Professional Documents

Culture Documents

Espey

Uploaded by

Guillermo Esteban Diaz QuezadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Espey

Uploaded by

Guillermo Esteban Diaz QuezadaCopyright:

Available Formats

Shaft seals

2.3

Content

Shaft seal series WD 200, e.g. for fans, steam 5

turbines, centrifuges

The company 2

General Information 3

Design variants for series WD 200 6

Shaft seal series WD 500, e.g. for fans, mixers, 7

dryers, centrifuges

Design variants for series WD 500 8

Shaft seal series WKA 300, e.g. for fans and 9

bearing seals low pressure range

Possible design variants for series WKA 300 10

Shaft seal series WKA 802 HD, e.g. for multi stage 13

compressors, steam turbines, very high pressure range

Shaft seal series WKA 1100 HP, e.g. for multi stage 14

compressors, steam turbines, ultra high pressure range

Shaft seal series WKA 250 ND, 11

e.g. for compressors, low pressure range

Shaft seal series WKA 400 HD, 12

e.g. for compressors, steam turbines, high pressure range

Special designs 15

Shaft sleeves & Coatings 16

Qualitt & Service 17

Design data sheet 18

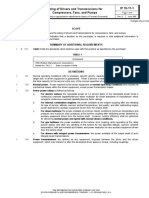

Series Operating pressure Splitt Chamber Seal right Commections Page

per seal housing housing sp mp S A F

WDS p

e

20 bar

WDA p

e

20 bar

WDSA p

e

20 bar

WDK p

e

20 bar

WDKF p

e

20 bar

WDKS p

e

20 bar

WDKSF p

e

20 bar

WDS p

e

3 bar

WDA p

e

3 bar

WDK p

e

3 bar

p

e

0,5 bar * * *

p

e

15 bar * *

p

e

75 bar * *

p

e

140 bar * *

p

e

250 bar * *

WKA 400 HD 12

WKA1100 HP 14

WKA 802 HD 13

WKA 250 ND 11

WKA 300 9, 10

WD 500 7, 8

WKA 3 4

p

e

0,075 bar

WD 200 5, 6

Legend: sp= single part mt= multi-part S= Gas barrier F= Grease barrier, max. operating pressure p

e

0,5 bar A= Suction *= onreguest

1

Shaft seal series WKA 3, e.g. for standard fresh air fans 4

The company

Location

For many years, the Ruhr region has been well

known as a major industrial conurbation. While this

region used to be associated exclusively with heavy

industry and mining, today it is synonymous with a

variety of economic sectors thanks to investments

and major development work. This is in addition

to steel production. Cultural, social and industrial

flows which are international in character have

influenced this new image of pulsating life. The Ruhr

region with all its facets has become a competitive

partner for international activities. It promises dedi-

cated people and a dynamic, industrial potential. A

regional biography which has also shaped Espey

Burgmann GmbH.

History

1888 Factory for metal stuffing boxes founded in Berlin

1927 Espey moved to Duisburg an der Ruhr

1998 Takeover by Burgmann Industries GmbH

2005 Espey moved to new facilities in Moers

2008 Extension of production area

Company

Location: Commercial area Genend in Moers

Employees: 70

Total area : 7747 qm

2

Products: Shaft seals for blowers, fans, compressors, centrifuges, dryers, turbines etc.

Burgmann Industries: One of worlds leading seal manufacturer (e.g. mechanical seals) with 50 subsidiaries

worldwide and totally more than 4900 employees.

2

General technical information

The Espey Burgmann shaft seals range has established a

strong position as a technically reliable and fully-developed

sealing system. Its convincing attributes include economy

and the high level of safety which it offers. You will find our

products in almost all industrial sectors such as chemistry,

power station and disposal systems, petrochemicals, the

pharmaceuticals industry, foodstuffs and marine engineering.

Shaft seal

The Espey Burgmann shaft seal is a labyrinth seal for sealing

gases, dusts and vapours. The sealing rings are movably

fitted in the housing and provide radial sealing with the shaft.

This design principle means that the seal is run with only a

very slight operating gap. It requires no additional lubrication

and is designed for dry running. Another advantage is that no

sealing components which would generate additional shaft

vibrations are mounted on the shaft. The number of sealing

rings and the housing design are determined by the operating

parameters. Compared with other sealing systems, it can be

fitted extremely quickly.

Sealing ring

The sealing rings are available in divided and undivided

versions. The divided versions is intended for an operating

pressure of 20 bar / 290 psi. The advantage of multi-

part rings is in the fact that they can be optimally fitted.

Undivided sealing rings are used in the high-pressure

range p

e

20 bar / 290 psi. Here, the sealing ring is in

one part and consists of two components: a carbon ring

and a bandage in which the carbon ring is shrunk. This

design principle gives it its dimensional stability.

Housing / chambers

There are two technical possibilities for holding the sealing

rings: the horizontally divided housing or the chamber

version. Horizontally divided housings are easy to fit. It is

therefore not necessary to disassemble the machine to

replace the sealing rings. Chamber version housings for low

pressure application are an economical alternative to the hori-

zontally divided housing. This is a modular system, in which

the individual sealing parts such as the chamber, intermediate

chamber, grease chamber and sealing gas chamber are

assembled according to the operating conditions.

