Professional Documents

Culture Documents

TechnicalData - LHM600 - TE - 8x2 - 06SEP13

Uploaded by

kbenjikaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TechnicalData - LHM600 - TE - 8x2 - 06SEP13

Uploaded by

kbenjikaCopyright:

Available Formats

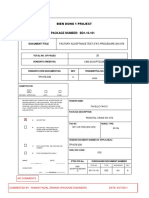

HARBOUR MOBILE CRANE

TYPE

LHM 600 Litronic

TECHNICAL DATA

LWN

28.12.2012

Rev. 2012/07

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 1

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

TECHNICAL DATA

TABLE OF CONTENTS

MAIN DATA

1.1

Load Table

1.1.1 Load Capacity Chart

1.1.2 Travelling Window

1.2

Operating Speeds

1.3

Weights

1.4

Dimensions

1.5

Environmental Conditions

1.6

Requirements on Quay

1.7

Drive System

1.8

Hydraulic Oil

1.9

Lighting

1.10 Heating

1.11 Group Classification of Crane and Components

1.12 Documentation

1.13 Protective Coat/Painting

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 2

10

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1

MAIN DATA

1.1

Load Table

1.1.1 Load Capacity Chart

Hook Operation

Utilisation of Tipping

75%

Radius

(m)

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Spreader

Operation

Spreader

Operation

under twin lift

Spreader

on Rope

on Hook

under

Spreader

(t)

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

104,0

102,0

98,3

94,8

91,6

88,6

85,7

82,7

80,0

77,3

74,6

72,2

69,8

67,6

65,4

63,5

61,4

59,6

57,9

56,1

54,5

53,0

51,6

50,2

49,0

47,8

(t)

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

101,0

99,0

95,3

91,8

88,6

85,6

82,7

79,7

77,0

74,3

71,6

69,2

66,8

64,6

62,4

60,5

58,4

56,6

54,9

53,1

51,5

50,0

48,6

47,2

46,0

44,8

(t)

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

41,0

39,6

38,2

37,0

35,8

Dead weight rotator =

3,0 t

Dead weight spreader single=

9,0 t

SWL spreader =

41,0 t

Dead weight spreader twin=

10,7 t

SWL twin lift spreader =

50,0 t

(t)

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

50,0

49,8

47,7

45,9

44,2

42,4

40,8

39,3

37,9

36,5

35,3

34,1

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 3

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1.1.2 Travelling Window

For travelling the boom of crane must be positioned either over front part

(slew angle = 0) or over rear part of undercarriage (slew angle = 180).

As standard the maximum load on ropes during travelling is (travelling in both

directions) 25t .

1.2

Operating Speeds

* 100 percent infinitely variable speed control from zero to maximum speed

* electronic-controlled acceleration/deceleration, to avoid shocks to crane

and load and to enable smoother speed control

* automatic power output regulators

* slewing, luffing, hoisting can be operated simultaneously

ac- / deceleration time

Hoisting / Lowering

appr. 1 sec

appr. 3 sec

20,0

25,0

33,0

40,0

120,0

m/min with

m/min with

m/min with

m/min with

m/min with

100

80

60

50

t

t

t

t

empty hook

Slewing

Luffing

Travelling

appr. 5-6 sec

appr. 2 sec

appr. 6 sec

Max. inclination in transverse direction

Max. inclination in longitudinal direction

1.3

0 - 1,6 rpm

280 m/min

360

max speed boom head

unlimited slewing range

41 sec

with full load from max. to min working

radius (theoretical without ac- and

deceleration)

68 m/min

average horizontal speed

0 - 5 km/h

2%

5%

without load

without load, during travelling

without load, during travelling

Weights

Total weight of crane

appr.

