Professional Documents

Culture Documents

Raex 400

Uploaded by

alexandrubuduOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raex 400

Uploaded by

alexandrubuduCopyright:

Available Formats

Raexwearresistantsteel

Raexishighstrengthandwearresistantsteelwithfavourablehardnessandimpacttoughness. WithRaexyoucanextendthelifespanofmachinery,decreasewearinstructuralcomponentsandsavecosts. Raex highstrength and wearresistant steelsalsoenableinnovative design and lightweight products improvingenergy efficiencyandloweringfuelcosts. Raex is utilised in various applications of mechanical engineering by, for example, the automotive, heavy lifting and transportation,andminingindustries. Applications: Bucketsandcontainers Cuttingedgesforearthmovingmachines Wearingpartsforminingmachines Wearingpartsforconcretemixingplantsandwoodprocessingmachines Platformstructures Feeders,funnels

Theinformationonourwebsiteisaccuratetothebestofourknowledgeandunderstanding.Althougheveryefforthasbeenmadetoensure accuracy,thecompanycannotacceptanyresponsibilityforanydirectorindirectdamagesresultingfrompossibleerrorsorincorrect applicationoftheinformationofthispublication.Wereservetherighttomakechanges. Copyright2013RautaruukkiCorporation.Allrightsreserved.

Documentprintedon07.03.2013

www.ruukki.com

Raexwearresistantsteel

Dimensions

Cutlengthswithmilledges

RuukkiRaex Raex300 Raex400 Raex450 Raex500 Thicknessmm 2.58 2.56 36 36.5 Widthmm 100015501) 100017501) 100017001) 100015251) Lengthm 2122) 2122) 2122) 2122)

1)Maximumwidthofacutlengthdependsonthethicknessandsteelgrade. 2)Cutlengthswithlengths(12)to13metresareavailablesubjecttospecialagreement.

Heavyplates

RuukkiRaex Raex400 Raex450 Raex500 Thicknessmm 640 640 640 Widthmm 180032001) 180032001) 180032001) Lengthm 2122) 2122) 2122)

1)Minimumandmaximumwidthofaheavyplatedependonthethickness. 2)Plateswithlengths(12)to16metresareavailablesubjecttospecialagreement.

Tolerances

Tolerancesondimensionsandshapes

Heavyplates: ThicknessEN10029ClassA WidthandlengthEN10029 FlatnessEN10029,ClassNnormaltolerancesonflatness,steeltypeH Cutlengths: Thickness,widthandlengthEN10051 FlatnessEN10029ClassN,steeltypeH TolerancesonthicknessaccordingtotheEN10051:2010categoryA.

Surfacequality

Cutlengthsaredeliveredinasrolledcondition. Heavyplatescanbedeliveredasrolledorinshopprimedcondition. Surfacequality:EN101632ClassA3.

Properties

Deliverycondition

ThedeliveryconditionofRaexsteelishardened.

Hardnessvalues

Steelgrade Raex300 Thicknessmm 2.58.0 Hardness(HBW) 270390 Productshape Cutlengths

Raexwearresistantsteel

Steelgrade Raex400 Raex400 Raex400 Raex450 Raex450 Raex450 Raex500 Raex500

Thicknessmm 2.56.4 630 30.0140 3.06.4 630 30.0140 4.05.0 640

Hardness(HBW) 360440 360440 360480 420500 420500 420520 450540 450540

Productshape Cutlengths Heavyplates Heavyplates Cutlengths Heavyplates Heavyplates Cutlengths Heavyplates

Materialstesting

HardnessismeasuredinBrinellunits(HBW)incompliancewithENISO65061onamilledsurface0.32mmbelowplate surface.Themeasurementdepthisdeterminedonthebasisofproductformandplatethickness.

Typicalmechanicalproperties

Steelgrade Raex300 Raex400 Raex450 Raex500 Yieldstrength Rp0,2MPa 900 1000 1200 1250 Tensilestrength RmMPa 1000 1250 1450 1600 ElongationA5% 11 10 8 8 Impactstrength CharpyV20J 40C 40C 40C 30C

Chemicalcomposition

Steelgrade Raex300 Raex400 Raex450 Raex500 Content%maximum(castanalysis) C 0.18 0.25 0.26 0.30 Si 0.80 0.80 0.80 0.80 Mn 1.70 1.70 1.70 1.70 P 0.025 0.025 0.025 0.025 S 0.015 0.015 0.015 0.015 Cr 1.50 1.50 1.00 1.00 Ni 1.00 1.00 1.00 1.00 Mo 0.50 0.50 0.50 0.50 B 0.005 0.005 0.005 0.005

Inaddition,aluminium(Al),niobium(Nb),vanadium(V)and/ortitanium(Ti)canbeusedasmicroalloymaterial.

