Professional Documents

Culture Documents

Computer Aided Pipe Stress Analysis

Uploaded by

Sandeep BhatiaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Aided Pipe Stress Analysis

Uploaded by

Sandeep BhatiaCopyright:

Available Formats

COMPUTER AIDED PIPE STRESS ANALYSIS TM CAESAR II

APPLICATIONS

CAESAR II from COADE evaluates the structural responses and stresses of piping systems to international codes and standards. As a registered user (No. 26440) we work with the latest version of the software to provide comprehensive pipe stress analysis services. Our COADE qualified engineers develop analysis models, while clearly indicating areas of concern and providing an excellent idea of the piping system's flexibility. Colour coded stress models and animated displacements for any stress load case are available. Besides the evaluation of a piping systems response to thermal, deadweight and pressure loads, CAESAR II analyses the effects of wind, support settlement, seismic loads and wave loads. CAESAR II also allows for the detailed modelling of expansion joints and restraints such as anchors, guides and skids, as well as selecting the proper springs for supporting systems with large vertical deflections. Dynamic analysis capabilities include modal, harmonic, response spectrum and time history analysis.

Isometric View of a Caesar II Model

INPUT INFORMATION

The pipe model has to be carefully built from scratch by accurately inputting all the parameters: Pipe Diameter Pipe Weight / Schedule Mill Tolerance Corrosion Allowance Insulation Thickness Ambient Temperature Temperature T1 T2 T3 Pressure P1 P2 Hydrostatic Test Pressure Fluid Density Insulation Material and Density Pipe Material; elastic moduli are taken from databases. Piping Code; allowable stresses are taken from databases.

PIPING CODES AND STANDARDS

Analysis can be made to the following international codes, specifications and standards: ASME ASME B31.1 ASME B31.2 ASME B31.3 ASME B31.4 ASME B31.5 ASME B31.8 ASME B31.9 ASME B31.11 BS 806 American Society of Mechanical Engineers Power Piping Fuel Gas Piping Process Piping Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids Refrigeration Piping Gas Transmission and Distribution Piping Systems Building Services Piping Slurry Transportation Piping Systems

MODEL INFORMATION

Pipe bends Reducers Rigids (i.e. valves, strainers, etc.) Tees Expansion joints Restraints (i.e. anchors, supports, guides, hangers, etc.) Displacements Spring Hangers Flanges Nozzels

LOAD CASES

Analysis will be performed in order to assess Static or Dynamic Load Case stresses. Load cases can selected from the following: Operating (OPE) Sustained (SUS) Expansion (EXP) Occasional (OCC) Fatigue (FAT)

12/10 E&OE

British - Specification for design and construction of ferrous piping installations for and in connection with land boilers BS 7159 British - Code of practice for design and construction of glass-reinforced plastic (GRP) piping systems for individual plants or sites CAN Z662 Canadian - Oil & Gas Pipeline Systems CODETI French - Petrochemical DNV Norwegian - Det Norske Veritas EN 13480 European - Metallic Industrial Piping FDBR German - Piping Code GPTC / Z380 American - Guide for Gas Transmission and Distribution Piping Systems HPGSL Japanese - High Pressure Gas Safety Law IGE / TD / 12 British - Institute of Gas Engineers ISO 14692 International Organisation for Standardisation Petroleum and natural gas industries glass-reinforced plastic (GRP) piping JPI Japanese - Piping Code Norwegian TBK-6 Norwegian - Piping Code PD 8010 British - Code of practice for pipelines RCC- M French - Nuclear Piping Code Swedish 1 Swedish - Piping Code Stoomwezen Dutch - Piping Code UKOOA UK Offshore Operators Association ...and more as new versions of Caesar II are released.

subject to alteration without notification

Tel 01423 878888

PIPE SOLUTIONS LTD

You might also like

- A Suggested Stress Analysis Procedure For Nozzle To Head Shell Element Model - A Case StudyDocument7 pagesA Suggested Stress Analysis Procedure For Nozzle To Head Shell Element Model - A Case StudyLincs lincolnNo ratings yet

