Professional Documents

Culture Documents

Revision Record Sheet: Title

Uploaded by

Sanjay MalhotraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Revision Record Sheet: Title

Uploaded by

Sanjay MalhotraCopyright:

Available Formats

REVISION RECORD SHEET

TITLE : PROCEDURE FOR

REV.NO 00 INVENTORY CONTROL. DESC. OF AMENDMENT DATE OF AMENDMENT FIRST ISSUE AS PER QS 9000 : 1995

PR.NO : QP-15-02 PAGE NO : 1 OF 3 ISSUE NO : 01 REV NO : 00 DATE : 16.03.1997 REASON FOR AMENDMENT

DISTRIBUTED TO :

SL.NO DESIGNATION NAME & SIGNATURE OF THE RECEIVER

PREPARED BY:

APPROVED & REVIEWED AND RELEASE CONTROLLED BY:

QUALITY ASSURANCE PROCEDURE

TITLE : Procedure for Inventory Control.

Purpose

PR.NO : QP-15-02 PAGE NO : 2 OF 3 ISSUE NO : 01 REV NO : 00 DATE : 16.03.1997

: To describe the details of system followed in control of material stocks to optimise the stock levels, without loss of production capacities or want of materials & at the same time avoiding blocking up of working capital. : The procedure is applicable for all types of regular items.

Scope

Reference : List of inventory levels. Procedure : 01. G.M. (Comm) shall be responsible for controlling the stock levels of all types of direct production materials. 02. Dy. Mgr (Materials) shall maintain a list of all direct materials and minimum stock levels to be maintained for each of them. The list shall include minimum & maximum stock levels for each item. 03. The minimum stock levels shall be arrived at considering various aspects like Consumption rate for the planned production, lead time of procurement, probability of consistent availability, price, storage facilities, shelf life etc. 04. The materials which are available consistently & procured from local market shall be having stock levels minimum as possible. However, it shall be sufficient to cater for interruptions in material supply in case of unavoidable circumstances beyond our control. 05. To have this system effective, 100 % on time delivery performance as described in chapter -QM-06 of quality manual shall be monitored by Materials department. 06. The inventory level list mentioned above shall be approved by G.M.(Comm) & copy shall be provided to stores incharge. 07. The Stores Incharge shall provide stock statement for items covered in the inventory level list to Materials department daily, for items having less than defined stock levels & weekly for excess stock levels. 08. Dy. Mgr. (Materials) shall review the statement to determine possible shortages and arrangement required for procurement. For vital materials, daily stock report FM-15-17 showing number of days for which the stock of each material will be sufficient, shall be maintained by Dy. Mgr. (Materials). 09. G.M. (Comm) shall ensure that, all the regular items required for production are available in stock, in quantities specified and the consumed quantities are replenished in time.

QUALITY ASSURANCE PROCEDURE

PR.NO : QP-15-02 PAGE NO : 3 OF 3 ISSUE NO : 01

TITLE : Procedure for Inventory Control.

REV NO DATE

: 00 : 16.03.1997

10. The items having long lead time shall be paid attention all the time by Dy. Mgr. (Materials) 11. To enable the suppliers to achieve 100 % on time delivery performance, an effective communication system & interfaces with supplier shall be ensured by Materials Deptt. The delivery schedules shall be clearly intimated in advance and healthy relationship with supplier shall be maintained. 12. Materials department shall make all efforts to assist suppliers in achieving their performance. The vendor rating findings as per procedure QP-06-02 shall be effective tools for keeping the suppliers informed about areas of improvements. 13. The trend of consumption pattern shall be studied and analysed periodically by Dy. Mgr. (Materials) to determine need or change in inventory levels. Also new or alternative material introduced from time to time, shall be included in the inventory level list, and the same shall be approved by GM(C).

