Professional Documents

Culture Documents

Weldspec ASME PQR

Uploaded by

Sunil KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weldspec ASME PQR

Uploaded by

Sunil KumarCopyright:

Available Formats

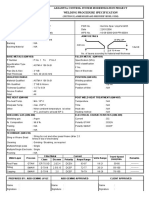

XYZ Fabrications Ltd

44 High St, Weldtown, Australia

ASME IX PQR

Weldspec software by TWI Ltd

PQR record number Date TWI-PQR-24 20/08/2002 Revision WPS record number Company name Welding standard TWI-WPS-213 XYZ Fabrications Ltd ASME Section IX Revision

BASE METALS (QW-403) Product form Welded to: and tested: Notes Pipe Pipe With PWHT, With hardness Specification (type or grade) SA-335 (P11) SA-335 (P12) P no. 4 5a Grp-no. 1 Size 254.00 254.00 Sch. 120 120 Thick. (mm) Dia. (mm) 21.44 21.44 273.05 273.05

POST WELD HEAT TREATMENT (QW-407) Temperature Heating rate Cooling rate Notes JOINTS (QW-402) Joint design Backing: Retainers Groove angle Root opening Root face Single-V-groove None (deg.) (mm) (mm) 50 3.2 0-1 (C) 710 (C/hr) 220 (C/hr) 260 Time Method Method (hrs) 2 Resistance heaters Air Type

WELDING PROCESSES Welding process Type FILLER METALS (QW-404) SFA specification Classification Filler metal F-number Weld metal A-number Filler metal nominal composition Filler metal trade name Filler metal size Deposited thickness Maximum pass thickness Weld deposit chemistry Supplemental filler metal Supplemental filler metal vol. POSITION (QW-405) Position of groove Weld progression PREHEAT (QW-406) Preheat temperature Maximum interpass temperature GAS (QW-408) Shielding gas: Trailing gas: Backing gas: Type Flow rate Type Flow rate Type Flow rate Argon 99.99% (l/min) (l/min) (l/min) 15-20 None Argon 99.99% 8-15 8-15 15-20 10-15 CO2 10-15 None None 10-15 (C) (C) 150 300 150 300 6G 6G 5.28 ER80S-G 6 3 TGS-1CM(Kobe) (mm) (mm) (mm) 2.4 7 4 Not specified 2.4 1.2 5.29 E81T1-B2 6 3 DS 8000-B2 1.2 13 5 Not specified None None GTAW Manual FCAW Semi-automatic

1.2

(mm)

ELECTRICAL (QW-409) Filler metal size Amperes Volts Travel speed Maximum heat input Tungsten size Tungsten type Current/polarity DC pulsing current Wire feed speed Arc transfer mode TECHNIQUE (QW-410) String or weave Orifice/gas cup size C.T.W.D Multi/Single pass per side Peening Initial/interpass cleaning Back gouging method Stringer and Weave No. 5-8 Multiple passes Not used Brushing/Chipping/Grinding Not applicable Stringer and Weave No. 12-20 Not specified Multiple passes Not used Brushing/Chipping/Grinding Not applicable (mm) 2.4 150 16 80 1.8 2.4 SFA 5.12 EWTh-2 DCSP (m/min) Not used DCSP DCRP 2.4 180 17 120 1.53 1.2 180 23 180-220 1.13-1.55 1.2 190 25 170-200 1.43-1.68 DCRP Spray 1.2 170 24 210-270 0.91-1.17

(mm/min) (kJ/mm) (mm)

DCRP

(mm)

Weldspec 4.5.000 Catalog n PQR00010

(c) Copyright 2005 TWI Software. All rights reserved worldwide. Page 1 of 2

XYZ Fabrications Ltd

44 High St, Weldtown, Australia

ASME - Procedure Qualification Record (PQR) - Test results (PWHT)

Weldspec software by TWI Ltd

PQR record number Date TWI-PQR-24 20/08/2002 Revision WPS record number Company name Welding standard TWI-WPS-213 XYZ Fabrications Ltd ASME Section IX Revision

TENSILE TESTS (QW-150) Specimen number 1 2 Specified Width (mm) 19.0 19.0 Thickness (mm) 20.6 20.5 Area (mm) 391.40 389.50 Ultimate total load (N) Ultimate unit stress (MPa) 537.5 538.6 413

Reduced section Type of failure and location Ductile-BM Ductile-BM

Comments

2 reduced section tension tests per QW-151.2 and QW-462.1(c) Acceptance criteria QW-163 Result Acceptable Comments see - ASME IX - QW-451.1