- Process Valv HandbookDocument14 pagesProcess Valv Handbookdenim89No ratings yet

- PV QCDocument1 pagePV QCrameshqcNo ratings yet

- Best Blackpowder2013Document24 pagesBest Blackpowder2013sohail1985No ratings yet

- Coordination Plant LayoutDocument7 pagesCoordination Plant Layoutvazzoleralex6884No ratings yet

- DC Pandey's Physics Quick BookDocument225 pagesDC Pandey's Physics Quick BookMayank DahotreNo ratings yet

- DD - 046973 - Clearances Between Underground ServicesDocument2 pagesDD - 046973 - Clearances Between Underground ServicesvincentNo ratings yet

- DesignExamples 15-18Document270 pagesDesignExamples 15-18Sandeep BhatiaNo ratings yet

- Piping Engineering Course OverviewDocument2 pagesPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Black Powder in Sales Gas Pipelines: Sources and Technical RecommendationsDocument15 pagesBlack Powder in Sales Gas Pipelines: Sources and Technical RecommendationsQueenNo ratings yet

- Steel Water Storage Tanks Design Construction Maintenance and Repair PDFDocument448 pagesSteel Water Storage Tanks Design Construction Maintenance and Repair PDFJiss Mathew100% (3)

- Chapter 8 Steam PipingDocument14 pagesChapter 8 Steam PipingChen WsNo ratings yet

- AISC MembersDocument22 pagesAISC MembersAvinash Pathania100% (1)

- AISC MembersDocument22 pagesAISC MembersAvinash Pathania100% (1)

- Piping Designers Vessel OrientationDocument13 pagesPiping Designers Vessel OrientationkazishidotaNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- Codes and Standards: ASME B31 Piping CodesDocument44 pagesCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahNo ratings yet

- Steps For The Procurement of Piping / Mechanical ItemsDocument2 pagesSteps For The Procurement of Piping / Mechanical ItemsSanjeev KumarNo ratings yet

- First Quarter - Curriculum Map - Science 8Document7 pagesFirst Quarter - Curriculum Map - Science 8Mich Hora100% (7)

- Expansion Joints DataDocument52 pagesExpansion Joints DatamehdiNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- August 2012 IssueDocument56 pagesAugust 2012 IssueGas, Oil & Mining Contractor Magazine100% (1)

- Piping MaterialsDocument1 pagePiping Materialslibid_rajNo ratings yet

- Overview of GRP PipesDocument14 pagesOverview of GRP PipesMD IBRARNo ratings yet

- Task KPI Prerequisite Post Task: Code ApplicationDocument6 pagesTask KPI Prerequisite Post Task: Code ApplicationvikasNo ratings yet

- ROHR2 FeaturelistDocument27 pagesROHR2 FeaturelistTalpes AlexandruNo ratings yet

- 01 Piping ComponentsDocument23 pages01 Piping Componentshwang2100% (1)

- Project Standards and Specifications Mechanical Design Rev01Document11 pagesProject Standards and Specifications Mechanical Design Rev01cvssbvNo ratings yet

- A Series of Enthalpy-Entropy Charts For Natural Gases: f:1H, f:1M f:1MZDocument12 pagesA Series of Enthalpy-Entropy Charts For Natural Gases: f:1H, f:1M f:1MZDogui AldasNo ratings yet

- Structural Design CriteriaDocument15 pagesStructural Design CriteriaAnonymous 3kDy7eNo ratings yet

- Liquid Nitrogen MSDSDocument9 pagesLiquid Nitrogen MSDSsalcabesNo ratings yet

- Pipe Stress AnalysisDocument7 pagesPipe Stress AnalysisTushar NaikNo ratings yet

- Piping Stress Analysis Specification for PTTEP Arthit Field DevelopmentDocument23 pagesPiping Stress Analysis Specification for PTTEP Arthit Field Developmentsamprof4vw83% (6)

- Piping Stress SpecificationDocument23 pagesPiping Stress Specificationpourang1361No ratings yet

