Professional Documents

Culture Documents

09 JSA For Excavation and Blinding at Pump House 1 & 3

Uploaded by

Hilbrecht De PedroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

09 JSA For Excavation and Blinding at Pump House 1 & 3

Uploaded by

Hilbrecht De PedroCopyright:

Available Formats

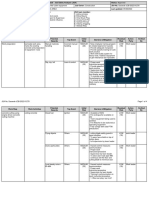

JOB SAFETY ANALYSIS FOR EXCAVATION AND BLINDING AT PH 1 & 3

COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE OF BASIC ACTIVITY STEPS 1.0 Weather POTENTIAL HAZARDS 1.1 Sun Burn 1.2 Heat stress and dehydration 1.3 Dust 2.0 Excavation 2.1 Collapse of Excavation 2.2 Fall and hit 2.3 Movement of Machinery HAZARDS CONTROL 1.1.1 Adequate shelter to be provided for workers to take rest 1.2.1 Sufficient quantity of cool drinking water will be made 1.2.2 Rotation of workers will be made suitably 1.3.1 Water will be sprayed to suppress the dust and dust mask to be provided to workers 2.1.1 Sloping,shoring benching will be applied as applicable. 2.2.1 Excavated materials to be kept away from 2 meters from the edge of excavation. 2.3.1 Equipment will be equiped with Reverse alarm and revolving warning light Banks Man will be provided for heavy equipments with reflective jackets 2.4.1 Excavated area must be barricaded with crash barrier and deep excavation sign board to be displayed. 2.4.2 Proper access and egress will be kept available 2.4.3 Aluminium lader or ladder with guard to be provided excavated place for access and egress 2.5.1 Underground services to be identified and start the work RESPONSIBLE Dodsal Supervisor

Dodsal Supervisor

2.4 Deep Fall

2.5 Underground services

1 of 4

JOB SAFETY ANALYSIS FOR EXCAVATION AND BLINDING AT PH 1 & 3

COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE OF BASIC ACTIVITY STEPS POTENTIAL HAZARDS HAZARDS CONTROL with trial pit method no mechanical excavation upto 3 meters

all the side.use only manual excavation.

RESPONSIBLE

3.0 Removal of excavated

materials through crane

3.1 Failure of crane, collapse and overturn

3.1.1 Crane and lifting tackles shall be certified by QP approved

3.1.2 3.1.3 third party and shall be colour coded accordingly Operators and rigger shall be certified with applicable licence by QP approved third party Crane shall be erected in a firm and level ground with outriggers fully extended with base pad Area must be barricaded with sign board of lifting is in progress to prevent any unauthorized entry Load suspended shall not swing over personnel and dont hold suspended load during break Tag line shall be used to hold the suspended load. Banksman shall be provided

Dodsal Supervisor

3.2 Fall of material and injury

3.2.1 3.2.2 3.2.3 3.2.4

4.0 Blinding / Masonary work 4.1 Fall of personel, material and injury and collapse

4.2 Equipments failure, collapse

4.1.1 Material handling and storage shall be done as per procedure. 4.1.2 Experienced and competent person shall be deployed 4.1.3 Blinding shall not be done when adverse weather condition prevails 4.1.4 House keeping to be maintained always 4.2.1 Operators of mixers, pumps and other equipments involved

Dodsal Supervisor

2 of 4

JOB SAFETY ANALYSIS FOR EXCAVATION AND BLINDING AT PH 1 & 3

COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE OF BASIC ACTIVITY STEPS POTENTIAL HAZARDS and injury 4.2.2 4.2.3 4.3 Enviornmental pollution 5.0 Compaction 5.1 Equipment failure and injury 5.2 Exposure to viberation 5.3 Collapse of form work and displacement of reinforcement 5.4 Noise 6.1 Equipment failure 4.3.1 5.1.1 5.1.2 5.2.1 5.3.1 5.3.2 5.4.1 6.1.1 6.1.2 6.2.1 HAZARDS CONTROL RESPONSIBLE

6.0 Curing of concrete

6.2 Fall of personnel and injury

shall be approved with relevant licence by QP approved third party All access road leading to site shall be safe for traffic movements with necessary signage No infringing activity shall be permitted when blinding work is going on Dumping, cleaning and disposal of blinding waste to be dump at designated area only Equipment shall be maintained and inspected for its suitablity Dodsal Supervisor Experienced workers shall be deployed Workers shall be rotated suitably to avoid prolonged exposure to vibration Inspect the form work prior to compaction Compactor shall not be used along the forms to avoid damage Ear plugs shall be used to avoid exposure to noise Equipment shall be certified by QP approved third party Dodsal Supervisor Operators shall be certified with licence by QP approved third party Clear access shall be maintained at all the time and working