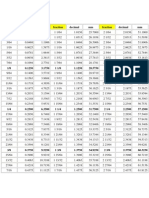

Typicalcarbonequivalentvalues(CEV)

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 Steelgrade Raex300 Raex400 Raex400 Raex400 Raex400 Raex400 Raex450 Raex450 Thicknessmm 2.58 2.54 4.016.4 620 20.0130 30.0140 36.4 630 CEV 0.46 0.48 0.53 0.42 0.50 0.56 0.52 0.47 Productshape Cutlength Cutlength Cutlength Heavyplate Heavyplate Heavyplate Cutlength Heavyplate

Raexwearresistantsteel

Steelgrade Raex450 Raex500 Raex500

Thicknessmm 30.0140 45 640

CEV 0.57 0.54 0.57

Productshape Heavyplate Cutlength Heavyplate

Prefabricationservices

Shopprimedplates

Shop priming gives steel temporary corrosion protection for the transport period, shortterm storing and workshop processing.Inengineeringworkshopoperationitimprovesthecleanlinessofworkingenvironmentandoccupationalsafety. Cuttingandweldingshopprimedplatesiseasy.Moreover,theadherenceofspattersonthesteelstructureissignificantly decreased.

Flatcutshapes

Using flat cut shapes, the manufacture andthroughput time of installation will decrease. The customer will receive the needed components ready for installation, and can thus avoid unnecessary material and storing costs. If ordered, the productsaredeliveredasshopprimed,bevelledandbent.

Processinginstructions

Weldingandthermalcutting

TheweldabilityofRaexsteelshasbeendevelopedtothetopclassamongwearresistantsteelsonthemarket.Practical weldinginstructionsfortheRaex400,Raex450andRaex500gradesarepresentedontheseparatetechnicalbrochure. Moreover,thebrochurespecifiesthespecialfeaturesregardingthermalcuttingofRaexsteels.

Coldforming

Raex300/400/450steelscanbecoldformeduptothethicknessof20mm,seethetablebelow.Formingtemperaturemust beaminimumof+20Candamaximumof+200C. Standardvaluesforfreebendingandflanging Steelgrade Thickness(mm) Freebending<90 Plungerradiusorcurvature/ platethicknessR/t Bendlinepositionvs.rollingdirection Raex300 Raex400 Raex450 Raex500 2.508.00 2.5020.00 3.0020.00 5.0020.00 Transverse 3 3 4 10 Longitudinal 3 4 5 12 Gapwidth/ platethicknessW/t Bendingto90 W/tVchannel

Transverse Longitudinal 9 9 11 23 9 11 13 27 15 15 15

ItisrecommendedtoconsultRuukkiTechnicalCustomerServicewhenbendingRaex500steelorplatesthickerthan20mm.

Heattreatment

Hardened steels are not intended to be heat treated.Tempering in the maximum temperature of 200 C is the only heat treatment which will maintain the abrasion resistance properties of the plate at a good level. Heat treatment in higher temperaturesdecreasesthestrength,hardnessandabrasionresistancepropertiesofsteels.

Drilling

Raex400andRaex450canbedrilledwithHSSdrills.FordrillingofRaex500,hardmetaldrillsarerecommended.General instructionsfordrillingofwearresistantsteelsare:

Raexwearresistantsteel

Thedrillingmachinehastoberigidandstableinordertominimizevibrations Clamptheworkpiecesecurelyandclosetotheareatobemachined Shortholedrills(DIN1897)arerecommended Theservicelifeofthedrillingtoolcanbeprolongedbydecreasingthefeed Provideanabundantsupplyofcuttingfluid

Mechanicalcutting

Hardenedsteelscanbecutmechanically.Thisis,however,challengingbecausetheplateisalmostashardasthecutting blade.Highshearforceisneededduetothehightensilestrengthofthesteel.Highsurfacepressuresduringcuttingare directedattheblade,whichincreaseswear.Themostrecommendedcuttingtoolisastraightcuttingtool. The most important cutting parameters are blade clearance and blade angle. The hardness of the blade is of great importance.Raex300/400/450steelscanbecutwithheavydutycuttingmachines,butthehardnessofthecuttingblade mustexceed53HRC.ThemechanicalcuttingofRaex500steelcanberecommendedonlywithcertainreservations,and thenonlyatthicknessesoflessthan10mmandbladehardnessover57HRC. MechanicalcuttingofRaex400steels,guidelinevalues Platethickness mmt 6 8 10 12 Bladeclearance mmU 0.600.72 0.801.28 1.001.80 1.202.16 Angleoftilt 34 35 46 46 Angleofskew 03 05 05 05 Shearingforceax103N 150200 250350 300450 400600

