Professional Documents

Culture Documents

Ignition

Uploaded by

Jhony FuiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ignition

Uploaded by

Jhony FuiCopyright:

Available Formats

1NZ-FE IGNITION IGNITION SYSTEM

IG1

IGNITION SYSTEM

1NZ-FE IGNITION ENGINE

PARTS LOCATION

ECM

IG

IGNITION COIL NO. 1 CAMSHAFT POSITION SENSOR

SPARK PLUG

CRANKSHAFT POSITION SENSOR

A116185E01

IG2

1NZ-FE IGNITION IGNITION SYSTEM

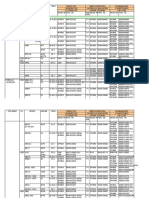

SYSTEM DIAGRAM

ECM

+B GND

IGT IGF

IGT1

Ignition Coil No. 1

+B GND IG2

IGT2 IGF

IGT2

Ignition Coil No. 2

IG

+B GND AM2 IG2 IGT3 IGF IGT3

Ignition Coil No. 3

Ignition Switch 15A AM2 +B GND IGT4 IGF IGT4 IGF

60A MAIN

Ignition Coil No. 4

Battery A1 C1

A118661E01

1NZ-FE IGNITION IGNITION SYSTEM

IG3

NE+ Crankshaft Position Sensor

NE(Shield)

IG

G24 Camshaft Position Sensor C1 ECM (Shield)

A118662E01

IG4

1NZ-FE IGNITION IGNITION SYSTEM

ON-VEHICLE INSPECTION

HINT: In this section, the terms Cold and Hot refer to the temperature of the coils. Cold means approximately -10 to 50 C (14 to 122 F). Hot means approximately 50 to 100 C (122 to 212 F). 1. INSPECT IGNITION COIL AND SPARK TEST (a) Check for DTCs. NOTICE: If a DTC is present, perform troubleshooting in accordance with the procedure for that DTC. (b) Check whether sparks occur. (1) Remove cylinder head cover No. 2 (See page IG-9). (2) Remove the 4 ignition coils (See page IG-9). (3) Using a 16 mm (0.63 in) plug wrench, remove the 4 spark plugs. (4) Install the spark plug onto each ignition coil and connect the ignition coil connectors. (5) Disconnect the 4 injector connectors. (6) Ground the spark plugs. (7) Check that sparks occur while the engine is being cranked. NOTICE: Ground the spark plug when checking it. Replace any ignition coils that have been subjected to any physical impact. Do not crank the engine for more than 2 seconds. If sparks do not occur, perform the following procedure. (c) Perform the spark test in accordance with the following procedure. (1) Check that the wire harness side connector of the ignition coil with igniter is securely connected. Result

Result NG OK Proceed to Connect securely Go to next step

IG

(2) Perform a spark test on each ignition coil with igniter. 1. Replace the ignition coil with igniter with a functioning one. 2. Perform the spark test again. Result

Result OK NG Proceed to Replace ignition coil with igniter Go to next step

1NZ-FE IGNITION IGNITION SYSTEM

IG5

(3) Check that the power is supplied to the ignition coil with igniter. 1. Turn the engine switch ON. 2. Check that the battery voltage is applied to the positive (+) terminal of the ignition coil (See page ES-172). Result

Result NG OK Proceed to Check wiring between ignition switch and ignition coil with igniter Go to next step

(4) Check the resistance of the camshaft position sensor. Standard resistance

Temperature Cold Hot Specified Condition 1,630 to 2,740 2,065 to 3,225

Result

Result NG OK Proceed to Replace camshaft position sensor Go to next step

(5) Check the resistance of the crankshaft position sensor. Standard resistance

Temperature Cold Hot Specified Condition 985 to 1,600 1,265 to 1,890

IG

Result

Result NG OK Proceed to Replace crankshaft position sensor Go to next step

(6) Check the IGT from the ECM (See page ES172). Result

Result NG OK Proceed to Check ECM Repair wiring between ignition coil and ECM

(d) Connect the 4 injector connectors. (e) Using a 16 mm (0.63 in) plug wrench, install the 4 spark plugs. Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf) (f) Install the 4 ignition coils (See page IG-9). (g) Install cylinder head cover No. 2 (See page IG-10). 2. INSPECT SPARK PLUG NOTICE: Do not use a wire brush for cleaning.