3 of 4

JOB SAFETY ANALYSIS FOR EXCAVATION AND BLINDING AT PH 1 & 3

COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE OF BASIC ACTIVITY STEPS 7.0 Water proofing POTENTIAL HAZARDS HAZARDS CONTROL platform shall be provided Workers shall be trained for application and safe handling of the material. Water proofing material shall be stored in designated area Signage to be displayed and MSDS to be display, eye wash system also ensured Material will be stored in their designated area Barricading will be provided for open and storage area Minimise the manual handling and used equipment. RESPONSIBLE

7.1 Corrosive material

7.1.1 7.1.2 7.1.3

Dodsal Supervisor

8.0 Material handling and Storage

8.1 Slip,trip, fall and injury

8.1.1 8.1.2 8.1.3

Dodsal Supervisor

Remarks: 1- Prior to start any work it will be made sure that personnel are safety inducted. 2- Prior to start any work Tool Box Talk will be carried out. 3- Personnel will wear all applicable PPE. 4- Adequate first aid facility will be provided. 5- Adequate fire extinguishers shall be provided with every equipments. Prepared By: M P Gupta ( Civil Engineer ) Reviewed By: Solayappan ( HSE Officer )

4 of 4

You might also like

- Solution Manual of Physics by Arthur BeiserDocument145 pagesSolution Manual of Physics by Arthur BeiserManuull71% (49)

- Fugro - Method Statement - For Geotechnical InvestigationDocument4 pagesFugro - Method Statement - For Geotechnical Investigationsindalisindi100% (1)

- JOB SAFETY ANALYSIS FOR EARTHWORKS (37Document32 pagesJOB SAFETY ANALYSIS FOR EARTHWORKS (37Hilbrecht De Pedro100% (1)

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- JHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEDocument8 pagesJHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEaloysius akpanNo ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- JSA For Soil ImprovementDocument4 pagesJSA For Soil ImprovementHilbrecht De Pedro100% (1)

- JSA Earthwork Receiving BasinDocument4 pagesJSA Earthwork Receiving BasinHilbrecht De Pedro100% (1)

- JSA For Soil ImprovementDocument4 pagesJSA For Soil ImprovementHilbrecht De Pedro100% (1)

- 04 Jsa For Camp Constn & Associated FacilitysDocument5 pages04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- 04 Jsa For Camp Constn & Associated FacilitysDocument5 pages04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- Black Girl Magic: Over 200+ AffirmationsDocument229 pagesBlack Girl Magic: Over 200+ AffirmationsDestiny S. Harris100% (2)

- Li Ching Wing V Xuan Yi Xiong (2004) 1 HKC 353Document11 pagesLi Ching Wing V Xuan Yi Xiong (2004) 1 HKC 353hNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- JHA For Positive IsolationDocument1 pageJHA For Positive IsolationShahid RazaNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- JHA (Excavation of IPS Rev. B)Document4 pagesJHA (Excavation of IPS Rev. B)Armando AballeNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- 0019 JSA Crane LiftingDocument4 pages0019 JSA Crane LiftingViron BaxhiaNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- Concrete Mixer Safety ChecklistDocument1 pageConcrete Mixer Safety ChecklistSafety Man Shop100% (1)

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- JSA For Work at HeightDocument3 pagesJSA For Work at Heightbagas prakoso100% (1)

- JSA For New EmployeesDocument20 pagesJSA For New EmployeesNilayNo ratings yet

- Job Safety Analysis for Poly Pipe InstallationDocument2 pagesJob Safety Analysis for Poly Pipe InstallationHow Chin Engineering Sdn BhdNo ratings yet

- SOP Grinding & CuttingDocument3 pagesSOP Grinding & CuttingIMRANNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- Job Safety Analysis for High Pressure TestingDocument5 pagesJob Safety Analysis for High Pressure TestingSaiyad RiyazaliNo ratings yet

- JHA Lifting-Moving Heavy ObjectsDocument5 pagesJHA Lifting-Moving Heavy ObjectsOgunwa EmmanuelNo ratings yet

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDocument4 pagesJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- JSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewDocument8 pagesJSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewHSE RHINo ratings yet

- JSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Document7 pagesJSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Marvin BerrensteinNo ratings yet

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisBrain Dee Tech LtdNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- Maintaining Structural Beams SafelyDocument1 pageMaintaining Structural Beams SafelySajith C PauloseNo ratings yet

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- Jha Crane OperationsDocument2 pagesJha Crane OperationsJaycee Bareng Pagador100% (1)

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- Rigging JSA RiggerDocument12 pagesRigging JSA RiggeraQiLGunawanNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Breaker Machine Safety ChecklistDocument1 pageBreaker Machine Safety ChecklistNair R RakeshNo ratings yet

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- Jsa Insulation WorkDocument20 pagesJsa Insulation WorkazerNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- JSA For Purging NitrogenDocument1 pageJSA For Purging Nitrogenlina ekawatiNo ratings yet

