Professional Documents

Culture Documents

SS Pipe Fab & Erect Costs

Uploaded by

wally55bearOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SS Pipe Fab & Erect Costs

Uploaded by

wally55bearCopyright:

Available Formats

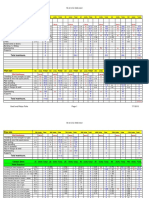

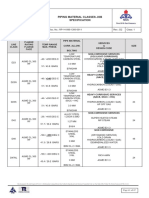

St-st & Cs field erect

Stainless 304L & 316

15

Units

Total

20

0

0

0

0

0

0

0

0

0

0

0

0

0

0.49

Units

Total

25

Units

0

0

0

0

0

0

0

0

0

0

0

0

0

0.52

20

0.92

11

0.18

Total

40

Units Total

50

Units

Total

80

Units

185

196

12.5

0

57.6

0

0

0

0

0

50

0

0

0.72

400

1.12

359

0.34

75

Total

100

Units

288

402

25.5

0

91.2

0

0

0

0

0

83

0

0

0.79

600

1.21

352

0.38

95

Total

Stainless Steel Erection Hours

Wall thickness

Field handling pipework..

Handle & erect fab spool pieces.

Pipe cutting

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

Socket weld

O'lets

Install vents or drains

Bending 1 x 90deg

Hydrotesting

Supports

1.5m/m

0.39

0.79

0.16

0.12

0.62

0.73

0.75

2.16

Total manhours.

1.5m/m

0.82

0.16

0.12

0.65

0.74

0.75

2.46

1.5m/m

0.14

0.73

0.84

0.82

3.06

1.5m/m

10.4 0.59

10.1 0.94

0.72 0.22

0

0.18

2.92 0.85

0

1.15

0

1.02

0

4.14

0

0

4

1

0

0

80

48

10

12

12

28.2

2m/m

47.2 0.66

45.1 0.98

2.2 0.26

0

0.2

10.2 1.2

0

1.36

0

1.15

0

5.76

0

0

12

1

0

0

281

200

48

48

50

117

2m/m

0.26

1.52

60

2.05

1.6

7.8

83

502

2m/m

0.32

1.78

70

2.57

0

9.96

120

890

474

425.9

36.1

0

124.6

0

0

0

0

0

120

0

0

1181

1536.2

Pipe size

Wall thickness

Handling & erect straight run pipe.

Handle & erect fab spool pieces.

Pipe cutting

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

O'lets

Hydrotesting

Supports

Total manhours.

150

Units

Total

200

356

402

64.4

20.4

217

0

0

100

0

0

1.05

200

1.64

109

1.08

30

0.88

15

3.75

30

2m/m

0.89

400

1.31

307

0.92

70

0.68

30

3.1

70

3.65

12.72

1

100

Units

Total

250

210

179

32.4

13.2

113

0

0

0

0

0

1.31

30

2.03

16

2m/m

1160

5.17

13.56

50

Units

Total

300

39.3

32.5

4.8

2.08

18.2

0

0

10

0

0

1.57

100

2.36

36

1.76

13

1.4

13

2m/m

546.86

1.2

1.04

4.56

6.45

1

10

Units

Total

350

157

85

22.9

8.4

65

0

0

36

0

0

1.8

30

2.69

2m/m

106.9

7.56

1

36

Units

Total

400

54

24.2

6

1.7

17.6

0

0

10

0

0

2.13

80

2.95

34

3.1

11

2.4

6.8

11

2.5m/m

374.2

1.7

5.86

8.85

1

10

Units

Total

450

170

100

34.1

12

74.8

0

0

40

0

0

2.46

3m/m

113.49

9.36

1

40

Units

Total

3m/m

0

0

0

0

0

0

0

0

0

0

3.61

4

3.2

8.7

10.02

431.6

0

2733.06

Geoff and Robyn Poile

Page 1

7/7/2013

St-st & Cs field erect

Pipe size

500 Units Total

Wall thickness

Handling & erect straight run pipe.