Barrier gas

Shaft seals to which barrier gas is applied seal against

products such as toxic and inflammable gases or gases

loaded with solids. Here, the sealing gas pressure must

always be above of the medium. In the high-temperatu-

re range, the sealing gas simultaneously cools the shaft

seal. The operating temperature of the sealed medium

is maximum 700C / 1,292F.

Suction

The suction port is for simultaneously dissipating the

leak, e.g. in the low-pressure part of the machine

(suction side). The escape of the medium into the

atmosphere is reduced or prevented.

General

Depending on the application, it is possible to combine

a barrier gas connection, suction removal and a grease

barrier.

The shaft design must be adapted to the respective seal

type (e.g. surface hardness and surface roughness). A

suitable shaft sleeve is also supplied if required.

Warranty

All technical data are based on many years of experi-

ence and tests. Nevertheless, because of the variety

of applications it can only be a guideline. To ensure

for a single case it is necessary for us to know from

the beginning the exact parameters of use and to

have a separate agreement. For very critical operation

circumstances, e.g. mixed products, we recommend the

consultation with our engineers. In principle it has to be

considered that the given operation limits have mutual

influence and not all the maximum values can be used

the same time.

Subject to changes.

Shaft seal with grease chamber

Shaft seal with barrier gas, chamber version

3

Series WKA 3

Cartridge seal

Chamber version housing

Axially short

Single part seal ring (first delivery)

Gap seal, radially flexible

Standardised dimensions

Series WKA 3 shaft seals are preassembled units

for the use for example in small and medium fresh

air blowers. This shaft seal is characterised by its

easy way of handling and maintenance. Calculated

as a mass-produced article it has a very good price

level.

The WKA 3 is a functional alternative to lip seals or

packings. In contrast to those it works nearly without

contact to the shaft. Because of that the wear is

minimal. The diameters are stepped in accordance

to typical motor shaft sizes.

M

e

d

i

u

m

s

i

d

e

Shaft seal WKA 3

operating pressure per seal 7500 Pa / 1.087 psi

Operation limits

operation temperature max. 200C / 392F

sliding velocity max. 40 m/s / 131 ft/s

shaft diameter 28 ... 80 mm / 1. 1 ... 3. 1 inch

radial clearance max. 2 mm / 0.07 inch

seal ring PTFE compound

Material

gather springs SST 1.4571 (only for spare seal rings)

housing parts Stainless sheet metal AISI

fan Reitz, Hxter

4

Series WD 200

Cartridge seal

Two-part housing

Axially short

Multi-part seal ring, radially cut

Gap seal

Standardised dimensions

Series WD 200 shaft seals are completely preas-

sembled units for installing in e.g. fans, blowers,

steam turbines and exhaust-vapour machines. They

can be easily installed, thanks to the split design of

the seal rings and of the housing. It is not necessary

to disassemble the machine to replace the seal

rings. The shaft seal is characterised by a very high

level of operational safety and easy maintenance.

The standardised seal rings can be adapted to the

customers specific installation situations thanks to

the special housing.

Barrier gas

M

e

d

i

u

m

s

i

d

e

Shaft seal WD 200, type WDKS

operating pressure(p

e

) -0.9 ... 20 bar / -13.0 ... 290 psi

seal with grease barrier max. 0.5 bar / 7.2 psi (max. 300C / 572F)

Operating limits

operating temperature -120 ... 800C / -184 ... 1,472F

max. 225C / 437F PTFE-compound

sliding velocity max. 150 m/s (492 ft/s) carbon graphite

max. 40 m/s ( 131 ft/s) PTFE-compound

shaft diameter 40 ... 340 mm / 1.77 ... 13.4 inch

radial clearance (shaft / housing) 1 ... 5 mm / 0.039 ... 0. 196 inch

recommended wear guard > 300HB (low pressure)

(coated shaft or sleeve) > 58 HRC (high pressure)

seal ring carbon graphite

PTFE-compound

Material

gather spring / detent stainless steel AISI

Hastelloy

, Titanium, Inconel

housing stainless steel, AISI

Aluminium Hastelloy

, Titanium, Inconel

5

Multi-part seal ring, radially cut

fan Flkt Woods Oy, Finnland

6

Design variants for series WD 200

WDS

Shaft seal with barrier gas and grease barrier connection.

The sealing gas pressure must be more than the opera-

ting pressure of the medium. Can be used for various

media i. e. toxic media and media loaded with solids, and

also in explosion protection areas.

Barrier gas

Grease barrier

Grease barrier

M

e

d

i

u

m

s

i

d

e

WDSA

Shaft seal with barrier gas and grease barrier connec-

tion and also Recirculation removal.

Barrier gas

Greace

barrier

Recirculation

M

e

d

i

u

m

s

i

d

e

WDKSF

Short shaft seal with reduced housing outside dia-

meter. Also includes barrier gas and grease barrier

connection.

Barrier gas Grease barrier

M

e

d

i

u

m

s

i

d

e

Bulkhead- Seal

Espey bulkhead seals of type WDK-BHS are installed

in ships with drive shafts that run through one or more

bulkheads. The bulkhead seals prevent water flooding

too fast into adjacent sections of the ship and therefore

provide a high level of protection against flooding.

M

e

d

i

u

m

s

i

d

e

WDK / WDKF

Short shaft seal with grease barrier connection, WDKF

design with reduced housing outside diameter. Can

only be used with pure media (no gases loaded with

solids).

