Professional Documents

Culture Documents

ABC Motors Case Study PDF

Uploaded by

Aniruddha ChakrabortyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABC Motors Case Study PDF

Uploaded by

Aniruddha ChakrabortyCopyright:

Available Formats

Case Study 1.

Introduction The CEO of ABC Motors International, through an extensive evaluation process, has decided that his company requires an integrated software system. Having examined a number of possible solutions, he has determined that SAPs R/3 system best suits the companys needs and growth, and has bought licenses for the FI, CO, SD, and MM modules. Your firm has been contracted to lead the installation project that includes some business process reengineering. Your team, assigned to assist ABC Motors International in the implementation of this business system, is to build a working prototype of the system and present it to the executive committee. Considering the attached information gathered from the client, your talented consulting team should design and configure the organizational structure and applicable master records to support the business. All appropriate posting documents and resulting accounting documents for each business transactions should be prototyped and tested. Document and justify any significant recommendations. In your presentation, significant attention should be given to integration and to the flow of business through the supply chain. The following key areas should be covered. Planning issues encountered and their resolution. Integration points throughout the software. Flow of business transactions. Problems and obstacles found in prototyping the proposed implementation model. Attached is the information already gathered by your project team. You have limited access to the Senior Management Steering Committee of ABC Motors International to respond to questions you may have and provide further information as required.

2. Background Information 2.1 Company information ABC Motors International Worldwide has its head office in Laguna Technopark. The company sells motorcycles, and accessories. ABC Motors International owns AMI Marketing, a distribution company in Cebu that handles sales for VizMin area. Financial statements are prepared at the corporate and subsidiary levels. The data and the application server are on a computer in the head office. 2.2 Organizational Structure The manufacturing plant in Laguna Technopark assembles all products sold by ABC Motors International. Inventory is then transferred from the plant to the other distribution centers in Quezon City and Cebu. AMI Marketing processes all sales to VizMin customers. Define the appropriate company codes in order to show the full range of required business functions in your prototype. Assign the appropriate business for internal balance sheets. The fiscal year is identical to the calendar year, however with four special periods. Each company code must have its own credit control area.

3. General Information The suggested priority is to focus on delivering the prototype presentation. Consider the following: Document No.SNPGN10002 Page 1 of 23

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Case Study Taxes - Configuration of Taxation is not essential for the case study Plants - Remember to use the copy plant function when defining additional plants. After completing the essential configuration required for the prototype, you should investigate the configuration for other components of the case study

3.1 Master Data G/L Account Master Data Create one chart of account per company. ABC Motors International (local currency PHP) AMI Marketing (local currency PHP) Automatic Account Assignment must be maintained so that the G/L accounts are posted automatically for the inventory management and invoice verification. 3.2 Bank Master Data Enter the house banks and the related bank accounts for the respective company codes. Bank BPI Citibank City Head Office Cebu Bank Id BPI Citibank Bank country PH PH ABA Routing No. 11000430 11040305

3.3 Customer Master Records Maintenance of customer master records is decentralized. Sales department first creates the customer master and they establish the customer number to be used. The accounting department is then responsible to extend this record to include the financial information. One of the project team members is the Credit Manager. He/she will determine the appropriate credit information for the credit controlling areas. 3.3.1 Account Groups For regular customers create master records using external alphanumeric number ranges. For the one time customers create one master record for the Philippines and one for US. For the line item display for one-time accounts, sort by name and city. Use field selection for the regular customer account group to control the following: Region, Industry and Terms of payment fields are to be mandatory. Sales district is to be suppressed. The following reconciliation accounts should be allocated to the individual customers: PH receivable PH receivable one time customer account

3.3.2 Incoterms The following Incoterms are currently used by ABC Motors International and AMI Ltd.: CIF Costs, insurance, freight Document No.SNPGN10002

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Page 2 of 23

Case Study CIP ZEX Cost insurance paid Express Freight Chargeable

Payment Terms The following payment terms are currently used: PT01 8 days 14 days 21 days 14 days 30 days 45 days 5% 2% net 3% 2% net

PT02

PT01 is used by the ABC Motors International head offices and payment term PTO2 applies to all other customers (including trade industry) 3.3.4 Customers The allocation of customers to sales organizations is determined by the assigned country and city listed in the customers master record. The customer listed below are interested in all product groups of ABC Motors International. The following customer represents the Cebu subsidiary. It is used for inter-company sales of finished goods:

Customer Address Contact AMI Marketing 101Yonge Street Rosa Ave., Cebu City

Currency Country Language PHP PH EN

Distribution Channel Wholesale

Terms of Payment PT01

The following companies represent the customers (wholesalers and retailers) that ABC Motors International and AMI Marketing sells their products to: Customer Address Contact Cycles Inc. 64 West Ave. Quezon City 3 Wheels Inc. 2115 Mt. Pleasant Road Paranaque 344-4355 Contact: Mr. Mendoza Bikes R Us. 12667 East Ave, Quezon City Contact: Ms. Nagin Document No.SNPGN10002 Currency Country Language PHP PH EN PHP PH EN Distribution Channel Wholesale Terms of Payment PT02

Retail

PT02

PHP PH EN

Wholesale

PT02

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Page 3 of 23

Case Study X-TremeCycles 315 North Ave., Cebu Contact: Ms. Sy PHP PH EN Wholesale PT02

3.4 Material Master Records Because of our commitment to quality, we have begun tracking changes to our key materials and products. We would like to see this practice continue through a change management facility that is built into the system. We currently group changes by engineering/ design project numbers. 3.4.1 Finished Products Material number 100001 100014 100025 100030 3.4.2Accessories The product assortment includes accessories (trading goods) in number range 5. These items are only bought and sold and are not used in any way for production. The following materials are to be considered. Material number 500020 500021 500022 500026 500099 Description Sissy Bar Screw Driver Grease Black Leather Riding Pants Lamp-Tiger eye Halogen Six pack Old Sturgis Best Ale Description 500 cc Street Motorcycle-Black 500 cc Motorcross motorcycle-Green 750 cc Street motorcycle- Black 750 cc Motorcross motorcycle-Green

3.4.3 Material Types In ABC Motors International, the following material types are used, with the corresponding number ranges. The material type Bike will have to be created. Bike should have the same functionality as a Material type HALB (semi finished). Beginning of range Finished products Bike Raw materials Operating supplies Trading goods Services 3.4.4 Material Groups 100001 300001 200001 400001 500001 600001 End of range 199999 399999 299999 499999 599999 699999 External/ Internal External External External External External External Account Cat. Ref 0009 0008 0001 0002 0005 0006

