Professional Documents

Culture Documents

Siemens Hydrogen-Cooled Generators With Water-Cooled Stator Windings

Uploaded by

Pradeep_VashistOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Siemens Hydrogen-Cooled Generators With Water-Cooled Stator Windings

Uploaded by

Pradeep_VashistCopyright:

Available Formats

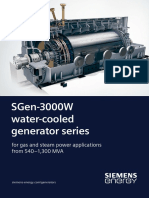

Siemens Hydrogen-Cooled Generators with Water-Cooled Stator Windings

SGen-3000W series with ratings from 600 up to 1,270 MVA

SGen5-3000W at Ulrich Hartmann Combined Cycle Power Plant in Irsching (Bavaria, Germany)

The SGen-3000W series of hydrogen-cooled, two-pole generators with water cooled stator windings is part of Siemens Generator (SGenTM) product line, with ratings up to 1,270 MVA for steam and combined cycle applications. Cooling performance is greatly improved through the use of hydrogen-cooled gas in place of air as coolant for the rotor winding and stator core. At the same time, frictional losses are significantly lower, thus improving overall generator efficiency.

An increased output of per unit volume of stator-winding active material is possible because of the higher thermal conductivity and specific heat of water. It is this advantage of water that makes it possible to build generators for higher ratings than possible using air or hydrogen as the cooling medium for the stator winding components.

Answers for energy.

Siemens Hydrogen-Cooled Generators with Water-Cooled Stator Windings

Customer Benefits

1 Four vertical independent heat exchangers are used on the turbine drive end of the generator for cooling of the hydrogen. 2 A single multi-stage blower at the turbine end of the generator circulates the hydrogen gas for cooling of the rotor, stator core and frame components. 3 Mechanically decoupled stator end winding system ensures maximum rigidity and flexibility for cyclic thermal expansion. 4 The stator winding uses Vacuum Pressure Impregnation (VPI) technology for the ground wall insulation. 5 Rotor winding is axially, directly cooled by hydrogen flowing through each turn of the winding. 6 Laminated stator core is cooled directly by hydrogen flowing through axial ventilation paths in the length of the stator core. 7 The stator core is flexibly supported in the outer casing by spring assemblies. This prevents vibrations from impacting the outer casing and the foundation. 8 Generator frame design enables generators to be installed outdoors.

Efficiency up to 99% Uniform temperature profile promotes reliability Simplified installation Design based on field-proven generator component designs

Proven design obviate obstruction of stator winding cooling ducts Welded junctions prevent circuit ring from corrosion

Technical data Frequency 50 Hz

1 6 3 4

Model SGen5-3000W SGen6-3000W

Power factor 0.85 0.85

Apparent power 675 MVA to 940 MVA 600 MVA to 1,270 MVA

Efficiency up to 99% up to 99%

Terminal voltage 15 kV to 21 kV 16 kV to 27 kV

60 Hz

Coolant Design Thermal classification

5 7

Hydrogen gas at 4 to 6 bar (gauge) / water cooled stator windings In accordance with IEC and ANSI Standards and EU Directives Class F insulation system IP64 (IEC60034); suitable for outdoor installation Static or brushless Suitable for rail transport in most countries

Type of enclosure Excitation Transport dimensions

The SGen-3000W Series: References

Our SGen-3000W series exceeds an availability of 99% and counts with almost 2 million operating hours which have earned Siemens a flawless reputation in the filed of reliable power generation steam and gas turbine applications. Therefore, the following references are only a few examples to illustrate the vast potentials of the SGen-3000W generator series.

Ulrich Hartmann Combined Cycle Power Plant, Irsching (Bavaria, Germany)

Longview Steam Power Plant, West Virginia (USA)

Waigaoqiao III Steam Power Plant, Shanghai (China)

Performance Net plant output: Commercial operation: Major components Generator: Steam turbine: Gas turbine: 1x SGen5-3000W 1x SST5-5000 1x SGT5-8000H 1x SGen6-3000W 1x SST6-6000 1x SGen5-3000W 2x SST5-6000 561 MW 2011 695 MW 2012 1000 MW 2008

For more information please contact your local Siemens sales representative.

