Professional Documents

Culture Documents

A333 Air

Uploaded by

Elias IruelaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A333 Air

Uploaded by

Elias IruelaCopyright:

Available Formats

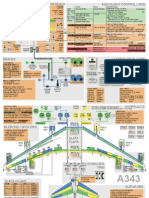

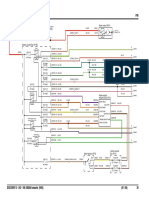

AIR SYSTEMS

Hot bleed air Cold air from fan / outside Cold air from packs Mixed conditionned air Cabin recirculated air AVIONICS VENT PANELS EQPMT RACKS COCKPIT

BLEED Regulated pressure 44-52 psi Leak detection Single loop for pylon ducts. Double loop for wing and APU ducts Temperature control 200C normal temperature 150C if wing a/ice OFF and enough for zone controller demand

PACK CTL channels 1 failed => no effect both failed => temp 1-15C by anti-ice valve. no ECAM indication. Flow 120% of NORM ZONE CTL channels 1 failed => no effect both failed => Packs deliver 20C. ECAM ind lost & display PACK REG MID CABIN

AIR CYCLE MACHINE failure Pack operates in heat exchanger cooling mode in-flight only HOT AIR VLV failure failed open => no effect 1 vlv failed closed => no effect (X-hot) 2 vlvs failed closed => reg by PACKS TRIM AIR VLV failure 1 failed closed => half this zone lost 1 failed open => half each zone lost AFT CABIN CABIN AIR CABIN FANs

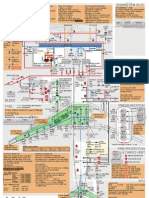

ENGINE

RR RB 211 TRENT

Thrust 71100lbs = ~32.2t =~28400HP N1: FAN + 4 Turb, 100%=3300rpm N2: 8 Comp + 1 Turb, 100%=7000rpm N3: 6 Comp + 1 Turb, 100%=10600rpm 24 Fuel nozzles + 2 Igniters Warm-up time 5 before T/O thrust Cool-down time 1' EIUs IGNITION

A [AC ESS] on gnd: B ENG1 [AC1] B ENG2 [AC2] inflight: B [AC ESS]

FWD CABIN CABIN RESTRICTOR AIR other side

[DC BAT]

AEVC

[AC1]

EXTRACT FAN [AC1] UNDERFLOOR EXTRACT OVBD EXTRACT VLV VLV on gnd engines not running

HOT AIR X-VLV TRIM AIR VLVs MIXER UNIT

to avionic vent

1 [AC1] 2 [AC2]

N3<8% CH A [AC ESS] N3<8% CHB [AC2] N3>8% CH A&B by own GEN

FADECs

1 [AC1] 2 [AC2]

RECIRC VLVs

N1 MODE A/THR & ALPHA FLOOR are lost.(JHA-J) ALPHA FLOOR available and A/THR may be recovered if one ENG in unrated N1 mode (JHK-L) RATED P2 and/or P5 lost. Can be selected by pushbutton ENG N1 MODE. UNRATED No protections, ECAM max value are lost EPR XX N1 MODE N1 limit only available CLB in RATED mode 92.6% on at least 1 engine

to FWD cargo heating HOT AIR 1 VLV

PACK 1 flow in by-pass mode COMPR CHECK VLV

BY PASS VLV

In-flight or Ditching ON Extract OVRD SMOKE EVAC WING A/ICE VLVs

[DC ESS SHED]

TEMP [DC ESS] CTL VLV PACK 1 CTL ZONE CTL

[AC1,DC1] CH1 [DC1] CH2 [DC2]

EMER with air from packs RAM AIR

Do not use GND AIR

LP GND INLETS

to FWD cargo cooling PACK 2 HOT AIR 2 VLV

PACK 2 CTL

[AC2,DC2]

CARGO EXT AIR APU PACK 1 HEAT FLOW CTL VLV

[DC ESS]