For control and reporting purposes, ABC Motors International has decided on the following material groups: Acc Accessories Other Other Cycles Motorcycles Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 4 of 23

Case Study

3.4.5 Additional Information for Sales Department The material master for finished goods is partially maintained. The sales department must maintain additional information. The maintenance consists of the following: Minimum order quantities for accessories Delivery plant Loading group Transport group Storage condition

3.5 Vendor Master Records Vendor master maintenance for trade vendors are maintained centrally by Purchasing Department while maintenance of non-trade vendor masters is maintained by Accounting. 3.5.1 Account Groups ABC Motors International normally purchases from a few, regulated suppliers. Where circumstances warrant, the occasional use of additional suppliers is possible. By policy, ABC Motors International will deal with these occasional vendors using the systems one time vendor capability. Account groups and number range information for vendors is in the following table: Account group KRLV KRFV KROT Description Local Vendors Foreign Vendors One-time vendors Number range Internal numeric Internal numeric External alphabetic

Other than for the one-time accounts, ABC Motors International will use internal number assignment. In order to facilitate reporting and control, there should be two one-time vendor accounts: one for foreign and one for the domestic suppliers. The field status for the account groups should reflect a mandatory field for payment method. The following reconciliation accounts should be used as appropriate. Local vendors payable Foreign vendors payable- one- time accounts US vendors payable US vendors payable- one- time accounts For the line item display for one- time- accounts, sort by name and city.

3.5.2 Vendors The following vendor master records need to be defined. Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 5 of 23

Case Study

Supplier Address Contact ABC Motors International 1001 First Street Laguna Contact: Ms. Martha Aldeguer Wheels on the Go 2811 West Avenue Quezon City Top Design Corp. 11453 Mockingbird Lane Roces Avenue, QC Contact: Mr. Bert N. Erny Cleaners, Inc. 14793 Sct. Tobias Roces Avenue, QC Contact: Mr. Jun Reyes Paints, etc. 234 Northridge Park, Chicago, IL Contact: Todd Williams

Description

Terms of payment Valid currency PT01 PHP

Laguna Tech distribution center

Motorcycle Manufacturer. Supplier for the Roces Avenue Plant This company deals with subcontract orders. Frames, color, and logo are the materials to be provided. Cleaning Service for Laguna

PT01 PHP

PT02 PHP

Provider of paints and colors.

PT01 USD

4. Materials Management All deliveries of materials will be entered as goods received by the inventory management department with invoice verification performed by the accounting department. 4.1 Materials Master Data Material type AMI uses the material type bike to describe all semi-finished products. The material type bike will have to be created. Be sure that the new material type has all the functionally of the standard HALB material type. 4.2 Procurement The following purchasing Groups are required: 001 for procurement of accessories 002 for procurement of services 003 for procurement of motorcycles Requirements for both Manufacturing and Marketing companies are ordered by one purchasing organization based in Manila. However, there are Cebu requirements that are ordered locally but under the same purchasing organization.

In addition, someone must consider the following points while ordering raw materials or semi-finished products: After their in-house production, the frames are given to an outside company. Top Design, contracted for the special Document No.SNPGN10002 Page 6 of 23 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Case Study finish. The required finishing color and the appropriate logo have to be considered as raw material of ABC Motors International. Handling fee per frame: Raw material costs for color (per frame): Raw material costs for logo (per frame): 4.3 Valuation ABC Motors International is valuing motorcycles at standard cost, accessories using moving average. 4.4 Physical Inventory Method Because ABC Motors International uses annual inventory count, all company stocks have to be physically inventoried by the balance sheet cut-off date. During the counting, the warehouse for material movements must be blocked. 4.4.1 Materials Requirements Planning AMI Marketing in Cebu orders motorcycles from Laguna, maintained through MRP. Material requirements planning will be carried out for the creation of purchase requisitions and planned orders. The requisitions are then automatically converted into purchase orders. All requisitions that do not have an explicit source of supply assigned to them are to be converted manually. Accessories are planned using automatic re-order point planning. Motorcycles are ordered based on manual stocks and Forecasts provided by the sales offices. ABC Motors International would like to utilize consumption of independent requirement. 4.4.2 Distribution Center Inventory Using the prescribed methods above, replenish the inventory levels at the distribution centers for all salable products. 4.4.3External Service Management AMIs Laguna plant annually requires duet work cleaning and air filter replacement to the plant HVAC System. AMI Roces Avenue has selected though competitive bid Cleaners, Inc for the project. The cleaning contract is valued at PhP15000. The cost of this service should be allocated to all production cost centers. All payments to quick cleaning are subjected to service entry and acceptance of the actual services rendered. PhP25.00 PhP2.50 PhP0.50

5. Sales and Distribution 5.1 Organization 5.1.1 Sales Organization Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 7 of 23

Case Study

Business in the Philippines is divided into two sales organizations, one for the ABC Motors International and one for AMI Marketing. Each sales organization is responsible for negotiation and fixing of conditions and characteristics of business transactions. 5.1.2 Distribution Channels Both the ABC Motors International and AMI Marketing sales organizations use two distribution channels through which to sell their goods: Wholesale trade Retail trade 5.1.3 Divisions The products of ABC Motors International are divided into three groups. All product lines can be sold through both distribution channels by both sales organizations. Street motorcycles Motorcross motorcycles Accessories 5.1.4 Sales Offices It has been decided to use sales offices to differentiate the sales made by the various regions. This will allow easy reporting of business volume by office. The following sales offices must be defined: Laguna Cebu There is no freight charge or profit, thus there is no accounting implication re transfer of stock between distribution points. 5.1.5 Distribution Centers As discussed earlier, Laguna is responsible for all manufacturing. The other locations Cebu, do not manufacture any products. Inventory at the Cebu distribution center is replenished through plant transfers that result from sales forecasts. There is no accounting implication since ABC Motors International owns both locations. The Marketing Company (AMI Marketing) purchases inventory in Cebu from ABC Motors International according to annual agreement. This agreement is in the form of a scheduling agreement, which outlines quantities and dates. ABC Motors International serves as a vendor for AMI Marketing, and AMI Marketing is defined as a customer of ABC Motors International. Therefore a scheduling agreement is created by ABC Motors International for the delivery schedule of their customer AMI Marketing. The lines in the scheduling agreement appear as demand in the Laguna distribution center. 5.1.6 Shipping Points Each plant has two shipping points that are responsible for the processing deliveries. For normal delivery there is a shipping point which processes the bulk of the deliveries. In addition ABC Motors International offers its customers an express delivery options using Guaranteed Overnight Delivery (G.O.D) which guarantees delivery in one day Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 8 of 23