Handle & erect fab spool pieces.

Pipe cutting

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

Hydrotesting

Supports

600 Units Total

5m/m

2.79

4.13

5.6

4.4

11.3

Total manhours.

700 Units

5m/m

0

0

0

0

0

0

0

0

3.28

4.76

7.6

12.5

12

Total

900 Units Total

5m/m

19.7

23.8

15.2

6

25

0

12

0

3.65

100

5.2

61

8.3

16

7.4

10

13.8

16

100

101.68

1200 Units

6m/m

Total

1500 Units

6m/m

Total

1700 Units Total

6m/m

6m/m

365

317

133

74

221

0

100

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1209.8

0

1311.48

Carbon Steel

15

Units Total

20 Units Total

25

Units Total

40 Units Total

50

Units Total

80

Units Total

100 Units Total

Field Erection

Handling & erect straight run

Handling & erect fab spools sch 10-60.

Handling & erect fab spools sch 80-100.

Handling & erect fab spools sch 120-160.

Make on screw fittings & valves.

Field handling valves & install. < 600#

Field erection bolt ups < 600#

Attaching flanges screw type.

Attaching flanges slip on type.

Attaching flanges weld neck.

Man B/W Tig root run sched 40 pipe.

Man B/W Tig root run sched 80 pipe.

Man B/W Tig root run sched 160 pipe.

Man B/W Tig root run sched 160 pipe.

Man B/W Tig root run sched 160 pipe.

Olet type welds.

Mark cut & bevel < 80.

Threading pipe including cut.

Bending

Pressure test 10% of piping manhours.

Total manhours.

Geoff and Robyn Poile

0.52

0.6

0.75

0.85

0.1

0.2

0.7

1.2

0.9

1.5

0.7

0.9

1.2

1.5

0.1

0.23

1.4

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.55

0.7

0.8

0.9

0.1

0.2

0.7

1.2

0.9

1.5

0.98

1.1

1.6

1.8

0.1

0.23

1.5

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.59

0.73

0.85

1

0.2

0.3

0.7

1.2

0.9

1.5

1.09

1.33

1.83

2.1

0.17

0.23

1.6

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 2

0.62

0.81

0.93

1.12

0.3

0.4

0.7

1.2

1

1.5

1.36

1.71

2.37

2.9

0.17

0.26

2

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.65

0.88

1.02

1.26

0.3

0.5

0.7

1.2

1.3

1.5

1.47

1.87

2.76

3.9

0.21

0.3

2.3

1

20

11

13

9.68

0

0

0

0

0

0

0

0

5.88

0

0

0

0

0

0.84

0

0

4

0

33.4

0.75

1.02

1.26

1.56

0.4

1.2

0.8

1.4

1.8

2.5

2.25

2.83

4.04

5.3

0.27

0.39

3.1

1

70

41

16

12

12

52.5

41.8

0

0

0

0

0

0

0

0

36

0

0

0

0

0

3.24

0

0

12

0

146

0.82

1.05

1.33

1.6

0.5

1.75

1.2

1.7

2.4

3.2

2.86

3.66

4.88

5.3

10

7

0.4

0.42

4.4

1

60

39

13

12

49.2

40.95

0

0

0

0

0

0

0

0

37.18

0

0

0

0

0

3.2

0

0

12

0

142.5

321.5

7/7/2013

St-st & Cs field erect

Pipe size

150 Units Total 200 Units Total

Handling & erect straight run pipe.

0.91 100 91 1.11 40 44.4

Handling & erect fab spools sch 10-60. 1.16 58 67.3 1.33 37 49.2

Handling & erect fab spools sch 80-100. 1.58

0

1.79

0

Handling & erect fab spools sch 120-160. 1.96

0

2.16

0

Field handling valves & install. < 600# 2.31

0

2.94

0

Bolt ups < 300#

1.5

0

2.1

0

Attaching flanges slip on type.