Occupationalsafety

Specialcaremustbetakeninallstagesofhandlinghardenedsteels.Flangingischallengingduetothehighstrengthand high flexural stresses of the plate. If the bending radius, for example, is too small and a crack is created in the bending point,theplatemayflyfromthebendingtoolinthedirectionofthebend. Those bending the plate must take appropriate precautions to protect themselves and no unauthorised persons must be allowedinthearea.Thesafestlocationisusuallybythebendingmachine.Thehandlinginstructionsofthesteelsupplier and safety instructions of the workshop must be adhered to in detail. New employees must receive appropriate training beforetheyareallowedtoprocesshardenedsteels.

Order&delivery

Deliverycondition

ThedeliveryconditionofRaexsteelishardened.

Inspectiondocument

Onthecustomersrequest,eitheraTestreport2.2orInspectioncertificate3.1incompliancewithEN10204isgrantedto Raex steels. The inspection document states the chemical composition of steel based on cast analysis and hardness in deliverycondition.

Generaldeliveryinformationforhotrolledsteels

Generaldeliveryinformationforhotrolledsteelscanbefoundfromdocuments Markingsandpacking,Ultrasonictesting andGeneraltermsofsale.

Thecontentofthisdocumenthasbeencreatedfromwebpagelastupdated22Feb2013 Oursalesandtechnicalsupportarehappytogiveyoumoreinformation.Visitwww.ruukki.com/contactus. 5

You might also like

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- Raex 500Document4 pagesRaex 500chara459254No ratings yet

- Ruukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCDocument9 pagesRuukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCM R PatraputraNo ratings yet

- Raex 500Document4 pagesRaex 500Daniel MauricioNo ratings yet

- Ruukki Hot Rolled Steels Welding and Thermal Cutting of RaexDocument24 pagesRuukki Hot Rolled Steels Welding and Thermal Cutting of RaexValentin Galben100% (1)

- Norris Polished Rods (P004-V02-072208) - 1Document5 pagesNorris Polished Rods (P004-V02-072208) - 1Rodrigo RuizNo ratings yet

- Application - Cast Iron RepairDocument16 pagesApplication - Cast Iron RepairAnonymous L0ChmPGNo ratings yet

- Wear Plate - RaexDocument3 pagesWear Plate - RaexmaulanaNo ratings yet

- How To Weld S Duplex SsDocument47 pagesHow To Weld S Duplex Sszebra9368No ratings yet

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Alloy Steels: Dr. Indika de SilvaDocument25 pagesAlloy Steels: Dr. Indika de SilvaChandima K PriyamalNo ratings yet

- Saben Silver Steel 1.2210: C Si MN CR Mo W V CoDocument1 pageSaben Silver Steel 1.2210: C Si MN CR Mo W V CoBernice JohnsonNo ratings yet

- 440C DS CarpenterDocument5 pages440C DS CarpenterdaymonNo ratings yet

- AISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDocument2 pagesAISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDhileepan Kumarasamy67% (3)

- Heavy Plates CapabilitiesDocument26 pagesHeavy Plates Capabilitieswindsurferke007No ratings yet

- Assab TableDocument8 pagesAssab TableIhfan MohdNo ratings yet

- Equinox International LTD - Stainless Steel - ST ST Fabrication - 62 PDFDocument3 pagesEquinox International LTD - Stainless Steel - ST ST Fabrication - 62 PDFeugenio.gutenbertNo ratings yet

- Comparing Steel Plate Grades Ebook PDFDocument5 pagesComparing Steel Plate Grades Ebook PDFJayaseelan GNo ratings yet

- Cutting Tool MaterialsDocument44 pagesCutting Tool MaterialsProframanujamNo ratings yet

- Otel de Scule - GBDocument37 pagesOtel de Scule - GBColta VictorNo ratings yet

- MDDocument17 pagesMDJay ShindeNo ratings yet

- Drill BitsDocument23 pagesDrill BitsIndah CharismasariNo ratings yet

- Wear Plate PDFDocument19 pagesWear Plate PDFNorma SalazarNo ratings yet

- Tool Steel - Wikipedia, The Free EncyclopediaDocument7 pagesTool Steel - Wikipedia, The Free EncyclopediaSohail ShaikhNo ratings yet