Published by and copyright 2012: Siemens AG Energy Sector Freyeslebenstrasse 1 91058 Erlangen, Germany Siemens Energy, Inc. 4400 Alafaya Trail Orlando, FL 32826-2399, USA

For more information, please contact our Customer Support Center. Phone: +49 180/524 70 00 Fax: +49 180/524 24 71 (Charges depending on provider) E-mail: support.energy@siemens.com

Fossil Power Generation Division Order No. E50001-G210-A178-X-4A00 Printed in Germany Dispo 34802, c4bs No. 7449 TH 214-111143 431564 DB 03121.0 Printed on elementary chlorine-free bleached paper.

All rights reserved. Trademarks mentioned in this document are the property of Siemens AG, its affiliates, or their respective owners. Subject to change without prior notice. The information in this document contains general descriptions of the technical options available, which may not apply in all cases. The required technical options should therefore be specified in the contract.

www.siemens.com/energy

You might also like

- Sgen-3000W Water-Cooled Generator Series: For Gas and Steam Power Applications From 540-1,300 MvaDocument4 pagesSgen-3000W Water-Cooled Generator Series: For Gas and Steam Power Applications From 540-1,300 Mvaasdop1567No ratings yet

- Generator Products GEA13489A PDFDocument16 pagesGenerator Products GEA13489A PDFMadusanka WeebeddaNo ratings yet

- Hydrogen / Water - Cooled Turbogenerators: A Mature Technology On The MoveDocument9 pagesHydrogen / Water - Cooled Turbogenerators: A Mature Technology On The MoveR0B0T2013100% (1)

- Power Diagnostics ServiceDocument20 pagesPower Diagnostics ServiceShahid KhanNo ratings yet

- Ger 3751 ADocument28 pagesGer 3751 Ahbh123456No ratings yet

- Manufacturing of Turbo GeneratorsDocument19 pagesManufacturing of Turbo GeneratorsKeerthana Kola100% (1)

- Bhel Summer Trainig Construction of Turbo-GeneratorDocument32 pagesBhel Summer Trainig Construction of Turbo-GeneratorAZHAR KhanNo ratings yet

- Fact Sheet Til 1292Document2 pagesFact Sheet Til 1292PervimNo ratings yet

- Fuel NozzlesDocument3 pagesFuel Nozzlesfrancisco_navas4479100% (1)

- Thermal Plant Ropar 1260MWDocument89 pagesThermal Plant Ropar 1260MWRahul Pandey67% (6)

- Static Frequency Converter Cubicle Simplifies InstallationDocument9 pagesStatic Frequency Converter Cubicle Simplifies InstallationRamot M HutabaratNo ratings yet

- Ge Gas Turbine Frame (9fa)Document7 pagesGe Gas Turbine Frame (9fa)ajo zinzoNo ratings yet

- A Presentation On Turbogenerator and ExcitorDocument15 pagesA Presentation On Turbogenerator and ExcitorPrakhar MehrotraNo ratings yet

- Manufacturing of Turbo Generators in BhelDocument26 pagesManufacturing of Turbo Generators in Bhelsarikasony100% (1)

- A Generator - Our Experience 23042016Document10 pagesA Generator - Our Experience 23042016Chilamkurti Siva Sankara RaoNo ratings yet

- EngDocument44 pagesEngzomglolzscribdNo ratings yet

- Prevention and Protection of Generator Rotor Earth Faults Ogn-Ops-Elect-007Document10 pagesPrevention and Protection of Generator Rotor Earth Faults Ogn-Ops-Elect-007Nitin SinghNo ratings yet

- Generator Construction: Major Parts and Their FunctionsDocument19 pagesGenerator Construction: Major Parts and Their FunctionsrahulNranaNo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- Turbogenerator Case StudiesDocument43 pagesTurbogenerator Case StudiesAnonymous q8EusUCNo ratings yet

- STG ArrangementDocument23 pagesSTG ArrangementAdel KlkNo ratings yet

- New Generator ProductsDocument28 pagesNew Generator Productssevero97100% (1)

- 220MW Turbin Generator-Q32JSYEDocument56 pages220MW Turbin Generator-Q32JSYEOry'sSebayangNo ratings yet

- Applicability Guide PDFDocument2 pagesApplicability Guide PDFtriplbingaziNo ratings yet

- TurboCare Engineered Solution For Turbine & Generator Repair (Litgeringen)Document51 pagesTurboCare Engineered Solution For Turbine & Generator Repair (Litgeringen)Dzulqcaefliey TsuelaymhaenNo ratings yet

- Gas Turbine Principles 2019-11-14Document11 pagesGas Turbine Principles 2019-11-14Josephine ChirwaNo ratings yet