Case Study anywhere in North America. This shipping point represents a special shipping area reserved for express deliveries. Shipping point R001 REXP C001 CEXP Description Laguna Regular delivery Laguna Express delivery Cebu Regular delivery Cebu Express delivery

5.2 Functions 5.2.1 Pricing Pricing used during order entry and invoicing is the responsibility of each sales organization. Therefore any material pricing, discounts and surcharges can vary depending on the sales organization. It has been decided that each sales organization is to have a separate pricing procedure to reflect its own pricing policy. Therefore certain condition types procedure used for Canadian customers. Furthermore, the distribution channel also influences pricing. A special discount is to be defined for wholesale customers, which reduces the gross price of the product. It has been decided that the price group field in the customer master will be used to determine if a wholesale discount applies. It would be possible to simply make the discount dependent on the distribution channel alone, but the use of the price group field was decided upon since it allowed for multiple discount rates based different price groups.

The following conditions apply to pricing at ABC Motors International: A basic material price is established for each sales organization scaled by quantity. Customer specific material prices are possible At 25%discount applies for wholesale customer orders Pricing determined at order entry is firm and is not re-determined at billing time The value of discount based on the terms of payment used should appear in the pricing details for an item. Material cost should also be included in item pricing details along with the computed Gross profit margin. An addition freight charge should be included in the item in the case of express delivery. The amount is dependent on the weight of the goods shipped and is triggered by a special Incoterms that you enter in the sales document for express delivery.

5.2.2 Availability checks and Transfer of Requirements Both ABC Motors International and AMI Marketing., would like to track each requirement generated by a sales order separately. This means that individual requirements will be passed for the materials. The alternative would be to accumulate demand into collective requirements for a day or a week but then the details of the source of the requirements is not available.

5.2.3 Shipping The data required for shipping should be defaulted as much as possible by the system. Areas where this determination is to be automated included shipping point, and picking location determination. 5.2.3.1 Shipping points Document No.SNPGN10002 Page 9 of 23

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Case Study The shipping point is specified for every order item. In the determination tables, one shipping point is specified as default and others can be specified as alternates. The default shipping point is influenced by the shipping condition from the customer master, loading group from the material, and delivery plant. Ensure that two shipping conditions, one for regular and one for express delivery are defined as well as the related determination table. A single group can be used since all materials are located onto trucks using a forklift. The shipping point should be determined as follows: Delivering Plant Laguna Laguna Cebu Cebu Shipping Condition 01 EX 01 EX Loading Group 002 001 001 001 Shipping point ROO1 REXP C001 CEXP

5.3 Additional Sales Information Configure the system to satisfy the following requirements: Use the standard order type available in the system to process regular customer orders. ABC Motors International does not require specialized orders. ABC Motors International has decided that in addition to the standard order type, credit and debit requests as well as the return order type will be used. Configure the system so that these document types are available at order entry but no others, e.g. Consignment order types. It has also been decided that the business terms in the sales document header are valid for all items and cannot be changed at the item level. The only partner function that can be different between items in a sales order is the ship-to-party. An incompletion procedure based on the standard procedure is to be used for order entry. However, do not include the purchase order number in the list of fields to be checked. Also issue a warning message if weights and volumes are missing. Input facilities must be used in order to facilitate fast and efficient order entry by defining a product proposal. 5.4 Additional shipping Information. The shipping must be processed optimally and quickly. The shipping team has decided the standard functionality is adequate and that the standard delivery document type will be used for sales orders. Due to the volume of deliveries expected, the creation of the delivery documents will be done daily using collective processing. The exception to this rule is the case of a order where the customer has requested the express delivery option. For express delivery, the delivery document will be created separately for the individual order. Warehouse management will not be incorporated since the warehousing structure is not complex. However, the storage location for picking should be proposed in the delivery document. 5.5 Additional Billing Information Consider the following billing related requirements: A standard invoice related to a delivery is to be used. Customers normally receive individual invoices for each delivery. However, it has been decided that billing schedules will be supported for customers who request it. Initially a bi-weekly calendar will be defined to consolidate all deliveries into a billing date falling on the Friday of 2nd and 4th week of every month. The accounting department maintains customer credit limits. The credit control area is the organizational unit, which sets the credit limit for customers and controls it. A credit control area at ABC Motors International Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 10 of 23

Case Study contains only one company code. For every sales document (order type etc) it can be determined, whether a credit limit check is warranted.

6. Financial and Cost Accounting

6.1 Document Processing Enter the following document types. If necessary add the appropriate DR DS DZ KR KG KZ SA Customer invoice Customer Credit memo Customer payment Vendor invoice Vendor credit memo Vendor Payments G/L accounts

Use an internal number assignment with the corresponding number range intervals. 6.2 Organization Information Both of the two company codes will roll up into one corresponding area. Define the controlling area and allocate it to the respective company codes. Enter the basic data as follows: Activate cost center accounting. The cost accounting currency in identical with the group currency of the company. Activate the charts of accounting. The periods correspond to the periods of financial accounting, i.e. 12 accounting periods and four special periods. Company code check. Maintain the controlling area currency and the two main currencies for the company code. Implement number range groups for activity related and period related activities in and actual. Allocate number ranges for those groups within cost center accounting. Complete data entry is only required in one company. Partial data entry is necessary in the other company to demonstrate aggregation of data at the corporate level. Design a line for AR, AP and GL to display all assigned currencies. 6.3 Cost Element Accounting For primary cost entry and primary cost allocation take over the G/L accounts of 4xxxxxFrom financial accounting into cost accounting. Therefore you need to analyze the chart of accounts and determine the appropriate cost element types. Implement the respective secondary cost elements, statistics ratio and activity types for the internal cost allocation.