- Pressure DropDocument23 pagesPressure DropAmr TarekNo ratings yet

- Pipe Support Design SoftwareDocument61 pagesPipe Support Design Softwaremuhammad0umar-4No ratings yet

- Benzophenone/THF StillDocument3 pagesBenzophenone/THF Stillbloggsjoe1970No ratings yet

- PDFDocument7 pagesPDFAngling DharmaNo ratings yet

- VMS-B018-6-44-0006._Rev-3Document672 pagesVMS-B018-6-44-0006._Rev-3Joseph ChakkeryNo ratings yet

- Piping: Piping Sometimes Refers To Piping Design, The Detailed Specification of TheDocument5 pagesPiping: Piping Sometimes Refers To Piping Design, The Detailed Specification of ThesiswoutNo ratings yet

- ECI Symposium Proceedings Optimizes Fouling Mitigation DesignDocument6 pagesECI Symposium Proceedings Optimizes Fouling Mitigation DesignJoseAndresCarreñoNo ratings yet

- Stress AnalysisDocument4 pagesStress AnalysisSandeep BhatiaNo ratings yet

- MEM201Thermodynamics QB (2018-19) With Syllabus-1 PDFDocument10 pagesMEM201Thermodynamics QB (2018-19) With Syllabus-1 PDFRohan DubeyNo ratings yet

- Packed Column Operating DiagramDocument1 pagePacked Column Operating DiagramdinakaranpatelNo ratings yet

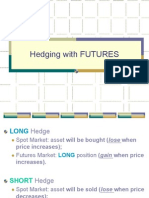

- 2 Hedging With FUTURESDocument27 pages2 Hedging With FUTURESAlexandra-Nicoleta MateescuNo ratings yet

- Caesar IiDocument2 pagesCaesar Iicena3135No ratings yet

- 5-Thermodynamics For CryogenicsDocument52 pages5-Thermodynamics For CryogenicsBhuvanaNo ratings yet

- Swagelok Fitting PDFDocument16 pagesSwagelok Fitting PDFmattuiffNo ratings yet

- Tm-1001 Aveva Plant (12 Series) Pdms Foundations Rev 2.0Document220 pagesTm-1001 Aveva Plant (12 Series) Pdms Foundations Rev 2.0Solomon EmavwodiaNo ratings yet

- SPLM Licensing InstallDocument9 pagesSPLM Licensing InstallAbdu AbdoulayeNo ratings yet

- Compressor ChecklistDocument1 pageCompressor ChecklistRolando DaclanNo ratings yet

- Acoustics Lesson 1 PDFDocument60 pagesAcoustics Lesson 1 PDFTejash SinghNo ratings yet

- Eia Report IoclDocument136 pagesEia Report IoclShubham WadavkarNo ratings yet

- Motor Torque and Load Torque SelectionDocument22 pagesMotor Torque and Load Torque Selectionrobertovm2002No ratings yet

- 1st Mar'14Document1 page1st Mar'14Avinash KumarNo ratings yet

- Main Principles of Pumps SelectionDocument19 pagesMain Principles of Pumps SelectionGodwinNo ratings yet

- Bestline Mining Supplies LTD - 2010 EditionDocument50 pagesBestline Mining Supplies LTD - 2010 EditionTalabarteria RaygozaNo ratings yet

- A194 AstmDocument12 pagesA194 AstmTran TrungttNo ratings yet

- New PPI-BoreAid Tool Designs HDD Plastic PipelinesDocument29 pagesNew PPI-BoreAid Tool Designs HDD Plastic PipelinesKarl LawrenceNo ratings yet

- Gaskets - Basics, Types, Working Principle, Calculation of Bolt Load - Mechanical Engineering SiteDocument12 pagesGaskets - Basics, Types, Working Principle, Calculation of Bolt Load - Mechanical Engineering Sitenoha azamaliNo ratings yet

- What Is Differences Between ASME 31.1 & 31Document2 pagesWhat Is Differences Between ASME 31.1 & 31Cheehoong YapNo ratings yet

- Product Key Autodesk 2016Document5 pagesProduct Key Autodesk 2016mila beusesNo ratings yet

