Professional Documents

Culture Documents

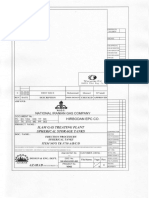

Demolition Notes: Mechanical Plan Demolition Plan

Uploaded by

walsarisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Demolition Notes: Mechanical Plan Demolition Plan

Uploaded by

walsarisCopyright:

Available Formats

MODIFY EXISTING GRAPHIC ANNUNICATOR! TO REFLECT CONDITIONS AT THE COMPLETION!

OF CONSTRUCTION

NEW LOCATION OF FLOOR MOUNTED ! 20 TON LIEBERT DS UNIT! EXTEND EXISTING REFRIGERENT, ! COLD WATER AND CONDENSATE ! PIPING AS REQUIRED! PROVIDE TOP MOUNTED! RETURN AIR SCOOP

NEW 2" SANITARY LINE TO MAIN, ! FOR CONTINUATION AND EXACT LOCATION ! SEE CIVIL ENGINEER SITE PLAN, ! MAINTAIN A MINIMUM OF 3'-6" COVER.

DEMOLITION NOTES

1.! EQUIPMENT INDICATED IN A DASHED LINE IS ! EXISTING TO BE REMOVED.! !! 2.! EQUIPMENT INDICATED IN A SOLID LINE IS ! EXISTING TO REMAIN OR BE RELOCATED.! !! 3.! WORK SHALL BE COMPLETED IN ACCORDANCE ! WITH THE PHASING SCHEDULE DEVELOPED BY ! THE GENERAL CONTRACTOR/CONSTRUCTION ! MANAGER.! !! 4.! WORK OUTSIDE THE DESIGNATED PHASE ZONES ! MAY BE REQUIRED TO BE COMPLETED DURING ! EARLY PHASES OF THE PROJECT. THE ! ELECTRICAL CONTRACTOR IS RESPONSIBLE FOR ! IDENTIFYING THAT WORK, COORDINATING WITH ! THE OWNER AND GENERAL ! CONTRACTOR/CONSTRUCTION MANAGER AND ! PROVIDING THAT WORK IN A TIMELY MANNER.! !! 5.! PRIOR TO START OF DEMOLITION, COORDINATE ! EXACT SCOPE AND EXTENT OF WORK WITH ! CONSTRUCTION MANAGER AND OWNERS ! REPRESENTITIVE.! !! 6.! WHERE EXISTING FACILITIES ARE BEING ALTERED, ! DISCONNECT AND REMOVE OR RELOCATE ALL ! EXISTING ELECTRICAL WORK THAT INTERFERES ! WITH OR IS NECESSARY BECAUSE OF NEW ! CONSTRUCTION AS SPECIFIED, SHOWN OR ! REQUIRED.! !! 7.! WHERE SPECIFIED OR REQUIRED, EXTEND ! EXISTING SYSTEMS OR TIE INTO SAME TO ! PROVIDE A COMPLETE COORDINATED ! MECHANICAL AND FIRE PROTECTIONSYSTEM TO ! SATISFACTION OF OWNER AND ARCHITECT.! !! 8.! PROVIDE ALL WORK NECESSARY TO PERMIT ! OPERATION OF ALL EXISTING SYSTEMS DURING ! THE CONSTRUCTION PERIOD. ! !! 9.! EXISTING EQUIPMENT OR SYSTEMS DAMAGED DURING CONSTRUCTION SHALL BE REPAIRED AND/OR REPLACED BY THE CONTRACTOR TO THE SATISFACTION OF THE ARCHITECT AND OWNER.!

(EX) FM200 EMERG. SHUTDOWN SW.

REMOVE OLD BUILDING FM200! BYPASS KEY SWITCHES. SINGLE! SWITCH TO REMAIN EXISTING FM 200 TANKS! TO BE REMOVED MODIFY OR REPLACE EXISTING ! FM200 CONTROL PANEL AS REQUIRED! DUE TO RENOVATION! MODIFY OR PREPLACE FM200 SYSTEM PIPING, ! CEILINGS HEADS, RAISED FLOOR HEADS, DETECTORS,! ETC AS REQUIRED TO PROVIDE A SINGLE BUILDING! PROTECTION SYSTEM EXISTING GRADE MOUNTED ! PACKAGED UNITS! TO BE REMOVED! REMOVE EXISTING DUCTWORK ! THERMSTATS AND CEILING ! DIFFUSERS AND GRILLES

S 1

CONNECT TO EXISTING! COLD WATER MAIN 1" BELOW RAISED FLOOR SK1 3/4"

