Professional Documents

Culture Documents

High Speed Gearboxes

Uploaded by

kh_chu_1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Speed Gearboxes

Uploaded by

kh_chu_1Copyright:

Available Formats

Innovative Power Transmission

HIGH SPEED

GEARBOXES

Innovative Gear in Power Plants Systems

First-Class Gearboxes

1 General

For many decades, RENK has been a leading manufacturer of highspeed gearboxes and enjoys an excellent reputation with their series TS, TB, TL, TNA and TNB. Supported by up-to-date CAD-systems and computercontrolled production, products of superior quality are built and delivered worldwide.

3 Type Designation

Construction series and centre distances are identified by the gearbox designation. The overview shown below explains the meaning of the alphanumerical designation. The numerical part refers to the centre distance. TNA and TL types are gear units with wide gear teeth which allow to realize low transmission ratios. TNB and TS have narrow gear teeth for high transmission ratios. For centre distances up to 400 mm, the gear casings are manufactures with high-quality cast iron; Casings with welded steel construction are used for centre distances up to 450 mm.

2 Gearboxes

Depending on the specification, the gearboxes are built according to DIN 3990, AGMA 421.06 or API 613 standard. In order to achieve optimum efficiency and excellent running characteristics regarding vibration and noise, the gear teeth, bearings, natural frequencies and rotor dynamics are calculated according to the latest state of the art.

Gearbox i low Series Series TL TNA

Transmission ratio i i high TNB TB TS

The following type code indicates the designations of the standard gearbox series: Type Code TS,TB,TL gearboxes

- centre distance [mm]

Type Code TNA,TNB gearboxes

- centre distance [mm]

TNA-355 - Casing made from high-quality grey cast iron

TB-900 - Steel casing - welded

- = standard Q = quill shaft - = double helical teeth E = single helical teeth S = narrow gearing B = mean tooth width. L = wide gearing - = without thrust collar D = thrust collar T = high-speed gearbox

- = standard Q = quill shaft

B = narrow gearing A = wide gearing N = double helical teeth E = single helical teeth D = trust collar + single helical teeth T = high-speed gearbox

Example 1: (T) High-speed gearbox, (L) low transmission ratio, (E) single helical teeth with (Q) quill shaft, centre distance 850 mm => designation: TLEQ-850 Example 2: (T) High-speed gearbox, (S) high transmission ratio, centre distance 710 mm => designation: TS-710

Example 3: (T) High-speed gearbox, (D) thrust collar, (B) mean transmission ratio, (E) single helical teeth, centre distance 800 mm => designation: TDBE-800

T T T

S B S

E E

- 560 - 900 - 630

written: TDSEQ-560 TB-900 TSE-630

T T T

D N E

A A B

- 355 - 315 - 400

written: TDA-355 TNA-315 TEB-400

Gearbox Elements

4.1 Gear Set

Different gear sets characterize the gearbox series. Following design options are possible:

single helical teeth single helical teeth with thrust collar double helical teeth Double helical teeth Single helical teeth Single helical teeth with thrust collar

The gear shaft is built in two different ways: The quill shaft design takes advantage of the higher resilience of al long shaft, whereby the power flow is directed into the output shaft that is located opposite to the driven machine.

4.2 Bearings

Split journal bearings are used for the standard design, and one bearing of the gear shaft is equipped with axial stop collars. If higher speeds are involved, radial tilting pad bearings are mounted. The use of separate axial thrust bearings according to API 613 is also possible.

4.3 Seals

The gearboxes require pressure oil lubrication. The oil may optionally be supplied by a separate or a flangemounted oil pump. The gearbox can also be connected to a central lubrication system. The shaft ends of the gearboxes are sealed by means of a split, noncontact labyrinth seal made from aluminium. Upon request, special seals are also available.

5 Power loss and

efficiency

With view to power loss and efficiency, RENK gearboxes are designed to the optimum possible. Decisive factors to achieve a high efficiency are the selection of the bearings and their dimensioning as well as the oil flow and type of teeth.

7 Instrumentation

The gearboxes can be supplied with a number of monitoring instruments, such as built-in resistance thermometers, thermocouples, vibration detectors, speed sensors, accelerometers, position detectors and oil pressure transmitters. These devices are also available in exproof or ATEX-design.