The validity period for cost elements and activity elements is from 01.01.2002 till 12.31.9999. Statistical figures Document No.SNPGN10002 91000(employees in ea.) Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 11 of 23

Case Study Statistical Key figure Activity type Activity type Activity type Cost element for internal allocation Cost elements for cafeteria assessment Internal Order settlement cost element 7800 (energy consumption in kWh) 1410 (repair hours) 1440 (assemble brakes ) 1450 (assemble motorcycles) 610000 510000 650000

To group similar cost elements, implement the following cost elements groups: Group GOAS Material Energy Personnel Plant maintenance Taxes Rents Assessment Activity allocation Settlements Cost Elements All other groups, object analysis sheet 40xxxx, 4150000 4161000, 416200,416300 42xxxx, 43xxxx, 44xxxxx 45xxxx 46xxxx 47xxxx 510000 610000 650000

6.4 Cost Center and Internal Order Accounting.

6.4.1

Cost Center Hierarchy

Set up appropriate standard hierarchies for your controlling area: K00 K99 K99X6 Standard hierarchy, ABC Motors. Clearing cost centers Clearing cost center X16099 Clearing cost center ABC Motors International, General cost center X11000 general cost center X11100 real estate/buildings X11200 cafeteria Service cost center X12000 service cost center X12100 plant maintenance X12200 internal transportation Production center X13000 production center X13100 street motorcycle assembly X13200 motocross motorcycle assembly

K00X K00X1

K00X2

K00X3

K00X4 Material center Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 12 of 23

Case Study X14000 X14100 X14200 material center material purchase operating funds purchase

K00X5 Distribution and Administration X15000 administration X15100 management X15110 sales Laguna X15210 sales Chicago X15310 administration Laguna X15410 administration Chicago Create the standard hierarchy for the PH (where X=1) and US (where X=2) following the chart above. K001 e.g. would represent the cost centers assigned to the Philippine Company code and K002 would represent all cost centers in the US Company code. Not all cost centers are relevant for both companies. Configure cost centers for all primary and secondary costs for actual and planned postings. Service cost centers also have to be managed on a quantity basis. The cost center currency corresponds to the company code currency. The validity period for the cost centers is from 01.01.2002 until 12.31.9999 Assign the cost centers to a business area of your choice.

6.4.2

Internal Orders

The ABC Motors international has decided to attend a rally held in Clark Field, Pampanga each year to promote their street motorcycle model. In an attempt to prove that there is actual business value to this annual free for all, the marketing manager has requested to see a detailed analysis of the commitments and the actual costs. An internal order will be used to track and report these costs. The costs will be settled to the sales Laguna cost center once all costs have been accounted for. In addition AMI maintains strict budget controls over the actual costs. Create an internal order type for promotions and marketing events that allows recording commitment items. 6.5 Planning The prices for activity types should represent given standards and not calculated values. Generate a plan for the following key figures, activity types and cost elements in the PH Company. Check with production for additional requirements. 6.5.1 Statistical Key Figure Planning 9100 No. of employees. To apportion the cost of the cafeteria corresponding to the no. of employees of the single cost center, the ratio for the following cost centers must be planned as a constant. General Cost center Service cost center Street motorcycle assembly Motocross motorcycle assembly Material Distribution and administration 15 employees 45 employees 50 employees 60 employees 25 employees 20 employees

6.5.2 Statistical Key Figure Planning 7800- Energy consumption Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 13 of 23

Case Study To apportion the cost of energy corresponding to the planned energy consumption rates of the single cost center, the key figure for the following cost centers must be planned as a constant: General cost center 1000kwh Service cost center 1500kwh Production 13000kwh Material 1500kwh Distribution 3000kwh

6.5.3 Activity Type Planning 1410 Repair The activity type repair must be planned on cost center X12100 plant maintenance with the following values: Planned activity 2000hr Standard rate PhP45.00/hr

6.5.4 Activity Type planning 1440- Assembly Brakes The activity type assemble brakes must be planned on cost center x13100 street motorcycle assembly with the following values: Planned activity 20000 hr. Standard time PhP15.00/hr. The activity type assemble brakes must be planned on cost center X13200 motocross motorcycle assembly with the following values: Planned activity 25000hr Standard time PhP15.00/hr. 6.5.5 Activity Type planning 1450-Assembly Motorcycles The activity type assemble motorcycles must be planned on cost center X13100 street motorcycle assembly with the following values: Planned activity Standard time 40000hr PhP18.00/hr

The activity type assemble motorcycles must be planned on cost center X13200 motocross motorcycle assembly with the following values Planned activity 45000hr Standard time PhP19.00/hr 6.5.6 Direct Planning Generate a plan for the following cost elements in ABC Motors International: Cost center 430000 415000 X11000- General CC salaries salaries PhP150, 000.00 yr. PhP 80,000.00 yr.

Cost center X11200 - Cafeteria 415000 421000 430000 cost for external procurement indirect labor costs salaries PhP120, 000.00 yr. PhP60, 0000.00 yr. PhP100, 000.00 yr. Page 14 of 23

Document No.SNPGN10002

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Case Study Cost center X12000 - Service 415000 421000 Cost center 415000 430000 Cost center 400000 420000 430000 Cost center 400000 420000 430000 Cost center 415000 430000 476000 Cost center 430000 476000 476500 cost for external procurement indirect labor cost X13000 - production cost of external procurement salaries X13100 Street motorcycle assembly other raw material direct labor cost salaries PhP400, 00.00 yr. PhP480, 000.00 yr. PhP100, 000.00 yr. PhP100, 000.00 yr. PhP100, 000.00 yr. PhP150, 000.00 yr. PhP80, 000.00 yr.

X13200 Motorcross motorcycle assembly other raw material direct labor cost salaries X14000 material center cost of external procurement salaries office supplies X15000 - administration salaries office supplies general management costs PhP200, 000.00 yr. PhP40, 000.00 yr. PhP100, 000.00 yr. PhP350, 000.00 yr. PhP200, 000.00 yr. PhP25, 000.00 yr. PhP500, 000.00 yr. PhP500, 000.00 yr. PhP110, 000.00 yr.

Cost center 416100 416200

X16099 - Clearing Electricity, fix Electricity, variable PhP10, 000.00 yr. PhP190, 000.00 yr.

