Professional Documents

Culture Documents

Check List Roll Handling System - Tissue Line

Uploaded by

DinhnamsgpOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List Roll Handling System - Tissue Line

Uploaded by

DinhnamsgpCopyright:

Available Formats

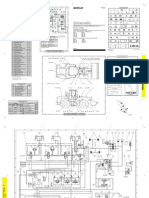

Check list motor For ROLL HANDLING SYSTEM (TISSUE LINE)

motor and power section, machine motor no. designation

power kW I(nom) A rpm 1/min voltage V Freq. Hz type of starter type of drive

Daily 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Remark

1 2 3 4 5 6 7 8 9 10

Traveling Shuttle motor Hydraulic kicker Hydraulic pump motor Turn table motor Turn table roller motor Wrapper head motor Wrapper up/down motor Turn table hydraulic pump motor Hydraulic elevator Hydraulic pump motor Elevator 1F door motor Elevator 2F door motor

1.5 5.5 5.5 2.2 0.75 0.37 2.2 15 0.37 0.37 33.76 kw

400 400 400 400 400 400 400 400 400 400

50 50 50 50 50 50 50 50 50 50

VSD DOL VSD VSD VSD VSD DOL SOFT REV REV

Pulse generator repeater

Pulse generator repeater Pulse generator repeater

Pulse generator repeater

Pulse generator repeater

total no of motors:

Thc hin

Kim tra

Type of starter: CB = Circuit breaker general DOL = Direct online starting circuit FUSE = Fuse feeder REV = Direct online reversing circuit SOFT = Soft starting VSD = Variable speed drive SD = Star/Delta starting circuit HS = Heavy Starter GFS = Frequency

Type of drive: FR= flat belt KR= V-belt dK = direct coupling GK= gearbox coupling TB = toothed belt GM = gear motor GB = gearbox belt sG = slip on gear

Phan Ngoc Tu

HS = Heavy Starter GFS = Frequency

motor and power section, machine motor no. designation

power kW I(nom) A rpm 1/min voltage V Freq. Hz type of starter type of drive

GB = gearbox belt sG = slip on gear

Daily 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Remark

Phan Ngoc Tu

D D D D D D D D D D

Phan Ngoc Tu

Phan Ngoc Tu

Check MCC FOR ROLL HANDLING SYSTEM (TISSUE LINE)

No. Device Nr & P(KW) Description Device CB_NFB1 1 M1 - Traveling Cont._MC1 Shuttle motor Bin tn-INVERTER1 1.5KW R le kin Dng in CB_NFB2 M2 - Hydraulic Cont._MC2 kicker Hydraulic R le nhit_EOCR2 pump motor R le kin 5.5KW Dng in CB_NFB3 3 M3 - Turn table Bin tn-INVERTER2 motor 5.5KW R le kin Dng in CB_NFB4 4 M4 - Turn table Cont._MC4 roller motor Bin tn-INVERTER3 2.2KW R le kin Dng in CB_NFB5 5 M5 - Wrapper head motor 0.75KW Cont._MC5 Bin tn-INVERTER4 R le kin Dng in ABS33/5AT GMC9 SV008iG5 - 4 ABS33/15AT GMC9 SV022iG5 - 4 Cont._MC3 ABS33/30AT GMC18 SSD Type & Manufacturer ABS33/10AT GMC9 SV015iG5 - 4 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Daily 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

ABS33/30AT GMC18 SV055iG5 - 4

Ngi thc hin

Ngi kim tra

Ghi ch: Mi thng thc hin cng vic trn 1 ln. X Binh thng O Khng binh thng HC Hiu chinh SC Sa cha TT Thay th

Phan Ngoc Tu

Check MCC FOR ROLL HANDLING SYSTEM (TISSUE LINE)

No. Device Nr & P(KW) Description Device CB_NFB6 M6 - Wrapper up/down motor 0.37KW Cont._MC6 Bin tn-INVERTER5 R le kin Dng in CB_NFB7 M7 - Turn table hydraulic pump motor 2.2KW Cont._MC7 R le nhit_EOCR7 R le kin Dng in CB_NFB8 M8 - Hydraulic elevator Hydraulic pump motor 15KW Cont._MC8 Softstarter R le kin Dng in CB_NFB9 M9 - Elevator 1F door motor 0.37KW Cont._MC9F (2pcs) R le nhit_EOCR9 R le kin Dng in CB_NFB10 M10 - Elevator 2F door motor 0.37KW Cont._MC10F (2pcs) R le nhit_EOCR10 R le kin Dng in ABS33/5AT GMC9R SSD ABS33/5AT GMC9R SSD ABS103/100AT GMC40 ATS01232QN ABS33/20AT GMC12 SSD Type & Manufacturer ABS33/5AT GMC9 SV004iG5 - 4 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Daily 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Ngi thc hin