6 Noise and

vibrations

Each gearbox is noise-optimised for nominal load. The dimensioning of the teeth, lubrication and casing is focused on low noise and quiet operation.

Journal bearing with offset profile

Quality Assurance

8 Accessories

The following accessories can be supplied:

rotor turning devices gear oil pump screw-spindle pump

Rotor turning device

Gear oil pump

Screw spindle pump

9 Production and

Assembly

The gearboxes obtain highest demands as the individual components are manufactured on Hi-Tech-equipment, and the gearbox assembly is carried out by highly qualified specialists. As far as quality assurence is concerned, our plant is certified according to DIN / ISO 9001 / EN 29001.

Assembly of a TB-950 gearbox

10 Trial run

Every gearbox is subjected to extensive inspections and tests during which efficiency, noise emission, vibration characteristics and proper function of the lubrication system are thoroughly checked. The results are recorded and documented.

TB-630 Test run

Service around the Product

Our service team can and will arrange and/or co-ordinate all necessary measures and ensures competent assistance with remedies without any loss of time. Our highly qualified team of experts will be supporting you

once the ordered gearbox or coupling has left our factory. The Service Team can be contacted at any time to assist you with any questions or problems you have.

In addition, our after-sales service department is flanked by a group of experienced field engineers. We provide constant support to these team members to ensure that complex queries are solved fast and accurately.

RENK Aktiengesellschaft Rheine Plant Service Rodder Damm 170 48432 Rheine Germany Phone: +49 59 71 / 790 260 Fax: +49 59 71 / 790 444 E-Mail: rheine@renk-ag.com Internet: http://www.renk.de

We maintain the most advanced test and inspection facilities:

3D gear teeth measurement 3D coordinate measurement machine crack testing, surface testing and ultrasonic testing endoscope for inspecting the inside

3 D measurement machine

Upon completion of the analysis, you will receive an examination report including suggestions and recommendations as how to proceed.

Gearing measurement

Inspection of a high-speed gearbox

Further products of our range of couplings

1 1 Curved tooth coupling with hardened and ground external and internal teeth and tooth-by-tooth injection lubrication 2 High-speed diaphragm coupling Type MCN 3 Raflex steel disk coupling Type MTP according to API 610

RENK Aktiengesellschaft Rheine works Rodder Damm 170 D-48432 Rheine Telephone: ++49 5971 790-0 Telefax: ++49 5971 790 208 und 790 256 E-mail: info.rheine@renk.biz Internet: http://www.renk.eu

Neudruck RR 063/6.10-3,e 101148

You might also like

- 02 RENK MAAG FieldService Maintenance enDocument18 pages02 RENK MAAG FieldService Maintenance enropmachadoNo ratings yet

- Renk High Torque Planetary Gears PBLZDocument12 pagesRenk High Torque Planetary Gears PBLZhumayun121No ratings yet

- Renk Bearings Type HGDocument8 pagesRenk Bearings Type HGhumayun121No ratings yet

- Renk High Speed Power GearsDocument12 pagesRenk High Speed Power Gearshumayun121No ratings yet

- Renk Planetary Gears Type Pls PwsDocument8 pagesRenk Planetary Gears Type Pls Pwshumayun121No ratings yet

- HYGUARD Safety CouplingsDocument32 pagesHYGUARD Safety CouplingsropmachadoNo ratings yet

- Caterpillar RC1000 Containerized Diesel Generator SetDocument4 pagesCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryNo ratings yet

- Renk Tunnel GearboxesDocument8 pagesRenk Tunnel Gearboxeshumayun121No ratings yet

- Untitled PDFDocument48 pagesUntitled PDFakhil9182No ratings yet

- Renk PBLZ enDocument7 pagesRenk PBLZ enhumayun121No ratings yet

- Intelligent Coupling Solutions For All Applications.: CouplingsDocument44 pagesIntelligent Coupling Solutions For All Applications.: Couplingsjvc hemitNo ratings yet

- Appendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Document17 pagesAppendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Dino AndrianNo ratings yet

