Professional Documents

Culture Documents

HeliCoil Stud-Lock Applications

Uploaded by

Ace Industrial SuppliesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HeliCoil Stud-Lock Applications

Uploaded by

Ace Industrial SuppliesCopyright:

Available Formats

Stud-Lock Inserts

Simplify Casting Repairs by Eliminating Oversized Studs

Application: Gear box and pump castings Challenge A military parts rebuilder and refurbisher required a more reliable solution to repair and refurbish large pump and gearbox castings that utilize interference fit studs for assembly. Traditionally maintenance includes dis-assembly and cleaning of each casting followed by inspection for cracks and wear. All tapped holes are inspected and new interference fit studs installed. Each and every stud is inspected and must exhibit a specified torque range on installation. If the running torque is too low, a larger stud must be used in place of the original stud, creating additional stress in the parent material creating an inventory need for non-standard studs. Customer Requirements Consistent running torque from stud to stud No surface damage or imperfections Improved reliability and speed of maintenance and repair process are a high torque version of the Heli-Coil Screw-Lock insert and allow the use of standard studs in place of the typical oversize interference fit stud. This eliminates the need for multiple inventories of oversize studs to fit varied degrees of oversize holes. At the same time running torque from stud to stud is maintained to a closer range.

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Eliminate need for oversize studs and additional inventory Solutions Emhart proposed the use of Stud-Lock wire inserts to repair any and all damaged holes uncovered during the inspection process. Stud-Lock inserts

Features & Benefits Allows standardization to one size

stud, eliminates inventory of larger size studs Eliminates stress in parent material Maintains consistent locking torque Prevents possible surface damage due to stress concentrations from interference fits Available for both straight and step studs, #10 through 1/2" UNC and UNF

Meets AS3080, 3081, 3082, 3083

Cast aluminum application using Heli-Coil Stud-Lock inserts adds strength to original casting.

emhart.com

HeliCoil Stud-Lock Inserts

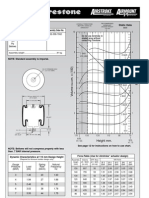

As shown in the Torque Comparison chart, Stud-Lock inserts offer more consistent torque when compared to interference fit studs. Heli-Coil Stud-Lock inserts offer several distinct advantages over both solid-bushing-type studs and interference-type studs. With Stud-Lock inserts, a lower-cost threaded rod can be used, resulting in a lower per piece cost. For purposes of identification, inserts for straight studs are dyed green and inserts for step studs are dyed lavender.

Stud Driving Torque Comparison

450 400 350 300 Driving Torque (in-lbs.) 250 200 150

150 in-lbs 240 in-lbs 425 in-lbs

Stud-Lock Insert Interference Fit Stud

100 50 0 1 2

125 in-lbs

3 4 5 6 Sample Number

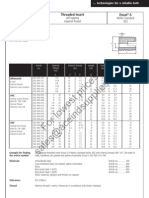

NOMINAL THREAD SIZE

10 (.190)-24 10 (.190)-32 1/4 (.250)-20 1/4 (.250)-28 5/16 (.3125)-18 5/16 (.3125)-24 3/8 (.375)-16 3/8(.375)-24 7/16 (.4375)-14 7/16 (.4375)-20 1/2 (.500)-13 1/2 (.500)-20

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

MAXIMUM MINUMUM LOCKING BREAKAWAY INSERT PART NUMBER TORQUE TORQUE MAXIMUM LOCKING TORQUE MINUMUM BREAKAWAY TORQUE NUT END THREAD SIZE HAND

STRAIGHT STUDS PER AS 1229-1 INSERT PART NUMBER

0285 0380 0475 0570

STEP STUDS PER AS 1229-2

INSTALLATION TOOLING POWER (F.E.Assy.)

3758-3CN 3759-3CN 3758-4CN 3759-4CN 3758-5CN 3759-5CN 3758-6CN 3759-6CN 3758-7CN 3759-7CN 3758-8CN 3759-8CN

5551-3 5552-3

5651-3 5652-3 5651-4 5651-4 5651-5 5651-5 5651-6 5651-6 5651-7 5651-7 5651-8 5651-8

45 lbf-in

23 lbf-in

{ {

0375 0500 0625 0750

5758-4CN

90

52

5759-4CN

{ {

0375 0500 0625 0750 0469 0625 0781 0938 0562 0750 0938 1125 0656 0875 1094 1312 0750 1000 1250 1500

