Professional Documents

Culture Documents

SAIC-A-2021 Rev 2

Uploaded by

ரமேஷ் பாலக்காடுCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-A-2021 Rev 2

Uploaded by

ரமேஷ் பாலக்காடுCopyright:

Available Formats

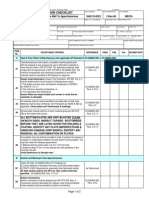

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pneumatic Test (Strength & Service)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2021

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

General Requirements for Test Conditions & Bubble Leak Test (Utilize with SAIC-A-2023, SATR-A-2001) Pneumatic Tests (Strength, Service) follow detailed and approved procedures containing specific test pkg instructions. Approved Procedure exists for Pneumatic Testing with subsection for Bubble Leak Testing. Refer to Note 1 & Attachment 1. Construction joints in system test are exposed, including all welds (seal welded threaded joints), flanges and threads. Construction joints in system test are properly illuminated. Note: ASME Sec V, Art. 10, Para. I-1075 & Article 9, Para. T-952 requires natural or supplemental white light with minimum light intensity at exam surface/site of 100 footcandles (1000 lux). Light source, technique used, & light level verification is required to be demonstrated one time, documented, and maintained on file. Tests utilizing natural sunlight more than meet this requirement. Tests in the morning are preferable as surface metal temperatures are still below 125 F (50C). Testing after sunset with lights/flashlights is extremely dangerous (prohibited) as personnel must climb, use mirrors & apply bubble solutions while wearing safety harnesses. Visual examination access for follow-up Soap Bubble Leak Test is safe & adequate to allow construction joint (thread, flange, weld) direct visual examination (24" and 30 degrees to the eye) per ASME Sec V, Article 10, Par. I-1075 & Article 9, Par. T-952, 953) Note 1: Mirrors are utilized to allow sufficient access to joints. Note 2: Plant system access utilizes manlifts and tied-off ladders. Unsafe climbing in piperacks is prohibited. Follow Safety rules. An approved Bubble forming solution is available in adequate quantity & compatible with surface metal test temperatures. DATA SHEET ON APPROVED SOLUTION IS AVAILABLE Note: Household soap or detergent use is prohibited per ASME V, Article 10, Mandatory Appendix 1, Para. I-1032 a) Note: As a standard technique, temperature of surface of part to be examined shall not be below 40F (4C) nor above 125F (52C) throughout the exam. (Test early in the day) (ASME Sec V, Article 10, Para. I-1032 b & I-1072) Bubble forming solution is to be applied to surfaces to be tested by flowing, spraying, or brushing the solution over the exam area. Note: Number of bubbles produced in solutions applied must be minimized to reduce the problem of masking bubbles and assure proper interpretation of results. (ASME Sec V, Art 10, Par. I-1073) SNOOP IS APPLIED TO JOINT USING SMALL DIA. TUBE Pressure Vessel Pneumatic test, met reqmts of UG-100 of ASME SEC VIII D1, or T-4 of ASME SEC VIII D2, as applicable. Pressure gages showed no loss in pressure. See Note 2. REFER TO SAIC-A-2023 Section B.

A1

SAEP-1160, Section 8

A2

SAES-L-150, Para. 7.3

A3

SAES-A-004, Para. 5.6.1

A4

SAES-A-004, Para. 5.6.1

A5

SAES-A-004, Para. 5.6.1

A6

SAES-A-004, Para. 5.6.1

A7

SAES-A-004, Para. 6.3.3 SAES-L-150, Para. 5.2

A8

Page 1 of 3

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pneumatic Test (Strength & Service)

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2021

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. REMARKS:

