Professional Documents

Culture Documents

Resin for Rebar Applications in Humid Conditions

Uploaded by

Jonathan DouglasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resin for Rebar Applications in Humid Conditions

Uploaded by

Jonathan DouglasCopyright:

Available Formats

EPOBAR

EPOBAR

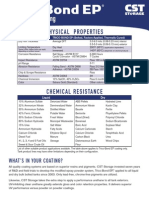

Resin specifically designed for rebars applications Suitable in humid conditions

C H E M I C A L

A N C H O R

R E S I N

Resin especially developed for construction jobsites

The only product on the market dedicated to concrete reinforcement

Ideal injection and rebar setting times up to -5C. Optimized performance for concrete in dry and humid conditions. Maximum bonding strength, even with diamond drilled holes.

Environment Eco designs are central to SPITS design for innovation

Operating instructions

1 2

2x

3

2x

4

2x

Research Manufacturing

High output anchor

A complete range offering for all your construction jobsite needs

A wide range of resin tube sizes suitable for even the largest of jobsites. A high flow mixer for deep anchorages and time saving. A Professional offer for manual, electrical an pneumatic injection tools.

Working & curing times

Product

5C 9C 10C 19C 22 min. 11 min. 6 min. 3 min. 3 min. 250 min. 190 min. 110 min. 65 min. 50 min.

Our development focus is on designing products that use raw materials which have less impact on the environment, reduce waste and ensure all our cartridges can be recycled.

Thanks to its rigid black cartridge, SPIT EPOBAR is shock resistant and protected against climate issues (UV, humidity). The cartridge design has a special plunger which reduces resin waste and limits the quantity of dangerous waste. This is not the case for the supple pouch system* *independent laboratory report

Our patented resins are designed and manufactured in our factories located in France. They follow ISO 9001 Quality standards and ISO 14001 Environmental standards.

20C 29C 30C 39C 40C

Performances*

Ultimate limit loads (Fe E500) (concrete reinforcement applications)

Performances with CE approvals

Approvals recognised throughout Europe

European Technical Agreement (CSTB) Fire rated (up to 4 hours) (CSTB) German approval (DIBT) "SPIT EXPERT" Calculation and Design software

0679-CPD-355 ETA 08/0201 ETAG 001-5 TR023

FIR

E T ES T

SPIT Z - 21.8-1885

Chemical anchors benefits

Compared to mechanical anchors, chemical anchors aresuitable foruse in all materials (hollow material, concrete, stone). Chemical anchors arestrong, durable, waterproof, and resistant to vibrations. They areideal for anyconstruction site situation with variable diameters and embedments.

Load (kg)

2100 8

3400 10

*

4900 12

6600 14

8700 16

13600 20

21100 25

34900 32

Indicative loads only. Performances must be checked and approved according to jobsite conditions.

Applications

Range and accessories

Calculation and Design software

EPCON C8

Resin for extreme rebars and studs applications

EPOBAR

Resin specifically designed for rebars applications

C-MIXplus

Fast curing multi-application resin

EPOMAX

Fast curing resin specifically designed for threaded studs and rebars applications

Distributor

www.spit.com

SPIT products are specifically designed for trained professional end users. Operation and safety instructions within the user manuals must be adhered to at all times. Anchors must be selected according to the nature of base materials, the load to be supported and exterior conditions. The selected product has to be checked and approved according to technical data, precise calculations and on-site tests if required, particularly in cases where there is undefined base materials or products without technical agreements. Please feel free to contact us for advice: www.spit.com.