Add some plan data for the AMI Ltd. 6.5.7 Planned Assessment

Costs have been planed and entered into the cafeteria cost center. Within the framework of plan assessment, the costs will be assessed based on the number of employees within the corresponding cost centers. Enter the corresponding sender recipient relationship. 6.5.8 Internal Order Planning

Plan the following costs for the Clark Field Rally & Beer Drinking Exhibition order: Travel Expenses Document No.SNPGN10002 10,000 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 15 of 23

Case Study Exhibition Booth Rental Promotion Material (including beer) Miscellaneous Expenses 6.6 Actual Costs recording 6.6.1 Business transactions Ensure that primary costs from MM and SD have been recorded in the cost centers. Create purchase requisitions for accessories and liquid supply you intent to use on the rally. Process the requisitions forward to partial goods received. In addition, enter the following FI transactions: Customers and vendors invoices, debit and credit memos on cost center Energy cost on the collective cost center Direct labor costs and salaries on material cost center Indirect labor costs on overhead cost center Actual costs for the Clark Field Rally 6.6.2 Internal cost Allocation Reproduce the following actual transactions for the internal cost allocation posting of statistical key figure 9100 General cost center 15 employees Service cost center 45 employees Material 25 employees Distribution and administration 20 employees 6.6.3 Actual Assessment Perform an actual assessment similar to the planned assessment. 6.6.4 Actual Order Settlement Perform a settlement of your Clark Field Rally Order To the Roces Avenue sales cost center. 6.7 Reporting Analyze the corresponding transactions in view of cost centers and cost elements. Perform a customer account analysis. Display vendor or customers line items and drill down to originating documents. 6.8 Closing operations A limited month-end closing should be completed in the respective company codes based on the current month. Therefore, it is necessary to close the accounting period by the last day of the month and to open the new period for the next month. Maintain the corresponding tables. Draw up the preparation of balance sheet and a profit and loss statement. Identify the account balance changes from prior month and reconcile the differences to the corresponding transactions. 6.8.1 Financial Statements In order to prepare balance sheet and profit and loss statement at the subsidiary level, a financial statement version with the corresponding hierarchy levels has been created. Version Name: MSCA Document No.SNPGN10002 Page 16 of 23 1,200 36,000 250

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Case Study Each group is totaled and sub-totaled. Each position has its allocated text. G/L accounts have been allocated to the lowest level. Revise if necessary.

7. Production Planning (Bonus Portion) 7.1 Work Centers The following work centers are available. SMBRAKE MCBRAKE SMASSM MCASSM EXTSUB Street Motorcycle Brake Assembly Motorcross Motorcycle Brake Assembly Street Motorcycle Assembly Motorcross Motorcycle Assembly External Sub Contracting

These workcenters are assigned to cost centers and activity types as defined by controlling and production management. The quantity of resources in the workcenter must match the quantities budgeted in controlling.

7.2 Capacity Assume all work centers are not hierarchically structured and have the following capacity. Start time 8:00 a.m. Stop time 6:00 p.m. One hour break time at lunch. Effectively at 80%. At each work center labor capacity is to be evaluated. The available capacity should be adapted after a planning run with capacity evaluation. Discuss possible bottlenecks and discuss methods to solve the problem.

7.3 Routings 7.3.1 Routings for the brake assembly Assemble front brake. Assemble rear brake Quality inspection. 7.3.2 Routings for the frame assembly Paint the frame Apply letter and AMI Screaming Eagle insignia. Inspection 7.3.3 Routings for the final assembly. Assemble components according to drawing number Quality inspection.

Document No.SNPGN10002

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Page 17 of 23

Case Study

7.4 7.4.1

Bills of Material Bill of Material of motocross motorcycle Motor Sports International Bill of Material Motocross Motorcycle. 500cc Motocross Motorcycle 100014

Frame Painted Green 71005

Brake Assemble 70033

Wheels 70030

Shift Assembly 70055

Frame Aluminium Document No.SNPGN10002 Color green 20022

Brake 30020

Saddle 70025

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Brake Lever Screwdriver Dated: Friday, 30023 October 07, 2005 30096

Gear Shift XTR RDM 900 70043 Page 18 of 23 Bearing 30112

Case Study

7.4.2

BILL OF MATERIAL STREET MOTORCYCLE

500 c:c Street MOTOR CYCLE 100001

Frame Painted Black 7.4.2 70005

Brake assembly STREET MOTORCYCLE Wheels BILL OF MATERIAL 70032 70033

Shift assembly 70055

500 c:c Street MOTOR CYCLE 100001

Frame Painted Black 70005

Brake

assembly 70033

Wheels Handle Bar 70032 70031

Shift assembly 70055

Frame Aluminum 20005 Document No.SNPGN10002

Brake 30020

Saddle 70035

Color Black 20012

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Brake Lever Screw drive 30023 30096

Shift Assembly RDM 900 Page 19 of 23 70043

Bearing 30112

Case Study 7.4.4 BILL OF MATERIAL STREET MOTORCYCLE

750 c:c Street MOTOR CYCLE 100025

Frame Painted Black 70005

Brake

assembly 70033

Wheels 70032

Shift assembly 70055

Frame Aluminum 20005

Brake 30020

Saddle 70035

Shift Assembly RDM 900 70043

Color Black 20012

Brake Lever 30023

Screw drive 30096

Bearing 30112

Character 20020

Brake Line 30024

Foot Rest 70036

Gearing Selector 30099

Brake Disk 30026

Engine 750c:c 75002

Brake Pull 30028

Handle Bar 70031

Brake Pull 30028

Document No.SNPGN10002

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Page 20 of 23

Case Study 7.5 Materials Requirements Planning Master production schedule / materials requirements planning needs to be carried out for the creation of dependent requirements & planned orders. The planned orders need to be converted to production orders on all levels of the assembly. 7.6 Production Orders The production orders should make use of the bills of material & routings. The assignment of materials to the operational steps is maintained in the routings. Component availability checking should include production orders and purchase orders at the time of the creation and only on-hand available stock at the time of the release of the production orders. Confirmation of the last operation in the routing should trigger a goods movement to inventory. If the automatic goods movement ever fails a rework goods movement should be processed. 7.7 Capacity Planning The capacity planning is used to identify bottlenecks in available production capacity. In the case that these exist, pre-production is increased in the month of least demand. If this is not sufficient, the earliest date available to promise is determined.