GUIDED BEND TESTS (QW-160) Type of test 4 transverse side bends per QW-161.1 and QW-462.2

Comments HARDNESS TEST Type (Scale) Vickers (HV5)

Dimensions - 9.5 x 22.6, 9.5 x 22.7, 9.5 x 22.7, 9.5 x 22.8. Bend - 180 deg, Mandrel diameter - 38mm Distance from surface SA-335 (P11) 169, 186 171, 181 183, 189 179, 179 174, 183 174, 193 See Report No. M02-08-90 Type of test Radiographic examination per QW-191 and QW-302.2 Penetrant test Macro examination Acceptance criteria Result Acceptable Acceptable Acceptable Comments HAZ 192, 227 225, 237 244, 246 235, 270 236, 262 224, 228 Weld 232, 241 214, 255 231, 251 HAZ SA-335 (P12)

Comments OTHER TESTS

Comments CERTIFICATION Welder's name Dick Hadfield

Report Nos - RT-WPQT-S-1027, PT-WPQT-S-0141 - Radiograph Nos - WP-BCCV-037, 0-1, 1-2, 2-3, 3-4, 4-0

ID Number 092

Stamp number 1005117-80

Mechanical testing by Laboratory test number Test file number Tests conducted by

S G Park

We certify that the statements in this record are correct and tested in accordance with DNV, LR and BV Rules.

Welding Engineer Name Andy Brightmore Date 13/10/2005 Examinig Body Name Signature Signature

QA Name Signature

Date

Date

Weldspec 4.5.000 Catalog n PQR00010

(c) Copyright 2005 TWI Software. All rights reserved worldwide. Page 2 of 2

You might also like

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Stainless steel welding procedure qualification recordDocument1 pageStainless steel welding procedure qualification recordchandraNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Document15 pagesWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960No ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Welder Visual Inspection ReportsDocument24 pagesWelder Visual Inspection ReportsKyNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocument2 pagesGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WELDER QUAL TEST REPORTDocument1 pageWELDER QUAL TEST REPORTtantri.hellyanti100% (1)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Welder Operators Qualification TestDocument2 pagesWelder Operators Qualification Testlokifarad100% (1)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- Al-Suwaidi Industrial Welding ReportDocument85 pagesAl-Suwaidi Industrial Welding ReportwalitedisonNo ratings yet

- Wps Register Last Updated May 12Document1 pageWps Register Last Updated May 12Abdullah Al JubayerNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- WELDER QUALIFICATION REPORTDocument2 pagesWELDER QUALIFICATION REPORTAkash Singh TomarNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- REGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRDocument2 pagesREGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRAnonymous Xa5rkMZm9ZNo ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Advaita Vedanta PDFDocument184 pagesAdvaita Vedanta PDFSunil KumarNo ratings yet

- Steel Production and Properties GuideDocument10 pagesSteel Production and Properties GuideSunil KumarNo ratings yet

- TWI UT of Butt WeldsDocument46 pagesTWI UT of Butt WeldsSunil Kumar75% (8)

- Welding of Cirrcumferential & FittingsDocument9 pagesWelding of Cirrcumferential & FittingsSunil KumarNo ratings yet

- MSS SP 54 Radiographic Examination MethodDocument9 pagesMSS SP 54 Radiographic Examination MethodSunil Kumar100% (1)

- ONGC Commissioning ProceduresDocument27 pagesONGC Commissioning Proceduresachmadh_2010100% (8)

- sss23 04Document4 pagessss23 04Sunil KumarNo ratings yet

- Concept of ManDocument84 pagesConcept of ManSunil Kumar100% (1)

- Adi ShankaraDocument34 pagesAdi ShankaraarrarrgeeNo ratings yet

- Advaita and African PhilosophyDocument285 pagesAdvaita and African PhilosophySunil KumarNo ratings yet

- PhilosophyDocument13 pagesPhilosophySunil KumarNo ratings yet

- Ggs Viii IssuesDocument3 pagesGgs Viii IssuesSunil KumarNo ratings yet

- Excavation Work Under Progress at Receiver Area For Pipe Line ApproachDocument48 pagesExcavation Work Under Progress at Receiver Area For Pipe Line ApproachSunil KumarNo ratings yet

- Tank Work and Pipe Rack Upgrades ProjectDocument19 pagesTank Work and Pipe Rack Upgrades ProjectSunil KumarNo ratings yet

- Development of Database of Cyclic Soil Properties From 94 Tests On 47 SoilsDocument10 pagesDevelopment of Database of Cyclic Soil Properties From 94 Tests On 47 SoilsJulio BetancurNo ratings yet

