Professional Documents

Culture Documents

System Guide

Uploaded by

thanh_79Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System Guide

Uploaded by

thanh_79Copyright:

Available Formats

Introduction

Heating

Air-Condition

Pressure Boosting

Wastewater

Tool box

Reference project

Introduction

How to use

Drawing library

1

.

1

The Flow THINKING is a concept especially developed for our partners in

commercial building services

FLOW THINKING means:

> Focusing on the customer

> Embracing system knowledge

> Being a competent partner & adviser

> Finding the right solutions

> Providing tools for your daily work

As an element of this concept we have developed The Gundfos System Guide

The Grundfos System Guide is an extensive reference book, which goes through the standard systems within:

heating

air-conditioning

pressure boosting

wastewater

The systems are evaluated, and the Guide gives recommendations on how to prepare the most energy-

optimal, reliable and comfortable system, considering the components, which form your system.

Contents

The Guide contains a short review of a few theoretical areas within the mentioned systems. This is meant as a

tool box, which can be used across of systems.

Overview: Here a short overview is given of the individual systems, and which Grundfos pumps are recom-

mended for use in the system.

System description: In this paragraph the specific systems are reviewed in details. Suggestions are given of

how to build up the system, so that the interaction between the components in the system is optimised

with regard to comfort, safety and energy. Here we focus on how speed-regulated pumps are used in the

systems.

How to select: Here it is shown how the pump/pump system is dimensioned and selected, provided the

system is built up as described under system description.

A Guide not a collection of formulas

The System Guide is designed to be a practical tool for professionals, who already have the theoretical

knowledge about systems. So the System Guide is not a completely slavish going through the structure of all

systems, but it can with advantage be used as a source of inspiration or a checklist.

The System Guide has been designed in co-operation with system specialists from all over Europe. Even

though many areas have been harmonized, there may still be examples of system constructions, which

traditionally are not used locally

Always updated

Grundfos will in future continue to design and spread competences within systems. So regularly there will be

supplements to the Grundfos System Guide.

How to use

1

.

2

DenwNc tsenev

How to use

Pump

Chiller

Cooling Tower

Cooling Tower

Cooling Tower

Buffer Tank

Fan Coil

2 pipe type

Fan Coil

4 pipe type

Fan Coil

Combination type

Air Unit

In-let

Air Unit

Out-let

Cooling

Surface

Heating

Surface

Heat/Cool

Recovering

Surface

1

.

3

M

MMMM

MMM

-

++

DenwNc tsenev

How to use

Pressureraizing

Unit

Diaphragm

Tank

Exspansion tank

Open Type

Hot WaterTank

With Heat Element

Hot Water

Storage Tank

Boiler

Heat excanger

Radiator

Termastatic

radiator valve

Throttle valve

Isolation valve

Non return valve

2 way motor valve

3 way motor valve

(divide)

3 way motor valve

(collecting)

Pressure control

valve

Pressure relief valve

Safety valve

1

.

4

2. Heating

Overview

System/products

Product description

Application System

Main pumps

Boiler shunt

Mixing loops

Heat surfaces

Heat recovery

DHW circulation

DHW production

How to select

Main pumps

Boiler shunts

Mixing loops

Heat surfaces

Heat recovery

DHW circulation

DHW production

2

.

1

2. Heating

5vstrm J reooucts

Overview

UPS Series 100 O O X

UPS Series 200 O O O O O X X

UPE Series 2000 X X X

TPE Series 2000 X X X X

TP/LM/LP/CLM O O O X X

TPE/LME/LPE/CLME X X X X X

NK/NB O O O X

NKE/NBE X X X

M

a

i

n

p

u

m

p

s

B

o

i

l

e

r

s

h

u

n

t

s

M

i

x

i

n

g

l

o

o

p

s

H

e

a

t

s

u

r

f

a

c

e

s

H

e

a

t

r

e

c

o

v

e

r

y

D

H

W

c

i

r

c

u

l

a

t

i

o

n

D

H

W

p

r

o

d

u

c

t

i

o

n

First choice = X Second choice = O

System Type

Product Type

Heat recovery

Heating surfaces

Main Pumps

Boiler shunts

Heat

Production

Mixing

loop

HW HWC CW

DWH

2

.

1

M

PMU

t p

G10

2. Heating

Peooucts J commuNcntoN

Overview

UPS Series 100

UPS Series 200 X X X X X

UPE Series 2000 X X X X X X

TPE Series 2000 X X X X X X

TP/LM/LP/CLM

TPE/LME/LPE/CLME X X X X X X X

NK/NB

NKE/NBE X X X X X X X

E

x

t

e

r

n

a

l

A

l

a

r

m

R

e

m

o

t

e

c

o

n

t

r

o

l

G

E

N

I

b

u

s

L

O

N

b

u

s

E

x

t

.

S

t

a

r

t

/

S

t

o

p

A

n

a

l

o

g

i

n

p

u

t

E

x

t

e

r

n

a

l

s

e

n

s

o

r

Communication

Product Type

PC User level

(BMS supply)

Sub-station level

(BMS supply)

Component level

(Grundfos)

PMU

G10

M

t p

2

.

2

2. Heating

Peooucts J coNteots

Overview

PMU

PFU

Delta Control

PCU

Management unit

for up to 8 pumps

Preset controller

for up to 4 pumps

Complete control

panel for up to

4 pumps

Contact unit for

up to 4 pumps

UPE Series 2000

TPE Series 2000

Inline E-pumps

In-Line E-pumps

In-Line

End suction E-Pumps

End suction

PMU

PFU

2.2 kW

7.5 kW

2.2 kW

7.5 kW

7.5 kW

315 kW

Functionality Used in Max. kW

connection pump size

with

p

2

.

3

2. Heating

Peoouct enNcr

Overview

Heating Product Range

Survey curve 50 Hz

H[m]

Q[m

3

/h]

End-suction Dry-runners

NB/NK

NBE/NKE

In-line Dry-runners

TP/LM/LP/CLM

TPE Series 2000

TPE/LME/LPE/CLME

In-line Wet-runners

UPS Series 100

UPS Series 200

UPE Series 2000

2

.

4

2. Heating

frntuers J srNrrts

Features

5rtrctoN

Wide product range

Wide system range

Support tools

INstnttntoN

Easy electrical connection

Easy access to speed regulator

Clear user interface

Integrated frequency converter

No need for motor protection

DrrentoN

Very low noise level

High quality material

Varible speed

High efficiency

Benefits

5rtrctoN

Only one supplier

Easy selection

Safe selection

INstnttntoN

Easy/safe installation

Safe/quick commencement

Quick commencement

Safe installation

Low installation cost

DrrentoN

High comfort

Long lifetime

Energy saving

Low operation cost

Overview

2

.

5

2. Heating

UP5 5rers 100

1rcuNcnt Dntn

Temperature -25 to +110C

Pressure PN 10 (10 bar)

Power range 25W to 250W

Speed 1 to 3 speed

Connections Unions; Flanges

Port to port 130 to 250 mm

Pump housing Cast iron; Bronze

Stainless Steel

CommuNcntoN

None

MnN Peoouct frntuers

Easy electrical connection

Easy access to speed regulator

Very low noise level

High quality material

High efficiency

No need for motor protection

Wide product range

Wide application range

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

2 years warranty

End user:

Maintenance free

Long lifetime

Low operating cost

High comfort

Overview

UPS Series 100

Q[m

3

/h]

H[m]

2

.

6

2. Heating

UP5 5rers 200

1rcuNcnt Dntn

Temperature -10 to +120C

Pressure PN 10 (10 bar)

Power range 250W to 2200W

Speed 3 speed

Connections Flanges (PN6/10)

Port to port 220 to 450 mm

Pump housing Cast iron; Bronze

CommuNcntoN

Alarm module (accessories)

GENIbus module (accessories)

MnN Peoouct frntuers

Easy electrical connection

Water lubricated bearings

Very low noise level

High quality material

High efficiency

Motor protection module

Wide product range

Wide application range

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

Easy to start-up

End user:

Long lifetime

Maintenance free

Low operating cost

High comfort

Overview

UPS Series 200

Q[m

3

/h]

H[m]

2

.