- JSA for Drain Line ReplacementDocument5 pagesJSA for Drain Line ReplacementMadhan KannanNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- JSA For Geotechnical Investigation at OffshoreDocument5 pagesJSA For Geotechnical Investigation at OffshoreHilbrecht De PedroNo ratings yet

- 07 JSA For Concreting at Outfall AreaDocument4 pages07 JSA For Concreting at Outfall AreaHilbrecht De PedroNo ratings yet

- 06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Document6 pages06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Hilbrecht De PedroNo ratings yet

- 02 JSA For Bathymatic SurveyDocument3 pages02 JSA For Bathymatic SurveyHilbrecht De Pedro100% (1)

- Luzon Surety Co Vs de GarciaDocument2 pagesLuzon Surety Co Vs de GarciaJedyne Tejada67% (3)

- G.R. No. L-72873 PDFDocument2 pagesG.R. No. L-72873 PDFbrecht1980No ratings yet

- Spoken ArabicDocument95 pagesSpoken ArabicHilbrecht De Pedro100% (1)

- Advance Notes On Criminal Law Book 2Document83 pagesAdvance Notes On Criminal Law Book 2Hilbrecht De PedroNo ratings yet

- AZ ATTR Concept Test Clean SCREENERDocument9 pagesAZ ATTR Concept Test Clean SCREENEREdwin BennyNo ratings yet

- Analisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiDocument10 pagesAnalisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiSYIFA ABIYU SAGITA 08211840000099No ratings yet

- Request Baha Alert PPMPDocument3 pagesRequest Baha Alert PPMPLö Räine AñascoNo ratings yet

- Annex 8 Qualification of BalancesDocument11 pagesAnnex 8 Qualification of BalancesMassimiliano PorcelliNo ratings yet

- CERADocument10 pagesCERAKeren Margarette AlcantaraNo ratings yet

- English Financial Assistance ApplicationDocument4 pagesEnglish Financial Assistance ApplicationAlyssa JenningsNo ratings yet

- Catherineresume 2Document3 pagesCatherineresume 2api-302133133No ratings yet

- Maual de Servicio TV LG 32lf15r-MaDocument31 pagesMaual de Servicio TV LG 32lf15r-MaJaime E FernandezNo ratings yet

- Grade Eleven Test 2019 Social StudiesDocument6 pagesGrade Eleven Test 2019 Social StudiesClair VickerieNo ratings yet

- Đề cương ôn tập tiếng anh 9Document28 pagesĐề cương ôn tập tiếng anh 9Nguyễn HoaNo ratings yet

- Workplace Hazard Analysis ProcedureDocument12 pagesWorkplace Hazard Analysis ProcedureKent Nabz60% (5)

- Aplikasi Berbagai Jenis Media Dan ZPT Terhadap Aklimatisasi Anggrek VandaDocument15 pagesAplikasi Berbagai Jenis Media Dan ZPT Terhadap Aklimatisasi Anggrek VandaSihonoNo ratings yet

- Jounce Therapeutics Company Events and Start DatesDocument48 pagesJounce Therapeutics Company Events and Start DatesEquity NestNo ratings yet

- Frank Wood S Business Accounting 1Document13 pagesFrank Wood S Business Accounting 1Kofi AsaaseNo ratings yet

- Cap 716 PDFDocument150 pagesCap 716 PDFjanhaviNo ratings yet

- Iso 28000Document11 pagesIso 28000Aida FatmawatiNo ratings yet

- Growth Developt Pearl MilletDocument17 pagesGrowth Developt Pearl MilletdarmaNo ratings yet

- 3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingDocument11 pages3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingBožana RadošNo ratings yet

- Philippines implements external quality assessment for clinical labsDocument2 pagesPhilippines implements external quality assessment for clinical labsKimberly PeranteNo ratings yet

- Cot 1 Vital SignsDocument22 pagesCot 1 Vital Signscristine g. magatNo ratings yet

- EO On Ban of Fireworks (Integrated)Document2 pagesEO On Ban of Fireworks (Integrated)Mario Roldan Jr.No ratings yet

- Tumors of The Central Nervous System - VOL 12Document412 pagesTumors of The Central Nervous System - VOL 12vitoNo ratings yet

- Owners Manual Water Mist PDFDocument6 pagesOwners Manual Water Mist PDFZeeNo ratings yet

- Human Capital FormationDocument9 pagesHuman Capital Formationtannu singh67% (6)

- Mufon Ufo JournalDocument21 pagesMufon Ufo JournalSAB78No ratings yet

- Practice of Epidemiology Performance of Floating Absolute RisksDocument4 pagesPractice of Epidemiology Performance of Floating Absolute RisksShreyaswi M KarthikNo ratings yet