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- VP - Rawat - Dev. FDocument28 pagesVP - Rawat - Dev. FMohammadShamimNo ratings yet

- HDPE Blow Molding Properties OverviewDocument2 pagesHDPE Blow Molding Properties Overviewtayyabmubarik2417No ratings yet

- Steam Trap and Drain Trap FunctionsDocument23 pagesSteam Trap and Drain Trap FunctionsMallela Sampath KumarNo ratings yet

- Dots in ASME B36.10 Under Schedule TableDocument5 pagesDots in ASME B36.10 Under Schedule TableIbrahim BashaNo ratings yet

- ASD Metal Services Guide to Tubes, Pipes and FittingsDocument8 pagesASD Metal Services Guide to Tubes, Pipes and FittingshaggNo ratings yet

- B and B+ TreeDocument33 pagesB and B+ TreeSEEMA BANSALNo ratings yet

- Relação de Normas Internacionais para Piping PDFDocument9 pagesRelação de Normas Internacionais para Piping PDFAlexandre LopesNo ratings yet

- Quiroga 2019 J. Phys. Conf. Ser. 1160 012008Document6 pagesQuiroga 2019 J. Phys. Conf. Ser. 1160 012008Sandeep BhatiaNo ratings yet

- Designofelevated00tree 1911 CivilDocument134 pagesDesignofelevated00tree 1911 CivilandysupaNo ratings yet

- Paper 329Document34 pagesPaper 329Sandeep BhatiaNo ratings yet

- FULLTEXT01Document106 pagesFULLTEXT01Sandeep BhatiaNo ratings yet

- Steady-State Analysis of Water Distribut PDFDocument9 pagesSteady-State Analysis of Water Distribut PDFSandeep BhatiaNo ratings yet

- Use of Shear Lugs For Anchorage To Concrete: January 2009Document9 pagesUse of Shear Lugs For Anchorage To Concrete: January 2009Sandeep BhatiaNo ratings yet

- Utilization Ratio EDDocument1 pageUtilization Ratio EDSandeep BhatiaNo ratings yet

- Irjet V3i7201 PDFDocument6 pagesIrjet V3i7201 PDFSandeep BhatiaNo ratings yet

- Appendix A - Tank Calculations - A4L0L6Document19 pagesAppendix A - Tank Calculations - A4L0L6Ignacio OñateNo ratings yet

- Ci33 1112 Pernos de AnclajeDocument10 pagesCi33 1112 Pernos de AnclajeShadin Asari ArabaniNo ratings yet

- Steady State Analysis of Water Distribution SystemsDocument3 pagesSteady State Analysis of Water Distribution SystemsSandeep BhatiaNo ratings yet

- Stress Analysis of Process Pipe Line Systems (ASME B 31.3) in A Plant Using Caeser-IIDocument7 pagesStress Analysis of Process Pipe Line Systems (ASME B 31.3) in A Plant Using Caeser-IISandeep BhatiaNo ratings yet

- Expansion Joint Automatically Locks Piping Against Reverse MovementDocument9 pagesExpansion Joint Automatically Locks Piping Against Reverse MovementSandeep BhatiaNo ratings yet

- Basic Flowchart and It's FunctionDocument9 pagesBasic Flowchart and It's FunctionJoey Slipknot JordisonNo ratings yet

- SP Loss WorksheetDocument9 pagesSP Loss WorksheetJojo FernandezNo ratings yet

- Design of liquid-storage tank: software vs Eurocode calculationsDocument13 pagesDesign of liquid-storage tank: software vs Eurocode calculationsSandeep BhatiaNo ratings yet

- API 650 Storage Tank Code GuideDocument15 pagesAPI 650 Storage Tank Code GuideDylan RamasamyNo ratings yet

- Expansion Joint Automatically Locks Piping Against Reverse MovementDocument9 pagesExpansion Joint Automatically Locks Piping Against Reverse MovementSandeep BhatiaNo ratings yet

- Shock Chloro CalcDocument2 pagesShock Chloro CalcSandeep BhatiaNo ratings yet

- AWWA Water Loss Control Committee (WLCC) Water Audit Software v3.0Document12 pagesAWWA Water Loss Control Committee (WLCC) Water Audit Software v3.0lamosy78No ratings yet