Ngi kim tra

Ghi ch: Mi thng thc hin cng vic trn 1 ln. X O HC SC TT Binh thng Khng binh thng Hiu chinh Sa cha Thay th

Phan Ngoc Tu

CHECK LIST_INVERTER FOR ROLL HANDLING SYSTEM (TISSUE LINE) Ngi thc hin : ..

Ngi .. kim tra : Motor Motor Nom Nom Current Volts Day. . . . . . . . . 1 2 Day. . . . . . . . . 1 2 Day. . . . . . . . . 1 2 Day. . . . . . . . . 1 2 Day. . . . . . . . . 1 2 Day. . . . . . . . . Remark 1 2

No.

Device Nr.

Description Position

P(KW)

Check (Parameter)

Output frequency (Hz) Speed (Rpm) Current (A) Torque (%)

SV015iG5 - 4

Traveling Shuttle motor

1.5

400

Power (%) Motor voltage (V) DC-link voltage (V) Unit tempertaure ( C ) MotorTempCalc (%) Output frequency (Hz) Speed (Rpm) Current (A) Torque (%)

O

SV055iG5 - 4

Turn table motor

5.5

400

Power (%) Motor voltage (V) DC-link voltage (V) Unit tempertaure ( OC ) MotorTempCalc (%) Output frequency (Hz) Speed (Rpm) Current (A) Torque (%)

SV022iG5 - 4

Turn table roller motor

2.2

400

Power (%) Motor voltage (V) DC-link voltage (V) Unit tempertaure ( OC ) MotorTempCalc (%)

Output frequency (Hz) Speed (Rpm) Current (A) Torque (%) 4 SV008iG5 - 4 Wrapper head motor 0.75 400 Power (%) Motor voltage (V) DC-link voltage (V) Unit tempertaure ( OC ) MotorTempCalc (%)

Output frequency (Hz)

Phan Ngoc Tu

5 SV004iG5 - 4 Wrapper up/down motor 0.37 400

Ngi thc hin :

..

Speed (Rpm) Current (A) Torque (%)

SV004iG5 - 4

Wrapper up/down motor

0.37

400

Power (%) Motor voltage (V) DC-link voltage (V) Unit tempertaure ( OC ) MotorTempCalc (%)

Output frequency (Hz) Speed (Rpm) Current (A) Torque (%) 6 Softstarter ATS01232QN Hydraulic elevator Hydraulic pump motor 1.5 400 Power (%) Motor voltage (V) DC-link voltage (V) Unit tempertaure ( OC ) MotorTempCalc (%)

Thc hin

Kim Tra

Ghi ch: Mi thng thc hin cng vic trn 1 ln.

X O HC SC TT Binh thng Khng binh thng Hiu chinh Sa cha Thay th

Phan Ngoc Tu

MAINTENANCE INVERTER FOR ROLL HANDLING SYSTEM (TISSUE LINE)

No. Device Nr. Type & Manufacturer Action job

1) Check the input and output terminals and control I/O-terminals. SV015iG5 - 4 Traveling Shuttle motor 1.5KW 2) Clean the cooling tunnel, external surfaces LG 3)Check operation of cooling fan, check for corrosion on terminals, busbars and other surfaces. 4)Check the door filters in the case of cabin installation. 1) Check the input and output terminals and control I/O-terminals. SV055iG5 - 4 Turn table motor 5.5KW 2) Clean the cooling tunnel, external surfaces LG 3)Check operation of cooling fan, check for corrosion on terminals, busbars and other surfaces. 4)Check the door filters in the case of cabin installation. 1) Check the input and output terminals and control I/O-terminals. SV022iG5 - 4 Turn table roller motor 2.2KW 2) Clean the cooling tunnel, external surfaces LG 3)Check operation of cooling fan, check for corrosion on terminals, busbars and other surfaces. 4)Check the door filters in the case of cabin installation. 1) Check the input and output terminals and control I/O-terminals. 2) Clean the cooling tunnel, external surfaces LG 3)Check operation of cooling fan, check for corrosion on terminals, busbars and other surfaces. 4)Check the door filters in the case of cabin installation. 1) Check the input and output terminals and control I/O-terminals. 2) Clean the cooling tunnel, external surfaces LG 3)Check operation of cooling fan, check for corrosion on terminals, busbars and other surfaces. 4)Check the door filters in the case of cabin installation. 1) Check the input and output terminals and control I/O-terminals. Softstarter ATS01232QN Hydraulic elevator Hydraulic pump motor 1.5KW 2) Clean the cooling tunnel, external surfaces LG 3)Check operation of cooling fan, check for corrosion on terminals, busbars and other surfaces. 4)Check the door filters in the case of cabin installation.

