Professional Documents

Culture Documents

SolidsHandouts4 PDF

Uploaded by

mahreza189Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SolidsHandouts4 PDF

Uploaded by

mahreza189Copyright:

Available Formats

SOLIDS PROCESSING HANDOUTS, George G.

Chase, The University of Akron

HANDOUT 4.1

1 0.9 0.8 0.7 Porosity 0.6 0.5 0.4 0.3 0.2 0.1 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Sphericity 1 Loose Normal Dense

Figure 4-5. Porosity as a function of sphericity and packing structure. Loose packed materials are ones that have not had much time to settle due to vibrations. A normal packed material is one that may have sat for several days or weeks. Dense packed materials are ones that have sat for a year or more and have had ample time to settle and vibrate into its most densely packed structure under force of gravity.

The plot in Figure 4-5 is obtained by curve fitting data. The loose packed porosity is a function of sphericity given by

Loose = 0.4411 2 1.1042 + 1.0873 All three curves are generated by defining a packing parameter, , such that 0 for Loose Packing = 0.5 for Normal Packing 1 for Dense Packing

and the porosity is given by for any packing condition.

(4-6)

(4-7)

= (1 0.297 ( 0.8)) Loose

(4-8)

SOLIDS PROCESSING HANDOUTS, George G. Chase, The University of Akron

HANDOUT 4.2

Krieger-Dougherty Equation for estimating bulk viscosity of slurries (I.M. Krieger and T.J. Dougherty, Trans.Soc. Rheol., 3, 137-152, 1959) has the form

(1 ) = 1 (1 ) c

0

A (1 c )

(4-9)

where A is a material parameter. Bird et.al. (R.B. Bird, W.E. Stewart, and E.N. Lightfoot, Transport Phenomena, 2nd ed., Wiley, New York, 2002) list values for parameter A from several references. A plot of the data in Figure 4-6 gives a rough approximation between A and c as A 10.1 c (4-10) The data points in the plot are scattered meaning that Eq.(4-6) should only be used if experimental data are not available.

12

Material

y = 10.107x R2 = 0.4134

A 2.7 3.28 3.25 5.0 9.0 9.25 9.87 5.8 3.8 5.03 6.0

c

0.29 0.39 0.31 0.45 0.65 0.732 .618 .629 0.626 0.74 0.767

10

Submicron spheres 40 micron spheres Ground Gypsum TiO2 Laterite Glass Rods 30x700m Glass Rods 100x400m Quartz grains 53-76 m Glass fiber aspect ratio 7 Glass fiber aspect ratio 14 Glass fiber aspect ratio 21

0 0 0.1 0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Figure 4-6 Relation between parameter A and c in Eq. (4-10).

SOLIDS PROCESSING HANDOUTS, George G. Chase, The University of Akron

HANDOUT 4.3

Janssens coefficient is defined as

K=

where rr and zz are the stress components in the r and z directions. These stresses are the total stresses acting on the multiphase material. These stresses are the sum of the fluid phase and solid phase stresses. Hence, this definition applies whether the material is totally liquid, totally solid, or a mixture in-between. This coefficient represents the ratio of the measurable stresses, as can be measured with a strain gauge to measure the force acting on a defined probe surface. For a pure liquid we know that the probe would measure an equal pressure in all directions within the liquid at a given point within the liquid at stagnant conditions. Hence for a pure liquid K=1. For a totally solid material K=0 because we know we can set a weight on top of a solid block and all of the stresses within the block are aligned vertically. Figure 4-9 gives a rough correlation showing the Janssens coefficient approximate values for several fluid-solid mixture materials. This correlation is crude, it only gives a rough approximation. For most granular materials we can take Janssens coefficient to be approximately 0.4.

rr zz

(4-22)

LIQUIDS LOW CONCENTRATION SLURRIES HIGH CONCENTRATION SLURRIES

FILTER CAKES PACKED BEDS GRANULAR MATERIALS POLYMERS

0 0

SOLIDS

VOLUME FRACTION LIQUID Figure 4-9. Janssens Coefficient for various materials.