3.6

0

5.1

0

Attaching flanges weld neck.

4.2

0

5.4

0

Man B/W Tig root run sched 40 pipe. 3.6

22 79.2 4.59 11 50.5

Man B/W Tig root run sched 80 pipe. 4.8

0

6.15

0

Man B/W Tig root run >> sched 160 pipe.

11

0

0

Mark cut & bevel < 80.

0.55 12

6.6 0.82 6

4.92

Pressure test 10% of piping manhours. 1

24

24

1

14

14

Install supports at approx 4mtr centres. 4

0

4.5

0

0

0

Total manhours.

268

163

Pipe size

500 Units Total 600 Units Total

Handling & erect straight run pipe.

3.37

0

3.77 40

151

Handling & erect fab spools sch 10-60. 3.68

0

4.76 13 61.9

Handling & erect fab spools sch 80-100.4.42

0

5.16

0

Handling & erect fab spools sch 120-160.5.23

0

6

0

Handling & erect fab spools sch >160.

0

0

Field handling valves & install. < 600# 5.67

0

6.3

0

Bolt ups < 300#

5.5

0

6.6

0

Attaching flanges slip on type.

14.6

0

18.3

0

Attaching flanges weld neck.

13.3

0

17.6

0

Man B/W Tig root run sched 40 pipe. 11

0

12.5 6

74.9

Man B/W Tig root run sched 80 pipe. 15.5

0

17.9

0

Mark cut & bevel < 80.

2.9

0

3.3

4

13.2

Pressure test 10% of piping manhours. 1

0

1

21

21

Install supports at approx 4mtr centres. 9

0

10

0

Total manhours.

0

322

Geoff and Robyn Poile

250 Units Total 300 Units Total

1.41

0

1.7

20

34

1.7

0

1.74 12 20.9

2.21

0

2.28

0

3

0

3.15

0

3.1

0

3.6

0

2.7

0

3.4

0

7.56

0

9.24

0

6.7

0

7.3

0

5.45

0

6.62

5 33.1

7.48

0

9.24

0

0

45.5

0

1.1

0

1.4

2

2.8

1

0

1

9

9

5.3

0

6

0

0

0

0

99.8

350 Units Total 400 Units Total 450 Units Total

2.09

30 62.7 2.46

12 29.5 2.88

0

1.93

18 34.7 2.61

3

7.83 3.05

0

2.78

0

3.18

0

3.75

0

3.56

0

4.15

0

4.76

0

3.85

0

4.55

0

5.2

0

3.8

0

4.4

0

4.8

0

10.8

0

12.6

0

14.64

0

8.8

0

9.6

0

12

0

7.56

7

52.9

8.6

2

17.2 10.05

0

10.6

0

11.97

0

13.94

0

0

52

0

0

1.6

3

4.8

2

1

2

2.5

0

1

15

15

1

6

6

1

0

6.5

0

7

0

7.5

0

0

0

0

170

62.6

0

763.6

750 Units Total 800 Units Total 950 Units Total 1400 Units Total 1500 Units Total

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

7.2

0

7.6

0

0

0

0

0

0

0

0

0

7.5

0

0

15.7

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

3.7

0

4

0

0

0

0

0

0

0

0

0

16

0

16

0

0

0

0

0

0

0

0

321.8

1407

Page 3

7/7/2013

Vissy Paper Tumet Stainless Steel.

Stainless 304L / 316 sch10

15

Units

Total

20

Units

Total

25

Units

Total

40

Page 4

Units Total

50

Units Total

80

Units Total

100

Units

Total

Workshop Spooling

Wall thickness

Shop handling pipe for fabrication. 0.13

Pipe cutting

Pipe bevelling

Tack & buttweld

0.85

Slip on flanges & weld

0.6

90 deg nozzle ( un reinforced )

0

90 deg nozzle ( reinforced )

0

45 deg nozzle ( un reinforced )

0

45 deg nozzle ( reinforced )

Socket weld

0.51

O'lets

1.51

Install vents or drains

3.5

Bending 1 x 90deg

1.9

Thread pipe including cut.