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

NOTES: 1: SAES-A-004 (March 2005 Edition, Para. 5.6.1) now requires ASME Code Leak Test (Direct Pressure Bubble Test) per ASME V, Article 10, Mandatory Appdix 1 "during" pneumatic strength tests. This also applies to service tests performed in lieu of pneumatic strength tests. It is advisable, but not mandatory, to perform a preliminary Soap Bubble Leak Test at 5 -10 psi to identify leakage at threaded and flanged joints (per SATIP-A-004-05). After repairs, a successful Mandatory soap bubble "Leak Test" AFTER strength test is presented to COMPANY (HOLD POINT). Leaks at pressures higher than 5-10 psi (such as 25 psi) make soap bubble solutions unreliable for leakage assessment as the solution can be immediately "blown away". COMPANY now requires "LEAK TEST" evaluation at 5-10 psi in accordance with an approved LEAK TESTING PROCEDURE to assure reliable leakage assessment for new systems. 2. TESTING FOR LEAKS AT ANY PRESSURE OTHER THAN 5-10 PSI (FOR ACCEPTANCE) IS STRICTLY PROHIBITED AT SAUDI ARAMCO. CONTRACTOR MAY EXAMINE LINES AT PNEUMATIC STRENGTH TEST PRESSURE ON HIS OWN. THEY SHALL BE EVALUATED FOR FINAL ACCEPTANCE BY SAUDI ARAMCO AT 5 - 10 PSI. Complete exams using SAIC-A-2023 & SATR-A-2010. ATTACHMENTS: Attachment 1 -- BUBBLE LEAK TEST PROCEDURE REQMTS (ASME V) ATTACHMENTS: 1. SAES-A-004, General Requirements for Pressure Testing, (30 March, 2005) 2. SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (30 September, 2003) 3. ASME Section V (2004 Edition, July 2005 Addenda) 4. Saudi Aramco General Instruction, G.I.-2.102, Pressure Testing Safely, (22 July, 2001) REFERENCE DOCUMENTS: 1. SAES-A-007, Hydrostatic Testing Fluids and Lay-Up Procedures, (5 October 2005)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 2 of 3

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Pneumatic Test (Strength & Service)

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-A-2021

1-Dec-06

MECH-

Attachment 1 -- BUBBLE LEAK TEST PROCEDURE REQMTS

Page 3 of 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TCM IO520 OpsInstallManualDocument78 pagesTCM IO520 OpsInstallManualleather_nunNo ratings yet

- Astm b214 16 PDFDocument4 pagesAstm b214 16 PDFWarsonoNo ratings yet

- Difference Between Voltage Tap & Test TapDocument3 pagesDifference Between Voltage Tap & Test TapaocalayNo ratings yet

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Computer Exam For QC WeldingDocument4 pagesSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Online Reg Certfct PDF PDFDocument2 pagesOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- Responabilities of A Welding InspectorDocument13 pagesResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுNo ratings yet

- Duties of A Welding Inspector 1Document12 pagesDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுNo ratings yet

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Document62 pagesSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுNo ratings yet

- Codes Standards and SpecificationsDocument15 pagesCodes Standards and Specificationsரமேஷ் பாலக்காடுNo ratings yet

- Welding Processes ModuleDocument27 pagesWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Air Carbon Arc Gouging: ElectrodeDocument1 pageAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- Gouging 01Document2 pagesGouging 01ரமேஷ் பாலக்காடுNo ratings yet

- Pew205 Slide ShowDocument23 pagesPew205 Slide Showரமேஷ் பாலக்காடுNo ratings yet

- SAIC-E-2001 Rev 2Document7 pagesSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Vedic Maths TutorialDocument12 pagesVedic Maths TutorialNitin Jain100% (15)

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-E-2002 Rev 2Document7 pagesSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocument362 pagesPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneNo ratings yet

- 0 Wis10 Contents ListDocument1 page0 Wis10 Contents ListSangram RoutarayNo ratings yet

- API 510 Examination Sample ItemsDocument3 pagesAPI 510 Examination Sample ItemsMagira PasaribuNo ratings yet

- Computer Kerala - 4 Folder LockDocument2 pagesComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNo ratings yet