DW 1

3"VENT UP ! THRU ROOF

A 4 300

HCU 1

ON ROOF

A 4 300

(EX) 1.5 TON ! SPLIT SYSTEM

WHERE EXISTING FIRE PROTECTION SYSTEM! PIPING IS TO REMAIN, RELOCATE AS REQUIRED! BY INSTALLATION OF NEW CABLE TRAY SYSTEMS

UNLESS OTHERWISE NOTED,! DISONNECT AND REMOVE ALL! MECHAINCAL, PLUMBING AND! FIRE PROTECTION SYSTEMS! FROM RENOVATION AREA

(EX) 1.5 TON ! SPLIT SYSTEM 3/4" BELOW! RAISED FLOOR EXISTING FLOOR MOUNTED ! LIEBERT DS UNIT! TO BE REMOVED! REMOVE EXISTING PIPING,! DUCTWORK AND CEILING! GRILLES

NEW EXHAUST ! DUCT UP! THROUGH ROOF, ! DUCT TO BE FULL ! SIZE OF OPENING. ! TERMINATE DUCT ! HIGH IN BATTERY ! ROOM WITH MESH ! SCREEN

DCU 1

ON ROOF

REFRIGERENT LINES TO PENETRATE EXTERIOR! WALL, RUN UP EXTERIOR WALL AND ALONG ROOF! TO OUTDOOR UNIT. MAXIMUM LENGTH AND! MINIMUM SIZE PER MANUFACTURERS REQUIREMENTS! (TYPICAL)

DCU 2

ON ROOF

DAC 1

EXISTING FLOOR MOUNTED ! 20 TON LIEBERT DS! UNIT TO BE RELOCATED! EXTEND EXISTING PIPING! AND CONTROL WIRING AS REQUIRED

EXISTING CONDENSER! TO BE REMOVED

EXISTING FM 200 TANKS! TO BE REMOVED

PROVIDE A HYDROGEN DETECTION AND! MONITORING SYSTEM. SYSTEM SHALL COVER! ENTIRE BATTERY ROOM.! THE MONITOR SHALL ALERT ON TWO LEVELS. ! THE FIRST SHALL SHALL CONTACT COMCAST ! WHEN THE HYDROGEN LEVEL IN THE BATTERY! ROOM REACHES 1 PERCENT. THE SECOND LEVEL ! SHALL SEND A SECOND SIGNAL TO COMCAST ! WHEN THE HYDROGEN LEVEL REACHES 2 PERCENT ! AND SHALL ENERGIZE EF-1 TO EVACUATE THE ! BATTERY ROOM.!

DCU 3

ON ROOF

DAC 2

48"x20" INTAKE LOUVER MOUNTED LOW IN EXISTING WALL. PROVIDE SECURITY BARS AND MOTOR OPERATED DAMPER INTERLOCKED WITH EF-1. PROVIDE CUTTING AND PATCHING AS REQUIRED