0.23

2.11

2.11

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Total manhours.

2.77

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.13

0.85

0.6

0

0

0

0.57

1.68

3.6

1.9

0.23

0.13

0.85

0.75

0

0

0

0.65

2

3.73

1.9

0.23

2.77

0

0

0

4.25

0

0

0

0

0

0

0

0

0

0

0.14

0.065

0.04

0.9

21

0.8

0

0

0

0.8

2.32

2.38

0.23

4.25

2.77

0

0

0

18.9

0

0

0

0

0

0

0

0

0

0

0.16

0.085

0.046

0.98

80

0.93

1.98

2.63

2.61

3.46

1.05

2.69

2.73

0.23

18.9

3.05

0

0

0

78.4

0

0

0

0

0

0

0

0

0

0

0.2

0.13

0.07

1.21

126

1.15

2.52

3.37

3.42

4.57

1.24

3.67

3.84

0.35

78.4

3.05

0

0

0

152

0

0

0

0

0

0

0

0

0

0

0.22

0.175

0.095

1.55

160

1.48

3.25

4.22

4.57

5.93

1.52

4.63

5.65

0.52

152.5

0

0

0

248

0

0

0

0

0

0

0

0

0

0

248

502.01

Pipe size

150

Wall thickness

3.05

Shop handling pipe for fabrication. 0.28

Pipe cutting

0.312

Pipe bevelling

0.168

Tack & buttweld

1.95

Slip on flanges & weld

1.86

90 deg nozzle ( un reinforced )

4.37

90 deg nozzle ( reinforced )

5.75

45 deg nozzle ( un reinforced )

6.01

45 deg nozzle ( reinforced )

7.91

Fab & weld insulation rings

O'lets

Install vents or drains

Total manhours.

Units

Total

200

Units

Total

3.76

130

0

0

0

254

0

0

0

0

0

0

0

0

254

0.416

0.224

51

2.23

5.38

7.52

7.57

10.58

2.86

Units

Total

4.19

0.34

2.34

250

54

0

0

0

119

0

0

0

0

0

154

0

0

273.8

0.52

0.28

2.79

6.73

8.93

9.09

12.06

Units Total

4.57

0.46

2.93

300

0

0

0

20.51

0

0

0

0

0

0

0

0

20.51

0.624

0.336

3.44

3.28

10.63

9.89

13.24

Units Total

4.78

0.53

7.94

350

1.06

2.5

1.34

0

19.7

0

0

0

0

0

0

0

24.58

0.728

0.392

4.11

9.78

13.01

10.68

14.21

Units Total

4.78

0.64

4.31

400

0

0

0

25.9

0

0

0

0

0

0

0

0

25.86

0.832

0.448

4.59

11

14.84

11.85

15.98

Units

Total

4.78

0.8

4.82

450

15

0

0

0

72.3

0

0

0

0

0

0

0

0

72.3

0.92

0.936

0.504

5.38

5.13

12.3

16.37

13.53

18

0

0

0

0

0

0

0

0

0

0

0

0

0

670.53

Prepared by Geoff and Robyn Poile 7/7/2013

Page 4

Vissy Paper Tumet Stainless Steel.

Pipe size

500

Units

Total

Wall thickness

5.54

Shop handling pipe for fabrication. 1.14

Pipe cutting

1.04

Pipe bevelling

0.56

Tack & buttweld

6.11

Slip on flanges & weld

5.82

90 deg nozzle ( un reinforced ) 13.89

90 deg nozzle ( reinforced )

18.18

45 deg nozzle ( un reinforced ) 15.42

45 deg nozzle ( reinforced )

20.18

Socket weld

O'lets

Install vents or drains

0

0

0

0

0

0

0

0

0

0

0

0

Total manhours.