- SP Loss WorksheetDocument9 pagesSP Loss WorksheetJojo FernandezNo ratings yet

- Shock Chloro CalcDocument2 pagesShock Chloro CalcSandeep BhatiaNo ratings yet

- Static Pressure Calculator r3 Rev1610 27Document1 pageStatic Pressure Calculator r3 Rev1610 27Dwiki Yudia BasukiNo ratings yet

- TheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Document60 pagesTheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Omar George Cayllahua SaicoNo ratings yet

- Chapter 5 Lennard Jones PotentialDocument6 pagesChapter 5 Lennard Jones PotentialMuhamad RayhanNo ratings yet

- POster EGU PDFDocument1 pagePOster EGU PDFAsaf Aguilar LemaNo ratings yet

- Surface Roughness Conversion Chart Tables - Engineers EdgeDocument10 pagesSurface Roughness Conversion Chart Tables - Engineers Edgejames.anitNo ratings yet

- VT2009B Eng 02 953680Document2 pagesVT2009B Eng 02 953680gabrieltracto100% (1)

- House of CardsDocument2 pagesHouse of CardsHello misterNo ratings yet

- Technical manual for Felt Compulsion mountain bike suspension systemDocument15 pagesTechnical manual for Felt Compulsion mountain bike suspension systemDiogo SilvaNo ratings yet

- Magnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingDocument10 pagesMagnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingedumacerenNo ratings yet

- SousVide Supreme Chef - PCV-00100Document2 pagesSousVide Supreme Chef - PCV-00100Nena OchoaNo ratings yet

- Software Test MetricsDocument8 pagesSoftware Test MetricscmarrivadaNo ratings yet

- Manual Hawk 4000 PDFDocument158 pagesManual Hawk 4000 PDFNebur MtzaNo ratings yet

- Solution of Problem Set 1 For Purity Hydrocarbon Data PDFDocument4 pagesSolution of Problem Set 1 For Purity Hydrocarbon Data PDFDrumil TrivediNo ratings yet

- Vector Integration - GATE Study Material in PDFDocument10 pagesVector Integration - GATE Study Material in PDFTestbook BlogNo ratings yet

- Mathematics T (954/1) Functions QuizDocument1 pageMathematics T (954/1) Functions QuizmasyatiNo ratings yet

- Leviton ManualDocument82 pagesLeviton ManualRobby Larson100% (1)

- UV-Vis method for quantifying anti-cancer drug CurcuminDocument6 pagesUV-Vis method for quantifying anti-cancer drug Curcuminwhy uNo ratings yet

- Measuring AssignmentDocument3 pagesMeasuring AssignmentArnab BhattacharyaNo ratings yet

- Discussion QuestionsDocument45 pagesDiscussion QuestionsSriRahayuNo ratings yet

- Microsoft Office Tips and TricksDocument12 pagesMicrosoft Office Tips and TricksJayr BVNo ratings yet

- EL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENDocument4 pagesEL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENfederico4thNo ratings yet

- HistoryDocument87 pagesHistoryMatthew MathewsNo ratings yet

- Perez, Alonso - Unknown - The Ultimate Approach For General Arrangement Definition-AnnotatedDocument6 pagesPerez, Alonso - Unknown - The Ultimate Approach For General Arrangement Definition-AnnotatedPANJI BRAMMASTANo ratings yet

- HM130 5Document1 pageHM130 5AntonelloNo ratings yet

- Graph Theory 6Document30 pagesGraph Theory 6Zeeshan AhmedNo ratings yet

- Fundamentals of Heat and Mass Transfer 7th Edition - Bergman, Lavine, Incropera, DeWitt (1) - p0015Document1 pageFundamentals of Heat and Mass Transfer 7th Edition - Bergman, Lavine, Incropera, DeWitt (1) - p0015CladyNo ratings yet

- CarbonatiteDocument9 pagesCarbonatiteWWW.1580.L0GN.CFNo ratings yet