- Hydro 2020 Water Turbine.Document26 pagesHydro 2020 Water Turbine.Mạnh Ngô VănNo ratings yet

- Operating Instruction PWS 18-E (Gearbox) SEL 12 PDFDocument278 pagesOperating Instruction PWS 18-E (Gearbox) SEL 12 PDFGiannis MylonasNo ratings yet

- CDR Catalogo Digital INA FAG PDFDocument1,460 pagesCDR Catalogo Digital INA FAG PDFAnonymous W3Kdy4pr100% (1)

- SKF N10 Series CatalogDocument24 pagesSKF N10 Series CatalogJeff HawkinsNo ratings yet

- Bearing Wear Monitoring SystemDocument16 pagesBearing Wear Monitoring Systempapaki2No ratings yet

- DNFT A-6348 Led-Ps PDFDocument4 pagesDNFT A-6348 Led-Ps PDFhugoheloNo ratings yet

- Cat 950 H PDFDocument20 pagesCat 950 H PDFdk_moehammedNo ratings yet

- Renk PSC Propeller Shaft ClutchDocument8 pagesRenk PSC Propeller Shaft Clutchhumayun121No ratings yet

- VLE Hooklift&Hookloader CatalogueDocument35 pagesVLE Hooklift&Hookloader CataloguevlehookliftNo ratings yet

- GV222TIDocument3 pagesGV222TInanocycleNo ratings yet

- Doosan Skoda Product BrochureDocument16 pagesDoosan Skoda Product BrochureSai Shankar Lakshminarayanan100% (1)

- BS 00046-1-1958 (2000)Document32 pagesBS 00046-1-1958 (2000)Mostafa Hussein AbdouNo ratings yet

- Repower Offshore - Turbines and Uk MarketDocument35 pagesRepower Offshore - Turbines and Uk MarketKaio Dos Santos SilvaNo ratings yet

- BS 6861 Part 2 (ISO 1940 Part 2)Document22 pagesBS 6861 Part 2 (ISO 1940 Part 2)Fenner Electromechanical100% (1)

- Renk Etax TechonologyDocument6 pagesRenk Etax Techonologyhumayun121No ratings yet

- Re92076 2005-03Document32 pagesRe92076 2005-03Şenol MemişNo ratings yet

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document4 pagesDoosan Infracore Generator Engine: Ratings (KWM/PS)moisesNo ratings yet

- Kenco - Oil Level Controller PDFDocument16 pagesKenco - Oil Level Controller PDFClemente Rafael Marval EscalonaNo ratings yet

- Predicting How a Centrifugal Compressor's Slip Factor Varies With Flow RateDocument13 pagesPredicting How a Centrifugal Compressor's Slip Factor Varies With Flow Ratetorrent0cataclysmNo ratings yet

- PIM130B1 - Daihatsu DT Series Archived JUN PDFDocument5 pagesPIM130B1 - Daihatsu DT Series Archived JUN PDFAnonymous XGsiY6rNo ratings yet

- Operating Manual: Planetary Gearbox EP - 45Document51 pagesOperating Manual: Planetary Gearbox EP - 45Ravi RamdeoNo ratings yet

- DMTP 5100Document41 pagesDMTP 5100Henry GelvisNo ratings yet

- Diesel Engine ConstructionDocument53 pagesDiesel Engine ConstructionLasse HansenNo ratings yet

- Mopico: Product Overview: Segment Gas Storage and Sealed TechnolgyDocument18 pagesMopico: Product Overview: Segment Gas Storage and Sealed Technolgyhernan plazasNo ratings yet

- Turbo CompoundDocument29 pagesTurbo CompoundDIONYBLINKNo ratings yet

- JC-364-TSKS IOM EN Final HiRes NoCropsDocument12 pagesJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiNo ratings yet

- EspeyDocument20 pagesEspeyGuillermo Esteban Diaz QuezadaNo ratings yet

- Bombas Parker Pvp16Document10 pagesBombas Parker Pvp16Gustavo HuertasNo ratings yet

- 0901d1968010a4d1-SKF4560 E 1 TCM 12-73075 PDFDocument117 pages0901d1968010a4d1-SKF4560 E 1 TCM 12-73075 PDFAnonymous BWxmaSf0qPNo ratings yet