600

Units

Total

6.35

1.46

1.248

0.672

7.31

6.97

16.63

20.93

18.54

23.33

700

Units

Total

6.35

0

0

0

21.9

0

0

0

0

0

0

0

0

21.93

1.45

0.725

8.2

18.8

23.5

21.5

26.3

Units Total

7.92

1.65

8.5

900

Page 5

26

0

0

0

221

0

0

0

0

0

0

0

0

221

2.18

1.856

0.999

10.86

10.35

24.72

29.64

27.69

33.2

1050

Units Total

6m/m

0

0

0

0

0

0

0

0

0

0

0

0

0

2.55

2.165

1.162

1200

Units Total

6m/m

0

0

0

2.92

1700

Units

Total

6m/m

0

0

0

0

0

0

12.67

12.07

28.84

37.06

32.45

41.7

242.9

1766

Prepared by Geoff and Robyn Poile 7/7/2013

Page 5

You might also like

- CS Pipe Fab & Erect CostsDocument6 pagesCS Pipe Fab & Erect Costswally55bear69% (16)

- Cs Pipe Fab Amp Erect CostsDocument6 pagesCs Pipe Fab Amp Erect CostsBudi SantonyNo ratings yet

- Piping Manhours (Weight)Document25 pagesPiping Manhours (Weight)Nejat AbabayNo ratings yet

- Piping ManhoursDocument32 pagesPiping ManhoursNejat Ababay75% (16)

- 54 - Process Plant Piping Estimate DetailDocument57 pages54 - Process Plant Piping Estimate Detailstefax2010100% (3)

- Estimate Piping LabourDocument5 pagesEstimate Piping Labourandy100% (7)

- Piping Works EstimationDocument3 pagesPiping Works Estimationakg20041100% (5)

- Thumb RuleDocument27 pagesThumb Ruleavinashudupa67% (6)

- Piping Manhour Costing Estimate SampleDocument24 pagesPiping Manhour Costing Estimate SampleMethosalem Haincadto85% (34)

- Manhour StandardsDocument6 pagesManhour StandardsNaing Lin Cho56% (18)

- Technical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Document107 pagesTechnical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Rezza Aditya47% (17)

- Piping EstimationDocument19 pagesPiping EstimationTitoFernandez86% (7)

- Estimation Man HourDocument422 pagesEstimation Man HourEngFaisal Alrai50% (2)

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (34)

- How To Estimate Pipe Welding - EhowDocument2 pagesHow To Estimate Pipe Welding - EhowKalai Kumar100% (3)

- Piping CostDocument33 pagesPiping CostAjay SastryNo ratings yet

- Cost Centers Vs ManhoursDocument166 pagesCost Centers Vs Manhoursguy88100% (1)

- CS Pipes Installation CostDocument12 pagesCS Pipes Installation Costrajkamal_e100% (2)

- Estimates For Epcc/ Epcm SkidsDocument3 pagesEstimates For Epcc/ Epcm SkidsshrieersNo ratings yet

- Draft Construction Productivity NormsDocument29 pagesDraft Construction Productivity NormsSubhojit Adhikary100% (2)

- Industrial Piping (Process Plant) Productivity StandardsDocument30 pagesIndustrial Piping (Process Plant) Productivity Standardsburerey100% (4)

- Piping Progress Measurement - Meter-Inch and Dia-InchDocument1 pagePiping Progress Measurement - Meter-Inch and Dia-InchdasubhaiNo ratings yet

- Standard Manhour Estimation: Fabrication & WeldingDocument3 pagesStandard Manhour Estimation: Fabrication & WeldingPratik Desai100% (7)

- Sharafco Man Hour Estimation (Pipeline)Document6 pagesSharafco Man Hour Estimation (Pipeline)Prasad67% (3)