- Documents - Pub Training Report 565de94aa5c26Document47 pagesDocuments - Pub Training Report 565de94aa5c26EE OPN1TTPSNo ratings yet

- Turbo GeneratorsDocument26 pagesTurbo Generatorsmani_sneNo ratings yet

- History Perawatan Generator Rev.01Document28 pagesHistory Perawatan Generator Rev.01Nur Ali SaidNo ratings yet

- HRSG Core Topics Student ManualDocument90 pagesHRSG Core Topics Student ManualRamalingam PrabhakaranNo ratings yet

- 9FA Recommended Parts ListingDocument1 page9FA Recommended Parts Listingalexandr_popov_2No ratings yet

- Gas TurbineDocument18 pagesGas TurbinenivasssvNo ratings yet

- GE Generator Technology UpdateDocument20 pagesGE Generator Technology Updatemohammed52033100% (1)

- RussiaPower 2012 Moscow SGT5-4000F Low Ambient Temperature Conditions Siemens Slad.Document11 pagesRussiaPower 2012 Moscow SGT5-4000F Low Ambient Temperature Conditions Siemens Slad.Uhrin ImreNo ratings yet

- Lifecycle Services For GeneratorsDocument20 pagesLifecycle Services For GeneratorsniaNo ratings yet

- Gen Air TestDocument14 pagesGen Air TestPRINCE SHARMANo ratings yet

- STG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052Document3 pagesSTG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052hudson100% (2)

- Generator Bolting and TorquesDocument2 pagesGenerator Bolting and TorquesAbisholita MecaTronics100% (1)

- Load Commutated InverterDocument26 pagesLoad Commutated InverterKVVNo ratings yet

- Turbine 6 Final ReportDocument20 pagesTurbine 6 Final ReportDangolNo ratings yet

- Section 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NoDocument17 pagesSection 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NovcharlesNo ratings yet

- Rotating diode exciter design for nuclear plantsDocument9 pagesRotating diode exciter design for nuclear plantsR0B0T2013No ratings yet

- What Is The Function of Turbine DroopDocument48 pagesWhat Is The Function of Turbine Droopanon_246649396100% (1)

- What Is Excitation System - Definition & Types of Excitation System - Circuit GlobeDocument11 pagesWhat Is Excitation System - Definition & Types of Excitation System - Circuit GlobeSabaMannan123No ratings yet

- TurboGen ConstructionDocument71 pagesTurboGen Constructiondevanand_sawantNo ratings yet

- GE Generators Explained in 40 StepsDocument30 pagesGE Generators Explained in 40 StepsRamon de Oliveira100% (2)

- Generator Protection Guide for Faults and Abnormal ConditionsDocument86 pagesGenerator Protection Guide for Faults and Abnormal ConditionsAbhishek RajputNo ratings yet

- Presentation Synopsis: 18 Unit Level Professional Circle ConventionDocument9 pagesPresentation Synopsis: 18 Unit Level Professional Circle ConventionSCE Stage2No ratings yet

- 328Document22 pages328raom_2No ratings yet

- Protection of GeneratorsDocument87 pagesProtection of GeneratorsTeja RamyaNo ratings yet

- EEI 7FA Supplement r1 2octDocument42 pagesEEI 7FA Supplement r1 2octAnonymous ieWpd823LgNo ratings yet

- F Technology StoryDocument16 pagesF Technology StoryTufail Memon100% (1)

- Manufacturing and Testing of Turbo GeneratorsDocument84 pagesManufacturing and Testing of Turbo Generatorsgnikhilreddy2No ratings yet

- BRUSH Generator Services Brochure - 20Document8 pagesBRUSH Generator Services Brochure - 20Chamrat TechanithiNo ratings yet

- Ics Powerplant of The FutureDocument64 pagesIcs Powerplant of The Futuretrung2iNo ratings yet

- Siemens Air Cooled Generators Sgen 1000a Brochure enDocument4 pagesSiemens Air Cooled Generators Sgen 1000a Brochure enmanohar_033No ratings yet

- A96001 S90 A129 V3 4a00Document6 pagesA96001 S90 A129 V3 4a00AbdulBasitNo ratings yet

- Siemens Air Cooled Generators Sgen 100a 2p Brochure enDocument4 pagesSiemens Air Cooled Generators Sgen 100a 2p Brochure enDanfer Huiza De La CruzNo ratings yet