DAC 3

NEW LOCATION OF! FLOOR MOUNTED ! 20 TON LIEBERT DS UNIT! PROVIDE TOP MOUNTED! RETURN AIR SCOOP

FIRE SUPPRESSION NOTES

1.! THE FIRE PROTECTION CONTRACTOR SHALL BE ! RESPONSIBLE FOR THE CALCULATION, DESIGN ! APPROVAL, CONFORMANCE AND OPERATION OF ! THE SUPPRESSION SYSTEMS. THE PLACEMENT ! OF THIS INFORMATION ON THE DRAWINGS IS FOR ! IDENTIFICATION ONLY.! !! 2.! THE FIRE PROTECTION CONTRACTOR IS TO ! PROVIDE THE FIRE PROTECTION SYSTEM AS ! REQUIRED. HE IS SOLELY RESPONSIBLE TO ! PROVIDE A COMPLETE WORKING FIRE ! PROTECTION SYSTEM DESIGNED AND INSTALLED ! IN ACCORDANCE WITH NFPA 13, STATE AND ! LOCAL CODES, LANDLORD REQUIREMENTS, THE ! OWNER'S INSURANCE UNDERWRITER'S ! REQUIREMENT, AND AS REQUIRED BY THE LOCAL ! FIRE MARSHALL. ! !! 3.! THE AREA WITHIN THE SCOPE OF THIS PROJECT, ! INCLUDING FLOOR SPACE, IS TO BE 100% ! PROTECTED BY THE FIRE SUPPRESSION SYSTEM.! !! 4.! THE COMPLETE INSTALLATION SHALL INCLUDE ! THE FOLLOWING: TIE-IN TO THE BUILDING FIRE ! ALARM SYSTEM; ALL PIPE, VALVES, FITTINGS, ! HEADS, DETECTORS, WIRING AND CONTROLS; ! ALL INSERTS, HANGERS AND SUPPORTS FOR PIPE ! AND EQUIPMENT. ALL HANGERS AND INSERTS ! SHALL MEET THE APPROVAL OF ALL AUTHORITIES ! HAVING JURISDICTION.! !! 5.! THE CONTRACTOR SHALL PAY FOR PERMITS, ! INSPECTIONS, TESTS AND APPROVALS RELATED ! TO THE SYSTEM AS REQUIRED BY ALL ! AUTHORITIES HAVING JURISDICTION. THIS ! INCLUDES SUPPLYING ERECTION DRAWINGS TO ! THE ARCHITECT IN ACCORDANCE WITH THE ! GENERAL CONDITIONS AND THE MECHANICAL ! TRADE REQUIREMENTS OF THE PROJECT.! !! 6.! THE FM-200 SYSTEM SHALL BE FURNISHED WITH A ! (24V) DRY CONTACT. FM-200 ALARMS SHALL BE REPEATED TO THE OWNERS MONITORING SYSTEM.!

RELOCATE EXISTING! FM200 EMERG. SHUTDOWN SW.

CCU 1

ON ROOF

DC

FM200 EMERG. SHUTDOWN SW.! TO BE REMOVED

DC

(EX) FLOOR MOUNTED! 20 TON LIEBERT DS UNIT

EXISTING 3 TON MITSUBISHI! SPLIT SYSTEM TO BE REMOVED

(EX) FLOOR MOUNTED! 20 TON LIEBERT DS UNIT

CONDENSATE LINE, RUN BELOW ! RAISED FLOOR, FROM UNIT TO ! NEW SAFEWASTE AT SINK. LINE TO! BE FULL SIZE OF UNIT OPENING

CAC 1

(EX) FM200 EMERG. SHUTDOWN SW.

(EX) 5 TON LIEBERT! THRU-WALL AC UNITS

(EX) 5 TON LIEBERT! THRU-WALL AC UNITS

(EX) CONDENSER

(EX) CONDENSER

(EX) CONDENSER

(EX) CONDENSER

(EX) CONDENSER

(EX) CONDENSER

(EX) CONDENSER

(EX) CONDENSER

DEMOLITION PLAN

1/8" = 1'-0"

MECHANICAL PLAN

1/8" = 1'-0"

FM200 GRAPHIC ANNUNICATOR ! AND CONTROL PANEL!