HYD RES

Do not use HP GND air with APU bleed

WATER TK

Main Heat Primary Heat Exchanger Exchanger

A/ICE VLV

Turbofan for pack bay cooling PACK 2 FLOW CTL VLV

[DC ESS]

SLAT 4 SLATS 5,6,7 FAN AIR VLVs A/ICE VLVs

ENG 1 [DC1] ENG 2 [DC2] ENG 1 [DC1] ENG 2 [DC2]

24 FUEL INJECTORS FILTER

X-BLEED VLV

MANUAL [DC ESS] AUTO [DC2]

OVERPRESS VLV (85psi) BLEED VLVs BMC

STARTER 3rd HP VLV

8th IP

F F F F F F B1 F F F F

FMU

FUEL FLOW

[DC ESS]

HP VLV

FWD CARGO COMP

[AC2]

EXTRACT OUTLET ISOL VLV FAN

[AC2]

FUEL METERING VLV HP

ENG 1 [DC ESS] ENG 2 [DC2]

1 [DC ESS] 2 [DC2]

HP VLVs

6th HP

B2

ENG 1 [DC1] ENG 2 [DC2]

FUEL PUMP UNIT

ENG OIL

LP

Fuel/Oil heat exchanger ENG LP VLVs

Bilge air BATTERY VENT Cabin by a venturi and an overboard vent air LAV & GALLEY VENT Cold air Hot air 1 by an extraction fan and an exhaust from Pack 2 TRIM COLD through a venturi AIR VLV AIR VLV PACK BAY VENT [AC2] [DC2, DC ESS SHED] Cabin by a NACA air inlet, a bleed air air driven turbofan. Controlled by INLET ISOL VLVs [AC2] Bilge air the AEVC X-FEED

MOT 1 [DC ESS] MOT 2 [DC2]

Forward Outflow Valve

FUEL

xfr / refueling / defueling lines feeding lines

MOT 1[HOT] MOT 2[DC2]

FWD APU PUMP

[AC1] APU

PRESSURIZATION

NEG RELIEF VALVE ECAM MOT 1

[DC ESS]

AFT XFR VLVs

L [DC1] R [DC2]

CPC 1

[DC ESS]

MANUAL BACKUP

TOTAL TANKS CAPACITY (den 0.8kg/l) 78024kg

INNER TANKS

L1 Lsby

L2

R2

R1 Rsby

2 X 32970kg

[DC ESS, HOT]

TRIM PIPE ISOL VLV

APU ISOL VLV

[HOT]

FWD OUT -FLOW VALVE

[DC BAT]

MAN MOT

[DC2]

MAN V/S SWITCH

[DC BAT]

MOT 2

CPC 2

[DC2]

OUTER TANKS

2 X 2865kg

[DC ESS, HOT]

INNER INLET VLVs

[DC ESS]

SPLIT VLVs

AUX FWD XFR VLV

[DC ESS]

MOT 1

[DC ESS]

LEFT INNER TK PUMPS

RIGHT INNER TK PUMPS

[DC ESS, HOT]

OUTER INLET VLVs

OUTER XFR VLVs

REFUEL VLVs

L1 [AC2, DC2] L2 [DC ESS, AC ESS] L STBY [AC1, DC1]

R1 [AC2, DC2] R2 [DC1, DC ESS, AC ESS] - ess bus only if L2 PMP OFF R STBY [AC1, DC1]

AFT OUT -FLOW VALVE

[DC BAT]

MAN MOT

[DC2]

MOT 2

[DC BAT, HOT]

- if RAM AIR ON and p<1psi, outflow valves are 50% open (if not in MANUAL)

[DC ESS]

VENT TANKS accept 2% increase of full tanks capacity OUTER TO INNER XFR Each Outer TK cycle its Inner TK between 3500kg and 4000kg until it is empty. The valves then close after 5min. If no AUTO XFR available, manual xfr via refueling pipe and inlet valve possible. LIMITATIONS Take-off fuel: min 5200kg and WING TK LO LVL not displayed on ECAM FUEL IMBALANCE INNER TK Full Half 7500kg OUTER TK Full 2400kg 1730kg max 2900kg max 4800kg max 7500kg max 1480kg max 1580kg max 1730kg