Months (note day) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

SV008iG5 - 4 Wrapper head motor 0.75KW

SV004iG5 - 4 Wrapper up/down motor 0.37KW

Phan Ngoc Tu

MAINTENANCE INVERTER FOR ROLL HANDLING SYSTEM (TISSUE LINE)

No. Device Nr. Type & Manufacturer Action job Months (note day)

Thc hin

`Kim tra

Ghi ch: Mi thng thc hin cng vic trn 1 ln.

X O HC SC TT Binh thng Khng binh thng Hiu chinh Sa cha Thay th

Phan Ngoc Tu

MAINTENANCE INVERTER FOR ROLL HANDLING SYSTEM (TISSUE LINE)

No. Device Nr. Type & Manufacturer Action job Months (note day)

Phan Ngoc Tu

Phan Ngoc Tu

Phan Ngoc Tu

Phan Ngoc Tu

Check List For Roll handling system_Tissue line

Tn my Stt Tn & chc nng thit b 1 PLC & I/0 card 1 Loadcell data 2 Key_ control power on/off 3 SS_mode select 4 PBL(G)_Run ready 5 PBL(G)_Cycle start 6 PBL(R)_Cycle stop 7 PB(B)_Lamp test 8 PB(B)_Buzzer stop 9 PB(Y)_Fault reset 10 SPB_Shuttle Fwd/Ret 11 SPB_HYD kicker Fwd/Ret 12 SPB_Elevator up/down 13 SPB_Graddle up/down 14 SPB_1F DOOR up/down 15 SPB_2F DOOR up/down 16 EPB_2F _Emergency stop 17 DIP SWITCH_WRAPPING COUNT Q02H_CPU BS-7200 AR30-JR KSL-30S2 KBL-30MP(G) KBL-30MP(G) KBL-30MP(R) KPB-30M(B) KPB-30M(B) KPB-30M(Y) KH-3130 KH-3130 KH-3130 KH-3131 KH-3132 KH-3133 KPB-30ER-R11 A7PS-206 RV24YN20S KH-3011 KH-513DL(G) KH-3008.(R) KH-3008(B) KH-3008(B) KH-3008(Y) KH-3130 Model Hng sn xut SL 1 Mitsubishi BONGSHIN Fuji KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO OMRON COSMOS KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO KOINO 1 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 DaiLy 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

18 VOLUME_TURN TABLE SPEED 19 SS_MODE SELECT 20 PBL(G)_WRAPPING START 21 PB(R)_WRAPPING STOP 22 PB(B) LAMP TEST 23 PB(B) BUZZER STOP 24 PB(Y) FAULT RESET SPB TURN TABLE 25 TURN/RETURN

26 SPB T/T ROLLER TURN/RETURN KH-3131 SPB WRAPPER HEAD 27 TURN/RETURN 28 SPB WRAPPER UP/DOWN KH-3132 KH-3133

Tn my

Stt Tn & chc nng thit b

Model

Hng sn xut SL 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

DaiLy 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

29 SPB PUSHER UP/DOWN 30 SPB RECIEVE UP/DOWN 31 SPB KICKER UP/DOWN 32 EPB EMERGENCY STOP 33 34 35 36 37 38 39 PX300 (Proximity) PUSHER DOWN SENSING PX301 (Proximity) PUSHER UP SENSING PX302 (Proximity) RECIEVE DOWN SENSING PX303 (Proximity) RECIEVE UP SENSING PX304 (Proximity) KICKER DOWN SENSING PX305 (Proximity) KICKER UP SENSING PH306 (Photo sensor) T/T WORK SENSING