7

2. Heating

UP 5rers 2000

1rcuNcnt Dntn

Temperature +2 to +95C

Pressure PN 10 (10 bar)

Power range 60W to 2200W

Speed Variable speed

Connections Unions; Flanges

Port to port 130 to 450 mm

Pump housing Cast iron; Bronze

CommuNcntoN

Alarm relay

Digital input

Analog input

GENIbus

MnN Peoouct frntuers

Easy electrical connection

Water lubricated bearings

Very low noise level

High quality material

High efficiency

Integrated frequency converter

No need for motor protection

Wide product range

Communication

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

Easy start-up

End user:

Long lifetime

Very low operating cost

Very high comfort

Access to operation data

Overview

UPS Series 2000

Q[m

3

/h]

H[m]

2

.

8

2. Heating

1P 5rers 2000

1rcuNcnt Dntn

Temperature -25 to +140C

Pressure PN 16 (16 bar)

Power range 1.1kW to 7.5kW

Speed Variable speed

Connections Flanges

Port to port 280 to 450 mm

Pump housing Cast iron

CommuNcntoN

Alarm relay

Digital input

Analog input

GENIbus

MnN Peoouct frntuers

Easy electrical connection

Integrated frequency converter

Integrated diff. pressure sensor

High quality material

High efficiency

No need for motor protection

Wide product range

Cataphoresis treated

Communication

MnN Customre 8rNrrts

Installer:

Easy installation

Easy start-up

Only one supplier

End user:

Long lifetime

Very low operating cost

High comfort

Access to operation data

Overview

TPE Series 2000

Q[m

3

/h]

H[m]

2

.

9

2. Heating

1PJLMJLPJCLM

1rcuNcnt Dntn

Temperature -25 to +140C

Pressure PN 20 (20 bar)

Power range 0.37kW to 45kW

Speed 1 speed

Connections Flanges

Port to port 280 to 820 mm

Pump housing Cast iron; Bronze

CommuNcntoN

None

MnN Peoouct frntuers

High quality material

High efficiency

Wide product range

Twin head pumps

Wide application range

Standard motor

Cataphoresis treated

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

End user:

Long lifetime

Low operating cost

High comfort

Overview

TP/LM/LP/CLM

Q[m

3

/h]

H[m]

2

.

1

0

2. Heating

1PJLMJLPJCLM

1rcuNcnt Dntn

Temperature -25 to + 140C

Pressure PN 16 (16 bar)

Power range 1.1kW to 7.5kW

Speed Variable speed

Connections Flanges

Port to port 280 to 450 mm

Pump housing Cast iron

CommuNcntoN

Alarm relay

Digital input

Analog input

GENIbus

MnN Peoouct frntuers

Easy electrical connection

Integrated frequency converter

High quality material

High efficiency

No need for motor protection

Wide product range

Cataphoresis treated

Communication

MnN Customre 8rNrrts

Installer:

Easy installation

Easy start-up

Only one supplier

End user:

Long lifetime

Very low operating cost

High comfort

Access to operation data

Overview

TPE/LME/LPE/CLME

Q[m

3

/h]

H[m]

2

.

1

1

2. Heating

N8JNk

1rcuNcnt Dntn

Temperature -10 to + 140C

Pressure PN 16 ( 16 bar )

Power range 0.37 KW to 355 KW

Speed 1 speed

Connections DN 32 - 300

Pump housing Cast iron, Bronze

CommuNcntoN

None

MnN Peoouct frntuers

Flexibility

High quality material

High efficiency

Wide product range

Spacer coupling

Wide system range

Standard motor

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

End user:

Long lifetime

Low operating cost

Overview

NB/NK

Q[m

3

/h]

H[m]

2

.

1

2

2. Heating

N8JNk

1rcuNcnt Dntn

Temperature -10 to +140C

Pressure PN 16 ( 16 bar )

Power range 0.75 KW to 7.5 KW

Speed Variable

Connections DN 32 - 125

Pump housing Cast iron

CommuNcntoN

Alarm relay

Digital input

Analog input

GENIbus

MnN Peoouct frntuers

Easy electrical connection

Integrated frequency converter

High quality material

High efficiency

No need for motor protection

Wide product range

Communication

MnN Customre 8rNrrts

Installer:

Easy installation

Easy start-up

Only one supplier

End user:

Long lifetime

Very low operating cost

High comfort

Access to operation data

Overview

NB/NK

Q[m

3

/h]

H[m]

2

.

1

3

2000 4000 6000 8000

100

80

60

40

20

100% 75% 25% 50%

2. Heating

MnN rumrs

fuNctoN

Due to variation in the heat demand and the flow,

we recommend to use speed controlled pumps in

parallel as main pumps. Maximum 3 pumps plus

1 as standby pump. By speed controlling all the

pumps it is possible to obtain the maximum energy

saving.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 60 UPE Series 2000

60 - 100 TPE Series 2000

100 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

It is important to check the efficiency at the duty

point where the system has a high number of

operating hours.

INstnttntoN

Using UPE and TPE Series 2000, no external pres-

sure sensor and motor protection is necessary, only

a PMU is needed for parallel operation.

It is possible to have proportional pressure without

a sensor placed in the system.

For pumps above 7.5 kW both external sensor,

motor protection and a pump control unit is neces-

sary.

System description

Flow variation in a

reference year (8760 hours)

Flow

%

Hours/year

Duty point with a high number

of operating hours

Flow

When pumps are installed in parallel

non-return valves must be installed

2

.

1

4

75% 25% 50%

100% 75% 25% 50%

100%

2. Heating

8otre suuNt

fuNctoN

The primary task of the boiler shunt pump is to

ensure that the temperature differences between

top and bottom of the boiler are not too big, big

temperature differences cause tension in the mate-

rial and thus reduce the life of the boiler.

For certain types of fuel there is a risk of corrosion

at too low temperatures at the bottom of the boiler.

Maximum safety is ensured when using a control-

led pump, and the energy saving is optimal.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 100 TPE/LME/LPE/CLME

100 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

Often the pumps have high flow and low head,

and then it is important to check the NPSH value

of the pump.

INstnttntoN

TPE/LME/LPE/CLME: The pumps have an integrated

frequency converter and a motor protection.

A temperature transmitter with an output signal of

0/5-10V or 0/4-20 mA should be used. R100 remote

control is used for start-up and later reading out of

operating data.

LM/LP/CLM/NK: The mentioned pump types require

an external frequency converter and an external

regulator.

System description

t

F

90C

t

R

50C

t

= 40C

Head

m

NPSH

m

Max. flow

Flow

Flow

Placing of temperature sensor

t

2

.

1

5

2. Heating

MxNc toors

fuNctoN

Due to variation in use and heat demand in differ-

ent parts of the building, the system is divided

into zones controlled by a mixing loop. The flow

temperature will be lower than in the mains sup-

ply, which will result in a higher flow in the zone

than in the mains supply. This will help obtain a

better hydraul-ic balance in the total system. Speed

controlling the pump makes it possible to obtain

the maximum energy saving.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 60 UPE Series 2000

60 - 100 TPE Series 2000

When using a two-way valve, the pressure lost in

the valve will be managed by the main pump. When

using a three-way valve, the pump in the mixing

loop also has to manage the pressure lost in the

valve.

INstnttntoN

Using UPE and TPE Series 2000 there is no need for

an external pressure sensor and a motor protection.

It is possible to have proportional pressure without

a sensor placed in the system.