NEW FM200! TANKS

HEAD END BUILDING FIRE PROTECTION SYSTEM SPECIFICATIONS

I. SCOPE - This specication outlines the requirements for an FM-200 total ooding re suppression system with automatic! D) Detectors - The detectors shall be spaced and installed in accordance with the manufacturers specications and within! detection and control and includes all requirements to monitor, supervise and control the system. The work described in this! the guidelines of NFPA No. 72 - 1993 edition.! specication includes all engineering, labor, materials, equipment and services necessary, and required, to complete and test the! ! suppression system.! E) Manual Release Switch - The manual release switch shall be a dual action device which provides a means of manually! ! discharging the FM-200 re suppression system when used in conjunction with the Fike Rhino Control System.! II. APPLICABLE STANDARDS AND PUBLICATIONS - The design, equipment, installation, testing and maintenance of the! ! FM-200 suppression system shall be in accordance with the applicable requirements set forth in the latest edition of the following! F) Abort Station - The Abort Station shall be the Dead Man type and shall be located next to each manual switch.! codes and standards:! ! ! G) Audible and Visual Alarms - Alarm signal devices shall operate from the FM-200 control panel.! 1) NFPA No. 2001 - Clean Agent Fire Extinguishing Systems! ! 2) NFPA No. 12 A - Halon 1301 Fire Extinguishing Systems! H) Caution/Advisory Signs - Provide signs as required to comply with NFPA 2001 and the recommendations of the FM-200! 3) NFPA No. 70 - National Electrical Code! equipment manufacturer.! 4) NFPA No. 72 - Standard for Protective Signaling! ! 5) NFPA No. 75 - Electronic Computer Systems! I) Auxiliary Panels - A Graphic Annunciator panel will be mounted adjacent to the FM-200 control panel. The graphic! 6) Factory Mutual Approval Guide! annunciator shall show a scale layout of the protected area and have indicator lamps to locate each system detector. The! 7) U.L. Listings! panel shall have a lamp test switch located on the panel face.! 8) Requirements of the Authority Having Jurisdiction (AHJ)! ! ! J) System and Control Wiring - All FM-200 system wiring shall be furnished and installed by the FM-200 system contractor.! The standards listed, as well as all other applicable codes and standards, shall be used as minimum design standards.! All wiring shall be installed in electrical metallic tubing (EMT) or conduit.! Also to be considered are the requirements of the Authority Having Jurisdiction and good engineering practices.! ! ! K) System Inspection and Checkout - After the system installation has been completed, the entire system shall be checked! III. QUALITY ASSURANCE:! out, inspected, and functionally tested by qualied trained personnel, in accordance with the manufacturers recommended! ! procedures and NFPA standards.! A. MANUFACTURER - The manufacturer of the FM-200 suppression system hardware and detection components shall have a! ! minimum of 10 years experience in the design and manufacture of similar types of suppression systems and who can refer to! L) Training Requirements - Prior to nal acceptance, the installing contractor shall provide operational training to each shift! similar installations providing satisfactory service. The name of the manufacturer, part numbers and serial numbers shall appear on! of the Owners personnel. Each training session shall include system control panel operation, manual and abort functions, trouble! all major components. All devices, components and equipment shall be the products of the same manufacturer. All devices,! procedures, auxiliary functions and emergency procedures.! components and equipment shall be new and standard products of the manufacturers latest design, suitable to perform the! ! functions intended. All devices and equipment shall be U.L. listed and/or FM approved. Locks for all cabinets shall be keyed alike.! M) Operation and Maintenance - Prior to nal acceptance, the installing contractor shall provide complete operation and! ! maintenance instruction manuals, four (4) copies for each system, to the owner. All aspects of system operation and maintenance! B. INSTALLER - The installing contractor shall be trained by the manufacturer to design, install, test and maintain FM-200 re! shall be detailed, including piping isometrics, wiring diagrams of all circuits, a written description of the system design, sequence of! suppression systems. The installing contractor shall employ a NICET certied special hazard designer, level 2 or above, who will! operation, drawing(s) illustrating control logic, and equipment used in the system. Checklists and procedures for emergency! be responsible for this project. The installing contractor shall be an experienced rm regularly engaged in the installation of! situations, trouble shooting techniques, and maintenance operations and procedures shall be included in the manual.! automatic FM-200 or similar, re suppression systems in strict accordance with NFPA standards. The installing contractor must! ! have a minimum of ve (5) years experience in the design, installation and testing of FM-200, or similar, re suppression systems.! N) As-Built Drawings - The contractor shall provide and maintain in good order a complete set of blueline prints of the contract drawings.! As the work progresses, the actual location of all work shall be clearly recorded, including all changes to the contract and equipment size and type.! A list of systems of a similar nature and scope shall be provided on request. The installing contractor shall show evidence that his! These prints shall be available at the site for inspection at all times. At the conclusion of the work, the contractor shall, at his own expense, obtain! company carries a minimum $2,000,000 liability and completed operations insurance policy. These limits shall supersede the! a set of reproducibles of the original contract drawings, and utilizing the symbols on the contract drawings, shall incorporate all "as built" data in a! general conditions of the specications. The installing contractor shall have an FM-200 recharging station. The installing contractor! clearly legible and reproducible manner. All schedules shall be corrected to indicate "as built" conditions. All revisions shall be incorporated on! shall provide proof of his ability to recharge the largest FM-200 system within 24 hours after a discharge. Include the amount of! these reproducibles including all sketches and written directives. Electronic/CADD as-built's shall be provided at the completion of the project.! FM-200 bulk storage available. The installing contractor shall be an authorized stocking distributor of the FM-200 system! Contractor shall update all affected oor plans, riser diagrams and details. Contractor shall provide to the landlord a complete updated CADD le! manufacturer so that immediate replacement parts are available from inventory. The installing contractor shall show proof of! on compact disk and 1 set of reproducibles of the updated system drawings.! emergency service available on a twenty-four hour, seven days a week basis; service personnel shall be available for emergency! ! service response at all times.! O) Acceptance Tests - At the time As-Built drawings and maintenance/operations manuals are submitted, the installing! ! contractor shall submit a Test Plan describing procedures to be used to test the FM-200 system(s). The Test Plan shall include! C. SUBMITTALS - Submit drawings, calculations and system component data sheets for approval to the Local Fire Prevent Bureau,! a step-by-step description of all tests to be performed and shall indicate the type and location of test apparatus to be employed.! Owners Insurance Underwriter and all other Authorities Having Jurisdiction between starting installation. Submit approved plans to! The tests shall demonstrate that the operational and installation requirements of this specication have been met. All tests shall! the Architect/Engineer for record.! be conducted in the presence of the Owner and shall not be conducted until the Test Plan has been approved.! ! ! IV. MATERIALS AND EQUIPMENT:! P) FM-200 System Inspections - The installing contractor shall provide two (2) inspections of each FM-200 system, installed! ! under this contract, during the one-year warranty period. The rst inspection shall be at the six month interval, and the second! A) GENERAL REQUIREMENTS - The FM-200 System materials and equipment shall be standard products of the manufacturers! inspection shall be at the twelve month intervals after system acceptance. Inspections shall be conducted in accordance with! latest design and suitable to perform the functions intended. When one or more pieces of equipment must perform the same! the manufacturers guidelines and shall comply with the recommendations of NFPA.! functions, they shall be duplicates produced by one manufacturer. All devices and equipment shall be U.L. Listed and/or F.M. approved.! ! ! Q) Warranty - All Fike FM-200 system components furnished, and installed under this contract, shall be guaranteed against! B) FM-200 Storage and Distribution - Each system shall have its own supply of FM-200 agent.! defects in design, materials and workmanship for the full warranty period which is standard with the manufacturer, but in no case! ! less than one (1) year from the date of system acceptance. C) Control Panel (VERIFY WITH OWNER) - The Control System and components shall be U.L. Listed and F.M. approved for use ! as a local re alarm system.