KH-3134 KH-3135 KH-3136 KH-3046-ER

KOINO KOINO KOINO KOINO

40 SOL320 solenoid valve _PUSHER 41 SOL321 solenoid valve _PUSHER 42 SOL322 solenoid valve RECEIVE 43 SOL323 solenoid valve RECEIVE 44 SOL324 solenoid valve KICKER 45 SOL325 solenoid valve KICKER SOL370 HYD' KICKER RETURN SOL V/V SOL371 HYD' KICKER 47 FORWARD SOL V/V SOL372 ELEVATOR DOWN SOL 48 V/V 46 49 SOL373 ELEVATOR UP SOL V/V 50 51 52 53 54 SOL374 ELEVATOR SLOW DOWN SOL V/V SOL375 ELEVATOR SLOW UP SOL V/V SOL376 CRADDLE RETURN SOL V/V SOL377 CRADDLE FORWARD SOL V/V PX340 SHUTTLE ENCORDER RESET

55 PH341 SHUTTLE WORK SENSING PX344 KICKER RETURN SENSING PX345 KICKER FORWARD 57 SENSING PH34C ELEVATOR INSIDE 58 WORK SENSING PH34D ELEVATOR OUTSIDE 59 WORK SENSING 56

Tn my

Stt Tn & chc nng thit b LS34E ELEVATOR DOWN SENSING LS34F ELEVATOR DOWN LOW 61 SPEED SENSING LS350 ELEVATOR UP LOW 62 SPEED SENSING 60 63 LS351 ELEVATOR UP SENSING LS352 ELEVATOR CHAIN CUT CHECK 1 LS353 ELEVATOR CHAIN CUT 65 CHECK 2 LS354 CRADDLE RETURN 66 SENSING LS355 CRADDLE FORWARD 67 SENSING 64 68 LS356 1F DOOR UP SENSING 69 LS357 1F DOOR DOWN SENSING 70 LS358 2F DOOR UP SENSING 71 LS359 2F DOOR DOWN SENSING 72 PX35A CRADDLE MIDDLE SENSING Rotary encoder: Power: 12-24 vdc

Model

Hng sn xut SL 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

DaiLy 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

73

Model: E80H32-512-3-N-24 Lot no: LD20 Power: 12-24 vdc

74 75

Ngi thc hin

Xc nhn ca xng sn xut

Ghi ch: Thc hin cng vic trn 1 ln/ngy. X O HC SC TT Binh thng Khng binh thng Hiu chinh Sa cha Thay th

You might also like

- SubaruDocument4,983 pagesSubarucalseamaster67% (3)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsFrom EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo ratings yet

- Control Valve Specification and Sizing DetailsDocument34 pagesControl Valve Specification and Sizing DetailsRahulTewari67% (3)

- Automotive Milestones: The Technological Development of the Automobile: Who, What, When, Where, and How It All WorksFrom EverandAutomotive Milestones: The Technological Development of the Automobile: Who, What, When, Where, and How It All WorksNo ratings yet

- 02 PA TransaxleDocument29 pages02 PA TransaxleJoaquimAndreLemos86% (7)

- 3DTouch Auto Leveling Sensor - GeeetechDocument11 pages3DTouch Auto Leveling Sensor - GeeetechordamNo ratings yet

- 12oh Motoniveladora Version Standar 5fm Plano ElectricoDocument2 pages12oh Motoniveladora Version Standar 5fm Plano Electricomiguelcastillo100% (1)

- Roboshot Midjet MK4Document312 pagesRoboshot Midjet MK4ctorres_505746100% (1)

- Zj50d Drilling Rig PartsDocument76 pagesZj50d Drilling Rig PartsAye Kywe100% (4)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Motor InvntryDocument41 pagesMotor InvntryChandu ChNo ratings yet

- Rotary Screw Spare Parts Book - Apr09 PDFDocument47 pagesRotary Screw Spare Parts Book - Apr09 PDFmuppetscrap100% (1)

- Liberty 1998 2003Document4,442 pagesLiberty 1998 2003riceboyler100% (1)

- Manual 950GDocument4 pagesManual 950Gabumagico85% (13)

- Plano Hidraulico 16m CatDocument2 pagesPlano Hidraulico 16m CatLuis Ramos100% (2)

- Solex z1Document12 pagesSolex z1designofclassic0% (2)

- K Series Data Radio KR900Document4 pagesK Series Data Radio KR900Geovane BarbosaNo ratings yet