You might also like

- Epcon G5 Adhesive Summary Brochure 584364Document2 pagesEpcon G5 Adhesive Summary Brochure 584364William MercadoNo ratings yet

- AERC8 Ramset-EpconC8 PDSDocument11 pagesAERC8 Ramset-EpconC8 PDSZilong ZhangNo ratings yet

- Fosroc Conbextra EP 0211Document4 pagesFosroc Conbextra EP 0211Tri SuhartantoNo ratings yet

- AETHER Cement - ECRA Barcelona PresentationDocument23 pagesAETHER Cement - ECRA Barcelona PresentationGilsayan100% (1)

- Sigma CoverDocument8 pagesSigma CoversatyandaruNo ratings yet

- Elgi PG Series Diesel DrivenDocument8 pagesElgi PG Series Diesel DrivenSatyajeet Sahu100% (1)

- SGL Carbon - Graphite HeDocument28 pagesSGL Carbon - Graphite HevenkateaNo ratings yet

- Recoatable Epoxy Systems For Maintenance and New Construction Recoatable Epoxy Systems For Maintenance and New ConstructionDocument8 pagesRecoatable Epoxy Systems For Maintenance and New Construction Recoatable Epoxy Systems For Maintenance and New ConstructionengindmecNo ratings yet

- Conbextra EP Data SheetDocument4 pagesConbextra EP Data Sheetprabhu81No ratings yet

- SigmacoverDocument8 pagesSigmacoverHaresh BhavnaniNo ratings yet

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpNo ratings yet

- Recotec Rotafil enDocument16 pagesRecotec Rotafil enJordan RileyNo ratings yet

- Chemor ENv 07 WebDocument12 pagesChemor ENv 07 WebAhmed TahaNo ratings yet

- HDPE Geomembrane - AlvatechDocument10 pagesHDPE Geomembrane - AlvatechshgsuhermanNo ratings yet

- Well Foam CombiDocument1 pageWell Foam CombiAnas EidNo ratings yet

- SLA Accura BluestoneDocument2 pagesSLA Accura BluestoneclevercogNo ratings yet

- CARBOTECH - Technical PresentationDocument37 pagesCARBOTECH - Technical PresentationpiojeziorNo ratings yet

- Proc HindDocument8 pagesProc HindWulan GlhNo ratings yet

- Grainger Catalog 401Document1 pageGrainger Catalog 401sam_wolf009No ratings yet

- Environmental Product Declaration ISO 14025Document12 pagesEnvironmental Product Declaration ISO 14025João Filipe RibeiroNo ratings yet

- PG 185 1500cfm Drilling Profits IndiaDocument8 pagesPG 185 1500cfm Drilling Profits IndiaAnbuNo ratings yet

- Nitobond Ep..Document4 pagesNitobond Ep..budhikurniawanNo ratings yet

- 2012 Burner Range: Leaders in Combustion TechnologyDocument5 pages2012 Burner Range: Leaders in Combustion TechnologyBbaPbaNo ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- TricoBondSpecSheet 2Document2 pagesTricoBondSpecSheet 2David HoffmanNo ratings yet

- Sikafloor®-169: Product Data SheetDocument4 pagesSikafloor®-169: Product Data SheetMohammed AwfNo ratings yet

- Dogumak Trailer Pressure Tank IndustryDocument23 pagesDogumak Trailer Pressure Tank IndustryIyad Abu-FirasNo ratings yet

- SigmaprimeDocument8 pagesSigmaprimeHaresh BhavnaniNo ratings yet

- Inter Shield 300 PICDocument2 pagesInter Shield 300 PICRifqi Fajri PrayudiNo ratings yet

- Epoxy Catalogue 2007 PDFDocument24 pagesEpoxy Catalogue 2007 PDFbreno_gcNo ratings yet

- Rockwool 159Document37 pagesRockwool 159ashish2783No ratings yet

- RTI Insulation Solutions CatalogueDocument45 pagesRTI Insulation Solutions CatalogueBeomHee Lee100% (1)

- SGL-PT-Brochure-Graphite Shell Tube Heat ExchangersDocument16 pagesSGL-PT-Brochure-Graphite Shell Tube Heat Exchangerselon_cardosoNo ratings yet

- DownloadDocument20 pagesDownloadkeyur1109No ratings yet

- Brochure-Advantex Generic UKDocument6 pagesBrochure-Advantex Generic UKcentaur150No ratings yet