System description

Q = 4.3 m

3

/h

t

F

= 60C

t

F

= 80C

Q = 2.15 m

3

/h

t

F

= 40C

t

F

= 40C

= 100kW

M

M

p

pump

Mixing loop with 2 way valve

M

p

pump

Mixing loop with 2 way valve

2

.

1

6

2. Heating

Hrnt suerncr

fuNctoN

A heating surface heats the air which through the

ventilation system is blown into the building. The

temperature in the heating surface depends on the

outdoor temperature and is controlled by way of the

ventilation systems control unit. The system has a

constant flow and variable temperature, where it

is important that the flow is correct. Normally the

flow is adjusted by a regulating valve, it may also be

an advantage to use an adjustable pump (E-pump).

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 60 UPE Series 2000

60 - 100 TPE/LME/LPE

INstnttntoN

UPE Series 2000:

The pump is set to constant curve and then adjusted

to the correct flow.

TPE/LME/LPE:

The pump is set at uncontrolled mode, and then

adjusted to the correct flow.

This is easily done with remote control R100.

System description

Flow adjusted

with a valve

Flow adjusted

with a pump

M

M

Head

Power

Max. speed

Flow adjusted

with a valve

Correct flow

Flow

p

valve

Head

Power

Max. speed

Correct flow

Flow

Reduced speed

2

.

1

7

2. Heating

Hrnt ercovreNc

fuNctoN

The purpose of the system is to recover the heat

of the outlet air. The primary task of the pump

is to ensure an optimal flow between the heating

surfaces. The pump/valve is controlled from the

general control unit of the ventilation system. The

saving potential of using a controlled pump in

stead of a three-way valve to reach the correct

temperature is very big.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 100 TPE/LME/LPE

The total efficiency of the system depends on

whether the circulated quantity of water is correct.

If there is a risk of temperatures below 0C in the air

intake of the system, the system must be applied

with an antifreeze agent. If a 37% glocyl mixture is

used, this will protect against frost down to 20C.

INstnttntoN

The pump is set at uncontrolled, and the signal

from the central control unit is connected to the

analog entry (0/5-10v or 0/4-20 mA).

R100 remote control must be used in connection

with setting up the pump.

System description

M

3 way valve controlled system

Pump controlled system

System efficiency =

t

2

- t

1

t

3

- t

1

Air out Air in

t

1

t

2 t

3

2

.

1

8

2. Heating

Hot wntre cecutntoN

fuNctoN

The purpose of the system is domestic hot water

heating. The function of the circulator pump is to

ensure that hot water is always available as close

to the tapping point as possible, in order to reduce

waste of water and increase the comfort. In certain

installations (loading circuits) the pump can at

the same time ensure the circulation between the

inverter and the storage tank.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h Uncontrolled Controlled

0.5 - 6 UPS Series 100 TPE

6 - 60 UPS Series 200 TPE

60 - 200 LM/LP/CLM LME/LPE/CLME

Normally uncontrolled pumps are used, because

usually the flow variation is only small. It may be

advantageous to use controlled pumps for adjust-

ment of the flow when starting up the system,

though.

In large systems it will also be an advantage to use

a temperature controlled pump.

INstnttntoN

Because of the contents of gasses in water, it is

important that this gas is not gathered in the pump,

thus reducing the lifetime of the pump. Therefore

it is always recommended to install the pump with

upward flow direction, and minimum horizontal

flow direction.

System description

Cold water

Hot

water

Hot

water

circulation

Temperature

transmitter

Cold water

Hot

water

Hot

water

circulation

Cold water

Air-vent

2

.

1

9

2. Heating

Hot wntre reoouctoN

fuNctoN

To make the system as flexible as possible, the

heating and storage of the domestic hot water are

divided into two units, one for heating and one for

accumulation of the hot water. The construction

of the systems among others depends on the kind

of heat exchanger (charger) used. The pump is con-

trolled by the temperature in the storage tank,

either ON/OFF or variable speed.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h Uncontrolled Controlled

0.5 - 6 UPS Series 100 TPE

6 - 60 UPS Series 200 TPE

60 - 200 LM/LP/CLM LME/LPE/CLME

If one pump is used for both accumulation and

circulation, the minimum flow of the pump must be

the same as the required flow for circulation.

INstnttntoN

If the pump is installed on the hot side of the

exchanger, it must be ensured that the temperature

does not exceed required max. temperature, as this

may cause lime depositing in the pump.

Because of the contents of gasses in water, it is

important that this gas is not gathered in the pump,

thus reducing the lifetime of the pump. Therefore

it is always recommended to install the pump with

upward flow direction, and minimum horizontal

flow direction.

System description

Recirculation pump

Charge pump

Hot water

storage tank

M

HWC

CW

HW

Recirculation and

charge pump

M

Hot water

storage tank

HWC

CW

HW

Charge

exchanger

Recirculation

exchanger

Charge pump Recirculation pump

Hot water

storage tank

HW

CW

HWC

M M

2

.

2

0

50 100 500

100

500

1,000

5,000

10,000

1,000

1000 5,000 10,000 50,000 100,000

1

5

10

50

100

10

2. Heating

MnN rumrs

Duck cuor roe srtrctNc rumr tvrr

Step 1: Define total m

2

heated area ex. 20,000 m

2

Step 2: Define heat loss per m

2

ex. 50 W/m

2

(total heat loss 1,000 kW)

Step 3: Define t of the system ex. t 20C (flow 43 m

3

/h)

Step 4: Define p of the pump ex. 10 m

Step 5: Find the exact pump in the data booklet ex. TPE 80-180 3.0 kW

How to select

100 W/m

2

= Old building (low insulation)

75 W/m

2

= Old building (medium insulation)

50 W/m

2

= New building (high insulation)

t = 40C ex. (t

F

90C - t

R

50C)

t = 30C ex. (t

F

80C - t

R

50C)

t = 20C ex. (t

F

70C - t

R

50C)

t = 10C ex. (t

F

60C - t

R

50C)

W/m

2

= 100

W/m

2

= 75

W/m

2

= 50

t = 40C

t = 30C

t = 20C

t = 10C

= 1 pump + 1 stand-by pump (wet runner)

= 1 pump + 1 stand-by pump (dry runner)

= 2 pumps + 1 stand-by pump (dry runner)

= 3 pumps + 1 stand-by pump (dry runner)

H

e

a

t

i

n

g

d

e

m

a

n

d

i

n

[

k

W

]

H

e

a

t

i

n

[

m

]

Heated area in [m

2

]

Flow in [m

3

/h]

2

.

2

1

50 100 500

100

500

1,000

5,000

10,000

1,000

1000 5,000 10,000 50,000 100,000

1

5

10

50

100

10

2. Heating

MnN rumrs

Duck cuor roe srtrctNc rumr tvrr

Step 1: Define total m

2

heated area

Step 2: Define heat loss per m

2

Step 3: Define t of the system

Step 4: Define p of the pump

Step 5: Find the exact pump in the data booklet

How to select

100 W/m

2

= Old building (low insulation)

75 W/m

2

= Old building (medium insulation)

50 W/m

2

= New building (high insulation)

t = 40C ex. (t

F

90C - t

R

50C)

t = 30C ex. (t

F

80C - t

R

50C)

t = 20C ex. (t

F

70C - t

R

50C)

t = 10C ex. (t

F

60C - t

R

50C)

W/m

2

= 100

W/m

2

= 75

W/m

2

= 50

t = 40C

t = 30C

t = 20C

t = 10C

= 1 pump + 1 stand-by pump (wet runner)

= 1 pump + 1 stand-by pump (dry runner)

= 2 pumps + 1 stand-by pump (dry runner)

= 3 pumps + 1 stand-by pump (dry runner)

H

e

a

t

i

n

g

d

e

m

a

n

d

i

n

[

k

W

]

H

e

a

t

i

n

[

m

]

Heated area in [m

2

]

Flow in [m

3

/h]

2

.