MAIN [DC ESS SHED] LVL Sensing[DC ESS SHED]

3 PNEUMATIC SAFETY VALVES ( > 8.85 or < -.73 p)

FCMC 1

MAIN [HOT] (refuel on BAT) LVL Sensing[DC ESS SHED]

FCMC 2

AFT CARGO COMP

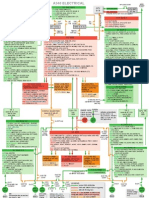

B1 BTL 1, 60s discharge B2 BTL 2, 4hrs discharge

SDCU 1 (JHA-J) CIDS-SDF 1 (JHK-L)

[DC ESS SHED]

FIRE PROTECTION & CARGO VENT

SMOKE DETECTORS Type optical F B FIRE (HEAT) DETECTORS FIREX BOTTLES

SDCU 2 (JHA-J) CIDS-SDF 2 (JHK-L)

[DC2]

BULK CG CONTROL AFT XFR starts if: Gear up, Slats in, Trim TK not full, Inner > 6250kg, above FL255 and CG not on target AFT XFR stops if: CG = target CG - 0.5% or Trim TK full or Inner <6250kg or FWD button pushed or MAN xfr outer-inner or center-inner. FWD XFR starts if: stops if: CG = target CG = target - 0.5% inner = 4000kg inner = 5000kg - 35 to dest or FL245 (or 75 if XFR PUMP u/s) - in EMER ELEC REFUELING Distribution trim TK 2400kg if more than 36.5t FOB TRIM TANK INLET ISOL VLV

[AC2]

[DC2, DC ESS SHED]

VENT CONT

Cabin air FAN HEATER Aft outflow valve

[AC2]

EXTRACT FAN

[AC2]

OUTLET ISOL VLV

[AC2]

ELECTRICAL SUPPLY ENG loop A [DC ESS], loop B [DC2] ENG BTL 1 squib A [HOT2], squib B [DC2] ENG BTL 2 squib A [HOT1], squib B [DC2] APU loop A [DC ESS], loop B [DC BAT] APU BTL squib A [HOT1] squib B [DC BAT] APU auto extinguish [HOT2] CARGO squib A [HOT1], squib B [DC2] LIMITATIONS RPM min 95% max 107% (auto shut down) running EGT max 650C start EGT max 1250C Minimum oil level for start: ADD at APU level indicator Cooling after 3 start attempts: 60min APU FUEL FLOW ~200 kg/hr ENVELOPE START with AC pwr up to 41450ft START with EMER ELEC pwr up to 25'000ft BLEED ON 2 packs max 17'500ft, 1 pack max 22'500ft BLEED ON for engine start max 20'000ft

FUEL TEMPERATURE JET A1 min -47C max +60C JET A min -40C max +60C

TRIM TK ISOL VLV [DC ESS] FWD XFR PUMP INLET VLV APU LP VLV

F

[AC2,DC2] [DC ESS, HOT]

to LEFT Bleed duct

APU

APU BLEED VLV

4891kg

!!! NOT FOR OPERATIONAL USE !!! A333 Pierre-Michel Gasser , 11.5.2012

A333 AIR/FIRE/FUEL/APU/ENG

[DC BAT, HOT]

APU

APU B

AFT APU PUMP

[AC ESS, HOT]

F F

[APU BAT, APU TR]

APU STARTER

[APU BAT DC ESS]

ECB

You might also like

- Hp10c Owner HandbookDocument127 pagesHp10c Owner HandbookElias IruelaNo ratings yet

- Casio FX-9700GH Calculator ManualDocument188 pagesCasio FX-9700GH Calculator ManualLuna StoneNo ratings yet

