Professional Documents

Culture Documents

Aci 304.3R-96

Uploaded by

minhnnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aci 304.3R-96

Uploaded by

minhnnCopyright:

Available Formats

ACI 304.

3R-96 Heavyweight Concrete: Measuring, Mixing, Transporting, and Placing

Reported by ACI Committee 304

Robert A. Kelsey, Chairman David J. Akers* James E. Bennett, Jr. Casimir Bognacki Tianxia Cao* James L. Cope Daniel Green Neil R. Guptil Terence C. Holland

*Members of the subcommittee who prepared revisions to the report.

Roger E. Phares Vice Chairman Thomas A. Johnson Samuel A. Kalat* John C. King William C. Krell Gary R. Mass Patrick McDowell Dipak T. Parekh

James S. Pierce* Subcommittee Chairman Paul E. Reinhart Royce J. Rhoads Kenneth L. Saucier Donald L. Schlegel Paul R. Stodola William X. Sypher Robert E. Tobin

Presents recommended methods and procedures for measuring, mixing, transporting, and placing heavyweight concretes that are used principally for radiation shielding in nuclear construction. Also covered are recommendations on cement, heavyweight aggregates, water, and admixtures. Mixture proportioning of heavyweight concrete is discussed. Recommendations for preplaced-aggregate heavyweight concrete are also included, together with suitable grout proportions. Mixing equipment, form construction, placing procedures, and methods of consolidation are described. Quality control, inspection, and testing are emphasized, and a list of references is included. Keywords: admixtures; aggregates; barite; cements; concrete construction; concretes; consolidation; construction equipment; conveying; density (mass/volume); formwork (construction); grout; heavyweight aggregates; heavyweight concretes; ilmenite; limonite; magnetite; mass concrete; materials handling; mix proportioning; mixing; placing; quality control; preplaced-aggregate concrete; radiation shielding; segregation.

2.4Admixtures 2.5Proprietary premixed mortar Chapter 3Concrete characteristics, p. 304.3R-4 3.1Physical properties 3.2Mixture proportioning Chapter 4Equipment, p. 304.3R-5 Chapter 5Formwork, p. 304.3R-5 5.1Conventional method 5.2Preplaced-aggregate method Chapter 6Placement, p. 304.3R-5 6.1Conventional method 6.2Preplaced-aggregate method Chapter 7Quality control, p. 304.3R-6 7.1Samples and tests 7.2Cement 7.3Aggregate 7.4Admixtures 7.5Control tests 7.6Inspection Chapter 8References, p. 304.3R-7 8.1Specified and/or recommended references 8.2Cited references

ACI 304.3R-96 supersedes ACI 304.3R-89 and became effective January 23, 1996. Copyright 1997, American Concrete Institute. All rights reserved including rights of reproduction and use in any form or by any means, including the making of copies by any photo process, or by electronic or mechanical device, printed, written, or oral, or recording for sound or visual reproduction or for use in any knowledge or retrieval system or device, unless permission in writing is obtained from the copyright proprietors.

CONTENTS Chapter 1General considerations, p. 304.3R-2 Chapter 2Materials, p. 304.3R-2 2.1Cement 2.2Aggregate 2.3Mixing water

ACI Committee Reports, Guides, Standard Practices, and Commentaries are intended for guidance in planning, designing, executing, and inspecting construction. This document is intended for the use of individuals who are competent to evaluate the significance and limitations of its content and recommendations and who will accept responsibility for the application of the material it contains. The American Concrete Institute disclaims any and all responsibility for the stated principles. The Institute shall not be liable for any loss or damage arising therefrom. Reference to this document shall not be made in contract documents. If items found in this document are desired by the Architect/Engineer to be a part of the contract documents, they shall be restated in mandatory language for incorporation by the Architect/Engineer.

304.3R-1

304.3R-2

ACI COMMITTEE REPORT

Table 1 Typical aggregates*

Heavy Aggregate Ilmenite Limonite-goethite Magnetite Magnetite Barite Barite Ferrophosphorous** Steel aggregate Iron shot Source Que. UT, MI NV, WY MT TN NV Punchings, sheared bars Cold chilled shot Composition Fe, Ti, O, etc. 2Fe2O3-3H2O Fe3O4, etc. Hydrous iron >92 percent BaSO4 >90 percent BaSO4 Fe3P, Fe2P, FeP Specific Gravity Coarse pieces Fine sand 4.50 4.60 3.45 3.70 4.50 4.55 4.30 4.34 4.20 4.24 4.28 4.31 6.30 6.28 7.78 7.50 Percent by weight Iron Fixed water 40 0 55 11 60 1 60 2-5 1-10 0 <1 0 70 0 99 99 0 0

*Source: Reference 4. Material water-saturated, with its surface dry. Other sources may be available. In some instances the composition may be more important than the specific gravity if the aggregates attenuation characteristics are good. **Ferrophosphorous when used in portland cement concrete will generate flammable and possibly toxic gases that can develop high pressures if confined.

CHAPTER 1GENERAL CONSIDERATIONS The procedures for measuring, mixing, transporting, and placing heavyweight concrete are similar to those used in conventional concrete construction; however, special expertise and thorough planning are necessary for the successful completion of this type of concrete work. The use of heavyweight concrete in construction is a specialized field, and it is advisable that the work be undertaken by qualified personnel.1 Heavyweight concrete is used in counterweights of bascule and lift bridges, but it is generally used in radiation shielding structures and differs from normal weight concrete by having a higher density and special compositions to improve its attenuation properties. When the heavyweight concrete is used to absorb gamma rays, the density and materials costs are of prime importance.1 When heavyweight shielding concrete is used to attenuate neutrons, sufficient material of light atomic weight, which produces hydrogen, should be included in the concrete mixture.2 Some aggregates are used because of their ability to retain water of crystallization at elevated temperatures, which ensures a source of hydrogen not necessarily available in heavyweight aggregates. CHAPTER 2MATERIALS 2.1Cement Cements conforming to ASTM C 150, which would be suitable for conventional concrete and produce the required physical properties, are suitable for use in heavyweight concrete. Low-alkali cement should be used when alkali-reactive constituents are present in the aggregates and a moderate or low-heat cement should be used for massive members in accordance with Chapter 14, Massive Concrete, of ACI 301. To avoid high and rapid heat of hydration and resultant cracking, it is advisable not to use Type III cement or accelerators unless the concrete temperature is controlled by specially designed refrigeration systems. Blended hydraulic cements meeting the requirements of ASTM C 595 also may be used in lieu of portland cements. However, blended hydraulic cements should be used only if their use does not reduce the density of the concrete below the specified limit.