548 t

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 4

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1.4

Dimensions

Support base

14 m x 14 m

Special size of supporting pads

Special supporting area of pads

8.0 m x 2.0 m

16 m

Overall width without supporting pads

Overall width with supporting pads

and swung in outriggers

Overall width in traveling position

and deployed outriggers

6,4 m

10,2 m

Overall length of undercarriage

Length of boom (centre sheaves)

Overall height (top of tower)

Height of boom fulcrum

Cab height (eye level)

24,7

60,0

43,5

23,4

29,9

Turning radius

Tail swing radius

0m

14,2 m

7,8 m

Max. hoisting height (measured at crane rope socket)

above quay at minimum radius

above quay at maximum radius

below quay

45,0 m

40,3 m

15,0 m

16 m

incl. supporting pads

Winchconfiguration

Number of winches

Diameter of hoisting rope

Diameter of sheaves at boom head

Ratio between diameter of hoisting rope to sheaves

Diameter of rope drum

Ratio between diameter of rope to drum

Number of axle sets

Axle sets driven

Axle sets steerable

No. of tyres

Tyres

Tyre pressure

m

m

m

m

m

inner

outer

1x104t

1 (2 ropes per winch)

46 mm

1046 mm

1 : 22,7

1100 mm

1 : 23,9

24

8

all

4 per axle set

285/70 R 19.5 make Continental

10 bar max

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 5

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1.5

Environmental Conditions

Ambient temperature

Humidity (relative)

Max. wind speed in operation

Max. wind speed out of operation

Max. wind speed during travelling

1.6

-20 C to +45

97

24

42

20

C

%

m/s

m/s

m/s

Requirements on Quay

During crane operation and driving,the following pressures are relevant

Assumed Conditions:

Normal

Extreme

=

=

Max. axle set loading:

all static loads are included

all static loads and dynamic factors are included

Normal

Extreme

( 2 axle sets = 1 axle line)

appr.

appr.

22,5 t

27,6 t

Max. Corner Loading:

Normal

(static excl. wind)

Normal

(static incl. wind)

Extreme

(dynamic incl. wind)

boom 45

boom 90

75%

323,5 t

276,7 t

Grab

262,3 t

230,9 t

boom 45

boom 90

343,6 t

285,3 t

273,8 t

239,0 t

boom 45

boom 90

365,5 t

294,6 t

292,6 t

251,7 t

boom 45

boom 90

75%

20,2 t/m

17,3 t/m

Grab

16,4 t/m

14,4 t/m

boom 45

boom 90

21,5 t/m

17,8 t/m

17,1 t/m

14,9 t/m

boom 45

boom 90

22,8 t/m

18,4 t/m

18,3 t/m

15,7 t/m

Max. Area Pressure:

Normal

(static excl. wind)

Normal

(static incl. wind)

Extreme

(dynamic incl. wind)

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 6

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1.7

Drive System

Prime mover

Make

Type

Combustion system

Number of cylinder

Cooling system

Max. torque

Output on the drive shaft

1.8

Diesel Engine

MAN

D 2842 LE

Diesel

12

Water

3300 Nm

670 kW

at 1300-1700 rpm

at 1900 rpm acc. ISO 9249

Average consumption

Fuel tank capacity

208 g/KWh

15000 l

Starter

Output

Dynamo

Nominal current

Voltage

Bosch

9

Bosch

140

24

QB

kW

Amp

V

Hydraulic Oil

Oil

See table of lubricants

Oil cooling

The hydraulic driven oil cooler is located outside

the machinery room, protected via cover,

cooling medium is fresh air

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 7

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1,9

Lighting

Appropriate illumination is fitted in

- machinery room

- switch cabinet room

- cabs

- access to the crane

Floodlight type

- high pressure sodium lamps

Position

- two on the boom

- one on the tower

Rating (per floodlight)

1000 W - 230 V

Steps from the tower cabin are provided with battery-buffered 24 VDC emergency lights.

Two warning lights (on undercarriage) and a ringing bell when travelling are standard

1.10 Heating

- Heating of driver's cabins (tower cab 6 kW, optional lower cab 4 kW)

- Heating of switch cabinet room (1 x 2 kW)

- Standstill heating of slipring collector, switch cabinet

- Total installed heating capacity approx. 12 kW.