2

2

2. Heating

MnN rumrs

5trr 1:

Calculate the flow required in the system:

x 0.86

(t

F

-t

R

)

= Heat demand in [kW]

Q = Volume flow rate in [m

3

/h]

t

F

= Dimensioning flow pipe temperature in [C]

t

R

= Dimensioning return-pipe temperature in [C]

0.86 is the conversion factor (kcal/h to kW)

Calculate the heat required in the system:

The value to the end farthest off or the high value

of the system is the basis for pump dimensioning.

5trr 2:

Lay down the flow variation of the system:

Ex. of variation in the flow:

100% flow for 5% hours

75% flow for 10% hours

50% flow for 35% hours

25% flow for 50% hours

5trr 3:

Lay down the operating hours per year:

System with domestic hot water production:

8,760 hours/year.

System without domestic hot water production,

depending on the location:

ex. 5,500 hours/year.

5trr 4:

Define if it is profitable to speed control the pump

depending on variation in flow and duration of

variation.

How to select

= Q

Head

[m]

Max.

duty point

System

characteristics

Required

head

Flow required

Flow [m

3

/h]

= Variation in flow

= Calculation profile

Operating hours in %

Flow in %

%

Profitable to speed

control the pump

Unprofitable to speed

control the pump

M

a

x

.

v

a

r

i

a

t

i

o

n

i

n

f

l

o

w

Duration of variation in flow

%

2

.

2

3

100

1

10

100

10 1,000

50

5

50 500

129

18

100% 75% 25% 50%

2. Heating

MnN rumrs

5trr 5:

Define number of pumps in the system

Systems with constant flow:

Pumps in operation and stand-by pumps.

When there is no variation in the flow, 1 pump in

operation and 1 stand-by pump are probably the

solution. Here, the efficiency in the duty point is

very important.

Systems with variable flow:

Having variation, it can be profitable to choose

more than 1 pump together with 1 stand-by pump.

Here it is also important to check the efficiency in

the duty point where there are a lot of operating

hours.

5trr 6:

Where to place the transmitter:

Define where to place the differential pressure

transmitter.

For smaller systems it is possible to use pumps

(pumps up to 7.5kW) with integrated transmitter

and controller; the pressure loss compensation will

be managed by the built-in controller.

For larger systems the differential pressure trans-

mitter can be placed either over the pump or at a

critical point in the system.

How to select

Head in

[m]

Flow in [m

3

/h]

Duty point with a lot of

operating hours

p pump

p system

Flow

2

.

2

4

129

18

2. Heating

How to select

MnN rumrs rx.

5vstrm Dntn:

80,000 m

2

old renovated building 75 W/m

2

Heat demand: (80,0000 m

2

x 0.075 W/m

2

) 6,000 kW

Flow temperature (t

F

): 90C

Return temperature (t

R

): 50C

t : (90C 50C) 40C

Flow ((6,000x0.86)/40) 129 m

3

/h

p at max. flow (129 m

3

/h): 18 m

5rtrctoN:

1 constant speed pump + 1 stand-by pump

Selected pump: 2 x NK 80-250/259

Motor size: 2 x 11.0 kW

Variation in flow:

100% flow for 5% hours

75% flow for 10% hours

50% flow for 35% hours

25% flow for 50% hours

Operating hours per year: 8,760 hours

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 438 9.8 4,292

75 876 8.3 7,270

50 3,066 6.6 20,235

25 4,380 4.8 21,024

Total 8,760 Total 52,821

H

e

a

t

i

n

g

p

r

o

d

u

c

t

i

o

n

D

i

s

t

r

i

b

u

t

i

o

n

n

e

t

t

F

t

R

p

outlet

p

inlet p

inlet

p

outlet

=

p

pump system

Q[m

3

/h]

H[m]

NK

2

.

2

5

100

1

10

100

10 1,000

50

5

50 500

129

18

2. Heating

MnN rumrs rx.

How to select

5vstrm Dntn:

80,000 m

2

old renovated building 75 W/m

2

Heat demand: (80,0000 m

2

x 0.075 W/m

2

) 6,000 kW

Flow temperature (t

F

): 90C

Return temperature (t

R

): 50C

t : (90C 50C) 40C

Flow ((6,000 x 0.86)/40) 129 m

3

/h

p at max. flow (129 m

3

/h): 18 m

5rtrctoN:

2 speed controlled pumps + 1 stand-by pump

Selected pump: 3 x TPE 80-240

Motor size: 3 x 5.5 kW

Variation in flow:

100% flow for 5% hours

75% flow for 10% hours

50% flow for 35% hours

25% flow for 50% hours

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 438 10.3 4,551

75 876 5.9 5,168

50 3,066 3.62 11,099

25 4,380 1.31 5,738

Total 8,760 Total 26,516

H

e

a

t

p

r

o

d

u

c

t

i

o

n

D

i

s

t

r

i

b

u

t

i

o

n

n

e

t

t

F

t

R

p

outlet

p

inlet p

inlet

p

outlet

=

p

pump system

Flow in [m

3

/h]

Head in

[m]

2

.

2

6

2. Heating

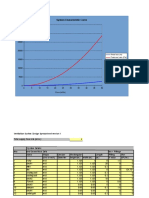

MnN rumrs comrnesoN

5vstrm 1:

1 constant speed pump + 1 stand-by pump

Selected pump: 2 x NK 80-250/259

Motor size: 2 x 11.0 kW

Control panel: Motor protection

Change-over switch

Access to system data: No

Price index: 100 (4,500 EURO)

5vstrm 2:

2 speed controlled pumps + 1 stand-by pump

Selected pump: 3 x TPE 80-240

Motor size: 3 x 5.5kW

Controller: PMU

Access to system data: Yes

Price index: 162 (7,290 EURO)

ComrnesoNJsrNrrt:

The comparison of the two systems makes it clear

that the large savings are gained by reduced flow.

Already at a flow of 75% the savings are 29%. In

addition to the energy saving there is also an in-

crease in comfort, due to the reduced pressure and

thereby reduced noise in the system valves.

Depending on the energy price the pay-back time is

very short for the extra costs of the speed controlled

pump system.

At a cost of 0.1 EURO per kWh, the pay-back time is

approximately 1.1 years.

How to select

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 438 9.8 4,292

75 876 8.3 7,270

50 3,066 6.6 20,235

25 4,380 4.8 21,024

Total Total

8,760 52,821

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 438 10.3 4,551

75 876 5.9 5,168

50 3,066 3.62 11,099

25 4,380 1.31 5,738

Total Total

8,760 26,516

Flow Sys.1 Sys. 2 Savings Savings

[%] [kWh] [kWh] [kWh] %

100 4,292 4,551 -259 -6

75 7,270 5,168 2,102 29

50 20,235 11,099 9,136 45

25 21,024 5,738 15,286 72

Total 52,821 26,516 26,305 50

2

.

2

7

100%

100%

2. Heating

8otre suuNt rx.

How to select

5vstrm Dntn:

Boiler effect: 2,000 kW

Flow temperature (t

F

): 90C

Return temperature (t

R

): 50C

Return temperature (t

RB

): 70C

Flow (Q

SH

): 86 m

3

/h

p with max. flow (129 m

3

/h): 8 m

5rtrctoN:

1 Constant speed pump

Selected pump: 1 x CLM 125-211

Motor size: 1 x 4,0 kW

Variation in flow:

100% flow for 33% hours

75% flow for 33% hours

50% flow for 33% hours

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 1,833 3.7 6,782

75 1,833 3.7 6,782

75 1,833 3.7 6,782

Total 5,500 Total 20,346

t

F

90C

t

R

50C

t

RB

70C

H

Q

Max. load

main system

Min. load

main system

p

valve

2

.

2

8

50% 75% 100%

100%

40%

12%

2. Heating

8otre suuNt rx.