IG6

1NZ-FE IGNITION IGNITION SYSTEM

Megaohmmeter

Ground

I039522E11

(a) Check the electrode. (1) Using a megaohmmeter, measure the insulation resistance. Standard resistance: 10 M or more HINT: If the result is not as specified, clean the spark plug with a spark plug cleaner and measure the resistance again. If a megaohmmeter is not available, perform the following simple inspection instead. (b) Alternative inspection method: (1) Quickly accelerate the engine to 4,000 rpm 5 times. (2) Remove the spark plug. (3) Visually check the spark plug. If the electrode is dry, the spark plug is functioning properly. If the electrode is damp, proceed to the next step. (c) Check the spark plug for any damage to its thread and insulator. If there is damage, replace the spark plug. Recommended spark plug

Manufacturer Product SK16R11 IFR5A11

IG

B001301E01

DENSO NGK

(d) Check the spark plug electrode gap. Maximum electrode gap for used spark plug: 1.3 mm (0.051 in.) If the gap is greater than the maximum, replace the spark plug. Electrode gap for new spark plug: 1.0 to 1.1 mm (0.039 to 0.043 in.)

Electrode Gap

B002101E04

B062019E03

(e) Clean the spark plug. If the electrode has traces of wet carbon, clean the electrode with a spark plug cleaner and then dry it. Air pressure: 588 kPa (6 kgf/cm2, 85 psi) Duration: 20 seconds or less HINT: Only use the spark plug cleaner when the electrode is free of oil. If the electrode has traces of oil, use gasoline to clean off the oil before using the spark plug cleaner.

1NZ-FE IGNITION IGNITION COIL

IG7

IGNITION COIL

1NZ-FE IGNITION ENGINE

COMPONENTS

7.0 (71, 62 in.*lbf)

CYLINDER HEAD COVER NO. 2

7.0 (71, 62 in.*lbf)

IG

N*m (kgf*cm, ft.*lbf) : Specified torque

A115136E01

IG8

1NZ-FE IGNITION IGNITION COIL

9.0 (92, 80 in.*lbf)

IGNITION COIL NO. 1

IG

N*m (kgf*cm, ft.*lbf) : Specified torque

A115486E01

1NZ-FE IGNITION IGNITION COIL

IG9

REMOVAL

1. 2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMIANL REMOVE CYLINDER HEAD COVER NO. 2 (a) Remove the 4 nuts and cylinder head cover No. 2.

A116235

3.

REMOVE IGNITION COIL NO. 1 (a) Disconnect the 4 ignition coil connectors.

A115484

(b) Remove the 4 bolts and 4 ignition coils.

IG

A115485

INSTALLATION

1. INSTALL IGNITION COIL NO. 1 (a) Install the 4 ignition coils with the 4 bolts. Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

A115485

IG10

1NZ-FE IGNITION IGNITION COIL

(b) Connect the 4 ignition coil connectors.

A115484

2.

A A

INSTALL CYLINDER HEAD COVER NO. 2 (a) Tighten the 2 A nuts, then the 2 B nuts. Torque: 7.0 N*m (71 kgf*cm, 62 in.*lbf) CONNECT CABLE TO NEGATIVE BATTERY TERMINAL Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

3.

B B

A116235E01

IG

You might also like

- Ignition PDFDocument16 pagesIgnition PDFDoDuyBacNo ratings yet

- Ignition System: On-Vehicle InspectionDocument12 pagesIgnition System: On-Vehicle Inspectionapi-3833108No ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- Terminals of Ecm: E17 E16 E15 E14Document5 pagesTerminals of Ecm: E17 E16 E15 E14Martin ChilbetNo ratings yet

- Engine D-4S. LexusDocument59 pagesEngine D-4S. LexusThanh DanhNo ratings yet

- Identification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaDocument54 pagesIdentification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaJuan Carlos Martinez NuñezNo ratings yet

- All-New Ford Ranger: Preliminary Technical Specifications: FeaturesDocument13 pagesAll-New Ford Ranger: Preliminary Technical Specifications: FeaturesLe VanNo ratings yet

- Checking VVT Sensor PDFDocument6 pagesChecking VVT Sensor PDFDoDuyBacNo ratings yet

- Adaptronic Blacktop Installation NotesDocument6 pagesAdaptronic Blacktop Installation NotesRayz GsrNo ratings yet

- Terminals of Ecu: DiagnosticsDocument4 pagesTerminals of Ecu: DiagnosticsDaniel Mamani ParedezNo ratings yet

- DTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Document3 pagesDTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Erln LimaNo ratings yet

- ECM I/O Signals DiagnosticsDocument5 pagesECM I/O Signals Diagnosticskofo3000No ratings yet

- Sienna SparkPlug RemovalDocument17 pagesSienna SparkPlug Removalazeemm1No ratings yet