SOLIDS PROCESSING HANDOUTS, George G. Chase, The University of Akron

HANDOUT 4.4

Table 4-2. Permeabilities of typical materials.

Material

Clean sand, sand-gravel mixture Non-woven glass fiber filter media fine sand, silt, loam peat filter aides (diatomaceous earth, etc.) clay sandstone granite

Permeability Coefficient, k (m2) 10-12 to 10-9 10-10 to 10-9 10-16 to 10-12 10-13 to 10-11 10-14 to 10-12 10-16 to 10-13 10-16 to 10-11 10-20 to 10-18

You might also like

- Kiln Shell CoolingDocument4 pagesKiln Shell CoolingjmpbarrosNo ratings yet

- 1-X Lift Liner CatalogueDocument6 pages1-X Lift Liner Cataloguemahreza189No ratings yet

- 1-X Win CatalogueDocument6 pages1-X Win Cataloguemahreza189No ratings yet

- Kiln StabilityDocument6 pagesKiln Stabilityraobabar21No ratings yet

- 6-SD Reference ListDocument5 pages6-SD Reference Listmahreza189No ratings yet

- 1 - Grinding Media Catalogue PDFDocument14 pages1 - Grinding Media Catalogue PDFmahreza189No ratings yet

- General InformationDocument1 pageGeneral Informationmahreza189No ratings yet

- Reframag AfDocument1 pageReframag Afmahreza189No ratings yet

- Irjet V2i151 PDFDocument9 pagesIrjet V2i151 PDFmahreza189No ratings yet

- Mcr-T1: Raw Material BasisDocument1 pageMcr-T1: Raw Material Basismahreza189No ratings yet

- New Developments in Monolithic ProductsDocument59 pagesNew Developments in Monolithic Productsmahreza189100% (1)

- Compac Shot B84 3Document1 pageCompac Shot B84 3mahreza189No ratings yet

- Energy and PowerDocument69 pagesEnergy and PowerFahadullah Khan AfridiNo ratings yet

- Mcr-T1: Raw Material BasisDocument1 pageMcr-T1: Raw Material Basismahreza189No ratings yet

- Compac Sol B82-6: General InformationDocument1 pageCompac Sol B82-6: General Informationmahreza189No ratings yet

- Divasil: General InformationDocument1 pageDivasil: General Informationmahreza189No ratings yet

- General InformationDocument1 pageGeneral Informationmahreza189No ratings yet

- Compac Sol F53G-6: General InformationDocument1 pageCompac Sol F53G-6: General Informationmahreza189No ratings yet

- Compac Sol FS98 3Document1 pageCompac Sol FS98 3mahreza189No ratings yet

- Compac Sol FS98 3Document1 pageCompac Sol FS98 3mahreza189No ratings yet

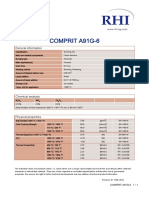

- Comprit A91g 6Document1 pageComprit A91g 6mahreza189No ratings yet

- Compac Sol A100 15 PDFDocument1 pageCompac Sol A100 15 PDFmahreza189No ratings yet

- Carsit Sol A10mb 15 PDFDocument1 pageCarsit Sol A10mb 15 PDFmahreza189No ratings yet

- Didomur B52V-03 M: General InformationDocument1 pageDidomur B52V-03 M: General Informationmahreza189No ratings yet

- Compac Sol F53 6Document1 pageCompac Sol F53 6mahreza189No ratings yet

- Compac Shot F49S-6: General InformationDocument1 pageCompac Shot F49S-6: General Informationmahreza189No ratings yet

- Compac Shot F49-6: General InformationDocument1 pageCompac Shot F49-6: General Informationmahreza189No ratings yet