- FX 850p ManualDocument419 pagesFX 850p ManualTopografia Artur FidalgoNo ratings yet

- Landing Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Document1 pageLanding Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Elias IruelaNo ratings yet

- The Art of The Middle GameDocument239 pagesThe Art of The Middle Gamealan_du2264589% (27)

- 71.power PlantDocument790 pages71.power PlantElias IruelaNo ratings yet

- A330 Etops DataDocument1 pageA330 Etops DataElias IruelaNo ratings yet

- A340 ElecDocument1 pageA340 ElecElias Iruela100% (1)

- A330 HydDocument1 pageA330 HydElias Iruela100% (7)

- HP GND Air With APU Bleed: CAUTION, Do Not UseDocument1 pageHP GND Air With APU Bleed: CAUTION, Do Not UseElias Iruela100% (1)

- 700 Chess ProblemsDocument288 pages700 Chess ProblemsMahesh Maggy89% (9)

- Guia Samsung Scx4200 InglesDocument93 pagesGuia Samsung Scx4200 InglesElias IruelaNo ratings yet

- Hybrid Electric VehiclesDocument144 pagesHybrid Electric VehiclesElias Iruela75% (4)

- Arduino Pinout SketchDocument1 pageArduino Pinout SketchElias IruelaNo ratings yet

- Atmega 644 PDocument1 pageAtmega 644 PTiago SantiniNo ratings yet

- Arduino Pinout SketchDocument1 pageArduino Pinout SketchElias IruelaNo ratings yet

- ATMEGA2560UDocument1 pageATMEGA2560UElias IruelaNo ratings yet

- Arduino Uno PinoutDocument1 pageArduino Uno PinoutElias IruelaNo ratings yet

- Atmega328 QTFPDocument1 pageAtmega328 QTFPElias IruelaNo ratings yet

- Arduino Mega PinoutDocument1 pageArduino Mega PinoutGlauco Aguiar100% (1)

- Airbus A320330 Panel DocumentationDocument62 pagesAirbus A320330 Panel DocumentationElias IruelaNo ratings yet

- Arduino Pinout SketchDocument1 pageArduino Pinout SketchElias IruelaNo ratings yet

- Arduino: Using Arduino As Icsp Programmer For Attiny45/85Document1 pageArduino: Using Arduino As Icsp Programmer For Attiny45/85Elias IruelaNo ratings yet

- Atmega328 QTFPDocument1 pageAtmega328 QTFPElias IruelaNo ratings yet

- ATMEGA328 & Arduino Pinout DiagramDocument1 pageATMEGA328 & Arduino Pinout DiagramElias IruelaNo ratings yet

- Arduino Uno PinoutDocument1 pageArduino Uno PinoutElias IruelaNo ratings yet

- SFE03 0012 SIK - Guide 300dpi 01Document80 pagesSFE03 0012 SIK - Guide 300dpi 01Elias IruelaNo ratings yet

- ATMEGA328 & Arduino Pinout DiagramDocument1 pageATMEGA328 & Arduino Pinout DiagramElias IruelaNo ratings yet

- Defcon 18 Crenshaw Phid Usb DeviceDocument36 pagesDefcon 18 Crenshaw Phid Usb DeviceElias IruelaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VV8 PDFDocument1 pageVV8 PDFgabotoyoNo ratings yet

- Boilers Efficiency & Boiler Heat BalanceDocument13 pagesBoilers Efficiency & Boiler Heat BalanceNipun Sabharwal100% (1)

- Basic Mechanical Engg: (S1S2 EEE-2011) Module 1, Part-3Document39 pagesBasic Mechanical Engg: (S1S2 EEE-2011) Module 1, Part-3Mathew JohnNo ratings yet

- Mohave County Board of Supervisors LetterDocument3 pagesMohave County Board of Supervisors LetterKJZZ PhoenixNo ratings yet

- Gas Cutting EquipmentDocument92 pagesGas Cutting EquipmentFord KatimNo ratings yet