Storage of cementitious materials should be in accordance with ACI 304R. 2.2Aggregate Thorough examination and evaluation of heavyweight aggregate sources are necessary to obtain material suitable for the type of shielding required.3 These sources are limited, and a material survey should be conducted to determine availability, chemical and physical qualities, and service records. Samples for test should be taken under the supervision of the owners representative to meet requirements of ASTM C 637. The suppliers sources should be inspected to evaluate rock composition, abrasion resistance, and density since these properties may vary from one location to another within a deposit. The purchaser must realize that mineral ores are not as uniform as normal weight concrete aggregates and make appropriate allowances. Purchase orders should specify strict limits on allowable deviations for each property and make specific provisions for remedial action in the event the tolerances are not met. Density and compositionAggregate density and composition for radiation shielding are described in ASTM C 638 and specified in ASTM C 637. Some typical properties for shielding aggregates are shown in Table 1. Coarse metallic aggregate for preplaced-aggregate concrete should have 100 percent retained on a 9.5-mm (3/8-in) sieve and be reasonably free of thin, flat, or elongated pieces of metal. Maximum particle size is usually limited to 11/2-in. (37.5-mm). Fine metallic aggregate should consist of commercial chilled-iron or steel shot or ground iron, meeting SAE J 444a. Metallic aggregates should have a specific gravity of 7.50 or greater and be clean and free from foreign coatings of grease, oil, machine shop compounds, zinc chromate, loose scale, and dirt. Shipment and storageAggregate should be shipped, handled, and sorted in a manner that will insure little loss of fines, no contamination by foreign material, and no significant aggregate breakage or segregation. Aggregates may be shipped in heavy wooden boxes, watertight bags, steel containers, or in bulk by railroad cars or

HEAVYWEIGHT CONCRETE: MEASURING, MIXING, TRANSPORTING, AND PLACING

304.3R-3

Table 2 Typical proportions for heavyweight concrete

Conventionally placed concrete Density (unit weight), Compressive strength, lb/ft3 age 3 months psi (MPa) (kg/m3) 300 5000 (4810) (34.5) Cement, lb/ft3 (kg/m3) 23.5 (376) Heavy aggregate, lb/ft3 (kg/m3) Coarse 195 Iron shot (3120) 70 Magnetite (1120) Ferrophospho92 Ferrophospho171 rous (1470) rous (2740) Ferrophospho70 Ferrophospho70 rous (1120) rous (1120) 35 50 Barite Barite (560) (800) 86 110 Magnetite Magnetite (1380) (1760) 86 105 Barite Barite (1380) (1680) Hydrous iron 82 Hydrous iron 100 ore (1310) ore (1600) 50 106 Serpentine Magnetite (800) (1700) Preplaced-aggregate method 44 270 Magnetite Punchings (700) (4330) 42 67 Magnetite Magnetite (670) (1070) 160 Punchings (2560) 28 60 Limonite Limonite (450) (960) 140 Punchings (2240) 42 122 Magnetite Magnetite (670) (1950) 67 Punchings (1070) 23 48 Serpentine Serpentine (370) (769) 145 Punchings (2320) 37 180 Magnetite Magnetite (590) (2880) 29 28 Limonite Limonite (460) (450) 122 Magnetite (1950) Fine Mix water, lb/ft3 (kg/m3) 12.0 (192) Water content* lb/ft3 (kg/m3) Minimum 3.5 (56) Maximum 12.0 (192)

300 (4810) 262 (4200)

4870 (33.6) 5350 (36.9)

24.1 (386) 23.7 (380)

12.7 (203) 12.8 (205)

3.6 (58) 3.6 (58)

12.7 (203) 12.8 (205)

232 (3720) 222 (3560) 219 (3510) 190 (3040) 346 (5540) 300 (4810)

6500 (44.8) 6000 (41.4) 6500 (44.8) 5750 (39.6) 3000 (207) 5000 (34.5)

24.3 (389) 19.3 (309) 24.9 (399) 20.9 (335) 20.6 (330) 19.8 (317)

11.5 (184) 11.6 (186) 12.0 (192) 13.0 (208) 11.3 (181) 10.9 (175)

5.7 (91) 2.9 (46) 9.2 (147) 9.1 (146) 3.5 (56) 4.1 (66)

13.5 (216) 11.6 (186) 17.5 (280) 19.0 (304) 11.8 (189) 12.0 (192)

263 (4210)

6000 (41.4)

22.2 (356)

12.2 (195)

13.0 (208)

21.9 (351)

262 (4200)

4800 (33.1)

19.8 (317)

10.9 (175)

4.7 (75)

12.6 (202)

245 (3920)

19.5 (312)

9.8 (157)

244 (3910) 215 (3440)

5000 (34.5) 5000 (34.5)

17.5 (280) 22.7 (364)

9.7 (155) 12.5 (200)

4.8 (77) 10.9 (175)

11.9 (191) 20.0 (320)

*Maximum water content is water weight when concrete is wet. Minimum water content is amount left after drying to constant weight at 185 F (85 C). Difference between the maximum water content and the amount of mix water added is the water of crystallization held by the aggregate. The difference between the minimum water content and the water of crystallization is the water retained by the hardened cement paste.

304.3R-4

ACI COMMITTEE REPORT

Table 3 Typical grout proportions

Grout Sand Magnetite Barite Limonite Conventional Sand-cement ratio by weight 2.13 1.49 1.28 1.00 Water-cement ratio by weight 0.55 0.54 0.55 0.42 Wet weight lb/ft 170 155 146 129

