Professional Documents

Culture Documents

SAP Manufacturing Execution

Uploaded by

rizqi_83Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAP Manufacturing Execution

Uploaded by

rizqi_83Copyright:

Available Formats

SAP Solution in Detail SAP Manufacturing SAP Manufacturing Execution

SAP Manufacturing Execution

Manage, Control, and Integrate Production with the Enterprise

With the SAP Manufacturing Execution application, you can manage, control, and execute shop-floor production and connect manufacturing operations with the rest of your enterprise. The application facilitates the closed-loop flow of information between the production floor and your global enterprise and supply chain. You can achieve more accurate, detail-oriented control over the shop floor, across your entire fleet of plants, and around the world. And by leveraging real-time data, you can improve product quality, satisfy customer expectations, and impact the bottom line.

CONTENT

4 Achieve Shop-Floor to Top-Floor Integration 5 Improve Production Process Visibility 6 Elevate Manufacturing Quality, Speed, and Flexibility 6 Higher Product and Process Quality 6 Better Throughput 6 Streamlined Compliance Processes 6 Greater Flexibility 6 Optimal Asset Utilization

7 Optimize Shop-Floor Execution 7 Coordinated Manufacturing Operations 8 Product Lifecycle Traceability 8 Support Continuous Improvement Initiatives 9 Labor Tracking 9 Identify Inefficiencies 9 Production Transfer 9 Match Production to Available Resources 9 Engineering Change Management 10 Keep Your Production Plans on Schedule 10 Nonconformance Management 10 Return and Repair Management 11 Strive for the Perfect Plant 12 Benefit from Greater Control and Visibility

Achieve Shop-Floor to Top-Floor Integration

Maximize Control of Production Operations

Leading manufacturers realize they must optimize control over shop-floor operations to succeed in a global economy characterized by intense competition, compliance requirements, ever-changing customer demands, and relentless pressure to reduce costs. To achieve this goal, manufacturers must integrate the shop floor to the enterprise, enabling closed-loop business processes. Companies frequently implement a manufacturing execution system (MES) to monitor, record, and guide production activities. The use of MESs gives rise to another complex issue: the need to integrate them with enterprise resource planning (ERP) solutions that guide top-floor decision making. Its also important to provide visibility across the value chain for better strategic business decisions and responsiveness. The SAP Manufacturing Execution application provides a powerful means for managing and controlling shopfloor operations. Because it enables enterprise-wide integration, the application facilitates processes critical to shop-floor execution, including process control, production quality,

traceability, labor management, production transfer, engineering change management, and return and repair management. It captures, shares, stores, and reports data that determines how a product is manufactured, enabling you to recognize and respond rapidly to configuration or quality changes. The result is improved product quality and delivery performance, yielding reduced production costs. In short, SAP Manufacturing Execution helps manufacturers accomplish the following: Meet regulatory compliance through powerful product traceability and reporting Improve production quality with better control and communication of manufacturing processes Address requirements for serialnumber generation and serialized traceability Implement and enforce standards across global operations Efficiently manage extensive work-inprocess (WIP) rework and frequent or complex engineering change orders Streamline the new-product introduction (NPI) process to realize ramp-to-volume manufacturing

SAP Manufacturing Execution provides a means for managing and controlling shopfloor and manufacturing operations. The application facilitates processes, including shop-floor execution and reporting, traceability, labor management, production transfer, return and complaint management, and test and repair. The result is improved quality and delivery performance, yielding reduced costs.

SAP Solution in Detail SAP Manufacturing Execution

Capture and Report Manufacturing Operation Details

Improve Production Process Visibility

Our customers spanning discrete industries such as high tech, aerospace and defense, automotive, industrial machinery and components, and medical devices tell us that they need to capture and report on critical details to better control production processes. The reasons vary from regulatory and customer compliance to the drive to reduce costs, meet production goals, improve product quality, and achieve other business-critical objectives. However, many organizations are saddled with legacy and point solutions, leaving crucial production process and product data details isolated in separate silos. In these cases, management must function without sufficient visibility into manufacturing operations, with manual inefficiencies and disparate data sources blocking the ability to make informed and timely business decisions.