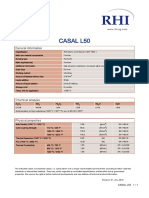

- Casal L50: General InformationDocument1 pageCasal L50: General Informationmahreza189No ratings yet

- Compac Shot F49-6: General InformationDocument1 pageCompac Shot F49-6: General Informationmahreza189No ratings yet

- Compac Shot B84 3Document1 pageCompac Shot B84 3mahreza189No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bs en 1991-1-5 2003 + 2009 Thermal Actions (Unsecured)Document52 pagesBs en 1991-1-5 2003 + 2009 Thermal Actions (Unsecured)Tan Gui SongNo ratings yet

- Ril Competitive AdvantageDocument7 pagesRil Competitive AdvantageMohitNo ratings yet

- Surge Arrester: Technical DataDocument5 pagesSurge Arrester: Technical Datamaruf048No ratings yet

- National Senior Certificate: Grade 12Document13 pagesNational Senior Certificate: Grade 12Marco Carminé SpidalieriNo ratings yet

- RFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonDocument8 pagesRFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonSteven MoietNo ratings yet

- Adjectives With Cork English TeacherDocument19 pagesAdjectives With Cork English TeacherAlisa PichkoNo ratings yet

- Pet Care in VietnamFull Market ReportDocument51 pagesPet Care in VietnamFull Market ReportTrâm Bảo100% (1)

- Vylto Seed DeckDocument17 pagesVylto Seed DeckBear MatthewsNo ratings yet

- Optimization of Crude Oil DistillationDocument8 pagesOptimization of Crude Oil DistillationJar RSNo ratings yet

- NCR Minimum WageDocument2 pagesNCR Minimum WageJohnBataraNo ratings yet

- The Fundamentals of Investing PPT 2.4.4.G1Document36 pagesThe Fundamentals of Investing PPT 2.4.4.G1Lùh HùñçhòNo ratings yet

- SKF LGMT-2 Data SheetDocument2 pagesSKF LGMT-2 Data SheetRahul SharmaNo ratings yet

- Appleyard ResúmenDocument3 pagesAppleyard ResúmenTomás J DCNo ratings yet

- Business-Model Casual Cleaning ServiceDocument1 pageBusiness-Model Casual Cleaning ServiceRudiny FarabyNo ratings yet

- Shares and Share CapitalDocument50 pagesShares and Share CapitalSteve Nteful100% (1)

- Effect of Internet Use To Academic PerformaceDocument4 pagesEffect of Internet Use To Academic PerformaceLeonard R. RodrigoNo ratings yet

- Common OPCRF Contents For 2021 2022 FINALE 2Document21 pagesCommon OPCRF Contents For 2021 2022 FINALE 2JENNIFER FONTANILLA100% (30)

- Kuper ManualDocument335 pagesKuper Manualdonkey slap100% (1)

- Sec2 8 PDFDocument3 pagesSec2 8 PDFpolistaNo ratings yet

- SOP No. 6Document22 pagesSOP No. 6Eli CohenNo ratings yet

- Idmt Curve CalulationDocument5 pagesIdmt Curve CalulationHimesh NairNo ratings yet

- Computerized AccountingDocument14 pagesComputerized Accountinglayyah2013No ratings yet

- Pharaoh TextDocument143 pagesPharaoh Textanon_31362848No ratings yet

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriNo ratings yet

- Ahakuelo IndictmentDocument24 pagesAhakuelo IndictmentHNNNo ratings yet

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDocument2 pagesHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaNo ratings yet

- Sikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPDocument15 pagesSikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPHemant MeenaNo ratings yet

- QuestionDocument7 pagesQuestionNgọc LuânNo ratings yet

- Computer System Sevicing NC Ii: SectorDocument44 pagesComputer System Sevicing NC Ii: SectorJess QuizzaganNo ratings yet

- Flyer Manuale - CON WATERMARK PAGINE SINGOLEDocument6 pagesFlyer Manuale - CON WATERMARK PAGINE SINGOLEjscmtNo ratings yet