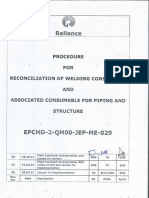

- Reconciliation of Welding ConsumablesDocument24 pagesReconciliation of Welding ConsumablesHema Nandh100% (1)

- Table For Piping Manhour Estimative CalculationDocument20 pagesTable For Piping Manhour Estimative CalculationdanieltraduNo ratings yet

- Overall CCTRDocument182 pagesOverall CCTRInaam Ullah Mughal100% (2)

- Reconcilation of Welding Consumable and Associated Consumable For Piping and StructureDocument44 pagesReconcilation of Welding Consumable and Associated Consumable For Piping and StructureRakesh Ranjan50% (2)

- Manhours For CS Piping Erection Including FitupDocument1 pageManhours For CS Piping Erection Including FitupSoham BanerjeeNo ratings yet

- Resource Planning & Productivity MonitoringDocument19 pagesResource Planning & Productivity MonitoringVinit Kant Majumdar67% (3)

- 2a Piping Estimate & Summary ExampleDocument29 pages2a Piping Estimate & Summary ExampleTutu RohanaNo ratings yet

- Technical Calculation and Estimators Man-Hour ManualDocument238 pagesTechnical Calculation and Estimators Man-Hour ManualN P Srinivasarao33% (12)

- Man Hour Estimate ProgramDocument15 pagesMan Hour Estimate ProgramnbnbNo ratings yet

- Metal Fabrication Pipe Cost Estimation SheetDocument1 pageMetal Fabrication Pipe Cost Estimation SheettunlinooNo ratings yet

- Pipes PoolsDocument3 pagesPipes PoolsjorgemachigueNo ratings yet

- Piping CostDocument4 pagesPiping CostYulianus SReaNo ratings yet

- Project Staffing and Cost BreakupDocument33 pagesProject Staffing and Cost BreakupVinayak PujariNo ratings yet

- Construction Norms Offshore PDFDocument80 pagesConstruction Norms Offshore PDFAzwan100% (3)

- DL Template in 8ths #1 ConcDocument1 pageDL Template in 8ths #1 ConcozchrisNo ratings yet

- Costing of PipelinesDocument18 pagesCosting of Pipelinesbjtiew100% (3)

- 2b Piping Estimate & Summary FormDocument14 pages2b Piping Estimate & Summary FormEK63100% (1)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- 37° Flared Tube Fitting GuideDocument13 pages37° Flared Tube Fitting GuidehernychtNo ratings yet

- Plumbing PIpe SizingDocument12 pagesPlumbing PIpe SizingAwokeNo ratings yet

- ReportDocument29 pagesReportAzri AhmedNo ratings yet

- Fluke 1650B Series: Multifunction Installation TestersDocument10 pagesFluke 1650B Series: Multifunction Installation TestersWasinchai KanjanapanNo ratings yet

- Friction Losses in Pipe Fittings Resistance Coefficient K (Use in Formula H KV /2g)Document12 pagesFriction Losses in Pipe Fittings Resistance Coefficient K (Use in Formula H KV /2g)Alvin KimNo ratings yet

- FRP Composite ComparisonDocument2 pagesFRP Composite Comparisonyanuar_adhiNo ratings yet

- Square Air Core Inductors: 1515SQ 2222SQ 2929SQDocument3 pagesSquare Air Core Inductors: 1515SQ 2222SQ 2929SQvidhya.dpi5566No ratings yet

- Watermain Testing and Commissioning ProceduresDocument6 pagesWatermain Testing and Commissioning ProceduresLaurence BeltranNo ratings yet

- External Sewege DesignDocument3 pagesExternal Sewege DesigngvgbabuNo ratings yet

- Reinforced Concrete DesignDocument28 pagesReinforced Concrete DesignJefNo ratings yet