To enable a more adaptive enterprise, organizations need transparency in all aspects of manufacturing operations. They need improved execution efficiency through real-time process monitoring and control; enhanced communications between management and production personnel; and fast access to accurate, relevant, and timely data. SAP Manufacturing Execution joins the shop floor with the rest of the enterprise, providing managers with rapid access to critical data, enhanced intrabusiness communication, and real-time process monitoring and reporting. Managers and executives can tap the pulse of the organization without slowing down the production process or adding to lead time. Shop-floor workers can perform more efficiently and effectively. And you can make engineering changes to products currently in production with greater speed, accuracy, and flexibility (see Figure 1).

Manufacturing engineering Work instructions, engineering changes

Figure 1: On-the-Fly Engineering Changes

Global manufacturing platform

SAP Solution in Detail SAP Manufacturing Execution

Elevate Manufacturing Quality, Speed, and Flexibility

Integrate Production Activities into the Enterprise

SAP Manufacturing Execution integrates production operations at key points throughout the enterprise, enabling you to monitor, record, and guide manufacturing activities, so your organization can realize the following business benefits.

Higher Product and Process Quality

With SAP Manufacturing Execution, you can boost productivity and product quality by improving your ability to measure, record, and evaluate processes and facilitate the adoption of best practices by employees. Real-time visibility into manufacturing operations helps you pinpoint and manage quality issues quickly, and traceability functionality reduces warranty and liability risks and costs.

example, it captures and references a complete and permanent genealogy record of the product being built. This enables you to establish a set of repeatable processes and access an audit trail of all processes, resources, components, and materials used during the manufacturing process. In addition, with tracking functionality that links completed products and components, you can identify the products most likely to be affected by or involved with a problem. As a result, you can limit exposure to warranties and mitigate risks while controlling recall cost.

Greater Flexibility

SAP Manufacturing Execution gives you the flexibility to provide custom orders and make products to meet market demand. You can better conform to specific customer requirements, simultaneously improving customer service and efficiency. The application facilitates shifting production from one product to another or from one plant to another while supporting plants with a large number of product offerings.

Better Throughput

With improved work status visibility and analytics, you can increase throughput by spotlighting problem areas where processes slow down, for example, due to nonconforming processes, logistical issues, or a shortage of production materials. The application enables best-practice adoption with up-to-date information on process plans and work instructions.

Optimal Asset Utilization

You can increase your return on assets and lower costs by maximizing asset use, performing work in the right location for the job, and reducing application and software downtime during changeovers. SAP Manufacturing Execution facilitates preventative maintenance by putting production and process data at employees fingertips, minimizing downtime, and keeping daily operations running smoothly.

Streamlined Compliance Processes

The application helps streamline compliance activities and reduce associated costs with genealogy management, performance management, and automated data collection functionality. For

With SAP Manufacturing Execution, you can boost productivity and product quality by improving your ability to measure, record, and evaluate processes and facilitate employee best-practice adoption. Real-time visibility into manufacturing operations helps you pinpoint and manage quality issues quickly, and traceability functionality reduces warranty and liability risks and costs.

SAP Solution in Detail SAP Manufacturing Execution

Optimize Shop-Floor Execution

Enable Better Decisions with Complete, Flexible Tools

SAP Manufacturing Execution is an enterprise-level, scalable, J2EE manufacturing application that enables global manufacturers to manage and control shop-floor operations. This powerful application provides a multifaceted set of features that integrates business systems with the shop floor, allowing complete component- and item-level traceability for single and global installations. SAP Manufacturing Execution helps ensure that products are built as designed and built right the first time. It collects data from multiple sources, integrating data systems with shop-floor activities to create one comprehensive as-built production record. The result is an aggregate record of the entire product history, stored and available to drive effective decision making and regulatory compliance. SAP Manufacturing Execution includes specific functionality that supports the following manufacturing requirements.