- Pexgol Engineering Guide Indus 2012-09 SingelDocument102 pagesPexgol Engineering Guide Indus 2012-09 SingelFlorin StanciuNo ratings yet

- FOAMGLAS Cellular Glass InsulationDocument18 pagesFOAMGLAS Cellular Glass InsulationAnton DeminNo ratings yet

- FOAMGLAS Cellular Glass InsulationDocument18 pagesFOAMGLAS Cellular Glass InsulationermizeNo ratings yet

- Fendolite Thickness IndustrialDocument4 pagesFendolite Thickness IndustrialMohamed Zain100% (1)

- EPD XCarb Magnelis updated--0df64a47ac077dddecefd2b24bd37df6Document17 pagesEPD XCarb Magnelis updated--0df64a47ac077dddecefd2b24bd37df6email.ysf.ramiNo ratings yet

- Epocoat 111 PDFDocument3 pagesEpocoat 111 PDFjunaid112No ratings yet

- Intergard 343 - Marine CoatingsDocument9 pagesIntergard 343 - Marine CoatingsSerggie TabanaoNo ratings yet

- Datasheet Dramix RC 6535 BNDocument1 pageDatasheet Dramix RC 6535 BNSahil GandhiNo ratings yet

- Sikafloor 82 EpocemDocument6 pagesSikafloor 82 Epocemthe pilotNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- CERBERITE Hollow Glass Speciality Contact MaterialDocument5 pagesCERBERITE Hollow Glass Speciality Contact MaterialPramendraSinghNo ratings yet

- Sentry Industrial Dry Chemical Hand Portable Extinguishers: Data/SpecificationsDocument2 pagesSentry Industrial Dry Chemical Hand Portable Extinguishers: Data/SpecificationsjohnzepolNo ratings yet

- High Strength Epoxy Tested in Accordance With ICC-ES AC308: Curing TimesDocument6 pagesHigh Strength Epoxy Tested in Accordance With ICC-ES AC308: Curing TimesflavioromuloaugustoNo ratings yet

- CS Corrosion Protection SystemDocument20 pagesCS Corrosion Protection SystemMichael AlbuquerqueNo ratings yet

- 00 B053 PC SigmaCoverDocument8 pages00 B053 PC SigmaCoverRoberto_PrrNo ratings yet

- BR Polyken Rev11 Sep10Document8 pagesBR Polyken Rev11 Sep10diaccessltd_17172961No ratings yet

- Drilling Profits: ELGi Compressors for Construction, Mining & MoreDocument8 pagesDrilling Profits: ELGi Compressors for Construction, Mining & MoreAmit KumarNo ratings yet

- NIC HDPE Manhole PDFDocument8 pagesNIC HDPE Manhole PDFreemNo ratings yet

- RHI MR Services Bulletin 1 2012-DataDocument64 pagesRHI MR Services Bulletin 1 2012-DataSuphi Yüksel100% (1)

- Piping - HDPE Product Catalogue - PipestarDocument12 pagesPiping - HDPE Product Catalogue - PipestarRotax_KidNo ratings yet

- New Vario Vfs TC 1622Document224 pagesNew Vario Vfs TC 1622radusumedreaNo ratings yet

- Fairtop STDDocument2 pagesFairtop STDAmit MagguNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- DF3 SS DatasheetDocument4 pagesDF3 SS DatasheetJonathan DouglasNo ratings yet

- 03 Gunnebo EN 2012Document14 pages03 Gunnebo EN 2012Jonathan DouglasNo ratings yet

- Ropower 50R PDFDocument2 pagesRopower 50R PDFJonathan DouglasNo ratings yet

- Mapa de Los Outlets PDFDocument1 pageMapa de Los Outlets PDFJonathan DouglasNo ratings yet

- Gunnebo 1Document21 pagesGunnebo 1Jonathan DouglasNo ratings yet

- C A 2018 ET HP DesigninfoDocument9 pagesC A 2018 ET HP DesigninfoJonathan DouglasNo ratings yet