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 8

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1.11 Group Classification of Crane and Components

Authorities, Regulations

EN, FEM, DIN, VDE, VDI, IEC, ISO

Classification of crane as a whole in appliance groups

Hook operation

Hook operation

Spreader Operation

Motor Grab Operation

Crane group at operation with

75%

Grab

SWL <104t

A3

SWL <47t

A8

SWL <63t

A7

SWL <52t

A8

Classification of individual mechanisms

Mechanism group

Hook

operation

Winch gear

Luffing gear

Slewing gear

Travelling gear

Hook

operation

spreader

M7 (70t) M4 (104t) M8 (63t)

M7

M7

M7

M6

M7

M6

M4

M4

M4

motor

grab

M8 (63t)

M7

M7

M4

1.12 Documentation

Standard scope of delivery includes

- 3 operation/maintenance manuals

- 3 spare parts books

- 3 works certificates

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 9

Liebherr Harbour Mobile Crane,

LHM 600 Litronic

1.13 Protective Coat/Painting

I

GENERAL

II

CRANE - INTERNAL SURFACES

- Liebherr LH N 983593014

- Cleaning and Substrate Preparation

Solvent Cleaning/Degreasing

Shot Blasting SA 2.5 (ISO 8501-1)

- Surface Profile: Comparator Type "G"

Segment 2-3 (ISO 8503-1)

Film thickness

1 Priming Coat

2-Pack Zinc Rich Epoxy Primer

Interzinc 315 HS

75(+30/-20) microns

3 Finish Coat

2-Pack Epoxy

Amerlock 400C

110(+15/-15) microns

-------------------------------------------------------------------------------------------------Total Min. Dry Film Thickness

185

microns

========================================================

III

CRANE - EXTERNAL SURFACES

Film thickness

1 Priming Coat

2-Pack Zinc Rich Epoxy Primer

Interzinc 315 HS

75(+30/-20) microns

2 Intermediate Coat

2-Pack Epoxy

Amerlock 400 C or Interseal 670 HS

100(+25/-15) microns

3 Finish Coat

2-Pack Polyurethane Finish

Interfine 979 or PSX 700

75(+15/-15) microns

-------------------------------------------------------------------------------------------------Total Min. Dry Film Thickness

250

microns

========================================================

Note:

Above values are related to primary structure.

The final colour shade for undercarriage, slewing platform steel construction, counter weights and tower is RAL 7043.

The colour shade for the slewing platform is Liebherr yellow (RAL 1006-1007), jib and housing of the cooling devices are in RAL 7047.

The cabin is in RAL 9002.

All ladders, stairs, walkways, etc. are hot dip galvanised.

- Subject to engineering modification -

--------------------------------------------------------------- Liebherr Werk Nenzing GmbH ----------------------------------------------------------- Page: 10

You might also like

- Sheet Pile Design HandbookDocument368 pagesSheet Pile Design HandbookLandon Mitchell92% (12)

- Steel Sheet Piling Design ManualDocument135 pagesSteel Sheet Piling Design Manualv100% (16)

- Drilling Rig Components and OperationsDocument67 pagesDrilling Rig Components and OperationsMohamed Kamal100% (1)

- Operator's Manual for MT-X 732 D-E3 and MT-X 1030 S T S4-E3 Lift TrucksDocument144 pagesOperator's Manual for MT-X 732 D-E3 and MT-X 1030 S T S4-E3 Lift TrucksYuda Perdana SamuraNo ratings yet

- Fishing Tool ManualDocument152 pagesFishing Tool ManualDozie Kesieme100% (8)

- RH 1170069Document403 pagesRH 1170069Luis ReyNo ratings yet

- BMK 1100 2 enDocument113 pagesBMK 1100 2 enEdilson100% (4)

- Operating Manual for Worm Gear Hydraulic WinchDocument32 pagesOperating Manual for Worm Gear Hydraulic WinchvinetamarinovicNo ratings yet