Grease barrier

M

e

d

i

u

m

s

i

d

e

fan Piller, Moringen

Series WD 500

Cartridge seal

Two-part housing

Axially short

Multi-part sealing ring, with gas-tight joints having

overlapping mortise

Self adjustable sealing rings

Standardised dimensions

Series WD 500 shaft seals are completely pre-

assembled units for sealing rotating shafts, e.g.

blowers, agitators, centrifuges and dryers. The

sealing ring slides on the shaft, is adjustable and has

gas-tight joints having overlapping mortise. This redu-

ces the radial gap to the shaft and the leakage rate.

The shaft seals can be easily fitted thanks to the

split design of the sealing rings and of the housing.

It is not necessary to disassemble the machine to

replace the sealing rings. The standardised sealing

rings can be adapted to the customers specific

installation situation thanks to the special housing.

Multi-part sealing ring, with gas-tight joints having

overlapping mortise

Recirculation

Shaft seal WD 500, type WDA

M

e

d

i

u

m

s

i

d

e

Shaft seal WD 500, type WDS

operating pressure(p

e

) -0.8 ... 3 bar / -11.6 ... 43.5 psi

(depending on sliding velocity)

Operation limits

operating temperature -120 ... 500C / -184 ... 932F

-120 ... 150C / -184 ... 302F PTFE-compound

sliding velocity max. 40 m/s ( 131.2 ft/s)

shaft diameter 45 ... 340 mm / 1.77 ... 13.38 inch

radial clearance (shaft/housing) 2.5 ... 5 mm / 0.098 ... 0. 196 inch

recommended wear guard > 58 HRC

(coated shaft or sleeve)

seal ring carbon graphite

PTFE-compound

Material

gather spring/detend stainless steel 1.4571 AISI

Hastelloy

, Titanium, Inconel

housing stainless steel AISI

Hastelloy

, Titanium, Inconel

7

Design variants for series WD 500

Centrifuge Siebtechnik, Mlheim a. d. Ruhr

8

WDS

Shaft seal with barrier gas connection. The barrier gas

pressure must be higher than the operating pressure

of the medium. Can be used with e.g. toxic gases

and media loaded with solids and also in explosion

protection areas.

Barrier gas

M

e

d

i

u

m

s

i

d

e

WDA

Shaft seal with recirculationn. Can only be used with

pure media (no gases loaded with solids).

Recirculation

M

e

d

i

u

m

s

i

d

e

WDK

Short shaft seal. Can only be used with pure media (no

gases loaded with solids).

M

e

d

i

u

m

s

i

d

e

WD200/WD500

The seal ring of type WD200 is placed on the process

side while type WD500 is employed on the atmosphere

side.

This combination improves the functionality of an

absolute WD200 type.

Due to that arrangement a more focused barrier gas

flow to the process side is guaranteed. This reliable

sealing principle is suitable especially for gases contai-

ning solid particles or mist. At the same time the total

leakage of the seal system will be reduced.

M

e

d

i

u

m

s

i

d

e

Series WKA 300

Cartridge seal

Chamber version housing

Axially short

Multi-part sealing ring, radially cut

Gap seal

Standardised dimensions

Series WKA 300 shaft seals are completely preas-

sembled units for installation in e.g. small and medi-

um-sized fans and bearing seals in the low-pressure

range to p

e

0.5 bar / 7.25 psi. The sealing rings

are split and are easy to fit. The shaft seal is cha-

racterised by a very high level of operational safety

and easy maintenance. The standardised sealing

rings combined with the modular system (chamber,

intermediate chamber, grease / suction or barrier

gas chamber) can be combined according to the

customer s specification.

Multi-part sealing ring, radially cut

Barrier gas

Shaft seal WKA 300, type 308.2/4

Grease barrier

M

e

d

i

u

m

s

i

d

e

Shaft seal

WKA 300

9

operating pressure (p

e

) -0.2 ... 0.5 bar / -2.9 ... 7.25 psi

seal with grease barrier max. 0.5 bar / 7.25 psi (max. 300C / 572F)

Operating limits

operating temperature -120 ... 500C / -184 ... 932F

max. 225C / 437F PTFE-compound

sliding velocity max. 150 m/s (492 ft/s) carbon graphite

max. 40 m/s ( 131 ft/s) PTFE-compound

shaft diameter 20 ... 340 mm / 0.78 ... 13.38 inch

radial clearance (shaft/chamber) 2 mm / 0.07 inch

recommended wear guard > 300HB

(coated shaft or sleeve)

seal ring carbon graphite

PTFE-compound

Material

gather spring stainless steel 1.4571 AISI

Hastelloy

, Titanium, Inconel

housing stainless steel 1.4571 AISI

Aluminium Hastelloy

, Titanium, Inconel

10

Possible design variants for series WKA 300

WKA 303.2/4

Shaft seal with two sealing rings, barrier gas or recircu-

lation connection, consisting of 1 chamber, 1 weld-on

ring, 1 barrier gas chamber / Repatriation chamber

Barrier gas/

Recirculation

M

e

d

i

u

m

s

i

d

e

WKA 305/4

Shaft seal with three sealing rings, grease barrier consi-

sting of 1 chamber, 1 end ring, 1 grease chamber and

1 intermediate chamber

Grease barrier

M

e

d

i

u

m

s

i

d

e

W

e

l

d

o

n

r

i

n

g

(

a

l

t

.