- Technical Data: Drillfast Stainless Df12-Ss Standard FastenersDocument6 pagesTechnical Data: Drillfast Stainless Df12-Ss Standard FastenersJonathan DouglasNo ratings yet

- DF2 SS LS DatasheetDocument4 pagesDF2 SS LS DatasheetJonathan DouglasNo ratings yet

- DF6 SS DatasheetDocument4 pagesDF6 SS DatasheetJonathan DouglasNo ratings yet

- Paper Inch Fasteners 2015-01-22Document18 pagesPaper Inch Fasteners 2015-01-22Jonathan DouglasNo ratings yet

- Iso 4014-Din 931Document2 pagesIso 4014-Din 931serzo75No ratings yet

- Chapter 4 - FasteningsDocument12 pagesChapter 4 - FasteningsJonathan DouglasNo ratings yet

- Chapter A DIN 931 ISO 4014 A2 STAINLESS PDFDocument5 pagesChapter A DIN 931 ISO 4014 A2 STAINLESS PDFJonathan DouglasNo ratings yet

- Chapter A DIN 931 ISO 4014 A2 STAINLESS PDFDocument5 pagesChapter A DIN 931 ISO 4014 A2 STAINLESS PDFJonathan DouglasNo ratings yet

- C A 2018 ET HP DesigninfoDocument9 pagesC A 2018 ET HP DesigninfoJonathan DouglasNo ratings yet

- HSBR14 Tec Dgu GB 1Document2 pagesHSBR14 Tec Dgu GB 1Jonathan DouglasNo ratings yet

- Performance Grinder Brochure US1069 051616ADocument4 pagesPerformance Grinder Brochure US1069 051616AJonathan DouglasNo ratings yet

- Chapter 1 Catalog Gunnebo 2016 enDocument64 pagesChapter 1 Catalog Gunnebo 2016 enduraeduNo ratings yet

- Angle Grinder Safety Training: 17 Steps to Prevent InjuriesDocument4 pagesAngle Grinder Safety Training: 17 Steps to Prevent InjuriesJonathan DouglasNo ratings yet

- Limited Edition Angle Grinder: Safety Clutch: 50 AnniversaryDocument1 pageLimited Edition Angle Grinder: Safety Clutch: 50 AnniversaryJonathan DouglasNo ratings yet

- Maximized Performance with Metabo Abrasives for Angle Grinder TechnologyDocument2 pagesMaximized Performance with Metabo Abrasives for Angle Grinder TechnologyJonathan DouglasNo ratings yet

- Performance Grinder Brochure US1069 051616ADocument4 pagesPerformance Grinder Brochure US1069 051616AJonathan DouglasNo ratings yet

- DS Grinder Sell Sheet US1074 051717Document2 pagesDS Grinder Sell Sheet US1074 051717Jonathan DouglasNo ratings yet

- FcsDocument2 pagesFcsEduardo Antonio Duran SepulvedaNo ratings yet

- Fixfast DF12 HT DatasheetDocument6 pagesFixfast DF12 HT DatasheetJonathan DouglasNo ratings yet

- FWADocument4 pagesFWAEduardo Antonio Duran SepulvedaNo ratings yet

- ASTM A194 - Portland BoltDocument3 pagesASTM A194 - Portland BoltJonathan DouglasNo ratings yet

- Fixfast DF12 HT DatasheetDocument6 pagesFixfast DF12 HT DatasheetJonathan DouglasNo ratings yet

- ASTM A193 - Portland Bolt PDFDocument2 pagesASTM A193 - Portland Bolt PDFJonathan Douglas100% (1)

- Fixfast DF2 LS Stitcher Datasheet 2Document6 pagesFixfast DF2 LS Stitcher Datasheet 2Jonathan DouglasNo ratings yet

- Frequently Asked Questions: Lecture 10 and 11 Hydraulic MotorsDocument4 pagesFrequently Asked Questions: Lecture 10 and 11 Hydraulic MotorsjtorerocNo ratings yet