Figure 2: Executive Dashboard

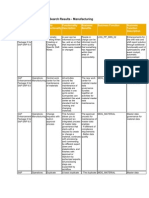

Coordinated Manufacturing Operations

The ability to collect information from multiple sources enables the coordination of manufacturing functions with data systems to create a single comprehensive production record. With role-based interfaces, users from the shop floor to the boardroom can access real-time information to perform more efficiently. Taking advantage of up-to-the-minute data on all operations, you can greatly streamline and empower decisionmaking processes while eliminating time-consuming production meetings that often work off outdated information and assumptions. You can manage plant activities with the executive dashboard

Figure 3: Production Operator Dashboard

viewer (see Figure 2) and get an upclose view of manufacturing activities with the production operator dashboard (see Figure 3).

You can even drill down into dashboard views to access additional detail.

SAP Solution in Detail SAP Manufacturing Execution

Product Lifecycle Traceability

The ability to trace the entire history of a product through design, planning, manufacturing, shipping, and maintenance is particularly important for regulatory compliance. With SAP Manufacturing Execution, you can capture a complete and permanent genealogy record of your products, including multilevel detail. This enables quick electronic recall of product, process, resource, and material information. The application tracks, collects, and verifies information on all product components, creating an audit trail of all processes, resources, components, and materials involved in manufacturing the product. For example, the solution enables you to trace device history (see Figure 4) and view activity log reports (see Figure 5). If a defect is detected, you can immediately trace back to the source of the problem (for example, the item, process, or supplier at fault) and take action to provide corrective and preventive steps while mitigating risks. Support Continuous Improvement Initiatives SAP Manufacturing Execution is a vital tool for continuous improvement initiatives. By capturing the complete, accurate product genealogy, from initial order to final shipment, the application enables you to respond in a timely manner to product concerns, customer questions, or regulatory inquiries. By providing greater insight into product movement, it helps management identify problem suppliers or weak elements in your production system, resolve bottlenecks, and meet future labor and scheduling needs while

Figure 4: Device History Report

Figure 5: Activity Log Report

SAP Solution in Detail SAP Manufacturing Execution

Transfer production globally

with the manual transfer of records and setup of a production line. This information can be received automatically or, at your shop-floor managers discretion, manually and then inserted into the production process. Match Production to Available Resources SAP Manufacturing Execution enables you to transfer current WIP to other sites, including all the traceability information, activity logs, and nonconformance data associated with the product configuration. This allows your planners to distribute production properly across available sites and labor resources. It also enables shop-floor managers to see all the information associated with the product. The application preserves a complete manufacturing history of the product at one site even if the product is produced at different sites, letting you work more efficiently, reduce product cycle times, and increase customer satisfaction.

Figure 6: Global Production Transfer

incorporating improvements into the production process. This quick access to information also helps decision makers observe trends, taking the steps necessary to reduce the risk of defects escaping from the shop floor.

Labor Tracking

SAP Manufacturing Execution provides tools to document and track employee time and attendance accurately, helping to satisfy payroll and contract billing requirements. The application also facilitates the assignment of labor costs to specific projects or shop orders, enabling the accurate allocation of these costs across the manufacturing process. You can track time spent working on particular components and units for greater visibility into projectand task-specific costs. For example, aerospace and defense companies working on government contracts can improve required time-tracking and employee data accrual processes, reducing costs and increasing efficiency. For longer manufacturing times, collection of earned standards will enable production personnel to take credit for partial work completed.

Identify Inefficiencies Using the data captured by SAP Manufacturing Execution, you can detect bottlenecks in the workforce, trace labor charge codes back to the appropriate contract, and rapidly identify labor shortages on the production line. As a result, you can improve procedural or process inefficiencies, reduce turnaround time for incoming orders, and meet customer delivery demands.