MODIFY OR PREPLACE FM200 SYSTEM PIPING, ! CEILINGS HEADS, RAISED FLOOR HEADS, DETECTORS,! ETC AS REQUIRED TO PROVIDE A SINGLE BUILDING! PROTECTION SYSTEM PROVIDE A NEW COMPLETE FM200 SYSTEM IN THIS AREA! CONNECT WITH REMAINDER OF BUILDING TO PROVIDE A ! SINGLE BUILDING PROTECTION SYSTEM

(EX) EXISTING FM200 EMERG. ! SHUTDOWN SWITCH RELOCATED

DC

SCALE: DATE:

MECHANICAL! FLOOR PLANS

FIRE SUPPRESSION PLAN

1/8" = 1'-0"

COMCAST EAST NORRITON RENOVATION

237 West Germantown Pike

East Norriton, PA

REVISIONS

AS NOTED 03 NOV 2011

M-1

TEL:(215)755-9318 FAX:(215)755-9319

HP 1

1812 SOUTH 22nd STREET PHILADELPHIA, PA. 19145

(EX) FLOOR MOUNTED! 20 TON LIEBERT DS UNIT

(EX) FLOOR MOUNTED! 20 TON LIEBERT DS UNIT

EF 1

BHG CONSULTING, INC.

26x6

10x12

MASSOTT

6X6 OUTSIDE AIR DUCT THROUGH WALL! WITH CAP. CONNECT TO RETURN DUCT WITH! AUTOMATIC AND MANUAL DAMPERS, INTERLOCK! AUTOMATIC DAMPER WITH UNIT

D E S I G N C O N S U L T A N T S, I N C. 1034 TWIN SILO LANE, HUNTINGDON VALLEY, PA 19006 215-325-0994 massottdesign@comcast.net

You might also like

- Residential Wiring GuideDocument32 pagesResidential Wiring Guideband12No ratings yet

- Electrical Load Schedule AppendixDocument4 pagesElectrical Load Schedule AppendixOmid TajikNo ratings yet

- RasGas Barzan Onshore Project Revision Description FormDocument40 pagesRasGas Barzan Onshore Project Revision Description FormJayce PinedaNo ratings yet

- Grounding and earthing system diagramDocument1 pageGrounding and earthing system diagramdharuNo ratings yet

- Control Scheme For Acb Bus-Coupler - PMCC - (Dae)Document15 pagesControl Scheme For Acb Bus-Coupler - PMCC - (Dae)AVIJIT MITRANo ratings yet

- Electrical BoqDocument29 pagesElectrical BoqPaulthiyagaraj SNo ratings yet

- HVAC Wiring DrawingDocument30 pagesHVAC Wiring Drawing王祚No ratings yet

- Busbar Rating TableDocument1 pageBusbar Rating TableRa ArNo ratings yet

- SS-1 Deep Well Earth PitDocument1 pageSS-1 Deep Well Earth PitM&N ProjectsNo ratings yet