Prototype Presentation A number of core business functions have been identified. The supporting R/3 transactions are to form the basis for the presentation made to the steering committee. 1. Demonstrate your Implementation project. Due to the lack of time no resource assignment and documentation is required. 2. Display the beginning Balance Sheets and P & Ls for the two subsidiaries. 3. Demonstrate the pre-planning in Cebu and the demand transfer to the production plant. Execute MRP for material 100001 in the production plant. 4. Create a purchase order for the vendor Wheels in Motion. Convert one of the requisitions generated by MRP into a Purchase Order. 5. Receive inventory against the purchase order 6. Show the service PO created for HVAC cleaning services in the Roces Avenue plant. 7. Demonstrate service entry and acceptance for HVAC cleaning services. 8. Invoice Verification. Use invoice verification to record the invoice from vendor Wheels in Motion. 9. Create a customer sales order for the Chicago sales office. Customer, All Terrain Cycles places an order for express delivery as follows: Material Quantity 100001 100 PC 100025 75 500026 50 500022 50

Verify the following are correct: Document No.SNPGN10002 Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005 Page 21 of 23

Case Study

Shipping point Delivery Plant Pricing

Process the delivery for this order. All materials are to be fully delivered. Complete picking and goods issue. Ensure that the storage locations were defaulted accordingly. 10. Create the billing document for this delivery. Create the billing document and ensure that the posting to financial accounting is successfully completed. Examine the accounting posting to validate the general ledger accounts used. 11. Create a returns order with reference to the sales order. The customer has called and complained about the quality of the finish on some of the motorcycles they received. Create a returns order for 5 pieces of material 100001. 12. Create the delivery for the returns order. Post goods receipt for the return of the damaged goods. 13. Create the corresponding credit memo. Create the credit for the returns order and examine the accounting posting. 14. Post an incoming payment. Receive a payment from customer X-Treme Cycles. A deduction was made for PhP23.00 for excess freight charges and USD27.00 for arriving 3 hours late. We have agreed to absorb the PhP23.00, however the USD27.00 still owes and should be recorded using a notation of 'item in dispute'. 15. Post a vendor invoice using an account assignment model. An invoice has been received by the landlord for the rent to be charged for the month. The charges are always recorded to the same cost centers prorated by the sq. footage for each cost center. Cost center Sq footage 11000 1000 12000 1200 15000 900 16. Generate a payment run for all the outstanding invoices. The payment run should contain at least 3 invoices, one of which is blocked from payment. Create an appropriate blocking reason. 17. Perform an assessment. The cafeteria costs will be assessed based on the number of employees. 18. Display the profit and loss statement for ABC Motors International. Display a financial calendar showing all payment runs and financial statements. Include a message, which reminds the controller when the month-end reports are finished and ready for preview. 19. Demonstrate the completion of the partial delivery for your Clark Field order. 20. Perform an actual settlement of the Clark Field rally order. 21. Be prepared to show and discuss the Cross Company Stock Transfer requirement between AMI ltd. and ABC Motors International. 22. Close the month and reconcile the Balance sheets and P & Ls for the two subsidiaries to the prior month. Document No.SNPGN10002 Page 22 of 23

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Case Study

Document No.SNPGN10002

Copy right S.N.Padhi 2005 http://www.surya-padhi.net/ Dated: Friday, October 07, 2005

Page 23 of 23

You might also like

- Digital Marketing Trends and Prospects: Develop an effective Digital Marketing strategy with SEO, SEM, PPC, Digital Display Ads & Email Marketing techniques. (English Edition)From EverandDigital Marketing Trends and Prospects: Develop an effective Digital Marketing strategy with SEO, SEM, PPC, Digital Display Ads & Email Marketing techniques. (English Edition)No ratings yet

- Aspects of Contract and Negligence For BusinessDocument22 pagesAspects of Contract and Negligence For BusinessVimukthi Adithya67% (3)

- Tata Motors AnalysisDocument6 pagesTata Motors AnalysisYatin GuptaNo ratings yet

- Abans Financials and StrategyDocument52 pagesAbans Financials and StrategyYasasi Jayawardana100% (2)

- Sales ManagementDocument15 pagesSales ManagementSiddharth puriNo ratings yet

- Marketting ManagementDocument1 pageMarketting ManagementyazhinNo ratings yet

- Amity School of Business: Public Relations & Corporate ImageDocument81 pagesAmity School of Business: Public Relations & Corporate ImagedivyaNo ratings yet

- Mkis Term PaperDocument20 pagesMkis Term PaperK M Masudul Hoque100% (1)

- Project of Marketing Plan For New Product Launch: Presented byDocument16 pagesProject of Marketing Plan For New Product Launch: Presented byArsalan TNo ratings yet

- New Product Management AssignmentDocument17 pagesNew Product Management AssignmentjifforeverNo ratings yet

- Chapter 12 Book QuizDocument27 pagesChapter 12 Book QuizTom Langland100% (2)

- BRM ReportDocument29 pagesBRM ReportMitisha GaurNo ratings yet

- Significance of Knowledge Management at Toyota & Role of RFID within SCM of Manufacturing firmsDocument10 pagesSignificance of Knowledge Management at Toyota & Role of RFID within SCM of Manufacturing firmsSalman AsifNo ratings yet

- Sales and Distribution Management: Buyer - Seller DyadDocument6 pagesSales and Distribution Management: Buyer - Seller DyadDIVYAM BHADORIA100% (1)

- Digital MarketingDocument7 pagesDigital MarketingAvni ShahNo ratings yet

- Enterprise SystemsDocument11 pagesEnterprise SystemsumairaleyNo ratings yet

- KPR Agrochem LTDDocument66 pagesKPR Agrochem LTDpronoyalfiNo ratings yet

- Aidas ModelDocument24 pagesAidas Modelshael786No ratings yet

- Models For Setting Advertising ObjectivesDocument8 pagesModels For Setting Advertising ObjectivesSabeer HamsaNo ratings yet

- Bhat Bhateni GroupDocument23 pagesBhat Bhateni Groupprakash_ghimire755183% (6)

- Global Market Opportunity AsessmentDocument23 pagesGlobal Market Opportunity Asessmentmentari fazrinniaNo ratings yet

- Marketing ProjectDocument15 pagesMarketing ProjectShretha lakshmi rNo ratings yet

- Marketing Project 2Document22 pagesMarketing Project 2RajatVimalNo ratings yet

- Usage and Attitude of Consumer Toward Pharmaceutical Over The Counter (OTC) Product - Rehan FaquihDocument353 pagesUsage and Attitude of Consumer Toward Pharmaceutical Over The Counter (OTC) Product - Rehan Faquihrehan_faquih8279100% (2)

- Impact of Brand Image On Consumer BehaviourDocument9 pagesImpact of Brand Image On Consumer BehaviourSahil SinghNo ratings yet

- MARKETING MIX IN SERVICE SECTOR (Full Paper)Document7 pagesMARKETING MIX IN SERVICE SECTOR (Full Paper)Jeni Cho ChweetNo ratings yet