Production Transfer

Beyond connecting the wider enterprise to the production organization, SAP Manufacturing Execution helps you integrate your enterprise with numerous production facilities, greatly enhancing visibility and flexibility across global locations. The application enables you to configure and automatically transfer product configuration and production information including related activity records, component traceability records, and nonconformance data to single or multiple sites (see Figure 6). This lets you preserve a complete, as-built history of the product for future reference. By electronically sending the complete product history from the NPI site to the recipient production site or sites, the application helps eliminate delays associated

Engineering Change Management

Traditionally, manufacturers have reacted to a change request by making the necessary adjustments to an order released into production. However, the change details often never make it back to engineering, leading to confusion when the job returns to the shop floor. To avoid confusion and keep production plans on schedule, you need to manage feedback from numerous parties. The SAP Manufacturing Execution application helps ensure an effective, closed-loop feedback process for changes driven by design integrity, cost control, inventory, and other issues

SAP Solution in Detail SAP Manufacturing Execution

time-based component traceability, and gauge the effectiveness of manual assembly processes. An integrated environment for optimizing all facets of test and repair from equipment control to repair loop management provides critical functionality that helps improve your operational efficiency and that of your service providers. Test results are compared and stored with existing database data to track repairs continuously and enable a fact-based diagnosis of issues. SAP Manufacturing Execution creates a dynamic knowledge base of verified repair actions that supports continuous improvement initiatives, minimizes defects, reduces scrap, and improves throughput and yields. You can even view summaries sorted by code reports and use sophisticated diagnostic functionality for product and process analysis.

Figure 7: Code Report Summaries

for example, a part requirement change in the bill of materials. Product and process engineering changes can be readily communicated to the shop floor. You can initiate change requests in real time, not after the fact, maintaining order integrity while controlling costs and keeping a complete historical reference. Further, you can process engineering change orders for products currently in production for great flexibility and speed. Keep Your Production Plans on Schedule By capturing revision history, SAP Manufacturing Execution helps ensure that your organization follows proper product builds and process flows without needing to establish new bills of materials or routings or get input from the engineers. Efficient, closedloop feedback helps keep production plans on schedule. The application

initiates real-time change requests to your released and pending orders to maintain order integrity and complete historical reference. You can also generate an engineering change order for multiple planned changes across one or more released orders. In addition, SAP Manufacturing Execution provides your decision makers with the visibility to implement change orders into production process in real time.

Return and Repair Management

Best-in-class customer service includes timely processing of returned products. SAP Manufacturing Execution effectively executes service orders and facilitates the management of returns throughout both the production environment and the enterprise as a whole. Feedback on the reasons for returns and repair provides valuable information useful in improving product quality. SAP Manufacturing Execution enables you to track returned products or components through their lifecycle right down to return delivery to customers. This provides companies with valuable information for product development, launch, design, and production.

Nonconformance Management

Delivering quality products on time is essential for any manufacturing organization. Now you can test, track, identify, and repair defects quickly with a comprehensive repair-loop management environment and create a database that supports essential continuous improvement initiatives. As a result, you can view complex design data, monitor critical components using

10

SAP Solution in Detail SAP Manufacturing Execution

Strive for the Perfect Plant

Improve Performance with Enhanced Visibility

To achieve the ultimate goal of running the perfect plant, you need 360degree visibility into all aspects of your manufacturing operations. With SAP software, you gain the visibility to optimize manufacturing asset utilization and increase production performance. Distributed enterprises face disconnects between crucial manufacturing processes and data that slow production, decrease quality, and reduce profits. For instance, a typical manufacturing plant may run between 10 and 50 shop-floor automation (SFA) systems, while a multisite manufacturer may have between 40 and 700 SFA systems across the enterprise. With SAP Manufacturing Execution, you can better address the challenges caused by disparities of solutions and data, align and improve key performance indicators, and drive real value in the following ways: Reduce manufacturing costs through process monitoring and increased visibility Increase plant efficiencies with process optimization and enterprise-wide integration Raise production yields through proactive event monitoring and timely corrective actions Lower maintenance costs with streamlined maintenance processes and alignment with manufacturing metrics Reduce capital investments with improved asset performance and reliability Decrease inventory by enforcing lean processes to streamline and reduce execution variability

With improved work status visibility, you can increase throughput by spotlighting problem areas where processes slow down, for example, due to logistical issues or a shortage of production materials. The application enables best-practice adoption with up-to-date information on process plans and work instructions. It helps you optimize plant production with advanced scheduling and automatic work-dispatching functionality.