- Specifications: Pruebas y AjustesDocument5 pagesSpecifications: Pruebas y AjustesJuan FerNo ratings yet

- Celcom Swap 3G Health Check - Rev2.0Document9 pagesCelcom Swap 3G Health Check - Rev2.0dhanamiwsNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Daewoo Manuals 1021Document39 pagesDaewoo Manuals 1021Erkan özdenNo ratings yet

- Partes Ga 15Document30 pagesPartes Ga 15Queco López100% (1)

- Generate PDFDocument11 pagesGenerate PDFGustavo RamirezNo ratings yet

- Electrical Motors DetailsDocument195 pagesElectrical Motors Details243avinashNo ratings yet

- Fan Uc Manuals 1787Document194 pagesFan Uc Manuals 1787Erik Hernandez100% (2)

- ASL GX7-11 RedesignDocument54 pagesASL GX7-11 RedesignMohammed Arshad100% (2)

- Inter-M A-60 - 120 Service ManualDocument9 pagesInter-M A-60 - 120 Service ManualGaniza Long0% (2)

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- FuelPurifier WestfaliaDocument193 pagesFuelPurifier WestfaliaHorst100% (2)

- Imo Ace PumpsDocument12 pagesImo Ace Pumpsrentz76No ratings yet

- BoqDocument18 pagesBoqPradeep Yallanki100% (1)

- M 11029 PDFDocument14 pagesM 11029 PDFquiphanvanNo ratings yet

- Msc-Ga20 25 35Document24 pagesMsc-Ga20 25 35Andrei GheorghitaNo ratings yet

- IBP1 Z2004E-7 991128 EN 10 2011 WebDocument94 pagesIBP1 Z2004E-7 991128 EN 10 2011 WebAnsuf WicaksonoNo ratings yet

- Manual Aire Acondiciona SamsungDocument46 pagesManual Aire Acondiciona Samsung5deivid5No ratings yet

- Grundfos SP A and SP submersible pumps data bookletDocument108 pagesGrundfos SP A and SP submersible pumps data bookletmitualvesNo ratings yet

- 415V Unit PMCC #1B loads and feedersDocument4 pages415V Unit PMCC #1B loads and feederslp mishraNo ratings yet

- Dwa 125RDocument35 pagesDwa 125RGuillermo HernandezNo ratings yet

- Pump Control (Output Flow) - Adjust - Stage 2 PumpDocument5 pagesPump Control (Output Flow) - Adjust - Stage 2 Pumpjorgetpr81No ratings yet

- CAT C175-16 2.5eMW Tier 4i QuoteDocument13 pagesCAT C175-16 2.5eMW Tier 4i Quoteraybugler100% (1)

- Samsung ML 1650exploded View & Part List PDFDocument11 pagesSamsung ML 1650exploded View & Part List PDFcataroxiNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- AKAI VS G260 General Information and Service SettingsDocument14 pagesAKAI VS G260 General Information and Service SettingsbartholomuszNo ratings yet

- Kenr5117kenr5117-05 SisDocument30 pagesKenr5117kenr5117-05 SisAnonymous Dq7m7Hq7ar100% (1)

- EASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Document24 pagesEASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Ken VanNo ratings yet

- Engine ArrangementDocument24 pagesEngine Arrangementmoldovan adrianNo ratings yet

- Altronic V Service Manual (FORM AV SM)Document15 pagesAltronic V Service Manual (FORM AV SM)francis_mouille_iiNo ratings yet

- Electrical Maintenance ListDocument390 pagesElectrical Maintenance ListYogendra Kumar SahuNo ratings yet

- FCPL asynchronous brake motors technical selection guideDocument10 pagesFCPL asynchronous brake motors technical selection guideehab8320014413No ratings yet

- Pump Control (Negative Flow) - Adjust - Stage 2 PumpDocument3 pagesPump Control (Negative Flow) - Adjust - Stage 2 Pumpjorgetpr81No ratings yet

- B3887BHF1Document4 pagesB3887BHF1xianmingNo ratings yet

- L00 5047 101.CDocument175 pagesL00 5047 101.CGhiță SfîraNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- SozitDocument2 pagesSozitDinhnamsgpNo ratings yet

- History and DNA of Sojitz IDocument23 pagesHistory and DNA of Sojitz IDinhnamsgpNo ratings yet