You might also like

- Cost Reduction TechniquesDocument48 pagesCost Reduction Techniquesramesh_july12No ratings yet

- Availablity Check ConfigurationDocument3 pagesAvailablity Check ConfigurationAshok kumar kethineniNo ratings yet

- Term Paper On Inventory Control Techniques: Nikhil Ratnakaran 1PT11MBA35 Section BDocument12 pagesTerm Paper On Inventory Control Techniques: Nikhil Ratnakaran 1PT11MBA35 Section BNikhil RatnakaranNo ratings yet

- Legal MaximsDocument7 pagesLegal MaximsSanjay MalhotraNo ratings yet

- Bank Statement LetterDocument2 pagesBank Statement LetterSanjay MalhotraNo ratings yet

- Inventory Control, Asset and Store Management and Distibution - ErickDocument30 pagesInventory Control, Asset and Store Management and Distibution - ErickBoard ArundaNo ratings yet

- 6 Most Important Techniques of Inventory Control SystemDocument5 pages6 Most Important Techniques of Inventory Control SystemArmel PalerNo ratings yet

- Stores and Spares Audit ChecklistDocument4 pagesStores and Spares Audit Checklistandruta197840% (5)

- Business Analysis - Food WarehousingDocument27 pagesBusiness Analysis - Food WarehousingsathishKumarNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Stores and Spare PartsDocument3 pagesStores and Spare PartsWalid Sonji0% (1)

- Supplier PPAP HandbookDocument40 pagesSupplier PPAP Handbookraba100100% (3)

- SITXINV401 Control Stock - Student Guide WMDocument7 pagesSITXINV401 Control Stock - Student Guide WMOm LalchandaniNo ratings yet

- Manage inventory levelsDocument84 pagesManage inventory levelsRahul TandonNo ratings yet

- Supply Chain DriversDocument5 pagesSupply Chain DriversBao TranNo ratings yet

- Strategic Business Management On NestleDocument26 pagesStrategic Business Management On Nestlebilal0% (1)

- Line of Balance TechniqueDocument6 pagesLine of Balance TechniqueSamarjit DeyNo ratings yet

- Inventory Management SystemDocument17 pagesInventory Management SystemPrathap100% (1)

- 01.21st Century Supply ChainsDocument16 pages01.21st Century Supply ChainsIkhsan AditamaNo ratings yet

- Lecture - Materials ManagementDocument48 pagesLecture - Materials ManagementJoju Johny100% (1)

- Availability CheckDocument41 pagesAvailability CheckTek's Notani50% (2)

- Protocol For Reporting WorkloadDocument3 pagesProtocol For Reporting WorkloadCarla Puno100% (7)

- Factors Affecting Production Planning and ControlDocument7 pagesFactors Affecting Production Planning and ControlAnamika Rai PandeyNo ratings yet

- Discussion QA 9to17Document56 pagesDiscussion QA 9to17April Reynolds100% (16)

- Ethiopia TextileDocument32 pagesEthiopia TextileLucky Parashar67% (3)

- Bcom 483 NotesDocument21 pagesBcom 483 NotesOmoja JansenNo ratings yet

- 4 & 5th ChaptersDocument41 pages4 & 5th ChaptersAnil Kumar KNo ratings yet

- Assignment-2 Spare Part Inventory Management For A Manufacturing CompanyDocument5 pagesAssignment-2 Spare Part Inventory Management For A Manufacturing Companyparth limbachiyaNo ratings yet

- Topic 5 DPLM 0211Document10 pagesTopic 5 DPLM 0211julian chepkongaNo ratings yet

- Production & OPN MGMTDocument42 pagesProduction & OPN MGMTdevendra kumarNo ratings yet

- 1.control Order StockDocument3 pages1.control Order StockAlexandra AndonasNo ratings yet

- Inventory ControlDocument7 pagesInventory ControlPreetyPriyaNo ratings yet

- Organizing and Producing Goods and ServicesDocument18 pagesOrganizing and Producing Goods and Servicesd-fbuser-65596417No ratings yet

- Inventory Managementgroup 02Document37 pagesInventory Managementgroup 02Sharifa SadiaNo ratings yet