3

kg/m3 2720 2480 2336 2064

trucks. Storage should be as near the batch plant as possible, and protected from moisture. The net weight of aggregate in each container should be plainly marked on the container. 2.3Mixing water Water and ice to be used in heavyweight concrete should conform to the requirements of ACI 301 or ASTM C 94. In addition, water should be clean and free from injurious amounts of oil, acid, alkali, organic matter, or other deleterious substances. 2.4Admixtures Conventionally placed heavyweight concrete may contain a chemical admixture meeting ASTM C 494 requirements for Type A or D. Type F or G may also be used to improve the placeability and reduce the tendency for segregation. When Type F or G is used, caution must be used to be sure the mixture is not over-vibrated and the heavyweight particles segregated. Air-entraining admixtures are not generally used in concrete that is not exposed to freezing and thawing because their use would tend to decrease the density of the concrete. However, if the concrete mixtures have sufficient density to allow 4 percent entrained air, there are definite advantages to be realized: reduced bleeding, greater workability, and a more homogeneous concrete. Preplaced-aggregate grout should contain a fluidifier conforming to ASTM C 937. Admixtures should be stored in accordance with requirements of ACI 304R. Fly ash meeting the requirements of ASTM C 618 may be used to enhance the workability of heavyweight mixtures. Other mineral admixtures such as natural pozzolans and silica fume also may be used. These admixtures should meet the requirements of ASTM C 618 and C 1240, respectively. However, their effect on the concrete density must be evaluated and the admixtures omitted if the resulting concrete density is lower than that specified. 2.5Proprietary premixed mortar Iron mortar concretes produced commercially by manufacturers for shielding concrete have been tested and found adequate. However, these materials should be tested prior to use for density, compressive strength, and the necessary properties for shielding. CHAPTER 3CONCRETE CHARACTERISTICS 3.1Physical properties High modulus of elasticity, low coefficient of thermal expansion, and low elastic and creep deformations are ideal properties for both conventional structural concrete and heavyweight concrete. Heavyweight concrete is used when

the thickness of the concrete is limited. High compressive strengths may be required if heavyweight concrete is to be subjected to high temperatures and stress levels. This strength requirement may necessitate the use of a low watercement ratio, and if placing conditions are difficult, a high cement content will also be required for workability, or a Type F or G chemical admixture may be used. Heavyweight concrete with high cement content and low water-cement ratio may exhibit increased creep and shrinkage, and in a massive concrete placement could generate high temperatures at early ages causing undesirable localized cracking from the thermally induced stresses and strains.4 When structural considerations require this cracking potential to be eliminated, it will be necessary to use appropriate temperature control measures that could include precooling or postcooling the concrete, or both, as described in ACI 207.1R, ACI 207.2R, and ACI 224R. 3.2Mixture proportioning Procedures outlined in ACI 211.1 should be used for mixture proportioning. Typical proportions for heavyweight concrete are shown in Table 2. Conventionally placed heavyweight concreteThe concrete mixture should be proportioned to provide the desired compressive strength, density, and adequate workability. Also, the chemical constituents and fixed water content of the resulting mixture must provide satisfactory shielding properties.5 (Fixed water is water necessary to supply hydrogen for shielding.) Preplaced-aggregate heavyweight concreteCoarse aggregate for heavyweight preplaced-aggregate concrete may be a heavyweight mineral aggregate, a blend of mineral aggregates, or a blend of mineral aggregates and steel particles. Because of high cost, steel particles are rarely used alone as coarse aggregate. Unpublished laboratory data of contractorengineers employed by the U.S. Atomic Energy Commission (now the Nuclear Regulatory Commission) at Hanford, WA, indicate that if steel punchings or smooth cubical pieces of steel or iron are used alone as coarse aggregate, compressive strengths will not exceed 3000 psi (20.7 MPa), regardless of the grout mixture or water-cement ratio used. However, when sheared reinforcing bars are used as aggregate with similar grout mixtures, concrete of normal strength will be produced. The compressive strengths of typical preplaced-aggregate concrete mixtures are shown in Table 2. Coarse aggregates should conform with Grading 1 in Table 7.2 of ACI 304R. Form configuration and embedment limitations usually preclude the use of coarse aggregate larger than 11/2 in. (37.5 mm). Sand grading should be within the limits but on the finer side of the grading shown in Table 7.2 (ACI 304R) since the smaller particles show less tendency to segregate. Some

HEAVYWEIGHT CONCRETE: MEASURING, MIXING, TRANSPORTING, AND PLACING

304.3R-5

heavyweight fine aggregate, e.g., ferrophosphorous, when used in grouts causes excessive bleeding and produces grouts that are extremely difficult to pump. Grout used in heavyweight preplaced-aggregate concrete should contain more cement than that used in normal density preplaced-aggregate concrete. Preplaced coarse aggregate proportions will vary in accordance with requirements for strength, density, and fixed water. Typical grout proportions are shown in Table 3. Guidance on proportioning grout mixtures is also available in ASTM C 938. Fluidifier admixtures as described in ACI 304R must be used in the grout to insure complete filling of the voids among coarse aggregate particles, to obtain controlled expansion of the matrix during its plastic stage for optimum coarse aggregate contact, to minimize bleeding, and to obtain satisfactory contact of the concrete with embedded items. Fly ash, which is frequently used with normal density preplaced-aggregate concrete, is used in heavyweight concrete only when its use does not reduce the concrete density below the specified limit. In addition, the lime-pozzolan hydration reaction is not as effective as the portland cement hydration action in chemically fixing the water for neutron attenuation. CHAPTER 4EQUIPMENT Standard mixing equipment is generally used to mix heavyweight concrete. Special care should be taken not to overload the equipment. In general, the allowable volume of heavyweight concrete mixed should be equivalent to the mix weight of normal density concrete rather than the volume capacity of the mixing equipment. Transporting heavyweight concrete without agitation tends to cause excessive consolidation or packing. The use of long, rigid chutes or drop pipes should be avoided. Where concrete must be placed in narrow forms or through restricted areas, a short flexible type drop chute that tends to collapse and restrain the fall of heavyweight concrete should be employed. CHAPTER 5FORMWORK 5.1Conventional method Formwork should conform to ACI 347R. The form designer should be aware that formwork for conventionally placed heavyweight concrete must be necessarily stronger than comparable formwork for ordinary concrete simply by reason of increased concrete density. Typical structures will be of a complex shape and will contain many penetrations through the formwork. The strutting and bracing system must be carefully designed to avoid unintentionally placing a load on penetrating members and to insure precise alignment of external fixtures corresponding to these penetrations. In a typically complex placement, consideration should be given to the use of permanent steel forms as sheeting. Steel penetrations are often precisely machined and fabricated assemblies that may be subject to delays in delivery. It may be prudent to allow for such delays by providing for blockouts to receive these penetrations, the blockouts to be