- Fuse Box E120Document3 pagesFuse Box E120Shahmeer AhmedNo ratings yet

- BeltsDocument89 pagesBeltszul100% (2)

- EMISSION CONTROL SYSTEM (2AZ FE) CamryDocument30 pagesEMISSION CONTROL SYSTEM (2AZ FE) CamryRahmat HidayatNo ratings yet

- Toyotabbreviationhare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.a AbbreviationsDocument3 pagesToyotabbreviationhare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.hare.qclt.com/汽车论坛免费资料第四期/TOYOTA-CAMRY/camry.pdf TOYOTA CAMRY. ELECTRICAL ... OVERALL ELECTRICAL WIRING DIAGRAM . .... WIRING ROUTING This section is closely related to the wiring diagram. ... ABBREVIATIONS. The following abbreviations are used in this manual. ABS. A/C.a AbbreviationsJustin LeoNo ratings yet

- '02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinDocument5 pages'02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinElvin Domingo100% (1)

- Glossary of Sae and Toyota TermsDocument3 pagesGlossary of Sae and Toyota TermsKevin StrongNo ratings yet

- Evo X ECUDocument2 pagesEvo X ECUJustin StarkNo ratings yet

- ENGINE CONTROL INPUT & OUTPUT OVERVIEWDocument30 pagesENGINE CONTROL INPUT & OUTPUT OVERVIEWDangLuyenNo ratings yet

- List of Toyota engine codes under 40 charactersDocument39 pagesList of Toyota engine codes under 40 charactersMwima Dafsow100% (1)

- J3 Meter Removal Installation and Troubleshooting GuideDocument32 pagesJ3 Meter Removal Installation and Troubleshooting GuideWaqar KhattakNo ratings yet

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDocument7 pages2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNo ratings yet

- Module Name Acronym SCP Address Can AddressDocument2 pagesModule Name Acronym SCP Address Can AddressMarius Neagoe0% (1)

- Mitsubishi EVO IV-VIII Installation ManualDocument27 pagesMitsubishi EVO IV-VIII Installation ManualAlexander RodriguezNo ratings yet

- Z18XE SCHDocument3 pagesZ18XE SCHJan WolnyNo ratings yet

- Installation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Document24 pagesInstallation Instructions For 30-1910: Fuel Ignition Controller (F/IC)Dmentall IllNo ratings yet

- 2azfe 12 PDFDocument20 pages2azfe 12 PDFmasakpNo ratings yet

- Electronically Controlled Transmission Communication CircuitDocument3 pagesElectronically Controlled Transmission Communication CircuitErln Lima100% (1)

- CAT055 Ignition PDFDocument19 pagesCAT055 Ignition PDFthailanNo ratings yet

- Toyota Training - FUEL SYSTEM DIAGNOSIS (L-TR-QL-811A-D)Document12 pagesToyota Training - FUEL SYSTEM DIAGNOSIS (L-TR-QL-811A-D)John BacsikNo ratings yet

- Toyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramDocument3 pagesToyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramSirleh SalehNo ratings yet

- 2JZ-GTE VVti Aristo ECU PINOUTDocument11 pages2JZ-GTE VVti Aristo ECU PINOUTDoichin Mitov100% (1)

- Daihatsu Fault Codes DTCDocument1 pageDaihatsu Fault Codes DTCمحمد عبد الفتاح محمدNo ratings yet

- Pinout Toyota Jza70Document1 pagePinout Toyota Jza70Anonymous 6Gi5uqJNo ratings yet

- sb0341t09 PDFDocument7 pagessb0341t09 PDFZool Car زول كارNo ratings yet

- Nissan Patrol ATDocument15 pagesNissan Patrol ATxgrapherNo ratings yet

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDocument15 pagesElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- 10-6620 For EMS - 30-6620Document14 pages10-6620 For EMS - 30-6620Michael AliNo ratings yet

- Ignition Coil Diagnostic Codes for 1GR-FE EngineDocument11 pagesIgnition Coil Diagnostic Codes for 1GR-FE Enginemike chenNo ratings yet

- GDIDocument7 pagesGDIlinhda561No ratings yet

- Ignition PDFDocument17 pagesIgnition PDFtavi2meNo ratings yet

- 05ewd PDFDocument251 pages05ewd PDFWawan SatiawanNo ratings yet

- 2008-06-04 124629 Corolla Tsib 5Document3 pages2008-06-04 124629 Corolla Tsib 5nuwan_nisha100% (2)

- "LCD Device Driver" For Reconfigurable Instrument ClusterDocument6 pages"LCD Device Driver" For Reconfigurable Instrument ClustersrikanthshenoyNo ratings yet