45 lbf-in

23 lbf-in

[ [

10-24

5551-4

10-32

5552-4

{ { {

0469 0625 0781 0938 0562 0750 0938 1125

5758-5CN

180

105

5759-5CN

{ { {

90

52

[ [ [

1/4-20 1/4-28

5551-5 5552-5

5758-6CN

5/16-18

5551-6

240

140

180

105

5759-6CN

5/16-24 3/8-16 3/8-24

5552-6

0656 0875 1094 1312

5758-7CN 5759-7CN

5551-7 5552-7

300

175

240

140

0750 1000 1250 1500

5758-8CN

7/16-14

5551-8

450

260

300

175

5759-8CN

7/16-20

5552-8

Americas Emhart Teknologies P.O. Box 859 50 Shelton Technology Center Shelton, CT 06484 USA To order, call customer service at Tel: (877) EMHART-1 Tel: (877) 364-2781 Fax: (800) 225-5614 Canada: (514) 351-0330 Brazil: + 55 11 3871-6460 Mxico: + 52-55-5326-7100

2011 Emhart Teknologies

sa l

HC1030 Rev.3 (07/11)

emhart.com

You might also like

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Valves, Valve Springs, Valve Rotocoils, and LocksDocument55 pagesValves, Valve Springs, Valve Rotocoils, and Locksbetoven8437No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Bar CouplerDocument6 pagesBar Couplerlwin_oo2435No ratings yet

- Shaffer ShpericalDocument11 pagesShaffer Shpericaljeinerdt100% (1)

- HeliCoil Aftermarket CatalogueDocument24 pagesHeliCoil Aftermarket CatalogueAce Industrial SuppliesNo ratings yet

- HeliCoil Product RangeDocument40 pagesHeliCoil Product RangeAce Industrial SuppliesNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- GE Large Induction MotorsDocument8 pagesGE Large Induction MotorsidontlikeebooksNo ratings yet

- Halfen Coupler Mechanical Rebar SplicingDocument33 pagesHalfen Coupler Mechanical Rebar Splicingcarlosfilipegomes3994No ratings yet

- Rotary Products 5632Document40 pagesRotary Products 5632Pablo AbalosNo ratings yet

- Axion DatabaseDocument25 pagesAxion Databasemacy williamsNo ratings yet

- Protech Seal BrochureDocument10 pagesProtech Seal BrochureRodrigo Jechéla Barrios0% (1)

- HeliCoil Screw Thread InsertsDocument36 pagesHeliCoil Screw Thread InsertsAce Industrial Supplies0% (1)

- Catalogo Giunti Samiflex - GB PDFDocument8 pagesCatalogo Giunti Samiflex - GB PDFDANE80No ratings yet

- Comparisonofweldingeconomy Kehlnaht 12551752Document10 pagesComparisonofweldingeconomy Kehlnaht 12551752Asebaho BadrNo ratings yet

- Final Idler and Roller CatalogDocument6 pagesFinal Idler and Roller CatalogShubham Khurana100% (1)

- Delta Et Vacuum SystemDocument16 pagesDelta Et Vacuum SystemsanjeevnnNo ratings yet

- Expension Joints Engineering AppliancesDocument30 pagesExpension Joints Engineering AppliancesAcid BurnsNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Superbolt CatalogDocument32 pagesSuperbolt CatalogwatcharpNo ratings yet

- Bonney Forge Branch ConnectionsDocument45 pagesBonney Forge Branch ConnectionsperoooNo ratings yet

- Superbolt Catalog PDFDocument32 pagesSuperbolt Catalog PDFAlireza TakrimiNo ratings yet

- Ecco ADocument5 pagesEcco Aouzun852No ratings yet

- AGITAN Defoamer Technologies PDFDocument15 pagesAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- Alignment Coupling Operation Manual Tyre-FlexDocument37 pagesAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelNo ratings yet

- Heli-Coil Catalog HC2000 Rev12Document40 pagesHeli-Coil Catalog HC2000 Rev12anon_512891835No ratings yet

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiNo ratings yet

- Tru-Tension Fasteners: TDS-006A 2-1-01Document6 pagesTru-Tension Fasteners: TDS-006A 2-1-01SOLRAKNo ratings yet

- DSI Ground Support Mechanical RockboltsDocument14 pagesDSI Ground Support Mechanical RockboltscuteshivNo ratings yet

- Double Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMDocument6 pagesDouble Acting and Spring Return Pneumatic Actuators For On/off or Modulating Control of Most Quarter Turn Applications. Output Torques To 2385 NMTeun HaperenNo ratings yet