provided with normal bends or step configuration to reduce the possibility of radiation streaming, or leakage that could occur with straight-line joints. The basic structure then may be completed around the blockouts. After the items to be embedded are placed, the blockouts are filled with heavyweight grout. Precautions should be taken to insure that penetrations and blockouts are tightly grouted. 5.2Preplaced-aggregate method The precautions normally required for formwork for preplaced-aggregate concrete of conventional density are applicable. Additionally, particular care must be taken to ensure a grout-tight seal at those points where penetrations or embedded items pass through the form. Concentrations of electrical conduits, in particular, will present a problem if due care is not exercised. In those instances where voids within the preplaced-aggregate must be measured by flooding with water to determine precise void content, unusual care must be taken not only to make forms grout-tight but also watertight. It is usually impossible to attempt construction of watertight forms other than by using permanent steel liners as the sheeting material, in which case penetrations will be welded, threaded, or gasketed. If grout is to be injected through permanent steel sheeting by means of horizontal insert piping, insert holes should be drilled, tapped, and provided with a simple compression packer to allow gradual withdrawal of the insert pipe during grout injection without objectionable loss of grout around the insert pipe. CHAPTER 6PLACEMENT 6.1Conventional method Placement of conventionally mixed heavyweight concrete is subject to the same considerations of quality control as normal density concrete, except that it is far more susceptible to variations in quality due to improper handling. It is particularly subject to segregation during placement. Segregation of heavyweight concrete results not only in variation of strength but, far more importantly, in variations in density that are intolerable for work of this type, since this adversely affects shielding properties. The placement of heavyweight concrete is frequently required in areas that are congested with reinforcing steel, penetrations, and instrumentation. Placement conditions dictate the strictest observance of good placement practice. Because of the complexity of forms and embedments, it is usually necessary to avoid pump or drop-pipe placement techniques in areas that are inaccessible to direct observation by workmen. However, in other accessible areas, if the mixtures are proportioned properly, they are pumpable and will pump better at a lower slump than normal weight concrete. Ferrophosphorous concrete because of its porosity is especially difficult to pump; therefore, pumping is not recommended for this concrete. Heavyweight concrete usually will not flow in a form and must be placed in each discrete area and compacted in place with a minimum of vibration. Under no circumstances should an attempt be made to move heavy-

304.3R-6

ACI COMMITTEE REPORT

weight concrete with vibration equipment. Lifts should be limited to a maximum 12-in. (300-mm) thickness. ConsolidationConsolidation should conform to ACI 309R, Chapter 14, and should be by internal vibrators to achieve uniform and optimum density. In heavyweight concrete, vibrators have a smaller effective area, or radius of action; therefore, greater care must be exercised to insure that the concrete is properly consolidated. Vibrators should be inserted at closely spaced intervals and only to a depth sufficient to cause complete intermixing of adjacent lifts. CleanupVibration and revibration to remove entrapped air and to establish aggregate-to-aggregate contact cause an excessive amount of grout to collect on the top of lift surfaces.6 This grout matrix (up to 3 in. [75 mm] thick) should be removed from the lift surface at the completion of each placement while the concrete is still in a plastic state. 6.2Preplaced-aggregate method The preplaced-aggregate method is particularly well-suited for use with concretes containing steel punchings or particles as part or all of the coarse aggregate matrix, because the steel particles tend to segregate easily when placed by conventional methods. Additional guidance on the preplaced-aggregate method may be found in ACI 304R and ACI 304.1R. Washing, blending, and handling coarse aggregateFor heavyweight preplaced-aggregate concrete it is essential that coarse aggregate particles be thoroughly washed and be free of any undersized particles prior to placement in the forms to insure unrestricted grout flow through the coarse aggregate matrix. Many of the heavyweight minerals are more susceptible to breakage than normal density crushed rock or gravel. Washing is normally accomplished in a trommel type or rotary wash screen. Frequently it is desirable to blend two types of aggregates by stream blending them into a trommel washer, thus achieving the density, washing, and blending at minimum cost. Careful preliminary tests and repeated quality control tests during this operation must be conducted to make allowances for loss through breakage of each of the two types of aggregates. A second method of blending can also be accomplished by washing the two coarse aggregate fractions separately and subsequently stream blending them onto the conveyor belt that is transferring them to the conveying mechanism. Although the equipment required in this method is more expensive, it has the advantage of permitting aggregate to be washed and stored in advance of placing requirements. Satisfactory results are obtained with this method if care is exercised in the operation of the blending gates. Another coarse aggregate blending method involves washing the various fractions separately, weighing and batching them individually into a blending device such as a concrete mixer, mixing them briefly, and then discharging them through a second washing screen. Steel punchings as delivered from the mill are usually coated with a heavy cutting oil. Degreasing is normally accomplished by tumbling the punchings in perchloroethylene using a transit mix truck. This is followed by rinsing over a washer. The solvent is saved and recirculated to the truck.

After the blending operation, the coarse aggregates are charged into concrete buckets or other means of conveyance, delivered to the forms, and placed in shallow lifts. Short, flexible drop pipes are ordinarily used to avoid breakage of the coarse aggregate and damage to embedded items, and to reduce hand placement of coarse aggregate within the forms. Frequently, hand packing coarse aggregate around embedded items and in severely restricted areas may be required. Coarse aggregate can be tamped lightly after placement, but heavy rodding should be avoided to prevent coarse aggregate breakage or damage to instrumentation. Movement of coarse aggregate particles into restricted areas may be accomplished by use of an air lance, using a short length of 3/8-in. (10-mm) pipe. Placement by this method should be limited insofar as possible to avoid segregation. GroutProcedures for mixing and placing heavyweight grout are the same as those employed with normal density grout. However, because of greater tendency for segregation, line blockages are more frequent. Therefore, ample preparations should be made for rapid clearing of grout hoses and pipes, and ample standby equipment should be available. Since some heavyweight grouts are difficult to pump, a trial is recommended prior to actual operation. CHAPTER 7QUALITY CONTROL 7.1Samples and tests Heavyweight concrete materials and heavyweight concrete should be sampled and tested prior to and during construction to insure conformance with applicable standards and specifications. Guidance presented in these standards as well as previous experience with the same materials will determine the required frequency of testing. The complexity of structures in which heavyweight concrete is placed usually precludes the possibility of taking test cores. Furthermore, extraction of test cores from concrete containing coarse metallic aggregate particles is costly. Unless great care is exercised, the metallic particles will be torn loose from the matrix, destroying both the bit and the core sample. It is, therefore, of the utmost importance that a thorough quality control program be established prior to the start of construction and maintained throughout the duration of construction. 7.2Cement The cement should comply with the requirements of ASTM C 150 or C 595. On projects requiring the submission of mill tests, comparative tests should also be made on samples taken from the cement received at the batch plant. Optional requirements such as heat of hydration, alkali content, and false set properties are important design considerations for some types of construction. 7.3Aggregate The quality of the aggregates should comply with the requirements of ASTM C 33 for normal weight aggregates and ASTM C 637 for heavyweight aggregates. Other special requirements that may be requested by the designer include the fixed water content and limitations on specific chemical con-