- Croatian PDFDocument21 pagesCroatian PDFkbenjikaNo ratings yet

- Croatian PDFDocument21 pagesCroatian PDFkbenjikaNo ratings yet

- Sauer-Danfoss Mcx103b D Rotary Position Sensor TechnicalDocument8 pagesSauer-Danfoss Mcx103b D Rotary Position Sensor TechnicalJosé Fidencio Carrillo Moreno0% (1)

- Demag Crawler Cranes Spec CC1800 (300T)Document58 pagesDemag Crawler Cranes Spec CC1800 (300T)hariridkNo ratings yet

- Section 1 Truck & Skid Mounted WL PPs & Spool UnitsDocument33 pagesSection 1 Truck & Skid Mounted WL PPs & Spool Unitstongsabai50% (2)

- FUELTANKSAFETY caaUKDocument40 pagesFUELTANKSAFETY caaUKVojinovic Vojin100% (2)

- Testing-and-Adjusting-Hydraulic-Systems-RENR-9585 330 PDFDocument133 pagesTesting-and-Adjusting-Hydraulic-Systems-RENR-9585 330 PDFCarlos Ushiña100% (4)

- Replacing Seals on KP 30 Hydraulic PumpsDocument174 pagesReplacing Seals on KP 30 Hydraulic PumpsSergeyNo ratings yet

- Europe's Longest Marine PE Pipe ProjectDocument8 pagesEurope's Longest Marine PE Pipe Projectmidhun1986No ratings yet

- 65M Construction Vessel SpecDocument98 pages65M Construction Vessel Specronny-su100% (1)

- China NFLG NFS780 Mobile Screen Spare Parts Manual 2022Document175 pagesChina NFLG NFS780 Mobile Screen Spare Parts Manual 2022JonesNo ratings yet

- HIGHPRESSUNIT-MS2059 - Operation & Maintenance ManualDocument33 pagesHIGHPRESSUNIT-MS2059 - Operation & Maintenance Manualzulu80No ratings yet

- Acoustics AACTx R150 L01 Introduction To AcousticsDocument71 pagesAcoustics AACTx R150 L01 Introduction To AcousticsPercy Romero MurilloNo ratings yet

- Autoclave Engineers - Valves Fittings and Tubing - Condensed CatalogDocument16 pagesAutoclave Engineers - Valves Fittings and Tubing - Condensed Catalogchristophedepaepe100% (1)

- GrabDocument15 pagesGrabvihaanNo ratings yet

- Boiler and Steam SystemDocument33 pagesBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Storm BrakesDocument63 pagesStorm Brakesrochim_putech_126885No ratings yet

- Heavy Oil Drag Reducing Agent PDFDocument12 pagesHeavy Oil Drag Reducing Agent PDFMichael MedinaNo ratings yet

- Stros7000 Full Instructions ManualDocument91 pagesStros7000 Full Instructions ManualCJCONSTANTENo ratings yet

- BRDM-2 Tech Manual enDocument107 pagesBRDM-2 Tech Manual enAndrewStaib86% (7)

- List of Machine Draft N. DraftDocument58 pagesList of Machine Draft N. DraftАлексей100% (2)

- Determinant of Global Crude Oil Pricing Theoretical ReviewDocument10 pagesDeterminant of Global Crude Oil Pricing Theoretical ReviewibidaboNo ratings yet

- HMK300 GottwaldDocument2 pagesHMK300 GottwaldkbenjikaNo ratings yet

- Bal 001 en PDFDocument651 pagesBal 001 en PDFAaron Muñozc100% (1)

- SMP Tiltrotator Installation ManualDocument36 pagesSMP Tiltrotator Installation ManualVeikko OnnelaNo ratings yet

- Active Heave Compensation Winch System - ACE Winches PDFDocument24 pagesActive Heave Compensation Winch System - ACE Winches PDFxxshNo ratings yet

- Cleanliness in Hydraulic SystemsDocument217 pagesCleanliness in Hydraulic SystemsSajeev NerurkarNo ratings yet