How to select

5vstrm Dntn:

Boiler effect: 2,000 kW

Flow temperature (t

F

): 90C

Return temperature (t

R

): 50C

Return temperature (t

RB

): 70C

Flow (Q

SH

): 86 m

3

/h

p with max. flow (129 m

3

/h): 8 m

5rtrctoN:

1 Constant speed pump

Selected pump: 1 x CLME 125-211

Motor size: 1 x 4,0 kW

Variation in flow:

100% flow for 33% hours

75% flow for 33% hours

50% flow for 33% hours

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 1,833 3.5 6,415

75 1,833 1.3 2,383

50 1,833 0.4 773

Total 5,500 Total 9,571

t

F

90C

t

R

50C

t

RB

70C

H

Q

Max. load

main system

Min. load

main system

t

2

.

2

9

2. Heating

MxNc toors rx.

5vstrm Dntn:

Example with two-way valve:

Heat demand in the zone: 60 kW

Flow temperature main system (t

F

): 90C

Flow temperature in the zone (t

FZ

): 70C

Return temperature in the zone (t

RZ

): 40C

Flow ((60 x 0.86)/30): 1.72 m

3

/h

p zone at max. flow (1.72 m

3

/h):

(radiators+RTV+pipes/valves)(0.2+0.8+1.0): 2 m

5rtrctoN:

1 speed controlled pump

Selected pump: UPE 25-40

Motor size: 1 x 60 W

Operating hours per year: 5,500

With an MC module it is possible to have an alarm

from the pump.

With an MB module it is possible to have GENIbus

communication, + G10 (gateway) being LONWORK.

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [W] [kWh]

100 275 54 14.9

75 550 44 24.2

50 1,925 36 69.3

25 2,750 29 79.8

Total 5,500 Total 118.2

How to select

Q zone:

1.72 m

3

/h

t

FZ

70C

t

RZ

50C

p pump:

2.0 m

t

F

90C

Q main

1.03 m

3

/h

M

Alarm: output

Min./Max. curve: input

Stop/start: input

Analog 0-10V: input

Min./Max. curve: input

Stop/start: input

GENIbus: in/output

+ G10 LONWORK: in/output

MB

40/60

MB

40/60

Power

supply

Power

supply

G10

2

.

3

0

2. Heating

MxNc toors rx.

5vstrm Dntn:

Example with three-way valve:

Heat demand in the zone: 60 kW

Flow temperature main system (t

F

): 90C

Flow temperature in the zone (t

FZ

): 70C

Return temperature in the zone (t

RZ

): 40C

Flow ((60 x 0.86)/30): 1.72 m

3

/h

p zone at max. flow (1.72 m

3

/h):

three-way valve: 2.0 m

(radiators+RTV+pipes/valves)(0.2+0.8+1.0): 2.0 m

Total p: 4.0 m

5rtrctoN:

1 speed controlled pump

Selected pump: UPE 25-80

Motor size: 1 x 250 W

Operating hours per year: 5,500

With an MC module it is possible to have an alarm

from the pump.

With an MB module it is possible to have GENIbus

communication, + G10 (gateway) being LONWORK.

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [W] [kWh]

100 275 130 35.8

75 550 107 58.9

50 1,925 89 171.3

25 2,750 78 214.5

Total 5,500 Total 480.5

How to select

Q zone:

1.72 m

3

/h

t

FZ

70C

t

RZ

50C

p pump:

4.0 m

t

F

90C

Q main

1.03 m

3

/h

M

Alarm: output

Min./Max. curve: input

Stop/start: input

Analog 0-10V: input

Min./Max. curve: input

Stop/start: input

GENIbus: in/output

+ G10 LONWORK: in/output

MB

80

MB

80

Power

supply

Power

supply

G10

2

.

3

1

2. Heating

Hrnt suerncr rx.

5vstrm Dntn:

Example with constant speed pump:

Heat demand: 100 kW

Flow temperature main system (t

F

): 75C

Flow temperature (t

FS

): 50C

Return temperature (t

R

): 25C

Flow ((100 x 0.86)/25): 3.4 m

3

/h

p at max. flow (3.4 m

3

/h):

(surface+pipes/valves)(1.5+0.8+1.0): 3.3 m

5rtrctoN:

1 constant speed pump

Selected pump: UPS 25-80

Motor size: 1 x 250 W

Operating hours per year: 5,500

The pump is set at speed 3, and the flow is adjusted

to calculated flow.

At speed 3 and a flow of 3.4 m

3

/h the head is 5.8 m.

The pressure loss over the adjustment valve has to

be (5.8 3.3) = 2.5 m more than at fully open valve.

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [W] [kWh]

100 5,500 221 1,216

Total 5,500 Total 1,216

How to select

Air flow

Adjustment

valve

Constant

speed pump

t

R

t

FS

t

F

M

Head

Flow

Adjustment

valve

5.8 m

3.3 m

3.4 m

3

/h

2

.

3

2

2. Heating

Hrnt suerncr rx.

5vstrm Dntn:

Example with variable speed pump:

Heat demand: 100 kW

Flow temperature main system (t

F

): 75C

Flow temperature (t

FS

): 50C

Return temperature (t

R

): 25C

Flow ((100 x 0.86)/25): 3.4 m

3

/h

p at max. flow (3.4 m

3

/h):

(surface+pipes/valves)(1.5+0.8): 2.3 m

5rtrctoN:

1 constant speed pump

Selected pump: UPE 25-80

Motor size: 1 x 250 W

Operating hours per year: 5,500

The pump is set at constant curve and adjusted to

the right flow. The total head is lower due to no

adjustment valve in the system. At the same time it

is possible to communicate with the pump.

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [W] [kWh]

100 5,500 140 770

Total 5,500 Total 770

5nvNc:

The energy saving compared to an installation

with an adjustment valve:

(1,216-770) = 446 kWh = 27%

Moreover, an adjustment valve is not required

(costs saved).

How to select

Air flow

Variable

speed pump

t

R

t

FS

t

F

M

Head

Flow

Max. curve

2.3 m

3.4 m

3

/h

Reduced speed

2

.

3

3

0

-40

-30

-20

-10

0 40 60 20 %

0 40 60 20 %

1100

1075

1050

1000

1025

2. Heating

Hrnt ercovrev rx.

5vstrm Dntn:

Example with three-way valve:

Heat transfer: 200 kW

Temperature air (t

1

): - 12C

Temperature air (t

2

): +10C

Temperature air (t

3

): +22C

Temperature liquid (t

F

): +12C

Temperature liquid (t

R

): + 0C

t liquid system (12-0): +12C

Anti-freeze protection down to: -20C

Calculation of flow:

Flow water((200 x 0.86)/12): 14.3 m

3

/h

Compensation factor for anti-freeze: 1.14

(The specific heat drops by 20%)

(Density increase 6%)

Flow with anti-freeze liquid (14.3x1.14): 16.3 m

3

/h

p system at max. flow

three-way valve: 3.3 m

(heat surface+pipes/valves)(2.3+1.0): 3.3 m

Compensation factor for anti-freeze: 1.3

Total p: ((3.3+3.3) x 1.3) 8.6 m

5rtrctoN:

1 constant speed pump

Selected pump: TP 65-120

Motor size: 1 x 1.1 kW

Operating hours per year: 5,500

Due to higher density the power consumption P2

will increase from 675 W to 715 W (P1=890W). To

prevent overload of the motor it is important to

check the max. P2 value of the motor. In this case

the value is 1100 W, which gives a good safety

margin. A dry-runner has been selected to avoid

problems with condensation in the motor, and the

shaft seal is of the RUUE type due to the liquid

with glycol.

How to select

Air flow

outlet

Air flow

inlet

t

3

t

R

t

F

t

1

t

2

M

Freezing point

Propylene glycol

Ethylene glycol

Glycol

Glycol

Ethylene glycol

0C

10C

0C

10C

Propylene glycol

Density kg/m

3

C

2

.

3

4

0

-40

-30

-20

-10

0 40 60 20 %

0 40 60 20 %

1100

1075

1050

1000

1025

2. Heating

Hrnt ercovrev rx.