HEAVYWEIGHT CONCRETE: MEASURING, MIXING, TRANSPORTING, AND PLACING

304.3R-7

stituents. When ferrophosphorous aggregates are used, tests should be made to determine if gases (nontoxic) might be released during construction. Aggregates should be carefully checked again after delivery to ensure that they conform completely with purchase specifications. Other conditions that are frequently evaluated are the effects of deleterious substances or aggregate coatings on concrete strength or the promotion of corrosion in metallic aggregates or embedments. 7.4Admixtures Chemical admixtures used in the concrete should meet ASTM C 494 requirements. Detailed recommendations for controlling, storing, and handling of admixtures are given in ACI 212.3R. As stated previously, pozzolans and silica fume used in heavyweight concrete should meet the requirements of ASTM C 618 and C 1240, respectively. Additional guidance on the use of fly ash in concrete is given in ACI 226.3R. 7.5Control tests Conventional heavyweight concreteThe quality of the concrete produced should be controlled by an established program of sampling and testing. This program should conform to the requirements of national standards such as ACI 318 and to the requirements of the construction specifications. Quality control tests of freshly mixed concrete should include tests of density, temperature, slump, and air content made in accordance with appropriate ASTM test methods. The limits of rejection for heavyweight concrete should be established in the construction specifications to conform to the design parameters of the structures involved. These tests and control limits are used to avoid incorporating questionable or substandard concrete in the permanent structure. Concrete uniformity tests to evaluate the mixing of the heavyweight concrete should be performed in accordance with procedures given in ASTM C 94. Sampling of concrete and tests for compressive strength and density of hardened concrete should be made in accordance with accepted standards. Preplaced-aggregate heavyweight concreteHeavyweight preplaced-aggregate concrete is adaptable to the use of sophisticated and exacting quality control tests. For example, density may be controlled to within a fixed range of values, the extent of control depending on the complexity and importance of the project. To accomplish this type of control, coarse aggregate should be weighed, and unit density of coarse aggregate should be determined at frequent intervals prior to placement of the coarse aggregate within the forms. If the density is particularly critical, the coarse aggregate in the forms may be flooded with water through a water meter to precisely measure the volume of voids within the coarse aggregate matrix. Records of weight of the aggregate placed, together with measurement of form volume and void volume, will give a precise measure of the density of the coarse aggregate placed. The pumpability of grout is determined with a standard flow cone in accordance with ASTM C 939, expansion and bleeding characteristics by ASTM C 940, water retentivity

by ASTM C 941, and setting characteristics by ASTM C 953. The compressive strength of preplaced-aggregate concrete should be determined in accordance with ASTM C 943 and C 39. The density of all concrete test cylinders should be determined. Where exact density is required, 4- x 4- x 10-in. (100x 100- x 250-mm) prisms should be cut from each test cylinder, except when steel shot or punchings are used, and the density of prism and segments removed should be compared with that of the complete cylinder for determination of the skin effect on density. This skin effect results from the density difference between the formed surface when a cylinder specimen is cast and the fresh surface of a sawed specimen. 7.6Inspection The inspection of heavyweight concrete should be in accordance with applicable ACI standards (ACI 311.1R). Special consideration should be given to the use and operation of equipment used in the production and handling of heavyweight concrete because of its greater density as compared with normal weight concrete. Reduced mixer loading and longer mixing time are usually required for satisfactory results. Other than special modifications required by high density, those items emphasized as important in ACI 304R are also important inspection items for heavyweight concrete. CHAPTER 8REFERENCES 8.1Specified and/or recommended references The documents of the various standards-producing organizations referred to in this document are listed below with their serial designation. The documents listed were the latest effort at the time this document was revised. Since some of these documents are revised frequently, generally in minor detail only, the user of this document should check directly with the sponsoring group if reference to the latest revision is desired. American Concrete Institute ACI 207.1R Mass Concrete ACI 207.2R Effect of Restraint, Volume Change, and Reinforcement on Cracking of Mass Concrete ACI 211.1 Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete ACI 212.3R Chemical Admixtures for Concrete ACI 224R Control of Cracking in Concrete Structures ACI 226.3R Use of Fly Ash in Concrete ACI 301 Specifications for Structural Concrete for Buildings ACI 304R Guide for Measuring, Mixing, Transporting, and Placing Concrete ACI 304.1R Guide for the Use of Preplaced Aggregate Concrete for Structural and Mass Concrete Applications ACI 309R Guide for Consolidation of Concrete ACI 311.1R ACI Manual of Concrete InspectionSP-2 ACI 318 Building Code Requirements for Structural Concrete

304.3R-8

ACI COMMITTEE REPORT

ACI 347R

Guide to Formwork for Concrete

C 1240

Specification for Silica Fume for Use in Hydraulic-Cement Concrete and Mortar

ASTM Standards C 33 Specification for Concrete Aggregates C 39 Test Method for Compressive Strength of Cylindrical Concrete Specimens C 94 Specification for Ready-Mixed Concrete C 150 Specification for Portland Cement C 494 Specification for Chemical Admixtures for Concrete C 595 Specification for Blended Hydraulic Cements C 618 Specification for Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Coal Concrete C 637 Specification for Aggregates for RadiationShielding Concrete C 638 Descriptive Nomenclature of Constituents of Aggregates for Radiation-Shielding Concrete C 937 Specification for Grout Fluidifier for Preplaced-Aggregate Concrete C 938 Practice for Proportioning Grout Mixtures for Preplaced-Aggregate Concrete C 939 Test Method for Flow of Grout for PreplacedAggregate Concrete (Flow Cone Method) C 940 Test Method for Expansion and Bleeding of Freshly Mixed Grouts for Preplaced-Aggregate Concrete in the Laboratory C 941 Test Method for Water Retentivity of Grout Mixtures for Preplaced-Aggregate Concrete in the Laboratory C 943 Practice for Making Test Cylinders and Prisms for Determining Strength and Density of Preplaced-Aggregate Concrete in the Laboratory C 953 Test Method for Time of Setting of Grouts for Preplaced-Aggregate Concrete in the Laboratory