- Working of Breather Valve Working On TanksDocument4 pagesWorking of Breather Valve Working On Tanks54045114No ratings yet

- Aluminium AW 6063 T6 AngleDocument4 pagesAluminium AW 6063 T6 Angledoshi78No ratings yet

- DR: Awad EL-Hashmy DR: Waleed Tawheed: Group:6Document30 pagesDR: Awad EL-Hashmy DR: Waleed Tawheed: Group:6Magic MasterNo ratings yet

- Chiller Selection MethodDocument9 pagesChiller Selection MethodAbdullah.N FAAliNo ratings yet

- Practice Exercises # 3 Fall 2023Document6 pagesPractice Exercises # 3 Fall 2023Nidhi ShettyNo ratings yet

- تصميم كل العناصر الأنشائيةDocument26 pagesتصميم كل العناصر الأنشائيةMohamed ElbahnsyNo ratings yet

- Concrete Design-UDocument28 pagesConcrete Design-UKhải TrươngNo ratings yet

- Hs Bolt SpecificationDocument6 pagesHs Bolt SpecificationncristiNo ratings yet

- Heathrow Airport Terminal 2 GuideDocument7 pagesHeathrow Airport Terminal 2 Guidewally55bearNo ratings yet

- Coldformed SectionsDocument56 pagesColdformed SectionsSwapnil ToraskarNo ratings yet

- Ebsray pumps V series model V40 technical brochureDocument8 pagesEbsray pumps V series model V40 technical brochurewally55bearNo ratings yet

- Coldformed SectionsDocument56 pagesColdformed SectionsSwapnil ToraskarNo ratings yet

- Heathrow T3 MapDocument6 pagesHeathrow T3 Mapwally55bearNo ratings yet

- 4 Internal FlowDocument40 pages4 Internal FlowMarilaine ColnagoNo ratings yet

- Cleveland SI Impact VibratorDocument4 pagesCleveland SI Impact Vibratorwally55bearNo ratings yet

- D-2N Brake DrawingDocument1 pageD-2N Brake Drawingwally55bearNo ratings yet

- Atlas Technical Handbook of SS Rev Aug 2013Document49 pagesAtlas Technical Handbook of SS Rev Aug 2013timparker01No ratings yet

- Tram Network Mapp TV A 4Document1 pageTram Network Mapp TV A 4Jason HoNo ratings yet

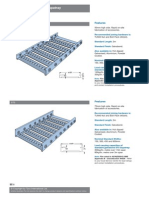

- 3F1 - Cable Ladder SCL Shaped AccessoriesDocument1 page3F1 - Cable Ladder SCL Shaped Accessorieswally55bearNo ratings yet

- 3J1 - Cable Ladder Accessory SupportsDocument1 page3J1 - Cable Ladder Accessory Supportswally55bearNo ratings yet

- Cable Tray - Supatray SectionDocument3 pagesCable Tray - Supatray Sectionwally55bearNo ratings yet

- Cable Tray - Supatray SectionDocument3 pagesCable Tray - Supatray Sectionwally55bearNo ratings yet

- Tram Network Mapp TV A 4Document1 pageTram Network Mapp TV A 4Jason HoNo ratings yet

- Mass CalcDocument3 pagesMass Calcwally55bear0% (1)

- Steel Pipe DimensionsDocument7 pagesSteel Pipe Dimensionswally55bearNo ratings yet

- Static Equipment Training ModulesDocument3 pagesStatic Equipment Training ModulesMohit SinghNo ratings yet

- F200cet'12 F225bet'12 Fl200cet'12 Fl225bet'12: (6al7) (6as6) (6am7) (6at6)Document88 pagesF200cet'12 F225bet'12 Fl200cet'12 Fl225bet'12: (6al7) (6as6) (6am7) (6at6)Vicent GarcioloNo ratings yet

- American Parts List PriceDocument314 pagesAmerican Parts List Priceejatch2No ratings yet