Reduce premium freight costs with integration of manufacturing events with the enterprise and supply chain Improve value-chain agility and customer responsiveness through complete value-chain integration and visibility In short, SAP Manufacturing Execution helps you leverage your existing data, infrastructure, and investments in enterprise applications and optimize front-line business processes and operations. Your company can strive toward the goal of the perfect plant by improving delivery times, increasing yields, and optimizing asset utilization and fulfillment processes, yielding lowering costs. SAP Manufacturing Execution facilitates control across the organization with improved visibility at many levels into individual plants, the extended supply chain, and enterprise-wide engineering and manufacturing operations.

SAP Solution in Detail SAP Manufacturing Execution

11

Benefit from Greater Control and Visibility

Manage and Coordinate Production Operations

Powered by the SAP NetWeaver technology platform, SAP Manufacturing Execution integrates smoothly with your SAP ERP application and can be deployed quickly. As a result, your company can realize the following business benefits: Better visibility into production operations to identify problem areas and increase throughput Greater control over shop-floor production in all plants to optimize quality and reduce costs Higher product quality, customer satisfaction, and bottom-line results To learn more about how SAP Manufacturing Execution can help you optimize your manufacturing operations, contact your SAP representative today or visit www.sap.com/solutions/manufacturing /manufacturing-execution.

12

SAP Solution in Detail SAP Manufacturing Execution

Quick facts

www.sap.com /contactsap

Summary Integrate shop-floor production operations with the rest of your enterprise with the SAP Manufacturing Execution application. The application facilitates real-time visibility and reporting into plant-floor activities to enable accurate, precise manufacturing execution across your global fleet of plants. Business Challenges Enable full visibility into production operations to achieve fact-based decision making Eliminate information lag to and from the manufacturing department and other areas of the enterprise Connect manufacturing execution systems with the enterprise for integrated shop-floor control, delivering timely and accurate information exchanges Satisfy requirements associated with complex compliance mandates and fluid customer demand Key Features Product quality and production Improve ability to monitor, record, and control manufacturing activities Throughput Speed up operations with improved visibility and best-practice adoption Preventative maintenance Optimize asset utilization Compliance Meet complex regulations more easily Production Increase flexibility and ability to meet varied and changeable customer demand Work-in-process engineering Execute changes smoothly Business Benefits Improve control over manufacturing operations with an integrated application connected with enterprise software solutions Decrease costs and time to market with lower manufacturing process downtime Meet highly specific and time-sensitive customer demands through more agile, flexible production operations Reduce compliance costs and risks with powerful product traceability For More Information Call your SAP representative, or visit us at www.sap.com/solutions/manufacturing/manufacturing-execution.

50 092 913 (11/09) 2011 SAP AG. All rights reserved. SAP, R/3, SAP NetWeaver, Duet, PartnerEdge, ByDesign, SAP BusinessObjects Explorer, StreamWork, SAP HANA, and other SAP products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of SAP AG in Germany and other countries. Business Objects and the Business Objects logo, BusinessObjects, Crystal Reports, Crystal Decisions, Web Intelligence, Xcelsius, and other Business Objects products and services mentioned herein as well as their respective logos are trademarks or registered trade marks of Business Objects Software Ltd. Business Objects is an SAP company. Sybase and Adaptive Server, iAnywhere, Sybase 365, SQL Anywhere, and other Sybase products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Sybase, Inc. Sybase is an SAP company. All other product and service names mentioned are the trademarks of their respective companies. Data contained in this document serves informational purposes only. National product specifications may vary. These materials are subject to change without notice. These materials are provided by SAP AG and its affiliated companies (SAP Group) for informational purposes only, without representation or warranty of any kind, and SAP Group shall not be liable for errors or omissions with respect to the materials. The only warranties for SAP Group products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty.