Society of Automotive Engineers SAE J 4 Specification for Cast Shot and Grit for Peening and Cleaning The above publications may be obtained from the following organizations: American Concrete Institute P.O. Box 9094 Farmington Hills, Mich. 48333-9094 ASTM 100 Barr Harbor Drive West Conshohocken, Pa. 19428-2959 Society of Automotive Engineers 400 Commonwealth Dr. Warrendale, Pa. 15096-0001 8.2Cited References

1. Pihlajavaara, S. E., Preliminary Recommendation for Design, Making, and Control of Radiation Shielding Structures, Concrete for Nuclear Reactors, SP-34, V. 1, American Concrete Institute, Farmington Hills, Mich., 1972, pp. 57-67. 2. Davis, Harold S., Concrete for Radiation ShieldingIn Perspective, Concrete for Nuclear Reactors, SP-34, V. 1, American Concrete Institute, Farmington Hills, Mich., 1972, pp. 3-13. 3. Browne, R. D., and Blundell, R., Relevance of Concrete Property Research to Pressure Vessel Design, Concrete for Nuclear Reactors, SP34, V. 1, American Concrete Institute, Farmington Hills, Mich., 1972, pp. 69-102. 4. Nucleonics, McGraw-Hill Publishing Co., New York, June 1955, pp. 60-65. 5. Davis, H. S., Iron Serpentine Concrete, Concrete for Nuclear Reactors, SP-34, V. 3, American Concrete Institute, Farmington Hills, Mich., 1972, pp. 1195-1224. 6. Davis, H. S., N-Reactor Shielding, Concrete for Nuclear Reactors, SP-34, V. 2, American Concrete Institute, Farmington Hills, Mich., 1972, pp. 1109-1161.

You might also like

- 311 4R-00Document12 pages311 4R-00farhadam50% (2)

- Renderoc TgxtraDocument2 pagesRenderoc TgxtratalatzahoorNo ratings yet

- ACI 301 05 SpecsDocument4 pagesACI 301 05 Specsnb_6049755660% (1)

- ACI 304R-00 Measuring, Placing, Mixing and Transporting ConcreteDocument46 pagesACI 304R-00 Measuring, Placing, Mixing and Transporting ConcreteKiramat ShahNo ratings yet

- Steel - and Synthetic Fibre ReinforcedDocument12 pagesSteel - and Synthetic Fibre ReinforcedMangisi Haryanto ParapatNo ratings yet

- ASTM C1550-03 Flexural Toughness of Fiber Reinforced ConcreteDocument9 pagesASTM C1550-03 Flexural Toughness of Fiber Reinforced ConcreteroostercockburnNo ratings yet

- Cold Weather Concreting: Reported by ACI Committee 306Document23 pagesCold Weather Concreting: Reported by ACI Committee 306Miguel DominguezNo ratings yet

- Aci 308 R-01Document31 pagesAci 308 R-01BuddhikaNo ratings yet

- 214.3R - 88simplified Version of The Recommended Practice For Evaluation of Strength Test Results of Concrete PDFDocument8 pages214.3R - 88simplified Version of The Recommended Practice For Evaluation of Strength Test Results of Concrete PDFWaleed AhmedNo ratings yet

- Astma615 615MDocument6 pagesAstma615 615MRahul Bhardwaj100% (1)

- C1107Document4 pagesC1107Pankaj PaulNo ratings yet

- Astm C 823 SamplingDocument7 pagesAstm C 823 SamplingJUBY MBNo ratings yet

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concrete - MyCivil - IrDocument41 pagesACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concrete - MyCivil - IrAyman ZakariaNo ratings yet

- ACI 309R-05 - Guide For Consolidation of ConcreteDocument36 pagesACI 309R-05 - Guide For Consolidation of ConcreteGgcs ConStruct100% (4)

- Wet-Mix-or-DryDocument1 pageWet-Mix-or-DryHuaman Chavez Jesus Angel100% (1)

- Water Penetration of Exterior Metal Roof Panel Systems by Uniform Static Air Pressure DifferenceDocument6 pagesWater Penetration of Exterior Metal Roof Panel Systems by Uniform Static Air Pressure DifferenceAhmad Zubair Rasuly100% (3)

- New Concrete StandardsDocument68 pagesNew Concrete StandardsMohlis Arifin Rukib Wardah0% (1)

- Control Temp in Mass ConcreteDocument9 pagesControl Temp in Mass ConcretechrtromNo ratings yet

- Ready-Mixed Concrete: Standard Specification ForDocument10 pagesReady-Mixed Concrete: Standard Specification ForMinor CastroNo ratings yet

- Astm c497dsvsdvdvDocument10 pagesAstm c497dsvsdvdvaj quintoNo ratings yet

- C933 PDFDocument2 pagesC933 PDFDIAZCORDOBANo ratings yet

- BS6089 Assess Existing Con Struct CORE TESTDocument21 pagesBS6089 Assess Existing Con Struct CORE TESTAnıl Özpirinçi100% (1)

- Astm C900 06Document10 pagesAstm C900 06abualamalNo ratings yet

- ASTM C580 Mortar FlexuralDocument6 pagesASTM C580 Mortar FlexuralHiren Joshi100% (1)

- ASTMDocument8 pagesASTMKalindaMadusankaDasanayakaNo ratings yet

- Astm C856C856M-2020Document15 pagesAstm C856C856M-2020k9999999100% (1)

- Astm A 36a 36M - 2008.05.15Document3 pagesAstm A 36a 36M - 2008.05.15Anonymous ySbxldR8F100% (2)

- Soil Cement ACI - 230 - 1R-09 - PreDocument4 pagesSoil Cement ACI - 230 - 1R-09 - PreIsuru Samaranayake100% (1)

- Sika® Latex PDFDocument2 pagesSika® Latex PDFGina GaelaNo ratings yet

- M55.1-12-Specification For Grouting of Post-Tensioned Structures-Addendum 1-130617Document4 pagesM55.1-12-Specification For Grouting of Post-Tensioned Structures-Addendum 1-130617Vipin Kumar ParasharNo ratings yet

- Silica Fume Used in Cementitious Mixtures: Standard Specification ForDocument7 pagesSilica Fume Used in Cementitious Mixtures: Standard Specification ForRahish RaviNo ratings yet