- Sumitomo WEX BrochureDocument8 pagesSumitomo WEX Brochurecentaurus553587No ratings yet

- ReinforcementDocument16 pagesReinforcementmohammed abdul sami munwerNo ratings yet

- SAE Steel GradesDocument21 pagesSAE Steel Gradescal2_uniNo ratings yet

- Apex Steel Catalogue - UpdatedDocument64 pagesApex Steel Catalogue - UpdatedAmos MutoroNo ratings yet

- HD (Heavy Duty) Buckets: Features and SpecsDocument1 pageHD (Heavy Duty) Buckets: Features and SpecsScott GuimondNo ratings yet

- Pro Dec PlateDocument9 pagesPro Dec PlateAbe VoigNo ratings yet

- WaterfordDocument12 pagesWaterfordCamilo MorenoNo ratings yet

- Wear Rate LoescheDocument8 pagesWear Rate LoescheEdson Ricardo Lima100% (2)

- DuplexSellSheet 01 12Document2 pagesDuplexSellSheet 01 12rickthetrickstertrickyNo ratings yet

- 14 Material and Heat Treatment of Jigs &Document18 pages14 Material and Heat Treatment of Jigs &GV RagunathanNo ratings yet

- Dr. Suvandan Saraswat: Machine Design I (NME-501)Document47 pagesDr. Suvandan Saraswat: Machine Design I (NME-501)Suvandan SaraswatNo ratings yet

- Introduction To Rolling Element Bearing Manufacturing ProcessDocument18 pagesIntroduction To Rolling Element Bearing Manufacturing ProcessRamakanth P JoshiNo ratings yet

- TK Materials Australia ProductCatalogue LOCKEDDocument24 pagesTK Materials Australia ProductCatalogue LOCKEDSugianto BarusNo ratings yet

- 6C High Strength Reinforcement G HalstedDocument36 pages6C High Strength Reinforcement G HalstedRafid RabbaniNo ratings yet

- Manufacturing Technology: Prepared By-Prakash Biswal, Dept. of Mechanical EnggDocument72 pagesManufacturing Technology: Prepared By-Prakash Biswal, Dept. of Mechanical EnggRamya Ranjan senapatiNo ratings yet

- Sumitomo WRCX-RED EndmillsDocument4 pagesSumitomo WRCX-RED Endmillscentaurus553587No ratings yet

- Stainless Steel From JindalDocument35 pagesStainless Steel From Jindalrajbir_singhNo ratings yet

- Classification of Stainless SteelsDocument4 pagesClassification of Stainless SteelsPaul Joseph MonsaludNo ratings yet

- US Patent For Dredger Teeth MaterialDocument6 pagesUS Patent For Dredger Teeth MaterialathiyanindyaNo ratings yet

- Ap Ac NotesDocument8 pagesAp Ac NotesAnju GuptaNo ratings yet

- Lawnmower Blade Case Study FinalDocument6 pagesLawnmower Blade Case Study FinalKyle MortensenNo ratings yet

- Stainless SteelDocument6 pagesStainless SteelNiko NištićNo ratings yet

- Steel Products and Effects of Contents On SteelDocument9 pagesSteel Products and Effects of Contents On SteelMina RemonNo ratings yet

- S690QLDocument4 pagesS690QLReginaldo Matias NunesNo ratings yet

- Manufacturing TechnologyDocument108 pagesManufacturing TechnologyRajesh MishraNo ratings yet

- Surfacing of MetalsDocument9 pagesSurfacing of MetalsNixon LionelNo ratings yet

- Cutting Tool MatlDocument57 pagesCutting Tool MatlVindy CADNo ratings yet

- Drill Bit - WikipediaDocument55 pagesDrill Bit - Wikipediaaddisugebre2125No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Flange Moto EngDocument6 pagesFlange Moto EngalexandrubuduNo ratings yet

- MOTOARE SEM-MT - Technical - Data - Manual PDFDocument65 pagesMOTOARE SEM-MT - Technical - Data - Manual PDFalexandrubuduNo ratings yet

- Follow A Myford Lathe Rebuild - Myford Factory RebuildsDocument13 pagesFollow A Myford Lathe Rebuild - Myford Factory Rebuildsalexandrubudu100% (2)