- SST 100Document4 pagesSST 100Amany Moawad SarhanNo ratings yet

- DCC Programming Front 1Document1 pageDCC Programming Front 1Pradeep_VashistNo ratings yet

- DCC Programming 1Document20 pagesDCC Programming 1Pradeep_VashistNo ratings yet

- DCC Programming 10Document216 pagesDCC Programming 10Pradeep_VashistNo ratings yet

- Manual for A Multi-machine Small-signal Stability ProgrammeDocument154 pagesManual for A Multi-machine Small-signal Stability ProgrammePradeep_VashistNo ratings yet

- Matlab Simulink Based Model of Single Machine Infinite Bus With TCSC For Stability Studies and Tuning Employing GaDocument10 pagesMatlab Simulink Based Model of Single Machine Infinite Bus With TCSC For Stability Studies and Tuning Employing GaPradeep_VashistNo ratings yet

- DCC Programming 4Document20 pagesDCC Programming 4Pradeep_VashistNo ratings yet

- DCC Programming 9Document56 pagesDCC Programming 9Pradeep_VashistNo ratings yet

- World Class Power Solutions RectifiersDocument8 pagesWorld Class Power Solutions RectifiersAsim KaleemNo ratings yet

- Transmission and Distribution Losses by CEADocument8 pagesTransmission and Distribution Losses by CEAPradeep_VashistNo ratings yet

- Pry-Cam Brochure NewDocument8 pagesPry-Cam Brochure NewPradeep_VashistNo ratings yet

- OELDocument6 pagesOELjunsanaNo ratings yet

- Coal-Fired Power Plants - Flexibility Options and ChallengesDocument32 pagesCoal-Fired Power Plants - Flexibility Options and ChallengesPradeep_VashistNo ratings yet

- NegativeSequenceCurrents NewDocument2 pagesNegativeSequenceCurrents NewPradeep_VashistNo ratings yet

- Generator Protection Settings CalculationsDocument112 pagesGenerator Protection Settings CalculationsPradeep_VashistNo ratings yet

- Rgmo FgmoDocument24 pagesRgmo FgmoPradeep_VashistNo ratings yet

- The Restricted Earth Fault Relay Operation: Impact of Current Transformer Knee Point VoltagesDocument5 pagesThe Restricted Earth Fault Relay Operation: Impact of Current Transformer Knee Point VoltagesPradeep_VashistNo ratings yet

- The Six Stages of Digital Transformation MaturityDocument30 pagesThe Six Stages of Digital Transformation MaturityPradeep_VashistNo ratings yet

- FBC BLRDocument12 pagesFBC BLRPradeep_VashistNo ratings yet

- 380kva N14 SeriesDocument4 pages380kva N14 SeriesPradeep_VashistNo ratings yet

- FBC BoilersDocument8 pagesFBC Boilerssk3146No ratings yet

- Chapter 17 - Transient Stability AnalysisDocument45 pagesChapter 17 - Transient Stability AnalysisPradeep_VashistNo ratings yet

- Differential Pressure Meters InstallationDocument2 pagesDifferential Pressure Meters InstallationPradeep_VashistNo ratings yet

- Grounding and ShieldingDocument41 pagesGrounding and ShieldingPradeep_VashistNo ratings yet

- TGN Restricted Earth Fault v1 - 0Document40 pagesTGN Restricted Earth Fault v1 - 0Anonymous dqbb02DUhNo ratings yet

- The Restricted Earth Fault Relay Operation: Impact of Current Transformer Knee Point VoltagesDocument5 pagesThe Restricted Earth Fault Relay Operation: Impact of Current Transformer Knee Point VoltagesPradeep_VashistNo ratings yet

- Power System DynamicDocument24 pagesPower System DynamicPradeep_VashistNo ratings yet

- Static Excitation SystemDocument61 pagesStatic Excitation SystemSiva Kumar Tutika100% (8)

- General Guidelines On Laying of Impulse PipeDocument9 pagesGeneral Guidelines On Laying of Impulse PipePradeep_VashistNo ratings yet

- Introduction To MatlabDocument45 pagesIntroduction To MatlabSivaraman ChidambaramNo ratings yet

- Using Ladders Safely - Information Sheet-1Document4 pagesUsing Ladders Safely - Information Sheet-1Pradeep_VashistNo ratings yet

- Merc Service Manual 30Document355 pagesMerc Service Manual 30Hayduke them100% (6)

- B30D MkVI ADT - Nov '09Document738 pagesB30D MkVI ADT - Nov '09BassieNo ratings yet