- 224 1R-93Document22 pages224 1R-93farhadamNo ratings yet

- ASTM C94 C94M 03 Ready Mixed ConcreteDocument10 pagesASTM C94 C94M 03 Ready Mixed ConcreteJuan Ch100% (1)

- Astm e 754Document8 pagesAstm e 754Mauricio RiquelmeNo ratings yet

- ASTM Standards for Corrosion, Erosion and Embrittlement TestingDocument3 pagesASTM Standards for Corrosion, Erosion and Embrittlement Testingabet_singkong8930No ratings yet

- Aci 308.1 PDFDocument13 pagesAci 308.1 PDFOSIIQPGRIS100% (1)

- Is 5512 1983 PDFDocument17 pagesIs 5512 1983 PDFBijaya RaulaNo ratings yet

- Aci 211.2 - 1998 PDFDocument18 pagesAci 211.2 - 1998 PDFBhavanishankar ShettyNo ratings yet

- Standards For Cement, Aggregate, Gupsum. Definitions, Requirements and Test MethodsDocument33 pagesStandards For Cement, Aggregate, Gupsum. Definitions, Requirements and Test MethodsfoxmancementNo ratings yet

- Jisg 3112.2010Document2 pagesJisg 3112.2010Mani MaNo ratings yet

- Hot-Formed Welded and Seamless Carbon Steel Structural TubingDocument6 pagesHot-Formed Welded and Seamless Carbon Steel Structural TubingVenreplast PueblaNo ratings yet

- ASTM C494-C49M-05aDocument10 pagesASTM C494-C49M-05aKidist MollaNo ratings yet

- Concrete in Hot Weather Conditions-Challanges - Precautions: Dr. S. Vijaya Mohan RaoDocument6 pagesConcrete in Hot Weather Conditions-Challanges - Precautions: Dr. S. Vijaya Mohan RaoHussain ElarabiNo ratings yet

- ACI 503.7-07 Specification For Crack Repair by Epoxy InjectionDocument11 pagesACI 503.7-07 Specification For Crack Repair by Epoxy InjectionSergio VianaNo ratings yet

- Astm D 1854 PDFDocument3 pagesAstm D 1854 PDFJohn Errol Saldevar MarcosNo ratings yet

- ACI-207.4R-93 Cooling and Insulating Systems For Mass ConcreteDocument22 pagesACI-207.4R-93 Cooling and Insulating Systems For Mass Concreteorlandomanriquez100% (2)

- Guide For Concrete Construction Quality Systems in Conformance With ISO 9001Document2 pagesGuide For Concrete Construction Quality Systems in Conformance With ISO 9001anigz570No ratings yet

- Air-Entraining Admixtures For ConcreteDocument4 pagesAir-Entraining Admixtures For ConcretemameniqNo ratings yet

- A 416 A416-M - 99Document5 pagesA 416 A416-M - 99Tan Tanju100% (1)

- ASTM C94 C94M Standard Specification For Ready-Mixed ConcreteDocument1 pageASTM C94 C94M Standard Specification For Ready-Mixed ConcreteAmanda Ariesta ApriliaNo ratings yet

- Acid-Soluble Chloride in Mortar and Concrete: Standard Test Method ForDocument4 pagesAcid-Soluble Chloride in Mortar and Concrete: Standard Test Method ForRodney SalazarNo ratings yet

- ASTM C881 Epoxy SystemsDocument1 pageASTM C881 Epoxy SystemsRodrigo GarcíaNo ratings yet

- ACI 207.1R-05 Guide To Mass ConcreteDocument31 pagesACI 207.1R-05 Guide To Mass ConcreteLukusa Badimuena100% (3)

- 3043r - 96 Heavyweight Concrete PDFDocument8 pages3043r - 96 Heavyweight Concrete PDFCarlos Henry Laura CastilloNo ratings yet

- ACI 3259r - 91 - Guide For Construction of Concrete Pavements & BasesDocument27 pagesACI 3259r - 91 - Guide For Construction of Concrete Pavements & BasesTrader Red100% (1)

- Lloyds Gre PDFDocument0 pagesLloyds Gre PDFLegend AnbuNo ratings yet

- Placing Concrete by Pumping Methods: ACI 304.2R-96Document25 pagesPlacing Concrete by Pumping Methods: ACI 304.2R-96منير أحمدNo ratings yet

- Quality and Durability of Stone For Construction Lan SimsDocument7 pagesQuality and Durability of Stone For Construction Lan SimsJaouad OuaâzizNo ratings yet

- 3043r - 96 - Heavyweight Concrete (Measuring, Mixing, Transporting, and Placing)Document8 pages3043r - 96 - Heavyweight Concrete (Measuring, Mixing, Transporting, and Placing)vireakthong chuonNo ratings yet

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteDocument41 pagesACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concretebonnico75% (4)

- AWS QC 11-96 Spec 4 Qualification Certification Advanced Level WelderDocument38 pagesAWS QC 11-96 Spec 4 Qualification Certification Advanced Level Welderminhnn50% (2)

- AWS QC 10-95 Spec 4 Qualification Certification Entry Level WelderDocument25 pagesAWS QC 10-95 Spec 4 Qualification Certification Entry Level WelderminhnnNo ratings yet

- 124 2R-94 PDFDocument1 page124 2R-94 PDFfarhadamNo ratings yet

- Aci 304.2R-96Document25 pagesAci 304.2R-96minhnnNo ratings yet

- Welding EngineerDocument10 pagesWelding EngineerNnamdi Celestine NnamdiNo ratings yet

- ACI 304 (1) .3R-96 - Heavyweight Concrete. Measuring, Mixing, TraDocument12 pagesACI 304 (1) .3R-96 - Heavyweight Concrete. Measuring, Mixing, TrawilsonschmittNo ratings yet

- Aci 117 - 90 Concrete Construction PDFDocument16 pagesAci 117 - 90 Concrete Construction PDFcessare08100% (4)

- Aws Qc5-91 - Standard For Certification of Welding EducatorsDocument12 pagesAws Qc5-91 - Standard For Certification of Welding Educatorscamelod555No ratings yet

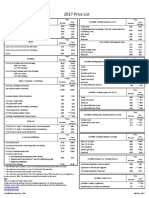

- 2236 Price List 2017 20170306Document1 page2236 Price List 2017 20170306minhnn100% (1)

- Aci 117 R90Document11 pagesAci 117 R90Rafael Elgueta Aravena100% (1)

- ACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteDocument10 pagesACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteZaki 'Eki' MuliawanNo ratings yet