You might also like

- SAP ME vs MII: Powerful Manufacturing SolutionsDocument6 pagesSAP ME vs MII: Powerful Manufacturing SolutionsFrancisco Abian GarciaNo ratings yet

- SAP Manufacturing Implementation Architecture-1Document17 pagesSAP Manufacturing Implementation Architecture-1andriesbuterNo ratings yet

- Master Guide SAP MII 12.2Document24 pagesMaster Guide SAP MII 12.2pepe_robNo ratings yet

- MES OverviewDocument29 pagesMES OverviewakitutNo ratings yet

- SAP Manufacturing IntegrationDocument20 pagesSAP Manufacturing IntegrationVassilis Papangelis100% (1)

- MII and SAP IntegrationDocument13 pagesMII and SAP IntegrationIvan SurovezhinNo ratings yet

- SAP MII Integration and Intelligence OverviewDocument106 pagesSAP MII Integration and Intelligence OverviewgkraoatlNo ratings yet

- SAP Variant Configuration: Your Successful Guide to ModelingFrom EverandSAP Variant Configuration: Your Successful Guide to ModelingRating: 5 out of 5 stars5/5 (2)

- Implementing MES in SAP Landscape to Improve Manufacturing OperationsDocument46 pagesImplementing MES in SAP Landscape to Improve Manufacturing Operationsclemen_ang100% (1)

- Using Digital Signatures in SAP QMDocument19 pagesUsing Digital Signatures in SAP QMmsandeepraja100% (1)

- Integrated business planning Standard RequirementsFrom EverandIntegrated business planning Standard RequirementsRating: 1 out of 5 stars1/5 (1)

- SAP Production Planning (PP)Document17 pagesSAP Production Planning (PP)manasiNo ratings yet

- Integrate It! - SAP and MES Integration. Step-By-Step Guide: QuoteDocument18 pagesIntegrate It! - SAP and MES Integration. Step-By-Step Guide: QuoteSANDEEP KKPNo ratings yet

- IS Mill Capabilities PDFDocument59 pagesIS Mill Capabilities PDFshai_m1No ratings yet

- SAP PP 50 Interview Questions and Answers PDFDocument20 pagesSAP PP 50 Interview Questions and Answers PDFHemamber ReddyNo ratings yet

- Mes - Case StudyDocument2 pagesMes - Case StudyMilton Fonseca ZuritaNo ratings yet

- Manufacturing ExecutionDocument1 pageManufacturing ExecutionShiji Shukla100% (1)

- SAP Manufacturing Integration & Intelligence Certification OverviewDocument10 pagesSAP Manufacturing Integration & Intelligence Certification OverviewNhâm NhiNo ratings yet

- Alternate and Parallel Sequence in RoutingDocument27 pagesAlternate and Parallel Sequence in Routingkrishna100% (1)

- 1311 SAP Manufacturing Integration and IntelligenceDocument21 pages1311 SAP Manufacturing Integration and IntelligenceAshok KrpNo ratings yet

- Using X-Step for Process Industries PI SheetsDocument32 pagesUsing X-Step for Process Industries PI SheetsRamesh KumarNo ratings yet

- Sap QMDocument8 pagesSap QMdhirajsatyam98982285No ratings yet

- PI Sheet ConfigDocument18 pagesPI Sheet ConfigKaushik BoseNo ratings yet

- PP-PI Process OverviewDocument33 pagesPP-PI Process OverviewLucilaNo ratings yet

- EHP5 Enhancements in PP ModuleDocument8 pagesEHP5 Enhancements in PP ModulekiranmagarNo ratings yet

- Serial Number Management in SAP SDDocument3 pagesSerial Number Management in SAP SDmohamadali138No ratings yet

- Integration of MES With ERPDocument8 pagesIntegration of MES With ERPSameenaNaseemNo ratings yet

- Sap PP Create RoutingDocument10 pagesSap PP Create RoutingswietkaNo ratings yet

- PP, Food and Beverage IndustryDocument6 pagesPP, Food and Beverage IndustryNiranjan PatroNo ratings yet

- SAP MII Workshop Nov 2014Document36 pagesSAP MII Workshop Nov 2014willemsjunkNo ratings yet

- Manufacturing Execution System A Complete Guide - 2020 EditionFrom EverandManufacturing Execution System A Complete Guide - 2020 EditionNo ratings yet