5vstrm Dntn:

Example speed controlled pump:

Heat transfer: 200 kW

Temperature air (t

1

): -12C

Temperature air (t

2

): +10C

Temperature air (t

3

): +22C

Temperature liquid (t

F

): +12C

Temperature liquid (t

R

): + 0C

t liquid system (12-0): +12C

Anti-freeze protection down to: -20C

Calculation of flow:

Flow water((200 x 0.86)/12): 14.3 m

3

/h

Compensation factor for anti-freeze: 1.14

(The specific heat drops by 20%)

(Density increase 6%)

Flow with anti-freeze liquid (14.3 x 1.14): 16.3 m

3

/h

p system at max. flow

(heat surface+pipes/valves)(2.3+1.0): 3.3 m

Compensation factor for anti-freeze: 1.3

Total p: (3.3 x 1.3) 4.3 m

5rtrctoN:

1 speed contolled pump

Selected pump: TPE 65-60

Motor size: 1 x 0.55 kW

Operating hours per year: 5,500

The pump is set at uncontrolled mode, and via

the 0-10V analog input it is controlled by the air

handling unit controller.

Due to higher density the power consumption P2

will increase from 360 W to 385 W (P1=511W).

To prevent overload of the motor it is important

to check the max. P2 value of the motor. In this

case the value is 550 W, which gives a good safety

margin.

A dry-runner has been selected to avoid problems

with condensation in the motor, and the shaft seal

is of the RUUE type due to the liquid with glycol.

How to select

Air flow

outlet

Air flow

inlet

t

3

t

R

t

F

t

1

t

2

Freezing point

Propylene glycol

Ethylene glycol

Glycol

Glycol

Ethylene glycol

0C

10C

0C

10C

Propylene glycol

Density kg/m

3

C

2

.

3

5

2. Heating

Hrnt ercovrev comrnesoN rx.

5vstrm 1:

1 constant speed pump

Selected pump: TP 65-120

Motor size: 1 x 1.1 kW

Operating hours per year: 5,500

Three-way valve: Yes

Access to system data: No

Price index: 100 (570 EURO)

5vstrm 2:

1 speed controlled pump

Selected pump: TPE 65-60

Motor size: 1 x 0.55 kW

Three-way valve: No

Operating hours per year: 5,500

Access to system data: Yes

Price index: 150 (860 EURO)

ComrnesoNJsrNrrt:

Using a speed controlled pump, the total pressure

loss in the system drops dramatically, and it is pos-

sible to get a variable flow in the system depending

on the actual situation. When the flow is readjusted

the pump will follow the system characteristics

giving high savings. On top of the energy savings

there is also a saving in investment and installation

costs, as there is no need for the motor valve and

the by-pass.

Depending on the energy price the pay-back time is

very short for the extra costs of the speed controlled

pump system. At a cost of 0.1 EURO per kWh the

pay-back time is 1 year.

How to select

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 5,500 890 4,895

Total Total

5,500 4,895

Flow Hours Effect Energy

[%] [h] [kW] [kWh]

100 2,200 511 1,124

75 2,200 308 678

50 1,100 173 190

Total Total

5,500 1,992

Flow Sys.1 Sys. 2 Saving Saving

[%] [kWh] [kWh] [kWh] %

100 4,895 1,124

75 678

50 190

Total 4,895 1,992 2,903 59

2

.

3

6

2. Heating

Hot wntre cecutntoN rx.

5vstrm Dntn:

Example with fixed speed pump:

Hotel with 320 rooms.

Circulation loss per room: 200 W

Total loss: 64 kW

Hot water temperature (t

H

): 55C

Circulation return temperature (t

C

): 45C

t system: 10C

Flow ((64 x 0.86)/10): 5.5 m

3

/h

p at max. flow (5.5 m

3

/h):

(tank+pipes/valves)(1.0+2.5+3.0): 7.0 m

5rtrctoN:

1 constant speed pump

Selected pump: UPS 32-120 FB

Motor size: 1 x 400 W

Operating hours per year: 8,760

With a relay module built into the terminal box,

there is no need for external motor protection, and

at the same time the pump will have an alarm

relay.

Due to risk of corrosion the pump housing is made

of bronze.

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [W] [kWh]

100 2,920 295 861

80 2,920 277 809

60 2,920 253 739

Total 8,760 Total 2,409

How to select

55C

45C

5.5 m

3

/h

7.0 m

Hot

water

Hot

water

circulation

Heat loss

Thermostatic

valve

Cold water

Air-vent

Heat loss

2

.

3

7

2. Heating

Hot wntre cecutntoN rx.

5vstrm Dntn:

Example with fixed speed pump:

Hotel with 320 rooms

Circulation loss per room: 200 W

Total loss: 64 kW

Hot water temperature (t

H

): 55C

Circulation return temperature (t

C

): 45C

t system: 10C

Flow ((64 x 0.86)/10): 5.5 m

3

/h

p at max. flow (5.5 m

3

/h):

(tank+pipes/valves)(1.0+2.5+1.0): 5.0 m

5rtrctoN:

1 speed controlled pump

Selected pump: TPE 40-60

Motor size: 1 x 370 W

Operating hours per year: 8,760

There is no need for motor protection, and at the

same time the pump will have an alarm relay.

The pump is set at controlled mode, and the signal

from the temperature transmitter is connected

directly to the terminal box.

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [W] [kWh]

100 2,920 260 760

80 2,920 185 540

60 2,920 126 368

Total 8,760 Total 1,668

Savings compared to a system with thermostatic

valves are 30%. Furthermore, investment and total

installation costs are lower.

How to select

55C

45C

5.5 m

3

/h

5.0 m

Hot

water

Hot

water

circulation

Heat loss

Temperature

transmitter

Cold water

Air-vent

Heat loss

2

.

3

8

M

Hot

storage

M

2. Heating

Hot wntre reoouctoN rx.

5vstrm Dntn:

Example with fixed speed pump:

Hotel with 320 rooms.

Total effect (9,600/10): 800 kW

Hot water temperature (t

H

): 55C

Cold water temperature (t

CO

): 8C

t system: 47C

Flow ((800 x0.86)/47): 14.6 m

3

/h

p at max. flow (14.6 m

3

/h):

(tank/exchanger+pipes/valves)

(1.0+3.5+0.5+1.5): 6.5 m

5rtrctoN:

1 speed controlled pump

Selected pump: TPE 50-120

Motor size: 1 x 1.1 kW

Operating hours per year: 5,110

There is no need for motor protection, and at the

same time the pump will have an alarm relay. The

pump is set at controlled mode, and the signal from

the temperature transmitter is connected directly

to the terminal box. The ON/OFF thermostat in

the storage tank is also connected direcly to the

terminal box.

Nrecv cntcutntoN:

Flow Hours Effect Energy

[%] [h] [W] [kWh]

100 730 606 442

80 2,190 374 819

60 2,190 168 368

Total 5,110 Total 1,629

How to select

HW

HWC

CW

Charge pump

Hot water

storage tank

Temp. transmitter

ON/OFF thermostat

M

= Water consumption

= Variation in flow charge pump

= Calculation profile

Flow in %

Day-and-night

2

.

3

9

3. Air-conditioning

Overview

System/products

Product description

System description

Chiller pumps

Cooling towers

Dry cooler

Main pumps

Cooling surfaces

Cooling ceilings/floors

Fan coils

How to select

Chiller pumps

Cooling towers

Dry cooler

Main pumps

Cooling surfaces

Cooling ceilings/floors

Fan coils

3

.