- W02 M58 3001Document30 pagesW02 M58 3001MROstop.comNo ratings yet

- W02 M58 5001Document30 pagesW02 M58 5001MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- RandD ShaftDocument4 pagesRandD ShaftloloNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 M58 6140Document30 pagesW01 M58 6140MROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- W01 358 7902Document30 pagesW01 358 7902MROstop.com100% (1)

- Max Air PDFDocument8 pagesMax Air PDFKNIGHTHAGENNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Thomson Super Metric Ball Bushing Bearings SpecsheetDocument11 pagesThomson Super Metric Ball Bushing Bearings SpecsheetElectromateNo ratings yet

- Formed-Cylinders 2007-04 LoDocument14 pagesFormed-Cylinders 2007-04 LomartinvandoornNo ratings yet

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocument12 pagesAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNo ratings yet

- PowerStop Shock Absorber CatalogDocument24 pagesPowerStop Shock Absorber CatalogAfiyat Nur100% (1)

- W02 M58 3019Document30 pagesW02 M58 3019MROstop.comNo ratings yet

- PEM Self Clinching Miniature FastenersDocument6 pagesPEM Self Clinching Miniature FastenersAce Industrial SuppliesNo ratings yet

- W02 358 7002Document30 pagesW02 358 7002MROstop.comNo ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- YCM GT SeriesDocument30 pagesYCM GT SeriesCNC SYSTEMSNo ratings yet

- High Tensile Industrial Fasteners and Precision ComponentsDocument12 pagesHigh Tensile Industrial Fasteners and Precision ComponentsSandeep KaundinyaNo ratings yet

- W02 358 7012Document30 pagesW02 358 7012MROstop.comNo ratings yet

- Air Mite CatalogDocument56 pagesAir Mite Catalogtemoc128No ratings yet

- Bolting of Dies PDFDocument24 pagesBolting of Dies PDFHimanshu sharmaNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- VekTek Miniature CylindersDocument13 pagesVekTek Miniature CylindersMike von BertouchNo ratings yet

- SAF 2507™ Super Duplex Weld FittingsDocument8 pagesSAF 2507™ Super Duplex Weld FittingsRoo FaNo ratings yet

- Industrial Penstocks Catalogue 2013Document21 pagesIndustrial Penstocks Catalogue 2013Heri SetyantoNo ratings yet

- Stargrip Cat PDFDocument12 pagesStargrip Cat PDFDGWNo ratings yet

- SEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series EnginesDocument19 pagesSEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series Enginesyahmanmahira4No ratings yet

- W02 358 7010Document30 pagesW02 358 7010MROstop.comNo ratings yet

- Millermatic 252: The Power of BlueDocument8 pagesMillermatic 252: The Power of BlueKeneth Del CarmenNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- HeliCoil Stud-Lock InsertsDocument2 pagesHeliCoil Stud-Lock InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless ApplicationsDocument2 pagesHeliCoil Tangless ApplicationsAce Industrial SuppliesNo ratings yet

- PowerCoil Screw Thread InsertsDocument103 pagesPowerCoil Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Self Tapping InsertsDocument4 pagesHeliCoil Self Tapping InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Serrated Spark Plug InsertsDocument4 pagesHeliCoil Serrated Spark Plug InsertsAce Industrial Supplies100% (1)

- HeliCoil Insert Specs ImperialDocument1 pageHeliCoil Insert Specs ImperialAce Industrial SuppliesNo ratings yet

- HeliCoil Gall Resistant InsertsDocument2 pagesHeliCoil Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs MetricDocument1 pageHeliCoil Insert Specs MetricAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless Gall Resistant InsertsDocument2 pagesHeliCoil Tangless Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Pipe Thread Inserts NPT ANPT NPSCDocument8 pagesHeliCoil Pipe Thread Inserts NPT ANPT NPSCAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Oxygen SensorDocument1 pageHeliCoil Aftermarket Kits Oxygen SensorAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket KIts Sav-A-Thread HTDocument1 pageHeliCoil Aftermarket KIts Sav-A-Thread HTAce Industrial SuppliesNo ratings yet