- Best Practices For Mill Products and Min PDFDocument21 pagesBest Practices For Mill Products and Min PDFSandeep Mahindra0% (1)

- WP Sap Mes 07 02 2014 PDFDocument18 pagesWP Sap Mes 07 02 2014 PDFSameenaNaseem100% (1)

- SAP PP Production Execution End User DocumentsDocument3 pagesSAP PP Production Execution End User Documentsshiv_patel14No ratings yet

- Models For MES in An Enterprise Architecture - MES - PLM - ERP PDFDocument19 pagesModels For MES in An Enterprise Architecture - MES - PLM - ERP PDFsenty100% (1)

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- SAP PP - Capacity Planning ProcessDocument5 pagesSAP PP - Capacity Planning ProcessKoustubha KhareNo ratings yet

- PP BlueprintDocument29 pagesPP Blueprintsamta_nagarNo ratings yet

- Warehouse Management Systems A Complete Guide - 2019 EditionFrom EverandWarehouse Management Systems A Complete Guide - 2019 EditionNo ratings yet

- Batch ManagementDocument18 pagesBatch ManagementDarsh RathodNo ratings yet

- MESDocument54 pagesMESGowrishankara.K.SNo ratings yet

- SAP QM Introduction DeckDocument22 pagesSAP QM Introduction DeckVikash RanjanNo ratings yet

- SAP NetWeaver Process Integration A Complete Guide - 2020 EditionFrom EverandSAP NetWeaver Process Integration A Complete Guide - 2020 EditionNo ratings yet

- SAP123 - Serial Numbers and MaterialsDocument5 pagesSAP123 - Serial Numbers and MaterialsJessica AlvarezNo ratings yet

- Class 10 SCM300 REM PP PI PDFDocument250 pagesClass 10 SCM300 REM PP PI PDFManiSekhar100% (3)

- SAP APO PPDS For Automotive PDFDocument92 pagesSAP APO PPDS For Automotive PDFOshun Tang100% (6)

- User Manual-SAP PP-RNAIPLDocument31 pagesUser Manual-SAP PP-RNAIPLramesh_lpkpnNo ratings yet

- Sap WM Kanban Master DataDocument11 pagesSap WM Kanban Master DataAbhijitNo ratings yet

- New SAP Manufacturing ERP Features and Functions For Discrete Manufacturers - Execution StepsDocument34 pagesNew SAP Manufacturing ERP Features and Functions For Discrete Manufacturers - Execution Stepsliram299188No ratings yet

- Work Centre SapDocument23 pagesWork Centre SapSimran KaurNo ratings yet

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- Automatic Batch Determination Shelf LifeDocument18 pagesAutomatic Batch Determination Shelf LifeKhalil EL KARAMANo ratings yet

- Indonesian Crude PriceDocument1 pageIndonesian Crude Pricerizqi_83No ratings yet

- Value Stream MapDocument4 pagesValue Stream MapsyedamiriqbalNo ratings yet

- Etios Leaflet Mar 2013Document6 pagesEtios Leaflet Mar 2013Dudy Adhi PrasetyoNo ratings yet

- Etios Leaflet Mar 2013Document6 pagesEtios Leaflet Mar 2013Dudy Adhi PrasetyoNo ratings yet

- Benfit Cost GuideDocument93 pagesBenfit Cost GuidesriabolfazlNo ratings yet

- ASTMchartwith DPproductsDocument1 pageASTMchartwith DPproductsrizqi_83No ratings yet

- A Field Seminar From Porong To Sangiran 19-23 February 2012Document4 pagesA Field Seminar From Porong To Sangiran 19-23 February 2012rizqi_83No ratings yet

- Ratio Analysis M&M and Maruti SuzukiDocument36 pagesRatio Analysis M&M and Maruti SuzukiSamiSherzai50% (2)

- MR Guide 81110 Rev B PDFDocument196 pagesMR Guide 81110 Rev B PDFlinkranjitNo ratings yet

- Ampco-Fristam-Replacement-Parts-GuideDocument2 pagesAmpco-Fristam-Replacement-Parts-GuideИбрагим НурмамедовNo ratings yet