- Service Bulletin: Fuel Injection PumpDocument28 pagesService Bulletin: Fuel Injection PumpKrunoslavNo ratings yet

- Integral Block & Bleed Valves: Catalog No. H-100PIV Feb. 2006Document24 pagesIntegral Block & Bleed Valves: Catalog No. H-100PIV Feb. 2006Rajesh RadeNo ratings yet

- Canalta Orifice Fitting Parts & Accessories: Precision Machined Accuracy Reliability PerformanceDocument90 pagesCanalta Orifice Fitting Parts & Accessories: Precision Machined Accuracy Reliability Performanceray mojicaNo ratings yet

- IVGE Butterfly ValveDocument2 pagesIVGE Butterfly ValvejprakashbandaruNo ratings yet

- Cast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscDocument3 pagesCast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscMina MagdyNo ratings yet

- Norma AP 6DDocument105 pagesNorma AP 6Dsabes26No ratings yet

- List of API StandardsDocument3 pagesList of API StandardsMuthuKumar Arunachalam100% (7)

- Orifice Plate Overview Rev5 Jan 2016Document14 pagesOrifice Plate Overview Rev5 Jan 2016Karuppiah VairavanNo ratings yet

- Piping Class TecnaDocument135 pagesPiping Class Tecnajulia.garciaNo ratings yet

- Piping Catalogue Component Naming StandardDocument121 pagesPiping Catalogue Component Naming StandardRené Abanto GarciaNo ratings yet

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Document1 pageParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Hardiansyah Simarmata100% (1)

- Control Valve SourcebookDocument218 pagesControl Valve SourcebookDoug LambNo ratings yet

- Marketing PlanDocument61 pagesMarketing PlanFendy ShirahNo ratings yet

- Pipe Stress Analysis Training Complete CourseDocument24 pagesPipe Stress Analysis Training Complete CourseFábio GamaNo ratings yet

- Potential For Fire, Smoke and Asphyxiation HazardsDocument24 pagesPotential For Fire, Smoke and Asphyxiation HazardsKeiko DavilaNo ratings yet

- DNVGL Ru Inv Pt4ch2Document29 pagesDNVGL Ru Inv Pt4ch2mustafa meseliNo ratings yet

- Daman Main Catalog 2013.1Document214 pagesDaman Main Catalog 2013.1mohammedNo ratings yet

- V03015Document20 pagesV03015krisNo ratings yet

- Section 90 - Cab - Chapter 3Document36 pagesSection 90 - Cab - Chapter 3Esteban MunaresNo ratings yet

- 7366 - 30 99 24 1607 - 1Document21 pages7366 - 30 99 24 1607 - 1Syed Qasim AbbasNo ratings yet

- MSS-SP-104 (1995)Document11 pagesMSS-SP-104 (1995)Islam SolimanNo ratings yet

- Pump Care ManualDocument52 pagesPump Care ManualGreenbuild ZM-JVNo ratings yet

- Boq - Sewer Pump Station Example: Project Name, Town Tender NoDocument8 pagesBoq - Sewer Pump Station Example: Project Name, Town Tender Nodelovan cheikhoNo ratings yet

- ATFD QUOTEr1Document12 pagesATFD QUOTEr1Hariharan M ENo ratings yet

- Piping Material Classes Job SpecificationDocument6 pagesPiping Material Classes Job SpecificationGERAILLYNo ratings yet

- Instruction Manual Fisher Vee Ball v150 v200 v300 Rotary Control Valves Nps 1 Through 12 en 135080Document56 pagesInstruction Manual Fisher Vee Ball v150 v200 v300 Rotary Control Valves Nps 1 Through 12 en 135080SebastianNo ratings yet

- API Standard 653: Tank Inspection, Repair, Alteration, and ReconstructionDocument1 pageAPI Standard 653: Tank Inspection, Repair, Alteration, and ReconstructionraselNo ratings yet