)

F

l

a

t

g

a

s

k

e

t

E

n

d

r

i

n

g

I

n

t

e

r

m

e

d

i

a

t

e

c

a

m

b

e

r

B

a

r

r

i

e

r

g

a

s

c

h

a

m

b

e

r

a

l

t

.

R

e

c

i

r

c

u

l

a

t

i

o

n

c

h

a

m

b

e

r

G

r

e

a

s

e

c

h

a

m

b

e

r

C

h

a

m

b

e

r

S

e

a

l

r

i

n

g

m

u

l

t

i

-

p

a

r

t

s

Modular principle of the WKA 300

All individual parts at a glance

M

e

d

i

u

m

s

i

d

e

fan TLT

Series WKA 250 ND

Chamber version, if required with support housing

and cover

Axially short

Multi-part sealing ring, radially cut in LP design

Gap seal

Standardised dimensions

Series WKA 250 ND shaft seals with support

housing and cover are completely preassembled

units for installation into e.g. multi shaft-compressors

and turbines (low pressure versions). The sealing

rings are split and are easy to fit. The standardised

sealing rings combined with the modular system

can be assembled in accordance with the customers

requirements.

Multi-part sealing ring, radially cut in ND design

Shaft seal WKA 250 ND

Barrier gas

M

e

d

i

u

m

s

i

d

e

recommended wear guard > 58 HRC

(coated shaft or sleeve)

operating pressure (p

e

) -0.5 ... 15 bar / -7.2 ... 217.5 psi

Operating limits

operating temperature -120 ... 500C / -184 ... 932F

max. 225C / 437F PTFE-compound

sliding velocity max. 240 m/s (492 ft/s) carbon graphite

max. 40 m/s ( 131 ft/s) PTFE-compound

shaft diameter 20 ... 300 mm / 0.78 ... 11.81 inch

radial clearance (shaft/chamber) max. 2 mm / 0.07 inch

seal ring carbon graphite

PTFE-compound

Material

gather spring stainless steel 1.4571 AISI

Hastelloy, Titanium, Inconel

chamber and housing parts stainless steel AISI

Hastelloy

,Titanium

, Inconel

secondary seal / Elastomer Fluorocaoutchouc (Viton

), nitrile-butadiene

caoutchouc (Perbunan

),

perfluorocaoutchouc (Kalrez

)

secondary seal / flat gasket Statotherm

HT/HD, KSiL C 4400

, u.a.

11

other on request

Series WKA 400 HD

Chamber version, if required with support housing

and cover

Axially short

Multi-part sealing ring, radially cut in HP version

Gap sealing

Standardised dimensions

Series WKA 400 HD shaft seals with support housing

and cover are completely preassembled units for use

in the high-pressure range. The standardised sealing

rings are split and are easy to fit. In conjunction

with the modular system, (e.g. chamber, sealing gas

chamber, lantern, end ring), they can be combined in

accordance with the customers specification.

Multi-part sealing ring, radially cut in

High Pressure (HP) version

Recirculation

Recirculation

Barrier gas

Shaft seal WKA 400 HD

M

e

d

i

u

m

s

i

d

e

recommended wear guard > 58 HRC

(coated shaft or sleeve)

operating pressure/seal (p

e

) -0.8 ... 75 bar / -11.6 ... 1,087.7 psi

Operating limits

operating temperature -120 ... 500C / -184 ... 932F

sliding velocity max. 240 m/s (492 ft/s)

shaft diameter 20 ... 300 mm / 0.78 ... 11.81 inch

radial clearance (shaft/housing) 1 ... 1.5 mm / 0.039 ... 0.059 inch

seal ring carbon graphite E10K, E10C, E12K

Material

gather spring stainless steel 1.4571

Hastelloy, Titanium, Inconel

chamber and housing parts stainless steel 1.4021, 1.4571

cast iron, Hastelloy,

Titanium, Inconel

Secondary seal / Elastomer Fluorocaoutchouc (Viton

), nitrile-butadiene

caoutchouc (Perbunan

),

perfluorocaoutchouc (Kalrez

)

Secondary seal / flat gasket Statotherm

HT/HD, KSiL C 4400

12

other on request

Series WKA 802 HD

Cartridge seal

Chamber version, if required with support housing

and cover

Axially short

Single part sealing ring

Vibration damping

Gap seal

Standardised dimensions

Series WKA 802 HD shaft seals are completely pre-

assembled units which were designed for high-pres-

sure applications (p

e

140 bar/2,030.5 psi) (e.g.

for steam turbines, multi shaft-compressors). The

sealing ring is designed for high differential pressu-

res. It is one part and consists of two components:

a carbon ring and a bandage into which the carbon

ring is shrunk. This design principle gives it its

dimensional stability. A damping element prevents

the sealing ring from swinging up during machine

operation without pressure. The housing is a modu-

lar system in which the individual sealing parts such

as the chamber, the intermediate chamber and the

barrier gas chamber are combined one behind the

other depending on the operating conditions.