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8wibowo wibowoNo ratings yet

- Vol.1 (CH 00 - CH 31)Document605 pagesVol.1 (CH 00 - CH 31)versineNo ratings yet

- 1st Floor DrawingsDocument1 page1st Floor DrawingsBedan KivuvaNo ratings yet

- Bom Main Outdoor Panel 1Document1 pageBom Main Outdoor Panel 1Hytech Pvt. Ltd.No ratings yet

- Erection, Testing, Commissioning, Trial OperationDocument131 pagesErection, Testing, Commissioning, Trial OperationTufan Maity100% (1)

- Shuqaiq Steam Power Plant: OwnerDocument441 pagesShuqaiq Steam Power Plant: OwnerAaqib MujtabaNo ratings yet

- 7) - Procedure FRP Tank InstallationDocument34 pages7) - Procedure FRP Tank Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- CommentsDocument10 pagesCommentsVarun GuptaNo ratings yet

- Form Cost EstimateDocument2 pagesForm Cost Estimatechompink6900No ratings yet

- LPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ADocument11 pagesLPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ARadhaNo ratings yet

- Electrical Unpriced BOQ-23 07 2019Document13 pagesElectrical Unpriced BOQ-23 07 2019Mitesh KhandwalaNo ratings yet

- EMC Cloud Security Risks and RecommendationsDocument32 pagesEMC Cloud Security Risks and RecommendationsDuy LươngNo ratings yet

- A2 SLD Electrical LTDocument1 pageA2 SLD Electrical LTArvind JainNo ratings yet

- Control Cable ScheduleDocument25 pagesControl Cable Scheduleshrikanth5singhNo ratings yet

- Electrical Tender SpecficationDocument40 pagesElectrical Tender SpecficationtrivedimechNo ratings yet

- Equipment Master in SAP PMDocument6 pagesEquipment Master in SAP PMMarco Antônio Claret TeixeiraNo ratings yet

- Electrical SpecificationsDocument4 pagesElectrical Specificationsjoe rommel riveraNo ratings yet

- Mastering ROS For Robotics Programming - Sample ChapterDocument65 pagesMastering ROS For Robotics Programming - Sample ChapterPackt PublishingNo ratings yet

- Enquiry For HT PANELDocument5 pagesEnquiry For HT PANELPrasenjit MaityNo ratings yet

- KNT 001 GE ST3 SP 005 - 0 - Specification For Wood MaterialsDocument14 pagesKNT 001 GE ST3 SP 005 - 0 - Specification For Wood MaterialsvamcodongNo ratings yet

- 303fg-2-V3.3-User Manual-20220914-1Document23 pages303fg-2-V3.3-User Manual-20220914-1Carlos MontalvanNo ratings yet

- An Introduction To Artificial Intelligence For Federal JudgesDocument102 pagesAn Introduction To Artificial Intelligence For Federal Judgescopias napolesNo ratings yet

- Cable alley and panel door elevation viewsDocument1 pageCable alley and panel door elevation viewsHytech Pvt. Ltd.No ratings yet

- 1 Steam Engine Generator Capacity Calculation 3.9.1 Normal OperationDocument31 pages1 Steam Engine Generator Capacity Calculation 3.9.1 Normal OperationIlham Rahmat KurniaNo ratings yet

- Fresh Air Handling Unit Control with Lonix ModulesDocument6 pagesFresh Air Handling Unit Control with Lonix ModuleswalsarisNo ratings yet

- Boiler Cable Tray RoutingDocument43 pagesBoiler Cable Tray RoutingJitendra DubeyNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- Spec For 415v MCC, MLDBDocument58 pagesSpec For 415v MCC, MLDBzalziza100% (1)

- KNT 001 GE ST3 SP 002 - 0 - Specification For Rubber MaterialDocument13 pagesKNT 001 GE ST3 SP 002 - 0 - Specification For Rubber MaterialvamcodongNo ratings yet

- NCP MCI 6.5 - DumpsbaseDocument61 pagesNCP MCI 6.5 - Dumpsbasemahmoudkerdieh1100% (1)

- KNT 001 GE ST3 SP 003 - 0 - Specification For Structural Steel MaterialsDocument34 pagesKNT 001 GE ST3 SP 003 - 0 - Specification For Structural Steel MaterialsvamcodongNo ratings yet

- York AHUDocument84 pagesYork AHUCCIgal60% (5)

- GVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantDocument15 pagesGVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantRohit100% (1)

- Reference TG - Cable ScheduleDocument21 pagesReference TG - Cable Scheduleerkamlakar2234No ratings yet

- IdentificationDocument1 pageIdentificationctoujagueNo ratings yet

- Fike Fm-200 With SHP ProDocument8 pagesFike Fm-200 With SHP ProGovinda GopinathNo ratings yet

- Fire Detection and Fm-200 Suppression SystemDocument11 pagesFire Detection and Fm-200 Suppression SystemNelson P. ColoNo ratings yet

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Document7 pagesTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument11 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Elec Cold Test - Smdb-Roof AtkinsDocument2 pagesElec Cold Test - Smdb-Roof AtkinsNabilBouabanaNo ratings yet

- Spero Split AC Option - 1 QuoteDocument18 pagesSpero Split AC Option - 1 QuotesperoNo ratings yet

- MAK MEP Drawing ListDocument11 pagesMAK MEP Drawing ListkenjoshiNo ratings yet

- Installation and Operating Manual For Pneumatic Control ValvesDocument1 pageInstallation and Operating Manual For Pneumatic Control ValvesFairos ZakariahNo ratings yet

- RM Install Maunal WebDocument63 pagesRM Install Maunal WebArthur Guilherme Fritscher Griesang100% (1)

- Attachment 12.4 - QA - QC Checklist - FDBDocument3 pagesAttachment 12.4 - QA - QC Checklist - FDBehteshamNo ratings yet

- Distribution Substation Design Code of PracticeDocument95 pagesDistribution Substation Design Code of PracticeKei WongNo ratings yet

- Bureau of Design: Schedule of Loads and Computations: General NotesDocument1 pageBureau of Design: Schedule of Loads and Computations: General NotesJuan IstilNo ratings yet

- Air foam chamber data sheetDocument1 pageAir foam chamber data sheetPinjala AnoopNo ratings yet

- Pressure Vacuum Relief Valve Flame Arrester 102Document3 pagesPressure Vacuum Relief Valve Flame Arrester 102vikramNo ratings yet

- EE Project MapuaDocument9 pagesEE Project MapuaGlenn Midel Delos SantosNo ratings yet

- Tanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Document2 pagesTanque de Almacenamiento para Espuma (ACERO AL CARBÓN) OPCION 1Paulo MaresNo ratings yet

- Check List For Design EngineerDocument1 pageCheck List For Design Engineerphalkejitu1No ratings yet

- Electrical Wiring EstimateDocument17 pagesElectrical Wiring EstimateTahameeali ShaikhNo ratings yet

- Electrical Load Schedule Al Mouj Business Park BL-03Document27 pagesElectrical Load Schedule Al Mouj Business Park BL-03Vinay PallivalppilNo ratings yet

- Cable Tray DATA SHEETDocument1 pageCable Tray DATA SHEETmuqtar100% (1)

- Dokumen - Tips Spherical Tanks Erection ProcedureDocument9 pagesDokumen - Tips Spherical Tanks Erection ProcedureAhmad Tedjo RukmonoNo ratings yet

- Tender For ElectricalDocument104 pagesTender For ElectricalbalabhaviniNo ratings yet

- 132KVF 1Document29 pages132KVF 1MeenakshiNo ratings yet

- Crane Specs - L. M. Handling - Sms Shed - 16.5 M SpanDocument12 pagesCrane Specs - L. M. Handling - Sms Shed - 16.5 M SpanekisangleNo ratings yet

- Karet Single - Line A1Document1 pageKaret Single - Line A1priyoNo ratings yet

- C9709 Foam ChamberDocument1 pageC9709 Foam Chamberkalimutu2010No ratings yet

- Technical Submittal For Transformer PDFDocument13 pagesTechnical Submittal For Transformer PDFBajibabu ProdduturiNo ratings yet

- B. 120/240-Volt, 3-Wire Service: 10 HandbookDocument1 pageB. 120/240-Volt, 3-Wire Service: 10 HandbookwalsarisNo ratings yet

- B. 120/240-Volt, 3-Wire Service: 10 HandbookDocument1 pageB. 120/240-Volt, 3-Wire Service: 10 HandbookwalsarisNo ratings yet

- Wiring Handbook 7Document1 pageWiring Handbook 7walsarisNo ratings yet

- C. 120/208-Volt or 277/480-Volt, 4-Wire, Wye Connected ServiceDocument1 pageC. 120/208-Volt or 277/480-Volt, 4-Wire, Wye Connected ServicewalsarisNo ratings yet