- Project On Inventory Management: Submitted To: Prof:-Subir Guha Submitted By:-Chandan Prasad ROLL NO:-40014 PGDM (MRK)Document13 pagesProject On Inventory Management: Submitted To: Prof:-Subir Guha Submitted By:-Chandan Prasad ROLL NO:-40014 PGDM (MRK)Chandan PrasadNo ratings yet

- Monitor Inventory Levels & Control StockDocument10 pagesMonitor Inventory Levels & Control StockAngelica Cinena GrajeraNo ratings yet

- Techniques of Inventory Management: Chapter - 3Document41 pagesTechniques of Inventory Management: Chapter - 3kapuNo ratings yet

- Chapter 13 - Material Requirements PlanningDocument3 pagesChapter 13 - Material Requirements Planninghello_khayNo ratings yet

- SPT SolutionsDocument172 pagesSPT SolutionskpmgadvisoryNo ratings yet

- Chapter 10 Production CycleDocument3 pagesChapter 10 Production CycleZenn Vanrim Lopez100% (1)

- Chetana'S Bachelor of Management Studies: SUBJECT: Production Management and Material ManagementDocument12 pagesChetana'S Bachelor of Management Studies: SUBJECT: Production Management and Material Managementkalley minogNo ratings yet

- EIE 4102 Lecture Topic 6Document27 pagesEIE 4102 Lecture Topic 6waireriannNo ratings yet

- Chapter 5.doc Inventory ManagementDocument7 pagesChapter 5.doc Inventory ManagementAntonio de GuzmanNo ratings yet

- 2.7 Inventory Control: Minimum LevelDocument7 pages2.7 Inventory Control: Minimum LevelSorabh JainNo ratings yet

- Inventory Management: An OverviewDocument26 pagesInventory Management: An OverviewMayank Agrawal100% (1)

- Jaipur National University, Jaipur: School of Distance Education & Learning Internal Assignment No. 1Document16 pagesJaipur National University, Jaipur: School of Distance Education & Learning Internal Assignment No. 1Mahesh KNo ratings yet

- Inventory Management and Control ObjectivesDocument10 pagesInventory Management and Control ObjectivesAmit BhardwajNo ratings yet

- Inventory ControlDocument24 pagesInventory ControlAdityaNo ratings yet

- Answer Tutorial 6-7-JIt, Quality RevisedDocument8 pagesAnswer Tutorial 6-7-JIt, Quality RevisedXinyee LooNo ratings yet

- Industrial ERP: Inventory ManagementDocument49 pagesIndustrial ERP: Inventory ManagementAmit RajputNo ratings yet

- Chapter 11 - Inventory ManagementDocument7 pagesChapter 11 - Inventory Managementhello_khayNo ratings yet

- Chapter 13 Inventory Management ReportDocument22 pagesChapter 13 Inventory Management ReportJanine SalesNo ratings yet

- Production Planning and Control: Key Concepts for Optimizing Manufacturing OperationsDocument51 pagesProduction Planning and Control: Key Concepts for Optimizing Manufacturing OperationsMohit MundraNo ratings yet

- Planning & Prog, Inventory, ReplenishingDocument18 pagesPlanning & Prog, Inventory, ReplenishingJoju JohnyNo ratings yet

- AS 16 Borrowing Cost FinalDocument21 pagesAS 16 Borrowing Cost FinalNilesh MandlikNo ratings yet

- Operations Research 2Document132 pagesOperations Research 2Cesar Amante TingNo ratings yet

- Costing Notes by CA Jatin Bansal ChandigarhDocument21 pagesCosting Notes by CA Jatin Bansal Chandigarhmldc2014No ratings yet

- OM-Inventory Management: Mahr Irfan Ahmad B.SC., Fcfma, Mipa, Afa, Ocp CdbmaDocument11 pagesOM-Inventory Management: Mahr Irfan Ahmad B.SC., Fcfma, Mipa, Afa, Ocp CdbmaMunaza SadiqaNo ratings yet

- Unit-1 Inventory Control: AccountingDocument6 pagesUnit-1 Inventory Control: AccountingMd NaseerNo ratings yet