Multi shaft-compressor MAN Turbo, Berlin

seal ring with bandage- single part

Recirculation e.g. to

former stage

Barrier gas

Shaft seal WKA 802 HD

M

e

d

i

u

m

s

i

d

e

operating pressure/seal (p

e

) -0.9 ... 140 bar / -13.0 ... 2,030.5 psi

Operating limits

operating temperature -120 ... 225C / -184 ... 437F

sliding velocity 240 m/s (492 ft/s)

shaft diameter 20 ... 200 mm / 0.787 ... 7.87 inch

radial clearance (shaft/chamber) 1 mm / 0.039 inch

recommended wear guard > 58 HRC

(coated shaft or sleeve)

seal ring with bandage seal ring carbon graphite

bandage e.g. Titanium

Material

chamber and housing parts stainless steel AISI

Hastelloy, Titanium, Inconel

secondary seal / Elastomer Fluorocaoutchouc (Viton

), nitrile-butadiene

caoutchouc (Perbunan

),

perfluorocaoutchouc (Kalrez

)

secondary seal / flat gasket Statotherm

HT/HD, KSiL C 4400

13

other on request

Series WKA 1100 HP

Cartridge seal

Chamber version, if required with support housing

and cover

Axially short

Single-part sealing ring

Vibration damping

Gap sealing

Standardised dimensions

Series WKA 1100 HP shaft seals are complete-

ly preassembled units which were designed for

extreme high-pressure applications (p

e

250 bar

/ 3,625.9 psi)) (e.g. for turbo compressors). The

sealing ring is designed for high differential pressu-

res. It is one part and consists of two components:

a carbon ring and a bandage into which the carbon

ring is shrunk. In contrast to the WKA 802HD, the

permissible operating parameters were increased

further by design measures on the sealing rings.

14

Single part sealing ring with bandage

operating pressure/seal (p

e

) -0,9 ... 250 bar / -13.0 ... 3,626 psi

Operating limits

operating temperature -120 ... 225C / -184 ... 437F

sliding velocity 240 m/s (492 ft/s)

shaft diameter 20 ... 200 mm / 0.787 ... 7.87 inch

radial clearance (shaft/chamber) 0,75 ... 1 mm / 0.029 ... 0.039 inch

recommended wear guard > 58 HRC

(coated sleeve)

seal ring with bandage seal ring carbon graphite E10C, E10K, E12K

bandage e.g. Titanium

Material

chamber and housing parts stainless steel 1.4021, 1.4571

Hastelloy, Titanium, Inconel

secondary seal / Elastomer Fluorocaoutchouc (Viton

), nitrile-butadiene

caoutchouc (Perbunan

),

perfluorocaoutchouc (Kalrez

)

secondary seal / flat gasket Statotherm

HT/HD, KSiL C 4400

Shaft seal WKA 1100 HP (assembly example)

P

r

o

c

e

s

s

s

i

d

e

A

t

m

o

s

p

h

e

r

e

s

i

d

e

other on request

Special design

Cartridge seal

Multi-part housing

Axially short

Multi-part seal ring, with overlapping mortice

and/or radially cut, special designs

Espey Burgmann shaft seals are produced in special

designs conforming to the customers specifications

for large machines such as coal mills, blast furnaces,

cement mills and dryers. Depending on the shaft

diameter, the seal rings consist of between 3 up to

50 segments. The special assembly openings in the

seal housing allow easy replacement of the sealing

elements.

Blast furnace shaft seal, project Rautarukki, Finland

Blast furnace shaft seal

Medium side

Barrier gas

Coal mill shaft seal

Barrier gas

Medium side

operating temperature ... 700C / ... 1,292F

Operating limits

sliding velocity max. 40 m/s ( 131 ft/s) carbon graphite

shaft diameter ... 4.000 mm / ... 157.48 inch

15

Shaft sleeves & Coatings

The efficiency and the service life of the Espey

Burgmann shaft seals depend crucially on the preci-

se production and the competent material selection

of the shaft sleeve and its surface quality. The design

must be adapted to the relevant sealing type (e.g.

surface hardness and surface roughness).

In particular, the seal series WD 500 with the adju-

stable sealing rings and shaft seals for high pressure

applications place high demands on the concentrici-

ty and wear protection of the shaft sleeve.

In addition to our standard variants, we manufacture

shaft sleeves according to customer specification.

They are either of a divided or undivided design,

guaranteeing safe and optimum running of the Espey

Burgmann shaft seals.

Shaft sleeve

with coating

Two-part shaft sleeve

16

WDB 210

Shaft sleeve with torque transfer through set screw,

seal between the shaft and shaft sleeve with 0 -ring

WDB 211

Shaft sleeve, clamped version between impeller and

shaft shoulder, seal with O-ring axial

General description Chromium carbide

FMP84 (metallic coating)

Coating process flame spray technique

Influence on the material structure none

Shrink acceptability very good

Hardness 65 HRC

Max. allowed operating temperature 1000C

Max. allowed circumferential speed 240 m/s

Remark For shaft sleeves, shafts and other

rotating parts

Field of application basically for applications without

high oxidation

General description chromium oxide (ceramic)

EMP 98 / FMP 130 (ceramic coating)

Coating process flame spray technique

Influence on the material structure none

Shrink acceptability yes, with reservations

Hardness 58 HRC

Max. allowed operating temperature 600C

Max. allowed circumferential speed 150 m/s

Remark for shaft sleeves, shafts and other

rotating parts

Field of application basically for applications with high

oxidation

Qualitt & Service

The exacting demands which we place on ourselves

are not only our motivation for producing innovative

sealing solutions. They are also reflected in the qua-

lity of our products. Our many decades of successful

work and our satisfied customers confirm this. The

basic design work, concept-related creativity and

the technical advancements made by our company

with regard to application limits, materials and areas

of use have made us one of the leading recognised

shaft seal manufacturers.

