the Scottish & Southern Energy

Power Systems Document Administrator, Inveralmond House, 200 Dunkeld Road, Perth PH1 3AQ.

14.3 There will be a cost of 50 for each specification to cover administration and copying costs.

Page 10 of 10

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- L10 OdeDocument14 pagesL10 OdeMahir MahmoodNo ratings yet

- CentroidDocument19 pagesCentroidragupathiindia100% (1)

- 7 e Full TOCdynamicsDocument5 pages7 e Full TOCdynamicsMahir MahmoodNo ratings yet

- L09 NumIntegDocument14 pagesL09 NumIntegMahir MahmoodNo ratings yet

- Kirch Off Appendix BDocument9 pagesKirch Off Appendix BMahir MahmoodNo ratings yet

- Panel With Radius R D 5 Mm. Determine The Circumfer-Ence C and Area A of The Hole To Four Significant DigitsDocument5 pagesPanel With Radius R D 5 Mm. Determine The Circumfer-Ence C and Area A of The Hole To Four Significant DigitsMahir MahmoodNo ratings yet

- ENG36 Statics Course OutlineDocument5 pagesENG36 Statics Course OutlineMahir MahmoodNo ratings yet

- Numerical Methods For EngineersDocument17 pagesNumerical Methods For EngineersMahir MahmoodNo ratings yet

- Roots of Equations SolvedDocument21 pagesRoots of Equations SolvedRibesha MushNo ratings yet

- Statics: ENGR 01.271 - Fall 2006 Section Place Meeting Times Instructor Office HoursDocument2 pagesStatics: ENGR 01.271 - Fall 2006 Section Place Meeting Times Instructor Office HoursMahir MahmoodNo ratings yet

- Are The Reactions at C in The Two Cases?: Problem 5.49 The Tension in Cable AB Is 2 Kn. WhatDocument5 pagesAre The Reactions at C in The Two Cases?: Problem 5.49 The Tension in Cable AB Is 2 Kn. WhatMahir MahmoodNo ratings yet

- Kirch Off Appendix ADocument13 pagesKirch Off Appendix AMahir MahmoodNo ratings yet

- Prerequisite:: The Ability To Determine Forces and Stresses in Elementary Structural SystemsDocument5 pagesPrerequisite:: The Ability To Determine Forces and Stresses in Elementary Structural SystemsMahir MahmoodNo ratings yet

- Find centroid coordinates for composite area problemDocument3 pagesFind centroid coordinates for composite area problemMahir MahmoodNo ratings yet

- Find centroid coordinates for composite area problemDocument3 pagesFind centroid coordinates for composite area problemMahir MahmoodNo ratings yet

- Formule Geometrijskih Slika I TijelaDocument3 pagesFormule Geometrijskih Slika I TijelaMahir MahmoodNo ratings yet

- Chapter 2: 1-D Kinematics:Velocity & Acceleration. - Updated 9/6/06Document5 pagesChapter 2: 1-D Kinematics:Velocity & Acceleration. - Updated 9/6/06Mahir MahmoodNo ratings yet

- CentroidDocument4 pagesCentroidMahir MahmoodNo ratings yet

- Ex MatlabDocument7 pagesEx MatlabAbdulrhman AL-MasreNo ratings yet

- Engr36 F10Document5 pagesEngr36 F10Mahir MahmoodNo ratings yet

- Engr36 F10Document5 pagesEngr36 F10Mahir MahmoodNo ratings yet

- 14 Thermal Lab 2009Document7 pages14 Thermal Lab 2009Mahir MahmoodNo ratings yet

- Projectile Motion: V V Sin V V CosDocument10 pagesProjectile Motion: V V Sin V V CosMahir MahmoodNo ratings yet

- Engineering Thermodynamics Lecture Notes (Draft) : Wayne HackerDocument24 pagesEngineering Thermodynamics Lecture Notes (Draft) : Wayne Hackerrkadiraj7011No ratings yet

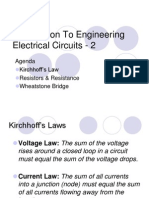

- Electrical Circuits Kirchhoff's Laws Resistors Wheatstone BridgeDocument9 pagesElectrical Circuits Kirchhoff's Laws Resistors Wheatstone BridgeMahir MahmoodNo ratings yet

- Series & Parallel CktsDocument13 pagesSeries & Parallel CktsGowri PonprakashNo ratings yet

- Electrical Circuits - 1Document13 pagesElectrical Circuits - 1Mahir MahmoodNo ratings yet

- House Electrical CircuitsDocument1 pageHouse Electrical CircuitsMahir MahmoodNo ratings yet

- Basic Electrical: Basic Electricity and ElectronicsDocument12 pagesBasic Electrical: Basic Electricity and ElectronicsRishabh JainNo ratings yet

- Elt 111 Circuit Analysis I Network Theorems: Lecture NotesDocument1 pageElt 111 Circuit Analysis I Network Theorems: Lecture NotesMahir MahmoodNo ratings yet