- Pt100 in 2-Wire or 3-Wire or 4-Wire ConnectionDocument4 pagesPt100 in 2-Wire or 3-Wire or 4-Wire ConnectionDinhnamsgpNo ratings yet

- History and DNA of Sojitz IIDocument31 pagesHistory and DNA of Sojitz IIDinhnamsgpNo ratings yet

- MCC162 16io1Document6 pagesMCC162 16io1DinhnamsgpNo ratings yet

- PLC Program for 5-Valve Process Control SystemDocument42 pagesPLC Program for 5-Valve Process Control SystemDinhnamsgpNo ratings yet

- Next Generation Physical, Virtual, Cloud Backup, Disaster Recovery, and Data Protection Solution From AcronisDocument16 pagesNext Generation Physical, Virtual, Cloud Backup, Disaster Recovery, and Data Protection Solution From AcronisDinhnamsgpNo ratings yet

- 4/2 and 4/3 Way Hand Lever Valves Spec SheetDocument2 pages4/2 and 4/3 Way Hand Lever Valves Spec SheetDinhnamsgpNo ratings yet

- FB12Document17 pagesFB12DinhnamsgpNo ratings yet

- Concept - and Module Description - R1503Document15 pagesConcept - and Module Description - R1503DinhnamsgpNo ratings yet

- FB12Document17 pagesFB12DinhnamsgpNo ratings yet

- FC30Document3 pagesFC30DinhnamsgpNo ratings yet

- Wincc Tao GD Qi PowerDocument14 pagesWincc Tao GD Qi PowerDinhnamsgpNo ratings yet

- 4.98 02ME-03-01 - Main & Emergency Gate AFCDocument1 page4.98 02ME-03-01 - Main & Emergency Gate AFCDinhnamsgpNo ratings yet

- 4.99 02ME-03-02 - Fences, Road and Yard Structure AFCDocument1 page4.99 02ME-03-02 - Fences, Road and Yard Structure AFCDinhnamsgpNo ratings yet

- 4.99 02ME-03-02 - Fences, Road and Yard Structure AFCDocument1 page4.99 02ME-03-02 - Fences, Road and Yard Structure AFCDinhnamsgpNo ratings yet

- Modify Panel LayoutDocument1 pageModify Panel LayoutDinhnamsgpNo ratings yet

- Power Meter ME96NSR Instruction ManualDocument70 pagesPower Meter ME96NSR Instruction ManualAndrew MaverickNo ratings yet

- 4.16 02AE-01-05-A - General Plot Plan of Vedan Station AFCDocument1 page4.16 02AE-01-05-A - General Plot Plan of Vedan Station AFCDinhnamsgpNo ratings yet

- 4.28 EQUI-05 - Equipment Arrangement For Vedan Station AFCDocument1 page4.28 EQUI-05 - Equipment Arrangement For Vedan Station AFCDinhnamsgpNo ratings yet

- 4.36 PIP-01-005 - Pipe Support Layout For Vedan Station AFCDocument1 page4.36 PIP-01-005 - Pipe Support Layout For Vedan Station AFCDinhnamsgpNo ratings yet

- Typical For 1TM605H1-M1Document1 pageTypical For 1TM605H1-M1DinhnamsgpNo ratings yet

- MCC Panel Layout For Saigon project+RIO PanelDocument2 pagesMCC Panel Layout For Saigon project+RIO PanelDinhnamsgpNo ratings yet

- 4.17 02AE-01-05-B - Piping Arrangement For Vedan Station AFCDocument1 page4.17 02AE-01-05-B - Piping Arrangement For Vedan Station AFCDinhnamsgpNo ratings yet

- Czujniki KCCDocument11 pagesCzujniki KCCDinhnamsgpNo ratings yet

- Modify - MCC Circuit Diagram For Saigon Project - VersionDDocument28 pagesModify - MCC Circuit Diagram For Saigon Project - VersionDDinhnamsgpNo ratings yet

- Circuit of Vacuum PM6Document1 pageCircuit of Vacuum PM6DinhnamsgpNo ratings yet

- Modify Pannel Layout RevADocument1 pageModify Pannel Layout RevADinhnamsgpNo ratings yet

- SAIGON network IP addressesDocument2 pagesSAIGON network IP addressesDinhnamsgpNo ratings yet