- Geotechnical Investigation SpecificationDocument39 pagesGeotechnical Investigation Specificationelnaqa176No ratings yet

- Deep Excavation via Soil Nailing Saves CostsDocument19 pagesDeep Excavation via Soil Nailing Saves CostsgahsoonNo ratings yet

- Course SyllabusDocument2 pagesCourse SyllabusNega Tesfa100% (1)

- Fluid Mechanics Yunus Cengel 4th Solution Manual PDFDocument5 pagesFluid Mechanics Yunus Cengel 4th Solution Manual PDFJuan Carlos Suescun Garcia0% (3)

- Civil Engineering ProjectDocument87 pagesCivil Engineering ProjectNeeraj Porwal100% (6)

- All Branch Time TableDocument10 pagesAll Branch Time TableUday hpNo ratings yet

- ACCE Bulletin highlights innovative bridge design awardDocument52 pagesACCE Bulletin highlights innovative bridge design awardcop593anti776No ratings yet

- Communication SecurityDocument15 pagesCommunication SecurityShahid AzeemNo ratings yet

- 2017 Postgraduate Convocation ListDocument11 pages2017 Postgraduate Convocation ListCheckNo ratings yet

- M 195-06 Lightweight Aggregates PDFDocument6 pagesM 195-06 Lightweight Aggregates PDFWalticoZegarraHerreraNo ratings yet

- Tugas 1Document2 pagesTugas 1Laisa HusrainiNo ratings yet

- Engineers: My Notes StructuralDocument14 pagesEngineers: My Notes StructuralGladies Mhay Binay SandovalNo ratings yet

- Mechanical 3Rd Sem Class Teacher-Ms. ROSHNI KUNWARE CRDocument6 pagesMechanical 3Rd Sem Class Teacher-Ms. ROSHNI KUNWARE CRSudeep MazumdarNo ratings yet

- PDFDocument6 pagesPDFAnonymous YDwBCts50% (2)

- Eurocode ListDocument2 pagesEurocode ListBobby WongNo ratings yet

- ISO/IEC 12207: An Introduction TODocument143 pagesISO/IEC 12207: An Introduction TOdanaNo ratings yet

- Building Project Proposal PDFDocument14 pagesBuilding Project Proposal PDFghogho2No ratings yet

- Manual PDFDocument932 pagesManual PDFSyed Baqir Hussain0% (1)

- Losses in PrestressDocument24 pagesLosses in PrestressNani Tirumalasetti100% (1)

- Strength of Materials IiDocument48 pagesStrength of Materials IiARUNRAJH.V.GNo ratings yet

- 160308131927Document4 pages160308131927hakrajputNo ratings yet

- Comparison Between Dynamic and Static Pile Load TestingDocument11 pagesComparison Between Dynamic and Static Pile Load TestingMOST PASONNo ratings yet

- DrillCAP AnnouncementDocument4 pagesDrillCAP AnnouncementremoNo ratings yet

- Standard Welded Beams Dimensions and PropertiesDocument35 pagesStandard Welded Beams Dimensions and PropertiesKmt_Ae100% (2)

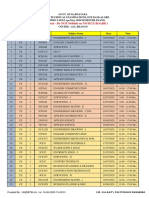

- ICCEET 2019 Programme OverviewDocument15 pagesICCEET 2019 Programme OverviewDr- Abdulhaq alhaddadNo ratings yet

- Inspection & Test Certificate Serial No: ....Document4 pagesInspection & Test Certificate Serial No: ....Somidu ChandimalNo ratings yet

- 117 Weldox 420 Uk DatasheetDocument2 pages117 Weldox 420 Uk DatasheetAndrewFranciscoNo ratings yet

- Tajeshwar SinghDocument2 pagesTajeshwar SinghTajeshwar SinghNo ratings yet

- CRDB Konnect - Test StrategyDocument31 pagesCRDB Konnect - Test StrategymsvinuNo ratings yet