- Wiring Handbook 4Document1 pageWiring Handbook 4walsarisNo ratings yet

- Report Outages and Service Issues with SPEC Co-opDocument1 pageReport Outages and Service Issues with SPEC Co-opwalsarisNo ratings yet

- Wiring Handbook 5Document1 pageWiring Handbook 5walsarisNo ratings yet

- Electrical Service & Wiring Installation Handbook: (806) 775-7732 Lubbock (806) 271-3311 Spur (940) 937-2565 ChildressDocument1 pageElectrical Service & Wiring Installation Handbook: (806) 775-7732 Lubbock (806) 271-3311 Spur (940) 937-2565 ChildresswalsarisNo ratings yet

- The Light Chapter-1Document259 pagesThe Light Chapter-1walsarisNo ratings yet

- Electric Service and Wiring: Installation HandbookDocument1 pageElectric Service and Wiring: Installation HandbookwalsarisNo ratings yet

- Numbers WorksheetsDocument9 pagesNumbers WorksheetswalsarisNo ratings yet

- Esserbus Transponder eDocument4 pagesEsserbus Transponder eFlorin FlorinNo ratings yet

- Know YourselfDocument1 pageKnow YourselfwalsarisNo ratings yet

- SO - in Top 10 - Construction Week 070510Document3 pagesSO - in Top 10 - Construction Week 070510walsarisNo ratings yet

- StandardCADDetails 002Document3 pagesStandardCADDetails 002walsarisNo ratings yet

- Comptia A+ (2009 Edition) Bridge Exam Objectives Exam Number: Br0-003Document17 pagesComptia A+ (2009 Edition) Bridge Exam Objectives Exam Number: Br0-003Ray ConferNo ratings yet

- RL & RC CircuitsDocument59 pagesRL & RC CircuitsPhan Phuong NgocNo ratings yet

- Anti Bag Snatching AlarmDocument1 pageAnti Bag Snatching Alarmharivandanam1989No ratings yet

- k350 Users GuideDocument40 pagesk350 Users GuidemgscrkNo ratings yet

- Joysticks Series CJDocument6 pagesJoysticks Series CJFolkwin LapNo ratings yet

- Souvik Ghosh - ResumeDocument2 pagesSouvik Ghosh - ResumeAnonymous 5XUZZE7No ratings yet

- University Competency Model PDFDocument8 pagesUniversity Competency Model PDFodescribdNo ratings yet

- Road Safety Strategy: Dr. Md. Jahir Bin AlamDocument18 pagesRoad Safety Strategy: Dr. Md. Jahir Bin AlamMd Habibur RahmanNo ratings yet

- Scorpius SRT 60 ROW Tracker DatasheetDocument4 pagesScorpius SRT 60 ROW Tracker DatasheetPhani ArvapalliNo ratings yet

- LJQHelp PaletteDocument2 pagesLJQHelp PaletteMuhammad AwaisNo ratings yet

- Control System Design Process by VisSimDocument6 pagesControl System Design Process by VisSimSreedhar MadichettyNo ratings yet

- RTI Information HandbookDocument179 pagesRTI Information Handbookcol.asyadavNo ratings yet

- Final ExamDocument3 pagesFinal Examjohn francisNo ratings yet

- BPSK, QamDocument6 pagesBPSK, QamYassine El HadakNo ratings yet

- Headlight Door AutoDocument4 pagesHeadlight Door AutoToua YajNo ratings yet

- Silnik A490 XinchaiDocument40 pagesSilnik A490 XinchaiTomaszNo ratings yet

- SEO-OPTIMIZED TITLE FOR P180P2/P200E2 GENERATOR SPECIFICATIONSDocument4 pagesSEO-OPTIMIZED TITLE FOR P180P2/P200E2 GENERATOR SPECIFICATIONSMH..2023No ratings yet

- Multitrack HistoryDocument5 pagesMultitrack HistoryMatt GoochNo ratings yet

- How To Perform Live Domain Migration On LDOM - Oracle VM SPARC - UnixArenaDocument1 pageHow To Perform Live Domain Migration On LDOM - Oracle VM SPARC - UnixArenarasimNo ratings yet

- The Benefits ofDocument6 pagesThe Benefits ofarindaNo ratings yet

- KDH 800 EngDocument1 pageKDH 800 EngAndy MonrroyNo ratings yet

- Automatic Transmission / Trans: PreparationDocument2 pagesAutomatic Transmission / Trans: PreparationRodrigo RubioNo ratings yet