- Circle Advertising Internship ReportDocument35 pagesCircle Advertising Internship ReportTaimoor Ul HassanNo ratings yet

- BHO3439 Marketing Services and Experiences Outline S1 2017Document16 pagesBHO3439 Marketing Services and Experiences Outline S1 2017Bolang chaiNo ratings yet

- Brand Management AssignmentDocument23 pagesBrand Management Assignmental mamunNo ratings yet

- Media Planning and Strategy Guide for Event ManagementDocument5 pagesMedia Planning and Strategy Guide for Event Managementharishk2060No ratings yet

- Operations Mangement AssignmentDocument21 pagesOperations Mangement AssignmentsherazNo ratings yet

- Assignment Principles of MarketingDocument3 pagesAssignment Principles of MarketingAndrewNo ratings yet

- Bba Syllabus 5th SemDocument18 pagesBba Syllabus 5th SemKiran KaurNo ratings yet

- Assignment 11 STM DavisDocument8 pagesAssignment 11 STM DavisWaris SalmanNo ratings yet

- Branding in Retail BusinessDocument10 pagesBranding in Retail BusinessFarooq AzamNo ratings yet

- MIS Case 2 - Group 8 - Frito-LayDocument2 pagesMIS Case 2 - Group 8 - Frito-Layv100% (1)

- Amework For Channel Design & ImlementationDocument11 pagesAmework For Channel Design & ImlementationJesun Shine SalinsNo ratings yet

- Competitor and CLC AnalysesDocument22 pagesCompetitor and CLC AnalysesAmandaNo ratings yet

- CRM Customer Relationship ManagementDocument17 pagesCRM Customer Relationship ManagementAbhijeet AgarwalNo ratings yet

- Brewberrys Marketing StrategyDocument6 pagesBrewberrys Marketing StrategyHarshParmarNo ratings yet

- Marketing AssignmentDocument28 pagesMarketing AssignmentSyed muhammad AsimNo ratings yet

- Apple 2Document4 pagesApple 2majidNo ratings yet

- MARKETING PROCESSES & PLANNING FOR COCONUT BLISSDocument19 pagesMARKETING PROCESSES & PLANNING FOR COCONUT BLISSMishahim SaeedNo ratings yet

- Mpel 04 Service EncounterDocument9 pagesMpel 04 Service EncounterHaris KaryadiNo ratings yet

- Home Solutions (India) Limited-Kitchen SectionDocument13 pagesHome Solutions (India) Limited-Kitchen SectionThameem Ul AnsariNo ratings yet

- Five Product Level of PepsiDocument13 pagesFive Product Level of PepsiAmna AliNo ratings yet

- A Study of Consumers Behaviour Towards Purchasing Decision of CarDocument14 pagesA Study of Consumers Behaviour Towards Purchasing Decision of CararcherselevatorsNo ratings yet

- M-Commerce and Its Applications: Prepared byDocument21 pagesM-Commerce and Its Applications: Prepared byMhamad Nasih100% (1)

- L'Oreal Case Study Group 3 Product and Communication StrategiesDocument4 pagesL'Oreal Case Study Group 3 Product and Communication StrategiesnikhildnerkarNo ratings yet

- Strategy Formulation: Situation Analysis and Business StrategyDocument22 pagesStrategy Formulation: Situation Analysis and Business Strategyreimarie120% (1)

- Universiti Malaysia Perlis: Tugasan Individu / Individual AssignmentDocument3 pagesUniversiti Malaysia Perlis: Tugasan Individu / Individual AssignmentTuanNaz-OneNo ratings yet

- Ia - Bs Matrix & Ad Little Life Cycle Approach: K.Chitra 11TM03Document22 pagesIa - Bs Matrix & Ad Little Life Cycle Approach: K.Chitra 11TM03Treesa Chitra JosNo ratings yet

- International Market OrientationDocument13 pagesInternational Market OrientationAakriti Rohatgi100% (1)

- Vimal Oil Company AssignmentDocument27 pagesVimal Oil Company AssignmentkeerthadinnuNo ratings yet

- A Comparative Study On Financial Performance of Public Sector Banks in India: An Analysis On Camel ModelDocument17 pagesA Comparative Study On Financial Performance of Public Sector Banks in India: An Analysis On Camel ModelkishoremeghaniNo ratings yet

- Mba Marketing PDFDocument5 pagesMba Marketing PDFDhivya KirupaNo ratings yet

- Marketing Plan FOR New Healthy Domty Kids SandwichDocument43 pagesMarketing Plan FOR New Healthy Domty Kids Sandwichmimo11112222No ratings yet

- GE Nine MatrixDocument9 pagesGE Nine MatrixSiddhartha GhoshNo ratings yet

- Profile Parameters For Logon and PasswordDocument15 pagesProfile Parameters For Logon and PasswordAniruddha ChakrabortyNo ratings yet

- Port Used in SAPDocument29 pagesPort Used in SAPAniruddha ChakrabortyNo ratings yet

- Install Canon LBP2900 On LinuxDocument3 pagesInstall Canon LBP2900 On LinuxAniruddha ChakrabortyNo ratings yet

- BDCDocument14 pagesBDCPihu SarmaNo ratings yet

- CCMS-Automatic Alert Notification - Configuration GuideDocument38 pagesCCMS-Automatic Alert Notification - Configuration GuidevikasnaiduNo ratings yet

- CCMS-Automatic Alert Notification - Configuration GuideDocument38 pagesCCMS-Automatic Alert Notification - Configuration GuidevikasnaiduNo ratings yet

- Exchange Rate CurrencyDocument9 pagesExchange Rate CurrencyAniruddha ChakrabortyNo ratings yet

- Company or Business AreaDocument12 pagesCompany or Business AreaAniruddha ChakrabortyNo ratings yet

- New Microsoft Office Word DocumentDocument4 pagesNew Microsoft Office Word DocumentAniruddha ChakrabortyNo ratings yet

- SAP Linux Gui InstallationDocument3 pagesSAP Linux Gui InstallationAniruddha ChakrabortyNo ratings yet

- RFC BasicsDocument13 pagesRFC BasicsAniruddha ChakrabortyNo ratings yet

- Basis Note Basis NoteDocument54 pagesBasis Note Basis NoteAniruddha ChakrabortyNo ratings yet

- Sap Transaction Codes ListDocument1 pageSap Transaction Codes Listchaitu121276No ratings yet