- Manual For 1215 Kva Rig AlternatorDocument18 pagesManual For 1215 Kva Rig Alternatorprem080910No ratings yet

- Operating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXDocument183 pagesOperating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXforuzzNo ratings yet

- 5650 TechDocument7 pages5650 Techamjath584No ratings yet

- HPFi Hydraulic Support System 0700Document35 pagesHPFi Hydraulic Support System 0700g665013No ratings yet

- Ansi S2-42 PDFDocument40 pagesAnsi S2-42 PDFAndres Antonio Moreno CastroNo ratings yet

- 220 2007 EnglischDocument134 pages220 2007 EnglischropmachadoNo ratings yet

- M2000Document7 pagesM2000kylegazeNo ratings yet

- Winches ChinosDocument3 pagesWinches Chinosfelixriosl100% (1)

- Reduce Engine Noise with Engine Exhaust SilencersDocument28 pagesReduce Engine Noise with Engine Exhaust SilencersMaarij AnjumNo ratings yet

- SKF Microlog Accessories CatalogueDocument89 pagesSKF Microlog Accessories CatalogueAlex Porro SeclenNo ratings yet

- Kingsbury Leg ComponentsDocument3 pagesKingsbury Leg ComponentsHatem Abdelrahman100% (1)

- Introduction to Turbomachinery FundamentalsDocument4 pagesIntroduction to Turbomachinery FundamentalsNah Sr AdNo ratings yet

- Thrust BearingDocument5 pagesThrust BearinghardaniNo ratings yet

- Renk EF 35-45 PDFDocument8 pagesRenk EF 35-45 PDFdanijelpartoviNo ratings yet

- 6 Testing and Qualification of Two-Stage Turbocharging SystemsDocument16 pages6 Testing and Qualification of Two-Stage Turbocharging SystemsMuzaffar Ali QuaziNo ratings yet

- TIMKEN - Zespoy Ozyskowe Typu E PDFDocument13 pagesTIMKEN - Zespoy Ozyskowe Typu E PDFPlamen KangalovNo ratings yet

- Wartsila O P Transverse ThrusterDocument8 pagesWartsila O P Transverse ThrusterionesqNo ratings yet

- Catálogo Nord Redutores Aluminio SmoothmotorsDocument28 pagesCatálogo Nord Redutores Aluminio Smoothmotorsleonardo silveiraNo ratings yet

- RENK MAAG Turbo Gearboxes 0413-1Document24 pagesRENK MAAG Turbo Gearboxes 0413-1RCMNo ratings yet

- Neuroscience Explains Why People Keep Believing Trump's Lies - QuartzDocument3 pagesNeuroscience Explains Why People Keep Believing Trump's Lies - Quartzkh_chu_1No ratings yet

- Climbing Training - How To Get Stronger Fingers - Climbing Magazine - Rock Climbing, Mountaineering, Bouldering, Ice ClimbingDocument5 pagesClimbing Training - How To Get Stronger Fingers - Climbing Magazine - Rock Climbing, Mountaineering, Bouldering, Ice Climbingkh_chu_1No ratings yet

- Search This Topic: Register Login Search Latest Topics Categories Binocular Questions & AnswersDocument5 pagesSearch This Topic: Register Login Search Latest Topics Categories Binocular Questions & Answerskh_chu_1No ratings yet

- Which Is The Worst Country in The World - QuoraDocument4 pagesWhich Is The Worst Country in The World - Quorakh_chu_1No ratings yet

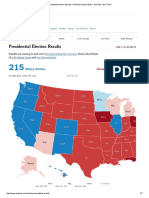

- Live Presidential Forecast - Election Results 2016 - The New York TimesDocument4 pagesLive Presidential Forecast - Election Results 2016 - The New York Timeskh_chu_1No ratings yet

- Why Do Russians Never Smile - The AtlanticDocument4 pagesWhy Do Russians Never Smile - The Atlantickh_chu_1No ratings yet

- Presidential Election Results - Election Results 2016 - The New York TimesDocument7 pagesPresidential Election Results - Election Results 2016 - The New York Timeskh_chu_1No ratings yet