Quality and dimension control

On-site service, quality and an international presence

are today important factors for success on the market.

Services which Espey Burgmann provides for you.

Here, we offer you not only the right sealing concepts

but also full service: from engineering through to after-

sales service with assembly, commissioning, on-site

repairs, failure and damage analysis or maintenance,

conversion and spare parts provision at the right time

all from a single source.

Competent consultation and concrete problem solution

suggestions with the aim of optimising the availability

and economical benefits of your system form part of

this service, along with compiling process-orientated,

maintenance and repair programs for sealing applica-

tions.

Production

Repair and assembly

Zertifikate:

z

ot|||z|ot|

L

LKkA Cot|||co||o

o

ISO 9001:2000

Quo||||smonogemen|

8JSTJOE[FSUJ[JFSU

koqo|o|qo |to|w||||qo

Ubotwoc|uoq ooc| lSO 9001.2000

Our strengths lie in our technical competence, our

production flexibility, our readiness to deliver and

high quality. To guarantee our high standard of quality

we are certified after DIN EN ISO 9001:2000 since

23. 12.2002. Espey Burgmann is famous for its well-

founded know-how in design and production, whether

in the processing of carbon graphite, cast materials

and special materials or the production of divided

housings.

17

18

Design data sheet

NOTE

To design a shaft seal optimally according to the operating conditions, we request that you return the completed design data sheet. The data sheet is absolutely necessary,

particularly for the high-pressure versions HD because both the sealing rings, the sealing housing and chamber must be adapted to the high demands.

To ensure that you receive your quotation as soon as

possible, please mail the data sheet to:

info@espey-burgmann.com

Customer: Contact:

Phone: Fax:

Project: Date of quotation:

Shaft diameter d

w

Shaft material

Material of the machine in seal area

Shaft sleeve diameter d

n

Shaft sleeve material

Speed n

Design temperature t

max.

Operating temperature Medium side t

Med.

Bearing side t

Bear.

Sealed medium (name):

Toxic: yes o no o

Aggressive: yes o no o

Solid matter load: yes o no o

Specific gravity of the medium

Operating pressure of the medium p

e,Med.

Barrier gas/medium (name): yes o no o

Specific gravity of the barrier medium

Operating pressure of the barrier medium p

e,Barrier gas.

Operating temperature of the barrier medium t

Barrier gas.

Suction: yes o no o

Operating pressure in the secution p

e,Suction.

Remarks:

o mm o inch

o mm o inch

rpm

o C o F

o C o F

o C o F

o kg/m

3

o lbs/ft

3

o bar o psi

o kg/m

3

o lbs/ft

3

o bar o psi

o C o F

o bar o psi

Argentina Australia Austria Belarus Belgium Bulgaria Brazil Canada Chile China Colombia Cyprus Czech Republic Denmark Ecuador Egypt Estonia

Finland France Germany Great Britain Greece Hungary India Indonesia Iraq Iran Israel Italy Japan Jordan Kazakhstan Korea Kuwait Latvia Libya

Lithuania Malaysia Mauritius Mexico Morocco Myanmar Netherlands New Zealand Nigeria Norway Oman Pakistan Paraguay Peru Philippines Poland

Qatar Romania Russia Saudi Arabia Singapore Slovenia Slovakian Republic South Africa Spain Sweden Switzerland Syria Taiwan Thailand Trinidad and

Tobago Tunisia Turkey Turkmenistan Ukraine United Arab Emirates Uruguay USA Uzbekistan Venezuela Vietnam www.eagleburgmann.com/world

EagleBurgmann is one of the leading international companies for industrial sealing technology. Our

products are used everywhere that safety and reliability are important: In the oil and gas industries,

petroleum refi ning, chemicals, energy, food, paper, water, marine applications, aerospace and mining.

Every day, more than 5000 employees contribute their ideas, solutions and commitment to ensuring

that customers all over the world can rely on our seals. Our modular seal service, TotalSealCare,

underlines our commitment to customer orientation and our provision of tailor-made services for

every application.

Espey Burgmann GmbH

Thomas-Edison-Str. 19

D - 47445 Moers

Tel.: +49 (0) 28 41 / 9 98 27-0

Fax: +49 (0) 28 41 / 9 98 27-56

info@espey-burgmann.com

http://www.espey-burgmann.com

You might also like

- Oil Wiper PackingDocument2 pagesOil Wiper PackingmehdiNo ratings yet

- Karhula - Model Z-Y100Z-2 - Manual.Document8 pagesKarhula - Model Z-Y100Z-2 - Manual.German ZuletaNo ratings yet

- Shaft Seal BulletinDocument2 pagesShaft Seal Bulletinkoniks519No ratings yet

- NEA - MaterialsDocument71 pagesNEA - MaterialsromuloacNo ratings yet

- Compresor GasDocument16 pagesCompresor GasvallenatoNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- Upa 150c Ing.Document7 pagesUpa 150c Ing.Alfredo HerreraNo ratings yet

- SENTRON LV36 Complete English 2014Document284 pagesSENTRON LV36 Complete English 2014charlonNo ratings yet

- Flender Load GearsDocument2 pagesFlender Load GearsAli EsentürkNo ratings yet

- FISHER Rotary Valve Selection GuideDocument16 pagesFISHER Rotary Valve Selection GuidemablangNo ratings yet