- Maxum 4600 SupplementDocument48 pagesMaxum 4600 SupplementAli IrvaliNo ratings yet

- Scarabeo 200ieDocument207 pagesScarabeo 200ieΧΑΡΑΛΑΜΠΟΣΣΕΛΙΜΗΣ100% (1)

- 2007 Subaru Forester 32910Document50 pages2007 Subaru Forester 32910Vidosav KicicNo ratings yet

- 1A) Exhaust Gas Cooler, Exhaust Plenum & Outlet BoxDocument2 pages1A) Exhaust Gas Cooler, Exhaust Plenum & Outlet BoxSonthi MooljindaNo ratings yet

- Troubleshooting: Testing and AdjustingDocument20 pagesTroubleshooting: Testing and AdjustingAndi KaNo ratings yet

- CATERPILLAR 3516B DP2 GENERATOR SYSTEMDocument22 pagesCATERPILLAR 3516B DP2 GENERATOR SYSTEMBembenk Supriyadi100% (1)

- ASHRAE 2011 Liquid Cooling WhitepaperDocument28 pagesASHRAE 2011 Liquid Cooling WhitepaperSargurusivaNo ratings yet

- Motores Auxiliares 3508BDocument10 pagesMotores Auxiliares 3508BIris IlsasNo ratings yet

- Aprilia Pegaso 650 Repair ManualDocument139 pagesAprilia Pegaso 650 Repair ManualphotarasNo ratings yet

- Manual de Partes 416EDocument765 pagesManual de Partes 416ERoxana Elizabeth Valencia Navarrte100% (6)

- Sullair LS10 Screw CompressorDocument19 pagesSullair LS10 Screw CompressorRahmasari Nur SetyonoNo ratings yet

- Perkins 4008Document72 pagesPerkins 4008Daniel Pagano67% (3)

- Carrier Aquaforce 30XW Water-Cooled Liquid Chiller: Flexibility for Heating, Cooling and Industrial ApplicationsDocument12 pagesCarrier Aquaforce 30XW Water-Cooled Liquid Chiller: Flexibility for Heating, Cooling and Industrial ApplicationsFABIO MOACIR KORNDOERFERNo ratings yet

- AAON RN RQ-Series Engineering CatalogDocument152 pagesAAON RN RQ-Series Engineering CataloglasNo ratings yet

- Framo Oil and Gas Pumping Systems: Overview of SolutionsDocument44 pagesFramo Oil and Gas Pumping Systems: Overview of SolutionsBrian Lee BantuganNo ratings yet

- ICE Components LabDocument78 pagesICE Components Labvivek kumarNo ratings yet

- 966H Buletin PreliminaryDocument52 pages966H Buletin PreliminaryGrober Campos CalixtoNo ratings yet

- 23.5 MW (IEC), Chilled Water, 25000 M: (Reference Design 103)Document9 pages23.5 MW (IEC), Chilled Water, 25000 M: (Reference Design 103)ahmadgce04No ratings yet

- Operation and Maintenance Instructions Manual: Ka4H Model Engines FOR Fire Pump ApplicationsDocument35 pagesOperation and Maintenance Instructions Manual: Ka4H Model Engines FOR Fire Pump Applicationsjose mauricio lucuaraNo ratings yet

- Cat 420 E Maintenance IntervalsDocument48 pagesCat 420 E Maintenance IntervalsDavid Alejandro RuizNo ratings yet

- Brochure - LMS Imagine - Lab AMESim Vehicle Thermal ManagementDocument10 pagesBrochure - LMS Imagine - Lab AMESim Vehicle Thermal ManagementrozzillaNo ratings yet

- EV NotesDocument16 pagesEV Notesgaddala kaladharNo ratings yet

- PDF SEEMP E-Module 2021-09-30Document33 pagesPDF SEEMP E-Module 2021-09-30Vipin T.A.No ratings yet

- Paver SUPER 1800-3 BrochureDocument22 pagesPaver SUPER 1800-3 BrochureMohammad Younes100% (1)

- Arctic Cat 1971-73 - ManualDocument200 pagesArctic Cat 1971-73 - ManualmbCAT90% (10)

- SANY SR250 Rotary Drilling RigDocument8 pagesSANY SR250 Rotary Drilling RigSandeep Kumar DangdaNo ratings yet

- 21734Document67 pages21734Jeef100% (4)

- Fist3 30Document87 pagesFist3 30flegias100% (1)