1

3. Air-conditioning

5vstrmsJreooucts

Overview

UPS Series 100 O

UPS Series 200 O

TPE Series 2000 X X X

TP/LM/LP/CLM O O O O O O O

TPE/LME/LPE/CLME X X X X X O O

NK/NB O O O O

NKE/NBE X X X X

C

h

i

l

l

e

r

p

u

m

p

s

C

o

o

l

i

n

g

t

o

w

e

r

s

D

r

y

c

o

o

l

e

r

M

a

i

n

p

u

m

p

s

C

o

o

l

i

n

g

s

u

r

f

a

c

e

s

C

o

o

l

i

n

g

c

e

i

l

i

n

g

s

/

f

l

o

o

r

s

F

a

n

c

o

i

l

s

First choice = X Second choice = O

System Type

Product Type

Cooling Tower or Air Cooled Condenser

Cooler

Battery Chilled Beam Fan coil

Buffer tank Chiller

M M M

Chiller pump

Main pump

3

.

1

M

PMU

t p

G10

3. Air-conditioning

Peooucts J commuNcntoN

Overview

UPS Series 100

UPS Series 200 X X X X X

TPE Series 2000 X X X X X X

TP/LM/LP/CLM

TPE/LME/LPE/CLME X X X X X X X

NK/NB

NKE/NBE X X X X X X X

E

x

t

e

r

n

a

l

A

l

a

r

m

R

1

0

0

R

e

m

o

t

e

c

o

n

t

r

o

l

G

E

N

I

b

u

s

L

O

N

b

u

s

E

x

t

.

S

t

a

r

t

/

S

t

o

p

A

n

a

l

o

g

u

e

i

n

p

u

t

E

x

t

e

r

n

a

l

s

e

n

s

o

r

Communication

Product Type

PC User level

(BMS supply)

Sub-station level

(BMS supply)

Component level

(Grundfos)

PMU

G10

M

t p

3

.

2

3. Air-conditioning

Peooucts J coNteots

Overview

PMU

PFU

Delta Control

PCU

Management unit

for up to 8 pumps

Preset controller

for up to 4 pumps

Complete control

panel for up to

4 pumps

Contact unit for

up to 4 pumps

TPE Series 2000

Inline E-pumps

In-Line E-pumps

In-Line

End suction E-Pumps

End suction

PMU

PFU

7.5 kW

7.5 kW

7.5 kW

315 kW

Functionality Used in Max. kW

connection pump size

with

p

3

.

3

3. Air-conditioning

Peoouct enNcr

Overview

Air-conditioning Product Range

Survey curve 50 Hz

H[m]

Q[m

3

/h]

End-suction Dry-runners

NB/NK

NBE/NKE

In-line Dry-runners

TP/LM/LP/CLM

TPE Series 2000

TPE/LME/LPE/CLME

In-line Glandless

UPS Series 100

UPS Series 200

3

.

4

3. Air-conditioning

frntuers J srNrrts

Overview

Features

5rtrctoN

Wide product range

Wide system range

Support tools

INstnttntoN

Easy electrical connection

Easy access to speed regulator

Clear user interface

Integrated frequency converter

No need for motor protection

DrrentoN

Very low noise level

High quality materials

Variable speed

High efficiency

Benefits

5rtrctoN

Only one supplier

Easy selection

Safe selection

INstnttntoN

Easy/safe installation

Safe/quick start up

Quick start up

Safe installation

Lower installation cost

DrrentoN

High comfort

Durability and Reliability

Energy saving and Controllability

Low operation cost

3

.

5

3. Air-conditioning

UP5 5rers 100

Overview

1rcuNcnt Dntn

Temperature -25 to +110C

Pressure PN 10 (10 bar)

Power range 25W to 250W

Speed 1 to 3 speed

Connections Unions; Flanges

Port to port 130 to 250 mm

Pump housing Cast iron; Bronze

Stainless Steel

CommuNcntoN

No

MnN Peoouct frntuers

Easy electrical connection

Easy access to speed switch

Very low noise level

High quality material

High efficiency

No need for motor protection

Wide product range

Wide application range

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

2 years warranty

End user:

Maintenance free

Durability

Low operating cost

High comfort

UPS Series 100

Q[m

3

/h]

H[m]

3

.

6

3. Air-conditioning

UP5 5rers 200

Overview

1rcuNcnt Dntn

Temperature -10 to +120C

Pressure PN 10 (10 bar)

Power range 250W to 2200W

Speed 3 speed

Connections Flanges (PN6/10)

Port to port 220 to 450 mm

Pump housing Cast iron; Bronze

CommuNcntoN

Alarm module (accessories)

GENIbus module (accessories)

MnN Peoouct frntuers

Easy electrical connection

Water lubricated bearings

Very low noise level

High quality material

High efficiency

Motor protection module

Wide product range

Wide application range

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

Easy to start-up

End user:

Long lifetime

Maintenance free

Low operating cost

High comfort

UPS Series 200

Q[m

3

/h]

H[m]

3

.

7

3. Air-conditioning

1P 5rers 2000

Overview

1rcuNcnt Dntn

Temperature -25 to +140C

Pressure PN 16 (16 bar)

Power range 0.37kW to 7.5kW

Speed Variable speed

Connections Flanges

Port to port 280 to 450 mm

Pump housing Cast iron

CommuNcntoN

Alarm relay

Digital input

Anlog input

GENIbus

MnN Peoouct frntuers

Easy electrical connection

Integrated frequency converter

Integrated diff. pressure sensor

High quality material

High efficiency

No need for motor protection

Wide product range

Catephoresis coated

Communication

MnN Customre 8rNrrts

Installer:

Easy installation

Easy start-up

Only one supplier

End user:

Long lifetime

Very low operating cost

High comfort

Access to operation data

TPE Series 2000

Q[m

3

/h]

H[m]

3

.

8

3. Air-conditioning

1PJLMJLPJCLM

Overview

1rcuNcnt Dntn

Temperature -25 to +140C

Pressure PN 20 (20 bar)

Power range 0.37kW to 45kW

Speed 1 speed

Connections Flanges

Port to port 280 to 820 mm

Pump housing Cast iron; Bronze

CommuNcntoN

None

MnN Peoouct frntuers

High quality material

High efficiency

Wide product range

Twin head pumps

Wide application range

Standard motor

Catephoresis coated

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

End user:

Long lifetime

Low operating cost

High comfort

TP/LM/LP/CLM

Q[m

3

/h]

H[m]

3

.

9

3. Air-conditioning

1PJLMJLPJCLM

Overview

1rcuNcnt Dntn

Temperature -25 to + 140C

Pressure PN 16 (16 bar)

Power range 0.37kW to 7.5kW

Speed Variable speed

Connections Flanges

Port to port 280 to 450 mm

Pump housing Cast iron

CommuNcntoN

Alarm relay

Digital input

Anlog input

GENIbus

MnN Peoouct frntuers

Easy electrical connection

Integrated frequency converter

High quality material

High efficiency

No need for motor protection

Wide product range

Catephoresis coated

Communication

MnN Customre 8rNrrts

Installer:

Easy installation

Easy start-up

Only one supplier

End user:

Long lifetime

Very low operating cost

High comfort

Access to operation data

TPE/LME/LPE/CLME

Q[m

3

/h]

H[m]

3

.

1

0

3. Air-conditioning

N8JNk

Overview

1rcuNcnt Dntn

Temperature -10 to + 140C

Pressure PN 16 ( 16 bar )

Power range 0.37 KW to 355 KW

Speed 50 Hz, 2 - 4 and 6 pol

Connections DN 32 - 300

Pump housing Cast iron; Bronze

CommuNcntoN

None

MnN Peoouct frntuers

Flexibility

High quality material

High efficiency

Wide product range

Spacer coupling

Wide application range

Standard motor

MnN Customre 8rNrrts

Installer:

Easy installation

Only one supplier

End user:

Long lifetime

Low operating cost

NB/NK

Q[m

3

/h]

H[m]

3

.