- Aquatherm PPR SDR 9 - DimensiuniDocument1 pageAquatherm PPR SDR 9 - DimensiuniDragut OvidiuNo ratings yet

- filedate_858Download ebook Shigleys Mechanical Engineering Design 11Th Ed Pdf full chapter pdfDocument67 pagesfiledate_858Download ebook Shigleys Mechanical Engineering Design 11Th Ed Pdf full chapter pdfjeremy.collins128100% (21)

- Eb-100 - VHP-NRLDocument4 pagesEb-100 - VHP-NRLsoundicalNo ratings yet

- Film Coat of Ciprofloxacin Using HPC Ans PovidoneDocument67 pagesFilm Coat of Ciprofloxacin Using HPC Ans Povidonemohamed basheirNo ratings yet

- AISC ASD Base Plate Thickness V2016-2Document9 pagesAISC ASD Base Plate Thickness V2016-2yusuf_jtNo ratings yet

- Chapter Two: Fundamentals of Damages Theory (McEng 5142Document34 pagesChapter Two: Fundamentals of Damages Theory (McEng 5142Mikias TeferaNo ratings yet

- Ryton PPS Design GuideDocument24 pagesRyton PPS Design GuideAnonymous l2sT4aENo ratings yet

- Verify Laws of Illumination Lab - IDocument2 pagesVerify Laws of Illumination Lab - ISK ASHIKNo ratings yet

- Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeDocument6 pagesFilament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeShaker QaidiNo ratings yet

- Beers Law Lab AP ChemDocument3 pagesBeers Law Lab AP ChembrokenfanNo ratings yet

- James B. Hartle Department of Physics University of California Santa Barbara, CA 93106Document25 pagesJames B. Hartle Department of Physics University of California Santa Barbara, CA 93106huevonomar05No ratings yet

- Temperature Load in STAADDocument4 pagesTemperature Load in STAADS DuttaNo ratings yet

- Lecture 4a Solar ThermalDocument34 pagesLecture 4a Solar ThermalTze Long GanNo ratings yet

- SRI CHAITANYA EDUCATIONAL INSTITUTIONS JR AIIMS S60 NEET-2024 SCHEDULEDocument5 pagesSRI CHAITANYA EDUCATIONAL INSTITUTIONS JR AIIMS S60 NEET-2024 SCHEDULEteen's teamNo ratings yet

- Evaluation of Fluid Storage Characteristics at Nanoscopic Scale For Some Natural ZeolitesDocument14 pagesEvaluation of Fluid Storage Characteristics at Nanoscopic Scale For Some Natural ZeolitesGözde BayazitNo ratings yet

- Assignment1 - ECW557 - NURUL NABILAH MOKTAR PDFDocument11 pagesAssignment1 - ECW557 - NURUL NABILAH MOKTAR PDFNabilah.MoktarNo ratings yet

- Stability Analysis of Soil Slope Subjected To Blast Induced Vibrations Using FLACDocument11 pagesStability Analysis of Soil Slope Subjected To Blast Induced Vibrations Using FLACResmi RosaliniNo ratings yet

- Automotive Air Conditioning SystemDocument46 pagesAutomotive Air Conditioning SystemHimanshu Katara80% (5)

- 5 Analysis of of Gravity DamsDocument10 pages5 Analysis of of Gravity DamsBillie Ian. Salamante JrNo ratings yet

- Aci-207.1r (1996) PDFDocument42 pagesAci-207.1r (1996) PDFFernando HerediaNo ratings yet

- 2005-021 MotwaniDocument6 pages2005-021 Motwanialexander100% (1)

- Vallorec P91 BOOKDocument69 pagesVallorec P91 BOOKhassan100% (2)

- Liebert PDX Technical Manual Eng PDFDocument150 pagesLiebert PDX Technical Manual Eng PDFJelena PerićNo ratings yet

- Corrosion and Its Control NFDocument93 pagesCorrosion and Its Control NFAayu JainNo ratings yet

- 3 04 LT Cooling SystemDocument25 pages3 04 LT Cooling Systemstopless_dalian685No ratings yet

- 6 InertingDocument9 pages6 InertingHasan CosalevNo ratings yet

- Analiza Termica Disc FranaDocument8 pagesAnaliza Termica Disc FranaLuca VictorNo ratings yet

- Physics STPM 2005 AnswerDocument23 pagesPhysics STPM 2005 AnswersuhailieliasNo ratings yet

- 472Document35 pages472Nahida BanoNo ratings yet