- CPKDocument2 pagesCPKMayank PatelNo ratings yet

- Knife Gate ValveDocument7 pagesKnife Gate ValveAbdul RaheemNo ratings yet

- Mopico: Product Overview: Segment Gas Storage and Sealed TechnolgyDocument18 pagesMopico: Product Overview: Segment Gas Storage and Sealed Technolgyhernan plazasNo ratings yet

- John Crane Type FFETDocument6 pagesJohn Crane Type FFETUntung S PrawotoNo ratings yet

- Ventiladores - VENTI OELDE - Computational Fluid Dynamics For Fans and Plants PDFDocument16 pagesVentiladores - VENTI OELDE - Computational Fluid Dynamics For Fans and Plants PDFLuis NovakNo ratings yet

- DuctIsolationSystems DiverterDampersDocument12 pagesDuctIsolationSystems DiverterDampersefte_14100% (1)

- Windows-1256 Mechanical Seals For ABS Pumps en PDFDocument4 pagesWindows-1256 Mechanical Seals For ABS Pumps en PDFaminjolesNo ratings yet

- Dry Gas Compressor Seals Piyush ShahDocument8 pagesDry Gas Compressor Seals Piyush Shahmarkus_naslundNo ratings yet

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- Sundyne LMC-347 Compressor Cross Section DiagramDocument1 pageSundyne LMC-347 Compressor Cross Section DiagrammohammadNo ratings yet

- Vibration Mounts: Evolo® Series: Evolo® 633: Grade A-DDocument0 pagesVibration Mounts: Evolo® Series: Evolo® 633: Grade A-Daleksandar_djordjicNo ratings yet

- Uk-Standard Asme Bladder AccumulatorDocument3 pagesUk-Standard Asme Bladder AccumulatorRamin SoadNo ratings yet

- BCL506Document1 pageBCL506hakimsalimiNo ratings yet

- Flameproof MotorsDocument16 pagesFlameproof MotorsKiran KumarNo ratings yet

- 5650 TechDocument7 pages5650 Techamjath584No ratings yet

- Lowara - ESHE - Data - Wcu PumpDocument74 pagesLowara - ESHE - Data - Wcu Pumpابراهيم عبدهNo ratings yet

- Torque para PrisionerosDocument3 pagesTorque para PrisionerosJulian Chia100% (1)

- KSB Sicca HP Cast Gate Valve PDFDocument4 pagesKSB Sicca HP Cast Gate Valve PDFJamalNo ratings yet

- OHH OHHL E00697 (Pump Zulzer)Document6 pagesOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojNo ratings yet

- 3300 XL 8mm Proximity Transducer System: Bently Nevada Asset Condition MonitoringDocument32 pages3300 XL 8mm Proximity Transducer System: Bently Nevada Asset Condition MonitoringFamilia Mena GodoyNo ratings yet

- Pieces de Rechange Pompe A Lobe Alfa Laval OptilobeDocument13 pagesPieces de Rechange Pompe A Lobe Alfa Laval OptilobeMahmoud FathyNo ratings yet

- Active magnetic bearing design and characterization for high temperature applicationsDocument147 pagesActive magnetic bearing design and characterization for high temperature applicationsVijayTijareNo ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- Mechanical Seals for PumpsDocument5 pagesMechanical Seals for PumpsbryandownNo ratings yet

- Metric DIN Hydraulic Fittings and Threads Chart & DimensionsDocument3 pagesMetric DIN Hydraulic Fittings and Threads Chart & DimensionsTiago SucupiraNo ratings yet

- Jeida Farm Supply Corporation Catalog 2014Document10 pagesJeida Farm Supply Corporation Catalog 2014Taj Deluria100% (3)

- Rotork GearboxDocument2 pagesRotork GearboxVIJIOCLNo ratings yet

- Goulds AF: Axial Flow PumpsDocument11 pagesGoulds AF: Axial Flow PumpsKarthick VenkateshNo ratings yet

- Ecoline GTC 150-600Document12 pagesEcoline GTC 150-600Ricardo BarrosNo ratings yet

- Hydro 2020 Water Turbine.Document26 pagesHydro 2020 Water Turbine.Mạnh Ngô VănNo ratings yet

- Diamondfaces The New Dimension in Mechanical Seal TechnologyDocument20 pagesDiamondfaces The New Dimension in Mechanical Seal TechnologyadamNo ratings yet

- QDP:24 Mechanical Seals Product RangeDocument16 pagesQDP:24 Mechanical Seals Product Rangeyogeshjain38No ratings yet

- Dokumen - Tips Dv200 Manual Master1Document45 pagesDokumen - Tips Dv200 Manual Master1Fermín Duarte RodríguezNo ratings yet

- WKM DynaSeal 370D4 PDFDocument40 pagesWKM DynaSeal 370D4 PDFAlfredo MedinaNo ratings yet

- Programm E 0803Document63 pagesProgramm E 0803Eng-Mohammed SalemNo ratings yet

- 10 OXLER VW Scotch Yoke Actuator 2Document2 pages10 OXLER VW Scotch Yoke Actuator 2DachyiNo ratings yet

- Donaldson Differential Pressure Switches & Gauges GuideDocument2 pagesDonaldson Differential Pressure Switches & Gauges GuideManikandan SenthilNo ratings yet

- Airfin Cooler Standard SpecificationDocument11 pagesAirfin Cooler Standard SpecificationShini100% (1)