- Bollhoff Rivkle RivnutsDocument52 pagesBollhoff Rivkle RivnutsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UN 2Document2 pagesHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 303 SeriesDocument1 pageEnsat Self Tapping Inserts 303 SeriesAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UNDocument4 pagesHeliCoil NPT Inserts 8UNAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 307 308 SeriesDocument1 pageEnsat Self Tapping Inserts 307 308 SeriesAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Catalogue 2Document24 pagesHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II ApplicationsDocument2 pagesHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series MetricDocument1 pageEnsat Self Tapping Inserts 302 Series MetricAce Industrial SuppliesNo ratings yet

- RivclinchDocument28 pagesRivclinchAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II InsertsDocument2 pagesHeliCoil Primer Free II InsertsAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- Ripp Lock WashersDocument8 pagesRipp Lock WashersAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Head Bolt Thread RepairDocument1 pageHeliCoil Aftermarket Kits Head Bolt Thread RepairAce Industrial SuppliesNo ratings yet

- Rivkle ElasticDocument12 pagesRivkle ElasticAce Industrial SuppliesNo ratings yet

- KL 8052N User ManualDocument33 pagesKL 8052N User ManualBiomédica HONo ratings yet

- Intermediate Financial Management 13th Edition Brigham Test BankDocument25 pagesIntermediate Financial Management 13th Edition Brigham Test BankMonicaHoustonwjtgz100% (56)

- Bachelor of Science in Tourism Management: Iloilo City Community College Ge 1. Understanding The SelfDocument4 pagesBachelor of Science in Tourism Management: Iloilo City Community College Ge 1. Understanding The SelfPaula Danielle HachuelaNo ratings yet

- Strategic Management Impact on Unilever PerformanceDocument7 pagesStrategic Management Impact on Unilever PerformanceWachira kabugiNo ratings yet

- Adjustment: - Electronic Modulated Air SuspensionDocument2 pagesAdjustment: - Electronic Modulated Air SuspensionThar KyiNo ratings yet

- Research Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGDocument3 pagesResearch Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGFiya ShahNo ratings yet

- Spatial Personality For Human Space InteractionDocument10 pagesSpatial Personality For Human Space Interactionavijitsaha bornoNo ratings yet

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDocument5 pagesPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyNo ratings yet

- Channel Line Up 2018 Manual TVDocument1 pageChannel Line Up 2018 Manual TVVher Christopher DucayNo ratings yet

- Project 4 FinalDocument2 pagesProject 4 Finalapi-307253935No ratings yet

- Power and Energy Meters: Model No. Remarks Sl. WH WH W Va Var 1. ET3021 ET4021Document1 pagePower and Energy Meters: Model No. Remarks Sl. WH WH W Va Var 1. ET3021 ET4021Ram KumarNo ratings yet

- Pointer C++ (UAMD)Document6 pagesPointer C++ (UAMD)SaiDj DulevicNo ratings yet

- PowerFlex 4M LabDocument22 pagesPowerFlex 4M Labmaria laura delgado morenoNo ratings yet

- Formulation and Evaluation of Lansoprazole Delayed Release PelletsDocument20 pagesFormulation and Evaluation of Lansoprazole Delayed Release PelletsUmair MazharNo ratings yet

- Baumann Forklift Dx50!14!40 S N 5361 Spare Parts CatalogueDocument22 pagesBaumann Forklift Dx50!14!40 S N 5361 Spare Parts Catalogueanneclark120297mgz100% (108)

- SNS Bank XS0382843802Document7 pagesSNS Bank XS0382843802Southey CapitalNo ratings yet

- Chapter 5: Attention and PerformanceDocument10 pagesChapter 5: Attention and Performancerebela29No ratings yet

- METRO Otherscape PlaytestDocument101 pagesMETRO Otherscape PlaytestthomasNo ratings yet

- FMVSS 139 2022-10-01Document7 pagesFMVSS 139 2022-10-01skr_757No ratings yet

- Let's Mingle Chat Invite ExamplesDocument22 pagesLet's Mingle Chat Invite ExamplesCarmen BalbuenaNo ratings yet

- E-Governance in KeralaDocument10 pagesE-Governance in KeralaRahmath SafeenaNo ratings yet

- GRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridayDocument3 pagesGRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridaySheilaMarB.Esteban100% (1)

- Experiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarDocument5 pagesExperiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarOne Love Jah LoveNo ratings yet

- A Simple Method To Transfer The SelectedDocument2 pagesA Simple Method To Transfer The SelectedrekabiNo ratings yet

- Beamware 2: Users ManualDocument14 pagesBeamware 2: Users ManualAdi FaizinNo ratings yet

- Duration of LTMDocument3 pagesDuration of LTMsamueldaNo ratings yet