- 2jzgte Uk Spec Ecu PinoutDocument2 pages2jzgte Uk Spec Ecu PinoutWilliamNo ratings yet

- Toyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcDocument9 pagesToyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcAlifNo ratings yet

- Transmission Fluid PDFDocument5 pagesTransmission Fluid PDFLv2mackNo ratings yet

- Quick Start Guide for ECU TuningDocument27 pagesQuick Start Guide for ECU TuningAce SpadeNo ratings yet

- How Does The VNT WorksDocument3 pagesHow Does The VNT WorksAyman Al ShabanahNo ratings yet

- Toyota Diagnostic Trouble Codes Full List Obdii365Document2 pagesToyota Diagnostic Trouble Codes Full List Obdii365kabuye NicholasNo ratings yet

- Immob Overview All Models 2005Document30 pagesImmob Overview All Models 2005BYU OTOVLOGNo ratings yet

- System CircuitsDocument234 pagesSystem CircuitsEme Elibe Johnson EmestarNo ratings yet

- 32d05 Control of ECTDocument12 pages32d05 Control of ECTMelvin MhdsNo ratings yet

- 2AZ FE IgnitionDocument8 pages2AZ FE IgnitionLuks Fernandez100% (3)

- Toyota Camry IgDocument56 pagesToyota Camry IgKulasekaran Amirthalingam100% (1)

- Diagnostico Dis Ignition System Toyota 2rzfe 3rzfeDocument6 pagesDiagnostico Dis Ignition System Toyota 2rzfe 3rzfecherokewag100% (1)

- Toyota Supra - Ignition Systems - 2JZ-GTEDocument13 pagesToyota Supra - Ignition Systems - 2JZ-GTETomislav RupčićNo ratings yet

- SDocument5 pagesSfirnadhiNo ratings yet

- Argollas, Eslabones Maestros y Otros Accesorios IMPDocument25 pagesArgollas, Eslabones Maestros y Otros Accesorios IMPTeo DeustchNo ratings yet

- Diagrama e Carga F455a E226 NL LMDocument1 pageDiagrama e Carga F455a E226 NL LMTeo DeustchNo ratings yet

- Diagrama e Carga F455a E226 NL LMDocument1 pageDiagrama e Carga F455a E226 NL LMTeo DeustchNo ratings yet

- Product GuideDocument64 pagesProduct Guidecheyenne_iqNo ratings yet

- Flake Nugget TechDocument292 pagesFlake Nugget TechPaco ScarpenisNo ratings yet

- Preparation - 1Nz-Fe Engine Control SystemDocument128 pagesPreparation - 1Nz-Fe Engine Control Systempayel_engNo ratings yet

- Standard Bolt Specs and Torque ValuesDocument85 pagesStandard Bolt Specs and Torque Valuescpgmotors83% (6)

- Standard Bolt Specs and Torque ValuesDocument85 pagesStandard Bolt Specs and Torque Valuescpgmotors83% (6)

- Can Communication System: PrecautionDocument106 pagesCan Communication System: PrecautionRicardo Watson100% (1)

- GMK Schematic HandbookDocument55 pagesGMK Schematic HandbookYukki Badamgarav100% (10)

- 345B ExcavadoraDocument55 pages345B ExcavadoraTeo Deustch100% (6)

- Business Class m2 Driver's Manual PDFDocument190 pagesBusiness Class m2 Driver's Manual PDFTeo DeustchNo ratings yet

- JCB 214 e Backhoe LoaderDocument8 pagesJCB 214 e Backhoe LoaderTeo DeustchNo ratings yet

- Fault Code ListDocument7 pagesFault Code ListTeo Deustch100% (1)

- Retarder O400 MBDocument1 pageRetarder O400 MBTeo Deustch100% (1)

- Presiones de Transmision d6r IIDocument5 pagesPresiones de Transmision d6r IITeo Deustch100% (5)

- Falla de Calibracion FANDocument12 pagesFalla de Calibracion FANTeo DeustchNo ratings yet

- Fault Code ListDocument7 pagesFault Code ListTeo Deustch100% (1)

- Sebu7731-08 BDocument6 pagesSebu7731-08 BTeo Deustch100% (2)

- Falla de Calibracion FANDocument12 pagesFalla de Calibracion FANTeo DeustchNo ratings yet

- Grove RT422 22TDocument4 pagesGrove RT422 22TTeo DeustchNo ratings yet

- Ingersolrand Portable Diesel Compressor PartsDocument163 pagesIngersolrand Portable Diesel Compressor PartsTeo Deustch100% (6)