- Word Macros 2007Document9 pagesWord Macros 2007Aniruddha ChakrabortyNo ratings yet

- SMS Your Voter Identity Card Number To 94336 33333Document1 pageSMS Your Voter Identity Card Number To 94336 33333Aniruddha ChakrabortyNo ratings yet

- SAP FI Configuration for TEILDocument45 pagesSAP FI Configuration for TEILHari ChandanNo ratings yet

- Month End Closing ProceduresDocument8 pagesMonth End Closing ProceduresAniruddha ChakrabortyNo ratings yet

- All About TransportDocument11 pagesAll About TransportAniruddha ChakrabortyNo ratings yet

- Sap CRM FaqsDocument15 pagesSap CRM Faqsjothimurugesan100% (1)

- Air PollutionDocument30 pagesAir Pollutionclass 11 ip guruNo ratings yet

- Air PollutionDocument30 pagesAir Pollutionclass 11 ip guruNo ratings yet

- SAP CRM Interview Questions & AnswersDocument7 pagesSAP CRM Interview Questions & AnswersDavid VaseNo ratings yet

- T2 Ent Struct DefDocument2 pagesT2 Ent Struct DefAniruddha ChakrabortyNo ratings yet

- Ashutosh-Sap CRM CVDocument4 pagesAshutosh-Sap CRM CVTom MarksNo ratings yet

- Sap CRM FaqsDocument15 pagesSap CRM Faqsjothimurugesan100% (1)

- Sap Fi Easy StepsDocument6 pagesSap Fi Easy StepsAniruddha ChakrabortyNo ratings yet

- Stock Transfer Configure DocumentDocument7 pagesStock Transfer Configure DocumentSatyendra Gupta100% (1)

- How To Do Rebate ProcessingDocument4 pagesHow To Do Rebate ProcessingAniruddha ChakrabortyNo ratings yet

- Delivery Item Category (DIC) T Code: 0VLPDocument6 pagesDelivery Item Category (DIC) T Code: 0VLPAniruddha ChakrabortyNo ratings yet

- How To Do Rebate ProcessingDocument4 pagesHow To Do Rebate ProcessingAniruddha ChakrabortyNo ratings yet

- 4.5 Uniform Customs & Practice For Documentary CREDITS (UCP 600) & eUCP v.1Document103 pages4.5 Uniform Customs & Practice For Documentary CREDITS (UCP 600) & eUCP v.1AprilNo ratings yet

- International Sale of Goods ContractDocument6 pagesInternational Sale of Goods ContractK59 Ngo Thi Tra LyNo ratings yet

- Incoterms Chart 2010Document2 pagesIncoterms Chart 2010Mohamad ArrajNo ratings yet

- Oil & Gas Sales Agreement for Nigerian Crude OilDocument26 pagesOil & Gas Sales Agreement for Nigerian Crude OilAnand Mohan0% (1)

- Project Report For Manufacturing ProcessDocument44 pagesProject Report For Manufacturing Processhimali lalwaniNo ratings yet

- 1353 InvDocument2 pages1353 InvAbishek AbiNo ratings yet

- Incoterms -2000 Explained in 40 CharactersDocument4 pagesIncoterms -2000 Explained in 40 CharactersMihir KumarNo ratings yet

- Iblaw A1Document16 pagesIblaw A1FeiyezNo ratings yet

- MCC's Export Business of Incense, Perfume Oils and TapestriesDocument25 pagesMCC's Export Business of Incense, Perfume Oils and TapestriesRajeev Ranjan BhartiNo ratings yet

- 1.13.2020 - BaaN 6 MTY Sales Order Status Overview (SP)Document134 pages1.13.2020 - BaaN 6 MTY Sales Order Status Overview (SP)Frank RojasNo ratings yet

- International Business Transactions Outline Professor Ramsey, Spring 2015Document77 pagesInternational Business Transactions Outline Professor Ramsey, Spring 2015Chen HakaniNo ratings yet

- Certification & international trade procedures overviewDocument18 pagesCertification & international trade procedures overviewyacine ouchiaNo ratings yet

- Petros Transacting Procedures Petroleum Coke.Document3 pagesPetros Transacting Procedures Petroleum Coke.Harold DiamondNo ratings yet

- Mi 63620000003Document4 pagesMi 63620000003ASC Tempest-128No ratings yet

- 1Document67 pages1Abhishek A. NadgireNo ratings yet

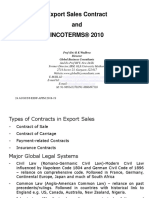

- Export Sales Contract & INCOTERMS 2010Document32 pagesExport Sales Contract & INCOTERMS 2010himanshusangaNo ratings yet

- Beatrice Gay Letter Writing SciptDocument23 pagesBeatrice Gay Letter Writing Sciptsalegosse0% (2)

- Green CoffeeDocument29 pagesGreen CoffeeMukhammad Ilham Irmansyah100% (1)

- ÔN - Vận Tải Bảo Hiểm PDFDocument56 pagesÔN - Vận Tải Bảo Hiểm PDFTuấn Nguyễn AnhNo ratings yet

- You Go Through The Contract.Document13 pagesYou Go Through The Contract.Emmanuel OpeyNo ratings yet

- Group Assignment. FinalDocument20 pagesGroup Assignment. Finalchunleong100% (3)

- Titanhi PiDocument1 pageTitanhi PiSebastian Rojas PeñaNo ratings yet

- Q3 and Q4 Eim PDFDocument14 pagesQ3 and Q4 Eim PDFNguyễn Ngọc Phương LinhNo ratings yet

- Multimodal Transportation Concept and FrameworkDocument158 pagesMultimodal Transportation Concept and FrameworkyenleNo ratings yet

- REPL - CUGL - OLC - 001 - 18 FinalDocument279 pagesREPL - CUGL - OLC - 001 - 18 Finalshank100No ratings yet

- Pir Sample DataDocument9 pagesPir Sample DataSandeepNo ratings yet

- Petroleum Marketing and Supply ChainDocument77 pagesPetroleum Marketing and Supply ChainsamwelNo ratings yet

- Incoterms 2010 Poster V5Document1 pageIncoterms 2010 Poster V5trafico7387No ratings yet

- Purchase Order LayoutDocument9 pagesPurchase Order LayoutRahul FulareNo ratings yet

- Import ExportDocument19 pagesImport ExportNeha ThakurNo ratings yet