- Timing Gear Case Installation (4JA1)Document39 pagesTiming Gear Case Installation (4JA1)thanhNo ratings yet

- Searching Geo Metro Forum for Information on Thermo WaxDocument16 pagesSearching Geo Metro Forum for Information on Thermo WaxJuan GuerraNo ratings yet

- f2 (2) (1) Reviewer Chief Officer Materials.Document20 pagesf2 (2) (1) Reviewer Chief Officer Materials.Alden Almaquer Delizo100% (1)

- Troubleshoot injector solenoidsDocument15 pagesTroubleshoot injector solenoidsb400013No ratings yet

- Ficha Tecnica SasobitDocument16 pagesFicha Tecnica SasobitFernandoAntonioAlvarezPachecoNo ratings yet

- Electronic Engine ControlsDocument6 pagesElectronic Engine ControlstuningNo ratings yet

- Chapter 05Document184 pagesChapter 05kphays_98104692875% (4)

- TurboX Brochure and InsertDocument11 pagesTurboX Brochure and InsertJohn SmithNo ratings yet

- 0B5 7 Speed Dual Clutch PDFDocument24 pages0B5 7 Speed Dual Clutch PDFBalica Lucian80% (5)

- V158TI-180TI-222TI, AD158TI-180TI-222TI (DOOSAN Yr.2003) (M00075) 65 99898-8117ADocument117 pagesV158TI-180TI-222TI, AD158TI-180TI-222TI (DOOSAN Yr.2003) (M00075) 65 99898-8117AHernan Campos Lucero63% (8)

- Sebu6400-05 - Cat Gas EngineDocument48 pagesSebu6400-05 - Cat Gas EnginetamailhamNo ratings yet

- Under Hood Parts IdentificationDocument6 pagesUnder Hood Parts Identificationhiwamot982100% (1)

- Motor DieselDocument3 pagesMotor DieselstricjackNo ratings yet

- Free-Piston Engine History and Applications ReviewDocument16 pagesFree-Piston Engine History and Applications ReviewAnonymous MVHQ97KEoPNo ratings yet

- Roga Test: Bon Lester L. Lamparero February 17, 2016 Che 140 Chemical Process IndustriesDocument2 pagesRoga Test: Bon Lester L. Lamparero February 17, 2016 Che 140 Chemical Process IndustriesBon Lester L. LampareroNo ratings yet

- FC 115Document6 pagesFC 115Alexander LopezNo ratings yet

- Steam Boilers - VVADocument87 pagesSteam Boilers - VVAvinay_ankolekar5676No ratings yet

- Problem Set 4 SolutionsDocument16 pagesProblem Set 4 SolutionsNikka LopezNo ratings yet

- ACC 8211 Oil and Gas AccountingDocument93 pagesACC 8211 Oil and Gas Accountingmanojjg72No ratings yet

- Sizing and Cost Estimation Methodology For Stand Alone Residential PV Power SystemDocument20 pagesSizing and Cost Estimation Methodology For Stand Alone Residential PV Power SystemvenvettyNo ratings yet

- The New 'Energy Dci 130' Diesel Engine - A High-Tech Package Derived From Renault'S F1 ExperienceDocument25 pagesThe New 'Energy Dci 130' Diesel Engine - A High-Tech Package Derived From Renault'S F1 ExperienceAntonio MendesNo ratings yet

- Petroland PL 01 (230810)Document9 pagesPetroland PL 01 (230810)mantenimiento keruiNo ratings yet

- DRAIN INTERVAL GUIDELINES FOR SCANIA ENGINESDocument4 pagesDRAIN INTERVAL GUIDELINES FOR SCANIA ENGINESviktor chervonenkoNo ratings yet

- Single Drum Soil Compactors: Full RangeDocument16 pagesSingle Drum Soil Compactors: Full Rangeeythor13543100% (2)

- Hydraulic Shovel: Engine BucketDocument32 pagesHydraulic Shovel: Engine BucketWilbort Encomenderos RuizNo ratings yet