- BBC - Future - The Strange Tanks That Helped Win D-DayDocument26 pagesBBC - Future - The Strange Tanks That Helped Win D-Daykh_chu_1No ratings yet

- Dealing With Sore Throats - The Little Things in My HeadDocument9 pagesDealing With Sore Throats - The Little Things in My Headkh_chu_1No ratings yet

- Rolls-Royce Considers Sale of Commercial Marine UnitDocument3 pagesRolls-Royce Considers Sale of Commercial Marine Unitkh_chu_1No ratings yet

- Are You Serving Coffee at The Ideal TemperatureDocument8 pagesAre You Serving Coffee at The Ideal Temperaturekh_chu_1No ratings yet

- The Worst Ways To DieDocument15 pagesThe Worst Ways To Diekh_chu_1No ratings yet

- FulltextDocument6 pagesFulltextkh_chu_1No ratings yet

- Your Inability To Form A Routine Is A Warning Sign That Something Deeper Is Wrong - QuartzDocument8 pagesYour Inability To Form A Routine Is A Warning Sign That Something Deeper Is Wrong - Quartzkh_chu_1No ratings yet

- BBC - Future - What Not To Do in A DisasterDocument20 pagesBBC - Future - What Not To Do in A Disasterkh_chu_1No ratings yet

- China Is Building The Most Extensive Global Commercial-Military Empire in History - QuartzDocument11 pagesChina Is Building The Most Extensive Global Commercial-Military Empire in History - Quartzkh_chu_1No ratings yet

- Dangerous Chemicals in Deodorant & Antiperspirant - A Detailed Review of The Chemicals, Research & Avoidance Tips - Natural Cosmetic NewsDocument10 pagesDangerous Chemicals in Deodorant & Antiperspirant - A Detailed Review of The Chemicals, Research & Avoidance Tips - Natural Cosmetic Newskh_chu_1No ratings yet

- Review of Bird Repellents: Digitalcommons@University of Nebraska - LincolnDocument9 pagesReview of Bird Repellents: Digitalcommons@University of Nebraska - Lincolnkh_chu_1No ratings yet

- BBC - Soutik Biswas's India - How Churchill 'Starved' IndiaDocument2 pagesBBC - Soutik Biswas's India - How Churchill 'Starved' Indiakh_chu_1No ratings yet

- BAM - The Slipperiest Material in The WorldDocument8 pagesBAM - The Slipperiest Material in The Worldkh_chu_1No ratings yet

- BBC - Future - What Not To Do in A DisasterDocument20 pagesBBC - Future - What Not To Do in A Disasterkh_chu_1No ratings yet

- Fulltext PDFDocument9 pagesFulltext PDFkh_chu_1No ratings yet

- How to beat an MMA fighter on the streetDocument2 pagesHow to beat an MMA fighter on the streetkh_chu_1No ratings yet

- Fulltext PDFDocument6 pagesFulltext PDFkh_chu_1No ratings yet

- BBC - Soutik Biswas's India - How Churchill 'Starved' India PDFDocument2 pagesBBC - Soutik Biswas's India - How Churchill 'Starved' India PDFkh_chu_1No ratings yet

- BBC - Future - The Strange Tanks That Helped Win D-DayDocument26 pagesBBC - Future - The Strange Tanks That Helped Win D-Daykh_chu_1No ratings yet

- BBC - Capital - This Is Why You Can't Switch Off at The WeekendDocument18 pagesBBC - Capital - This Is Why You Can't Switch Off at The Weekendkh_chu_1No ratings yet

- BAM - The Slipperiest Material in The WorldDocument8 pagesBAM - The Slipperiest Material in The Worldkh_chu_1No ratings yet

- How To Turn Off Windows Update in Windows 10Document14 pagesHow To Turn Off Windows Update in Windows 10kh_chu_1No ratings yet

- Neuroscience Explains Why People Keep Believing Trump's Lies - QuartzDocument3 pagesNeuroscience Explains Why People Keep Believing Trump's Lies - Quartzkh_chu_1No ratings yet