- Conversie Inch MMDocument3 pagesConversie Inch MMalexandrubuduNo ratings yet

- Local and Distortional BucklingDocument121 pagesLocal and Distortional BucklingMarco PlebaniNo ratings yet

- Beam Design ReportDocument57 pagesBeam Design ReportOkechukwu NwaewoNo ratings yet

- Computation: Reinforced Concrete Slab DesignDocument4 pagesComputation: Reinforced Concrete Slab DesignARSENo ratings yet

- Chapter 4. Strip Method PDFDocument67 pagesChapter 4. Strip Method PDFIyœ Møsisæ100% (3)

- JL-03-November-December The Strutted Box Widening Method For Prestressed Concrete Segmental BridgesDocument18 pagesJL-03-November-December The Strutted Box Widening Method For Prestressed Concrete Segmental BridgesVivek PremjiNo ratings yet

- ENERCALC Biaxial Concrete Solver BasisDocument11 pagesENERCALC Biaxial Concrete Solver BasismagdyamdbNo ratings yet

- Release Notes: 8.5.13.0 (27 Sept 2013)Document104 pagesRelease Notes: 8.5.13.0 (27 Sept 2013)Allen YaoNo ratings yet

- CH 12Document96 pagesCH 12abdallah ghannamNo ratings yet

- Pile Footing Detailed Design CalculationDocument3 pagesPile Footing Detailed Design CalculationChris LeeNo ratings yet

- Sae Technical Paper Series: Todd M. LinkDocument10 pagesSae Technical Paper Series: Todd M. LinkhjnNo ratings yet

- B85 - Tie Beam Transverse TB-1Document8 pagesB85 - Tie Beam Transverse TB-1FrederickV.VelascoNo ratings yet

- ASCCS 2015 ProceedingsDocument811 pagesASCCS 2015 ProceedingsWadbor WahlangNo ratings yet

- 02 1 001Document5 pages02 1 001cmkohNo ratings yet

- Strength of Material Notes 03 07 19 7 PDFDocument6 pagesStrength of Material Notes 03 07 19 7 PDFROYAL ENFIELDNo ratings yet

- Steel Connections Theory Enu PDFDocument120 pagesSteel Connections Theory Enu PDFTiago Castelani100% (1)

- JAA ATPL BOOK 02 - Oxford Aviation - Jeppesen - Airframes and SystemsDocument421 pagesJAA ATPL BOOK 02 - Oxford Aviation - Jeppesen - Airframes and SystemsRicardo BorbaNo ratings yet

- Cable Stayed Bridge (Content)Document70 pagesCable Stayed Bridge (Content)Ram Nepali100% (3)

- Bending Loss in Optical FibersDocument18 pagesBending Loss in Optical FibersRajat AnandNo ratings yet

- Strain EnergyDocument10 pagesStrain EnergyJayakumar VenkataramanNo ratings yet

- Bridge Engineering Chapter TwoDocument45 pagesBridge Engineering Chapter TwoEng-Mohamed Ahmed AbdiNo ratings yet

- TOPIC 10 Foundation PDFDocument24 pagesTOPIC 10 Foundation PDFnasyahrahNo ratings yet

- Total Strength Assessment: Buckling and Ultimate StrengthDocument30 pagesTotal Strength Assessment: Buckling and Ultimate Strengthding liuNo ratings yet

- Wa0007.Document79 pagesWa0007.yashNo ratings yet

- Faculty of Environment and TechnologyDocument8 pagesFaculty of Environment and TechnologyLibraryNo ratings yet

- Spcolumn Manual PDFDocument202 pagesSpcolumn Manual PDFNeng SetNo ratings yet

- Working Stress Method (WSM) and Limit State Method (LSM)Document5 pagesWorking Stress Method (WSM) and Limit State Method (LSM)Mandar NadgaundiNo ratings yet

- 4.12 Extension of The Extended Rod Theory 107Document1 page4.12 Extension of The Extended Rod Theory 107Hemal MistryNo ratings yet

- Plank Et Al-1974-International Journal For Numerical Methods in Engineering PDFDocument17 pagesPlank Et Al-1974-International Journal For Numerical Methods in Engineering PDFtien2506onlineNo ratings yet

- Reinforced Concrete Design 1 Design of Column (Examples and Tutorials)Document19 pagesReinforced Concrete Design 1 Design of Column (Examples and Tutorials)maizansofiaNo ratings yet

- JCEE Chowdhury and Islam 2015 FRP ShearDocument10 pagesJCEE Chowdhury and Islam 2015 FRP ShearMashfiqul IslamNo ratings yet