1

1

3. Air-conditioning

N8JNk

Overview

1rcuNcnt Dntn

Temperature -10 to +140C

Pressure PN 16 ( 16 bar )

Power range 0.75 KW to 7.5 KW

Speed Variable

Connections DN 32 - 125

Pump housing Cast iron

CommuNcntoN

Alarm relay

Digital input

Anlog input

GENIbus

MnN Peoouct frntuers

Easy electrical connection

Integrated frequency converter

High quality material

High efficiency

No need for motor protection

Wide product range

Communication

MnN Customre 8rNrrts

Installer:

Easy installation

Easy start-up

Only one supplier

End user:

Long lifetime

Very low operating cost

High comfort

Access to operation data

NBE/NKE

Q[m

3

/h]

H[m]

3

.

1

2

3. Air-conditioning

System description

Cuttro Wntre Pumrs

fuNctoN

Application with one chiller.

The chiller is fitted with temperature sensors which

control the temperature difference depending on

the cooling load. Care must be taken to ensure

that there is no freezing up of the evaporator coils.

Because of this, a constant water flow is required

and usually a fixed speed pump is installed.

Control is normally via a regulating valve, but it may

be possible to use a variable speed pump which is

controlled according to the start/stop sequence of

the chiller.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 150 TPE/LME/LPE/CLME

150 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

INstnttntoN

Pump is set to uncontrolled operation and then

adjusted to the correct flow. It is easily done with

the remote control R100.

Pump terminals for start/stop input are connected.

To secure a high comfort a standby pump can be

added. Controller PFU will be used for alternation

between two pumps.

Chiller pump

Chiller pump

Flow adjusted

with a valve

Flow adjusted

with a pump

Flow adjusted

with a valve Head

Power

Max. speed

Flow

Correct flow

p

valve

Flow adjusted

with a variable

speed pump

Head

Power

Max. speed

Flow

Correct flow

Reduced speed

3

.

1

3

p

3. Air-conditioning

Cuttro Wntre Pumrs

fuNctoN

2 chillers are connected in parallel, each having

their own pump.

The chillers have their own control systems and as

there is a risk of ice forming inside the evaporators,

a constant water flow is recommended.

The chillers run in cascade with the pumps being

controlled by a start/stop signal from the chillers.

On start, pumps start before the chillers start.

On stop, pumps stop just after the chillers stop.

With fixed speed (uncontrolled) pumps there is a

variation of pressure in the circuit hence a flow

variation.

See diagram Solution: Using variable speed pumps

the pressure drops through the evaporators are

controlled by differential pressure sensors. In order

to keep this pressure constant, pump performances

are controlled, the right flow attained and energy

consumption minimized.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 150 TPE/LME/LPE/CLME

150 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

INstnttntoN

Pump is set to controlled operation (p control). It is

easily done with the remote control R100.

Pump terminals for start/stop input are connected.

To secure a high comfort, a standby pump can be

added. Controller PFU will be used for alternation

between two pumps.

System description

p will increase when

2 pumps are running

p

p

Duty point when

2 pumps are running

Duty point when

1 pump is running

Uncontrolled pump

Q Q2 Q1

H

H2

H1

H

H2

H1

Q2 Q

Duty point when

2 pumps are running

Duty point when

1 pump is running

Variable speed pump

3

.

1

4

T

T

T

3. Air-conditioning

Ae Cootro CoNorNsre

fuNctoN

The chiller varies its performance according to the

cooling demand of the system. It is recommended

that the system has a constant flow, normally

adjusted by an regulating valve. It may be an

advantage to use a variable speed pump which can

provide a financially viable alternative.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 150 TPE/LME/LPE/CLME

150 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

In such systems, risk of frost will involve the use

of glycol mixture.

INstnttntoN

Pump is set to uncontrolled operation and then

adjusted to the correct flow. It is easily done with

the remote control R100.

To secure a high comfort, a standby pump can be

added. Controller PFU has to be used for alternation

between two pumps.

System description

Flow adjusted with a valve

Flow adjusted with a pump

Flow adjusted

with a valve Head

Power

Max. speed

Flow

Correct flow

p

valve

Flow adjusted

with a pump

Head

Power

Max. speed

Flow

Correct flow

Reduced speed

T

T

3

.

1

5

100% 75% 30% 50%

M

T

M

T

TT

100

80

60

20

40

0 1200 2400

3. Air-conditioning

CootNc towres

fuNctoN

The chiller varies its performance according to the

cooling demand of the system. The cooling tower

has to be controlled, in order to keep a constant

return water temperature for the condenser.

Usually, the cooling tower water flow is controlled

by a three-way valve. The condenser has a constant

flow, normally adjusted by a regulating valve.

As an alternative, we recommend control of cooling

tower water flow by variable speed pumps. Pumps

adapt their speed according to the return water

temperature measured by the sensor. The complete

system has a variable flow, and therefore maximum

energy savings can be obtained.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 150 TPE/LME/LPE/CLME

150 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

In such systems, risk of frost will involve the use

of glycol mixture.

INstnttntoN

Temperature sensor is placed on the return pipe.

When using TPE, LME, LPE or CLME, no motor

protection is necessary, but a pump control unit

must be added for parallel operation. For bigger

systems, motor protection and pump control unit

are necessary.

An open cooling tower must be located on the

upper point of the circuit. This in order to obtain a

sufficient inlet pressure to avoid cavitation in the

pump.

System description

Parallel operation

T

M

T

Hours/year

F

l

o

w

i

n

%

Flow

3

.

1

6

100% 75% 30% 50%

100

80

60

20

40

0 1200 2400

B

u

f

f

e

r

t

a

n

k

3. Air-conditioning

Pemnev CecutntNc rumrs

fuNctoN

Installation with 2 way valves.

The demand for cooling varies greatly during the

year. When the installation is equipped with two-

way valves, the flow is variable. In this case

we recommend the use of variable speed pumps

installed in parallel as main pumps. Using a PFU

controller a maximum of 4 pumps can be controlled.

By varying the speed of all the pumps, maximum

energy savings can be obtained.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 100 TPE Series 2000

100 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

It is important to check the efficiency at the duty

point, where the system has a high number of

operating hours.

INstnttntoN

Using TPE Series 2000, no external pressure sensor

and motor protection is necessary, only a PMU is

needed for parallel operation. It is possible to have

proportional pressure without a sensor placed in

the system.

For bigger systems, both external sensor, motor

protection and a pump control unit is necessary.

System description

Hours/year

F

l

o

w

i

n

%

Duty point with a high number

of operatin hours

When pumps are installed in parallel

non-return valves must be installed

Flow

B

u

f

f

e

r

t

a

n

k

3

.

1

7

M M M M

t

MM MM MM MM

100

80

60

20

40

0 1200 2400

100% 75% 30% 50%

M M M M

t

MM MM MM MM

100

80

60

20

40

0 1200 2400

100% 75% 30% 50%

3. Air-conditioning

Pemnev CecutntNc rumrs

fuNctoN

The demand for cooling varies greatly during the

year. When the installation is equipped with three-

way valves, the flow around the primary circuit

is constant, with the flow to the room coolers

being controlled by the three way valves. When

the cooling demand is low, water coming from the

chiller is by-passed and the return temperature is

reduced.

If the chiller is not controlled by this return

temperature, we recommend the use of variable

speed pumps mounted in parallel up to a maximum

of 4 pumps.

By controlling the speed of all the pumps, the return

temperature is maintained, and maximum energy

savings obtained.

DmrNsoNNc

Flow

per Pump Pump type

m

3

/h

5 - 150 TPE/LME/LPE/CLME

150 - 200 LM/LP/CLM + External freq. converter

200 - 1000 NK+ External freq. converter

INstnttntoN

Temperature sensor is placed on the return pipe

after the last connecting point. Using TPE, LME,

LPE or CLME, no motor protection is necessary, but

a pump control unit must be added for parallel

operation. For bigger systems, motor protection and

pump control unit are necessary.

System description

Parallel operation

t

M

Hours/year

F

l

o

w

i

n

%

Flow