- 126 3R-99 PDFDocument50 pages126 3R-99 PDFfarhadamNo ratings yet

- Aci 304.6R-91Document14 pagesAci 304.6R-91minhnnNo ratings yet

- Batching, Mixing and Job-Control of Lightweight ConcreteDocument9 pagesBatching, Mixing and Job-Control of Lightweight ConcreteRonaldo HertezNo ratings yet

- QCF005 Survey LogDocument2 pagesQCF005 Survey LogminhnnNo ratings yet

- ACI 304R-89. Guide For Measuring, Mixing, Transporting, andDocument54 pagesACI 304R-89. Guide For Measuring, Mixing, Transporting, andminhnnNo ratings yet

- QCF006 Placement & Compaction of Fill MaterialDocument1 pageQCF006 Placement & Compaction of Fill MaterialminhnnNo ratings yet

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteDocument41 pagesACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concretebonnico75% (4)

- QCF007 Post Pour Inspection and Concrete RepairDocument1 pageQCF007 Post Pour Inspection and Concrete Repairminhnn100% (1)

- CQC008Document1 pageCQC008minhnnNo ratings yet

- QCF011 Asphalt Concrete Site ControlDocument3 pagesQCF011 Asphalt Concrete Site ControlminhnnNo ratings yet

- QCF009 Insp Report-Precast ConcreteDocument1 pageQCF009 Insp Report-Precast ConcreteminhnnNo ratings yet

- QC Form Dung Quat Refinery ProjectDocument1 pageQC Form Dung Quat Refinery ProjectminhnnNo ratings yet

- QCF010 Works Inspection Report GeotextileDocument1 pageQCF010 Works Inspection Report GeotextileminhnnNo ratings yet

- QCF012 Authorisation To BackfillDocument1 pageQCF012 Authorisation To BackfillminhnnNo ratings yet

- QCF102 Concrete Pouring RecordDocument1 pageQCF102 Concrete Pouring RecordminhnnNo ratings yet

- Dung Quat Refinery Project: Works Inspection ReportDocument1 pageDung Quat Refinery Project: Works Inspection ReportminhnnNo ratings yet

- QCF013 Materials Inspection ReportDocument1 pageQCF013 Materials Inspection ReportminhnnNo ratings yet

- QCF101 Compaction Test ReportDocument1 pageQCF101 Compaction Test ReportminhnnNo ratings yet

- Chapter9 EscabarteDocument30 pagesChapter9 EscabarteDarwin CruzNo ratings yet

- Metallurgy - Chapter (5) - Steels and Cast IronsDocument79 pagesMetallurgy - Chapter (5) - Steels and Cast IronsKarim Mamdouh100% (1)

- 2-Volume I Part IIDocument48 pages2-Volume I Part IIBasava NNo ratings yet

- Finishing ChemicalsDocument8 pagesFinishing ChemicalsL.N.CHEMICAL INDUSTRYNo ratings yet

- Understanding and Minimizing Gas Defects in Iron CastingsDocument2 pagesUnderstanding and Minimizing Gas Defects in Iron Castingsmecaunidos7771No ratings yet

- Differientiation Through The Weave PU Hoses From 3 Ply PU HosesDocument9 pagesDifferientiation Through The Weave PU Hoses From 3 Ply PU HosesAaron Homing NiNo ratings yet

- Bo Bergman Knifemaking PDFDocument154 pagesBo Bergman Knifemaking PDFFrancisco Bustos-González75% (4)

- Seminar On Orthodontic MaterialsDocument223 pagesSeminar On Orthodontic MaterialsChirag Patil100% (1)

- Basement Waterproofing New ConstructionDocument19 pagesBasement Waterproofing New ConstructionDevinder ChawlaNo ratings yet

- Structural SpecificationsDocument102 pagesStructural SpecificationsAlden CayagaNo ratings yet

- On Fly Ash by Sumit SumanDocument20 pagesOn Fly Ash by Sumit SumanSumit Suman100% (3)

- Introduction To PolymersDocument110 pagesIntroduction To Polymersykhamidi3889100% (1)

- Armstrong LaminateDocument68 pagesArmstrong LaminateJaime RiveraNo ratings yet

- SCC With CoirDocument10 pagesSCC With CoirgobinathdpiNo ratings yet

- Milling of GFRP CompositesDocument5 pagesMilling of GFRP CompositesNaresh DeshpandeNo ratings yet

- Char Waste as a Viable Road MaterialDocument34 pagesChar Waste as a Viable Road MaterialUmer FarooqNo ratings yet

- Surface Preparation & Painting Procedure SampleDocument29 pagesSurface Preparation & Painting Procedure SampleSyaiful Rasyidi TamsirNo ratings yet

- Chapter 16. PolymersDocument4 pagesChapter 16. PolymersAnonNo ratings yet

- Evince Textile Limited: Internship ExperienceDocument9 pagesEvince Textile Limited: Internship ExperienceAnik IslamNo ratings yet

- Nitomortar TC2000 Epoxy ResinDocument3 pagesNitomortar TC2000 Epoxy ResingrtunaNo ratings yet

- Vacman's Notes - Bag Penetration Fittings For CompositesDocument2 pagesVacman's Notes - Bag Penetration Fittings For CompositesopytnymoryakNo ratings yet

- Permanent Mold CastingDocument2 pagesPermanent Mold CastingEditor IJRITCCNo ratings yet

- Plywood Used in So Many Different Ways: Eaturing Lywood in UildingsDocument23 pagesPlywood Used in So Many Different Ways: Eaturing Lywood in Uildingspilapil_jNo ratings yet

- Puradrain CatalogueDocument20 pagesPuradrain CatalogueCristina StamateNo ratings yet

- Rochor Station Pile Design CalculationsDocument15 pagesRochor Station Pile Design CalculationsDifa LiuNo ratings yet

- Cotton ListDocument22 pagesCotton ListL.N.CHEMICAL INDUSTRYNo ratings yet

- Flat RoofDocument2 pagesFlat RoofHarry ThienNo ratings yet

- Viton Material - Dopont PDFDocument1 pageViton Material - Dopont PDFKamlesh DalavadiNo ratings yet

- Construction hydro techniques and dam evolutionDocument47 pagesConstruction hydro techniques and dam evolutionGaftoi Daniel AndreiNo ratings yet

- 3M Brand Abrasive CatalogueDocument48 pages3M Brand Abrasive Cataloguetoxicity23No ratings yet