- SAD Chaper8Document33 pagesSAD Chaper8VJ Tang100% (1)

- (SpringerBriefs in Electrical and Computer Engineering) Hema Singh, Simy Antony, Rakesh Mohan Jha (Auth.) - Plasma-Based Radar Cross Section Reduction-Springer-Verlag Singapur (2016)Document67 pages(SpringerBriefs in Electrical and Computer Engineering) Hema Singh, Simy Antony, Rakesh Mohan Jha (Auth.) - Plasma-Based Radar Cross Section Reduction-Springer-Verlag Singapur (2016)edbraga-1No ratings yet

- ROTORCOMP Company ProfileDocument26 pagesROTORCOMP Company ProfileJose Santos0% (1)

- Ch1 (Introduction-Database System Concepts)Document27 pagesCh1 (Introduction-Database System Concepts)S M Akash100% (1)

- LSIS - Company Presentation - 140108 PDFDocument35 pagesLSIS - Company Presentation - 140108 PDFMinh VienNo ratings yet

- Ideas On How To Start A BusinessDocument5 pagesIdeas On How To Start A Businesskevin cosnerNo ratings yet

- SMK 345 A7 DM PDFDocument1 pageSMK 345 A7 DM PDFMelchorRdzNo ratings yet

- FIDIC Case Study Assignment Oct15Document3 pagesFIDIC Case Study Assignment Oct15Dixon CheongNo ratings yet

- FrameworkDocument8 pagesFrameworkAmr Abu AlamNo ratings yet

- Xtra Strong (XS) Size Steel Pipe Weights TAble CalculatorDocument1 pageXtra Strong (XS) Size Steel Pipe Weights TAble CalculatorshownpuNo ratings yet

- FABTEKDocument11 pagesFABTEKKarthik ArumughamNo ratings yet

- Modelling, Analysis and Development of Progressive Die For Seat RailDocument9 pagesModelling, Analysis and Development of Progressive Die For Seat RailVineela ChNo ratings yet

- BS4660Document16 pagesBS4660Tim Chong100% (3)

- PIA Business Policy ProjectDocument68 pagesPIA Business Policy ProjectRao Waqas100% (1)

- Crew Tasks on WatchDocument10 pagesCrew Tasks on WatchmytnameNo ratings yet

- Wheel Model 6 CatalogDocument40 pagesWheel Model 6 CatalogHernan LopezNo ratings yet

- GE 8077 - TQM Principles and ToolsDocument36 pagesGE 8077 - TQM Principles and ToolsmenakadevieceNo ratings yet

- Hybrid IDEF0 IDEF03 HoustonDocument3 pagesHybrid IDEF0 IDEF03 HoustonHouston Mandar TrivediNo ratings yet

- Supply Chain ManagementDocument10 pagesSupply Chain ManagementGurunathan MariayyahNo ratings yet

- Estimation and CostingDocument19 pagesEstimation and CostingAditi ShahNo ratings yet

- Interface Technology 2009 PDFDocument352 pagesInterface Technology 2009 PDFrakacyuNo ratings yet

- SAP Data Archiving - Added Value by SAP Document AccessDocument7 pagesSAP Data Archiving - Added Value by SAP Document Accesssiddiq412No ratings yet

- Strategies For Minimising Dilution in Narrow Vein Mine PDFDocument12 pagesStrategies For Minimising Dilution in Narrow Vein Mine PDFRoy MaldonadoNo ratings yet

- Glasgow Tower Project Case StudyDocument11 pagesGlasgow Tower Project Case Studykyledoyle0% (1)

- CBAP and BABOK Overview for IIBA ChapterDocument29 pagesCBAP and BABOK Overview for IIBA ChapterAndre MulpyanaNo ratings yet

- Ssas Real Time Interview Questions and AnswersDocument7 pagesSsas Real Time Interview Questions and AnswersraamanNo ratings yet

- Capital IQ Interview Questions Answers Capital IQ Placement All Papers PDFDocument38 pagesCapital IQ Interview Questions Answers Capital IQ Placement All Papers PDFsusruth mulukalapallyNo ratings yet