- Tarea 7, IaccDocument3 pagesTarea 7, Iaccandres cardenasNo ratings yet

- MEANING AND TYPES OF INVENTORYDocument49 pagesMEANING AND TYPES OF INVENTORYTeena ChawlaNo ratings yet

- Inventory management essentialsDocument16 pagesInventory management essentialskkkktNo ratings yet

- Assignment 5Document3 pagesAssignment 5Ankit SainiNo ratings yet

- List Manufacturers Empanelled VendorsDocument14 pagesList Manufacturers Empanelled VendorsSanjay MalhotraNo ratings yet

- Pipeline Basics 2. 3. 4. 5. 6. Repairing FracturesDocument36 pagesPipeline Basics 2. 3. 4. 5. 6. Repairing FracturesSanjay MalhotraNo ratings yet

- Ts CertificateDocument1 pageTs CertificateSanjay MalhotraNo ratings yet

- LIST Engineering ArchitectDocument5 pagesLIST Engineering ArchitectSanjay MalhotraNo ratings yet

- Consultants List S.No. Name of The Consultants Job Title Address Office Phone Mobile No. Fax 1 Spectral Services Consultants Pvt. LTDDocument2 pagesConsultants List S.No. Name of The Consultants Job Title Address Office Phone Mobile No. Fax 1 Spectral Services Consultants Pvt. LTDSanjay MalhotraNo ratings yet

- New Technology in Solar CellDocument5 pagesNew Technology in Solar CellSanjay MalhotraNo ratings yet

- BiochemistryDocument1 pageBiochemistrySanjay MalhotraNo ratings yet

- HamburgDocument2 pagesHamburgSanjay MalhotraNo ratings yet

- Promoters Profile: Mr. ABC Having - Years of Experience in Finance, AccountsDocument1 pagePromoters Profile: Mr. ABC Having - Years of Experience in Finance, AccountsSanjay MalhotraNo ratings yet

- Project 5Document1 pageProject 5Sanjay MalhotraNo ratings yet

- Measure Words Chinese AssignmentDocument7 pagesMeasure Words Chinese AssignmentSanjay MalhotraNo ratings yet

- Production Facilities and Machinery: ExportsDocument1 pageProduction Facilities and Machinery: ExportsSanjay MalhotraNo ratings yet

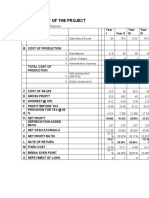

- Profitibility of The Project: (All Values in Lacs of Rupees)Document1 pageProfitibility of The Project: (All Values in Lacs of Rupees)Sanjay MalhotraNo ratings yet

- 1) Salary and Wages (Per Month) : (Incld. Stores, Power and Maintenance)Document1 page1) Salary and Wages (Per Month) : (Incld. Stores, Power and Maintenance)Sanjay MalhotraNo ratings yet

- Project at Glance: Project: Material Handling, Automation and Special Purpose Machines. Promoters: MRDocument2 pagesProject at Glance: Project: Material Handling, Automation and Special Purpose Machines. Promoters: MRSanjay MalhotraNo ratings yet

- Bible 2Document2 pagesBible 2Sanjay MalhotraNo ratings yet

- Project 8Document1 pageProject 8Sanjay MalhotraNo ratings yet

- Result With Held Dean PUDocument2 pagesResult With Held Dean PUSanjay MalhotraNo ratings yet

- PU Chinese Fees DepositDocument1 pagePU Chinese Fees DepositSanjay MalhotraNo ratings yet

- Products To Be Manufactured: Marketing DemandDocument1 pageProducts To Be Manufactured: Marketing DemandSanjay MalhotraNo ratings yet

- Project 1Document1 pageProject 1Sanjay MalhotraNo ratings yet

- Check ListDocument14 pagesCheck ListSanjay MalhotraNo ratings yet

- Bible 3Document1 pageBible 3Sanjay MalhotraNo ratings yet

- Bible 1Document1 pageBible 1Sanjay MalhotraNo ratings yet

- Law and Ethics PDFDocument18 pagesLaw and Ethics PDFSanjay MalhotraNo ratings yet