- SAIC-F-2007 Rev 2Document1 pageSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2023 Rev 2Document2 pagesSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Yacht Devices NMEA 0183 Gateway User ManualDocument36 pagesYacht Devices NMEA 0183 Gateway User ManualAlexander GorlachNo ratings yet

- Microsoft Visual C++ 2008 Express Edition EnuDocument5 pagesMicrosoft Visual C++ 2008 Express Edition EnuMeghan WoodsNo ratings yet

- Distance Learning Assignment ProjectDocument28 pagesDistance Learning Assignment ProjectFaisal SattiNo ratings yet

- Manual Reparos Ohaus Linha ArDocument56 pagesManual Reparos Ohaus Linha ArJoao Victor BNo ratings yet

- Circuit Breaker - Wikipedia, The Free EncyclopediaDocument12 pagesCircuit Breaker - Wikipedia, The Free EncyclopediaMuhammad NabilNo ratings yet

- Origo Arc 150i Origo Arc 200i 2Document16 pagesOrigo Arc 150i Origo Arc 200i 2snovovi1100% (1)

- UA08 1 RNC Paging Engineering Guidelines V02Document84 pagesUA08 1 RNC Paging Engineering Guidelines V02SORO YALAMOUSSANo ratings yet

- ABAP Unit Test Driven DevelopmentDocument17 pagesABAP Unit Test Driven Developmentshadydogv5No ratings yet

- Sun and VMWare Quick Start GuideDocument10 pagesSun and VMWare Quick Start GuideAnuchit ChalothornNo ratings yet

- UMA & Optimus Schematics Document IVY Bridge (rPGA989)Document103 pagesUMA & Optimus Schematics Document IVY Bridge (rPGA989)AnilVarmaNo ratings yet

- D 869 - 85 R98 - Rdg2oq - PDFDocument2 pagesD 869 - 85 R98 - Rdg2oq - PDFphaindikaNo ratings yet

- Xuper-6868-XHD Castolin Electrode PDFDocument2 pagesXuper-6868-XHD Castolin Electrode PDFswapneel_kulkarniNo ratings yet

- M1911 A1 ReduxDocument59 pagesM1911 A1 Reduxaudrea100% (1)

- Cisco PGW 2200Document622 pagesCisco PGW 2200LukmanFolarin100% (1)

- Analog TV StandardsDocument5 pagesAnalog TV StandardsJayson AlvaNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument7 pagesIndustrial Diesel Generator Set: Standby Power RatingJavier SilvaNo ratings yet

- Krohne Flow Meter PDFDocument40 pagesKrohne Flow Meter PDFavabhyankar9393No ratings yet

- NGN Module 2 PDFDocument19 pagesNGN Module 2 PDFkikinjoNo ratings yet

- 11071414113824Document68 pages11071414113824Ermin MutapcicNo ratings yet

- Masterpact ManualDocument152 pagesMasterpact Manual322399mk7086100% (2)

- Datasheet SG2000-SG2500Document2 pagesDatasheet SG2000-SG2500Ashutosh SharmaNo ratings yet

- Circuit Breaker Technical SpecificationsDocument24 pagesCircuit Breaker Technical SpecificationssanjayNo ratings yet

- ISA 61010-031-2002 - Safety Req - Hand Held Probe AssembDocument78 pagesISA 61010-031-2002 - Safety Req - Hand Held Probe AssembRahul SinganiaNo ratings yet

- Compliance CertificateDocument2 pagesCompliance CertificateSwat Guratai by javed Javed iqbalNo ratings yet

- Ansi Asabe Ad730-2009 (R2012-12)Document17 pagesAnsi Asabe Ad730-2009 (R2012-12)StephanNo ratings yet

- Building Scalable Apps With Redis and Node - Js Sample ChapterDocument44 pagesBuilding Scalable Apps With Redis and Node - Js Sample ChapterPackt PublishingNo ratings yet

- Product data sheet RGZE1S48MDocument4 pagesProduct data sheet RGZE1S48MINGWIRBONo ratings yet