- Plasticization Effect of Triacetin On Structure and Properties of Starch Ester FilmDocument8 pagesPlasticization Effect of Triacetin On Structure and Properties of Starch Ester FilmNanik HendrawatiNo ratings yet

- Application of NanozymesDocument15 pagesApplication of NanozymeslalaNo ratings yet

- Heatwave Climate Change IntDocument5 pagesHeatwave Climate Change IntPulkit VasudhaNo ratings yet

- Iso 10456 2007 en PDFDocument11 pagesIso 10456 2007 en PDFClaudia Carhuani25% (4)

- Set2-PetE418-Midterm Examination-SignedDocument5 pagesSet2-PetE418-Midterm Examination-SignedRoxanne NavarroNo ratings yet

- Applications of Thermo Gravimetric Analysis (Tga)Document13 pagesApplications of Thermo Gravimetric Analysis (Tga)Usman GhaniNo ratings yet

- App C PDFDocument2 pagesApp C PDFRustika SafitriNo ratings yet

- TDS Cerafak 111 enDocument2 pagesTDS Cerafak 111 enoptimus_1404No ratings yet

- SSC-JE Mechanical Obj. Paper 9789389269475Document23 pagesSSC-JE Mechanical Obj. Paper 9789389269475Shivam AgrawalNo ratings yet

- Cold Formed Purlin - CDocument12 pagesCold Formed Purlin - CHarjasa AdhiNo ratings yet

- Light Soaking ChamberDocument3 pagesLight Soaking ChamberUmer MahmoodNo ratings yet

- Phonon VibrationsDocument12 pagesPhonon Vibrationspricil99No ratings yet

- Design components of MHP for hydraulic dataDocument34 pagesDesign components of MHP for hydraulic dataSomprasad PradhanNo ratings yet

- Fine Art Flowers PDFDocument23 pagesFine Art Flowers PDFmrpiracyNo ratings yet

- Free Electron TheoryDocument68 pagesFree Electron TheoryV Sree Suswara SuswaraNo ratings yet

- The Effects of Initial TemperatureDocument5 pagesThe Effects of Initial TemperatureErhan Sedat EnerNo ratings yet

- Doppler Effect ExplainedDocument6 pagesDoppler Effect ExplainedBrandonNo ratings yet

- King Saud University Statics Midterm Exam QuestionsDocument5 pagesKing Saud University Statics Midterm Exam QuestionsIbraheem AdarbehNo ratings yet

- Climate Change Test ReviewDocument1 pageClimate Change Test ReviewSabrina Lavega67% (3)

- Prof. Dr.-Ing. Uwe Franzke ILK Dresden Cooling Loads - The New Standard VDI 2078Document25 pagesProf. Dr.-Ing. Uwe Franzke ILK Dresden Cooling Loads - The New Standard VDI 2078Sashko GjorgievskiNo ratings yet

- Module 1 Lesson 1 2023Document5 pagesModule 1 Lesson 1 2023Cielo Nicole De GuzmanNo ratings yet

- Qip Ice 31 Stirling EnginesDocument20 pagesQip Ice 31 Stirling EnginesChetanPrajapatiNo ratings yet

- DATA SheetDocument5 pagesDATA SheetKhalifaNo ratings yet

- API 5CT Coupling Stock2Document10 pagesAPI 5CT Coupling Stock2tarno12No ratings yet

- Brochure DVE Laser Film 201505Document2 pagesBrochure DVE Laser Film 201505RDII YANMEDRSDSNo ratings yet

- GK 3165 Serti̇fi̇kaDocument1 pageGK 3165 Serti̇fi̇kanedim cılızNo ratings yet

- Dictionary April 2017 - Teflon CoatingsDocument2 pagesDictionary April 2017 - Teflon CoatingsCoatresa Recubrimientos TecnicosNo ratings yet

- Equilibrium of Coplanar Non-Concurrent Force SystemDocument5 pagesEquilibrium of Coplanar Non-Concurrent Force SystemkrismkarNo ratings yet

- CalibrationDocument13 pagesCalibrationAmanjit SinghNo ratings yet

- Hq153en Balinit-Dlc SeriesDocument4 pagesHq153en Balinit-Dlc SeriesJoão TarelhoNo ratings yet