- Panel LayoutDocument1 pagePanel LayoutDinhnamsgpNo ratings yet

- Quadrature Phase-Shift Keying (QPSK) : ImplementationDocument8 pagesQuadrature Phase-Shift Keying (QPSK) : ImplementationSayid FerdianNo ratings yet

- SM Core CompetencyDocument53 pagesSM Core CompetencyDileep Bajaj100% (1)

- For Power Amplification (60V, 3A) : TransistorsDocument2 pagesFor Power Amplification (60V, 3A) : TransistorsKato CanalesNo ratings yet

- Digital Modified Sine Wave Inverter CircuitDocument6 pagesDigital Modified Sine Wave Inverter CircuitMaster RajaNo ratings yet

- Microelectronics Circuits Syllabus For EC 6 Sem 2010 Scheme - Vtu 10EC63 SyllabusDocument2 pagesMicroelectronics Circuits Syllabus For EC 6 Sem 2010 Scheme - Vtu 10EC63 Syllabusvinu_kb89No ratings yet

- Dual Gate MOSFET Gain and AGC PerformanceDocument4 pagesDual Gate MOSFET Gain and AGC Performanceverd leonardNo ratings yet

- CounterDocument11 pagesCounterDatpmNo ratings yet

- Abs HaldexDocument2 pagesAbs HaldexBom_Jovi_681No ratings yet

- 19.CDMA Link Budget (V0.1)Document31 pages19.CDMA Link Budget (V0.1)Hadi AgustanaNo ratings yet

- Closed Loop Power Control For LTE Systems - Performance Evaluation With The Open Loop Error, TPC Command Delay and Power Headroom ReportingDocument6 pagesClosed Loop Power Control For LTE Systems - Performance Evaluation With The Open Loop Error, TPC Command Delay and Power Headroom ReportingBilalNo ratings yet

- Dat, Over-Undervoltage RELAY S3UM, PILZDocument4 pagesDat, Over-Undervoltage RELAY S3UM, PILZeliasrvc22No ratings yet

- Event Gift Items 2017Document124 pagesEvent Gift Items 2017Ahmed Yasser Fouad SalehNo ratings yet

- D12 ExpertDocument12 pagesD12 ExpertaeduardocgNo ratings yet

- 24 DB Octave 2 and 3-Way Linkwitz-Riley Electronic CrossoverDocument12 pages24 DB Octave 2 and 3-Way Linkwitz-Riley Electronic CrossoverMarcelo ZapataNo ratings yet

- VSWRDocument8 pagesVSWRManas PramanikNo ratings yet

- Sky77643 11 203396eDocument2 pagesSky77643 11 203396eYilmer VivasNo ratings yet

- TP Advanced IC Packaging Technology OverviewDocument25 pagesTP Advanced IC Packaging Technology Overviewalbertsdeguzman100% (1)

- Battery CHGDocument4 pagesBattery CHGHosam JabrallahNo ratings yet

- DUPLEX Receivers GuideDocument12 pagesDUPLEX Receivers GuideFilipe MacomeNo ratings yet

- Pga 103Document5 pagesPga 103ppatstewNo ratings yet

- Kavita With SuvicharDocument38 pagesKavita With SuvicharGUNVANTRAY M.GAJJARNo ratings yet

- Online Free Course in Mobile Repairing (Card & Chip Level Training)Document80 pagesOnline Free Course in Mobile Repairing (Card & Chip Level Training)Priyanka VikrantNo ratings yet

- Direct Sequence Spread-Spectrum With Frequency HoppingDocument30 pagesDirect Sequence Spread-Spectrum With Frequency HoppingMaki-Bum MaharotNo ratings yet

- SLV-24N Smoke Detector Specs & FeaturesDocument1 pageSLV-24N Smoke Detector Specs & Featureschris sakettNo ratings yet

- BE2101 - Basic Electronics: (1 Semester - CS, IT) Credits: 3 Contact Hours: 3Document3 pagesBE2101 - Basic Electronics: (1 Semester - CS, IT) Credits: 3 Contact Hours: 3Minimol RajNo ratings yet

- All Digital PLL For RF Transmitter: Liangge Xu, Jukka-Pekka Pöyhtäri, Saska LindforsDocument27 pagesAll Digital PLL For RF Transmitter: Liangge Xu, Jukka-Pekka Pöyhtäri, Saska Lindforsjubidown100% (2)

- Data Sheet: 74HC/HCT32Document6 pagesData Sheet: 74HC/HCT32malirezazadeh5549No ratings yet