- Merit List Chinese PUDocument7 pagesMerit List Chinese PUSanjay MalhotraNo ratings yet

- Mohit Marketing CVDocument3 pagesMohit Marketing CVSanjay MalhotraNo ratings yet

- Share Stock Portfolio Based On Dolly Khanna 25 OctDocument4 pagesShare Stock Portfolio Based On Dolly Khanna 25 OctSanjay MalhotraNo ratings yet

- The GleanerDocument32 pagesThe GleanerAshley MorganNo ratings yet

- Pricing and Revenue Management in A Supply Chain: True/FalseDocument16 pagesPricing and Revenue Management in A Supply Chain: True/FalseHaris AmirNo ratings yet

- CA Final SCM Saviour Revision BookDocument324 pagesCA Final SCM Saviour Revision BookTanny KhatriNo ratings yet

- CSCPDocument5 pagesCSCPygugaNo ratings yet

- Green Supply Chain Management Practices Impact On Performance-1Document16 pagesGreen Supply Chain Management Practices Impact On Performance-1Emmy SukhNo ratings yet

- MetalTek Alloy Guide PDFDocument12 pagesMetalTek Alloy Guide PDFmohammed rafiNo ratings yet

- WhitePaper - Omnichannel Retailing When It Becomes A Commodity What ThenDocument11 pagesWhitePaper - Omnichannel Retailing When It Becomes A Commodity What ThenRajat MishraNo ratings yet

- POM Module 3Document16 pagesPOM Module 3fifalegends0730No ratings yet

- Sat Hi SHDocument67 pagesSat Hi SHselmuthusamy100% (2)

- Group 2Document57 pagesGroup 2Abdunnajar Mahamud100% (1)

- Ignite Perfumes AazimDocument62 pagesIgnite Perfumes AazimREGI MEMANA VARUGHESENo ratings yet

- Supply Chain Management Definitions and Theories PerspectiveDocument14 pagesSupply Chain Management Definitions and Theories PerspectiveakyregisterNo ratings yet

- Cocoa Life Progress Report PDFDocument64 pagesCocoa Life Progress Report PDFSalve A. EjeNo ratings yet

- 2015 Blue Orchid Business Plan Template Word OnlyDocument18 pages2015 Blue Orchid Business Plan Template Word OnlyPrince Horwolabi HifeoluwahNo ratings yet

- Cost Leadership and Differentiation Strategies at WalmartDocument14 pagesCost Leadership and Differentiation Strategies at WalmartSherry Yong PkTianNo ratings yet

- Ais MCQSDocument7 pagesAis MCQSAbdul wahabNo ratings yet

- Test Bank For Operations and Supply Chain Management 16th Edition F Robert Jacobs Richard ChaseDocument36 pagesTest Bank For Operations and Supply Chain Management 16th Edition F Robert Jacobs Richard Chaseutmostfriary0v6a6100% (40)

- Unit 5.1 Functional Areas of International BusinessDocument12 pagesUnit 5.1 Functional Areas of International BusinessVikas ShahiNo ratings yet

- TDC CH02Document4 pagesTDC CH02David AguirreNo ratings yet

- Contact Directory with 18 Contacts & DetailsDocument14 pagesContact Directory with 18 Contacts & DetailssirfanalizaidiNo ratings yet

- CRM SowDocument27 pagesCRM Sowsowmyasrinivas22441No ratings yet

- SITXFIN003 Manage Finances Within A Budget PDFDocument12 pagesSITXFIN003 Manage Finances Within A Budget PDFEsteban BuitragoNo ratings yet

- Modern Organizations Chapter from ResearchGateDocument25 pagesModern Organizations Chapter from ResearchGateABDHULNo ratings yet

- 1) What Are LEGO's Resources and Capabilities That Contribute To Its SuccessDocument2 pages1) What Are LEGO's Resources and Capabilities That Contribute To Its SuccessAndre EspinozaNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)