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Bettis CBA 725Document16 pagesBettis CBA 725kutts76100% (1)

- BS en Iso 6553-2017Document14 pagesBS en Iso 6553-2017GT-LUCAS BARCINo ratings yet

- Aircraft Refuelling HoseDocument4 pagesAircraft Refuelling HoseBimo IndroNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- Forum Fluid End Pump PartsDocument18 pagesForum Fluid End Pump PartsriskvisionNo ratings yet

- Garlock: Compression Packing Technical ManualDocument28 pagesGarlock: Compression Packing Technical ManualjbertralNo ratings yet

- Product Overview: Valves Actuators Automation TechnologyDocument36 pagesProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaNo ratings yet

- Spirax Sarco PDFDocument4 pagesSpirax Sarco PDFandresaroNo ratings yet

- Mechanical Seals in AgitatorsDocument6 pagesMechanical Seals in AgitatorsLy Ca TieuNo ratings yet

- Steam Trap OverviewDocument15 pagesSteam Trap OverviewJodin Alido MahinayNo ratings yet

- Fan Schedule: Job Name: Fiber OpticalDocument15 pagesFan Schedule: Job Name: Fiber OpticalHiei ArshavinNo ratings yet

- SHF CruisairDocument2 pagesSHF CruisairninatenaNo ratings yet

- Mitsubishi Split SystemsDocument17 pagesMitsubishi Split Systemspatel_kiranNo ratings yet

- DARI Cat DBS EN 0117 9990014Document28 pagesDARI Cat DBS EN 0117 9990014Moncef RedNo ratings yet

- Maintenance Handbook On Roof Mounted AC CoachDocument87 pagesMaintenance Handbook On Roof Mounted AC CoachMd Rohim. SkNo ratings yet

- 201 18-NM8Document156 pages201 18-NM8iwanNo ratings yet

- Use and Care Guide: Campbell 52-Inch Ceiling FanDocument32 pagesUse and Care Guide: Campbell 52-Inch Ceiling FanArmando ChavezNo ratings yet

- Actom-Ep Brochure 2016Document12 pagesActom-Ep Brochure 2016tongaiNo ratings yet

- CFM56-5A-5B CO-063 Basic Engine Feb2014Document27 pagesCFM56-5A-5B CO-063 Basic Engine Feb2014Kelik Arif100% (1)

- APH Maintenance Procedure for Wartsila India Ltd. PlantDocument15 pagesAPH Maintenance Procedure for Wartsila India Ltd. PlantKarthi KeyanNo ratings yet

- Exxon IP 10-11-1 Sizing of DriversDocument4 pagesExxon IP 10-11-1 Sizing of DriversNur Achmad BusairiNo ratings yet

- Solar Powered Fan ProjectDocument18 pagesSolar Powered Fan ProjectJanica ZialcitaNo ratings yet

- Etp Progress Report - g70Document18 pagesEtp Progress Report - g70EeHuey ChooNo ratings yet

- BAS For VAV SystemDocument19 pagesBAS For VAV Systemwissam248100% (3)

- Blow Moulding MachineDocument2 pagesBlow Moulding MachineAYEBAZE BIEM2025No ratings yet

- NMB5915 PCDocument1 pageNMB5915 PCHarera SastanedaNo ratings yet

- Dayton PSC and Shaded Pole Blowers: DescriptionDocument2 pagesDayton PSC and Shaded Pole Blowers: DescriptionMiguel Cárdenas JaramilloNo ratings yet

- AX Series Installation and Operating InstructionsDocument32 pagesAX Series Installation and Operating InstructionsrkssNo ratings yet

- Nf-Sms-21-0905-Na-Proposed 567 G+3P +14 - 800774Document3 pagesNf-Sms-21-0905-Na-Proposed 567 G+3P +14 - 800774MUBASHIRNo ratings yet

- Chapter 6 Inventions Make Life Easier REPORTDocument11 pagesChapter 6 Inventions Make Life Easier REPORTAsh ArtNo ratings yet

- Axair Fans - EC Fan TechnologyDocument10 pagesAxair Fans - EC Fan TechnologyAnurag KashyapNo ratings yet

- Maintain traction motor cooling blowerDocument55 pagesMaintain traction motor cooling blowersupriya rakshitNo ratings yet

- MJC Reverse Jet Cartridge FilterDocument6 pagesMJC Reverse Jet Cartridge FilterJuan Karlos Alberca AlfaroNo ratings yet

- Bueco Clean Room AHUDocument26 pagesBueco Clean Room AHUHENRY100% (1)

- R134a, R410a and R407c chillers and heat pumpsDocument36 pagesR134a, R410a and R407c chillers and heat pumpsDirt FilterNo ratings yet

- Saudi FanDocument29 pagesSaudi Fangreg_n5No ratings yet

- FprEN 50216-12 2010Document13 pagesFprEN 50216-12 2010Mahmoud ShaheenNo ratings yet

- Engineering Thermodynamics ExperimentDocument5 pagesEngineering Thermodynamics ExperimentinxludezNo ratings yet

- Air Smart Controller ManualDocument67 pagesAir Smart Controller ManualChris Chen100% (6)

- Bansilal Ramnath Agarwal Charitable Trust'S Vishwakarma Institute of Technology PUNE-411048Document28 pagesBansilal Ramnath Agarwal Charitable Trust'S Vishwakarma Institute of Technology PUNE-411048Sanika TalathiNo ratings yet