- The Design of Interlocking Concrete Block Pavements For Road TrafficDocument10 pagesThe Design of Interlocking Concrete Block Pavements For Road Traffickbenjika100% (1)

- CBB 450 (250) /17Document204 pagesCBB 450 (250) /17Oleg100% (1)

- Bromma - EH170U PDFDocument458 pagesBromma - EH170U PDFTopo MendigoNo ratings yet

- Buch80107en PDFDocument324 pagesBuch80107en PDFNikolay KirovNo ratings yet

- Liebherr Slewing Bearings Product Catalogue en Metric WebDocument158 pagesLiebherr Slewing Bearings Product Catalogue en Metric WebИгорьNo ratings yet

- HMK300EDocument9 pagesHMK300EkbenjikaNo ratings yet

- HMK300EDocument9 pagesHMK300EkbenjikaNo ratings yet

- Liebherr LRB355 Piling and Drilling Rig Data Sheet 11890403 EnglishDocument20 pagesLiebherr LRB355 Piling and Drilling Rig Data Sheet 11890403 EnglishManuelNo ratings yet

- DSH PresentationDocument16 pagesDSH Presentationkbenjika100% (1)

- API Safety and Fire Protection PublicationDocument6 pagesAPI Safety and Fire Protection PublicationDan PascoNo ratings yet

- Capacity 5,0 m3 (1) New CraneDocument64 pagesCapacity 5,0 m3 (1) New CraneAnonymous iI88LtNo ratings yet

- Jet GroutingDocument8 pagesJet GroutingiskeletorsNo ratings yet

- Parts Manual: Date Group Fig. 4Document20 pagesParts Manual: Date Group Fig. 4ruslanNo ratings yet

- Terex PDFDocument48 pagesTerex PDFmovie hunter100% (1)

- 05 Melcal Crane SpecificationDocument21 pages05 Melcal Crane SpecificationGabriel Cujia QuinteroNo ratings yet

- Installation Manual for Liebherr Crane Model BOS 4200-100 LITRONICDocument55 pagesInstallation Manual for Liebherr Crane Model BOS 4200-100 LITRONICLaur Iri100% (2)

- LH 185 DS 0062 6Document6 pagesLH 185 DS 0062 6Primelift Safety Resources LimitedNo ratings yet

- Steel Pipe Piles 1999Document84 pagesSteel Pipe Piles 1999vothephuong100% (3)

- Steel Pipe Piles 1999Document84 pagesSteel Pipe Piles 1999vothephuong100% (3)

- Kerosene PDFDocument9 pagesKerosene PDFishnafathonahNo ratings yet

- AD - 001 - EN Spreader BROMADocument682 pagesAD - 001 - EN Spreader BROMAKevin Leon Izaguirre100% (2)

- Getting Strated With Aspen PIMS (1st Ed)Document180 pagesGetting Strated With Aspen PIMS (1st Ed)Ahsan Jalal89% (36)

- Technical Data LHM 550Document10 pagesTechnical Data LHM 550Amine Dhahri100% (1)

- Assembly LHM 600HR, 58 M, Disassembled With Photos AddDocument13 pagesAssembly LHM 600HR, 58 M, Disassembled With Photos AddReinaldo ZorrillaNo ratings yet

- Ad 001 en PDFDocument84 pagesAd 001 en PDFEstebanCortezNo ratings yet

- Palfinger Wind - The For Innovative and High-QualityDocument16 pagesPalfinger Wind - The For Innovative and High-QualityChieuNo ratings yet

- 2 En1Document90 pages2 En1Ngà NguyễnNo ratings yet

- AtlasGroup Album enDocument84 pagesAtlasGroup Album envatasaNo ratings yet

- 058120-000 TL-49 sn1001+ E.PSDocument115 pages058120-000 TL-49 sn1001+ E.PSwillooohNo ratings yet

- Danbar - Eurodrill HeadDocument55 pagesDanbar - Eurodrill Headmark100% (1)

- Factory Acceptance Test Procedure for Pedestal Crane 1676Document29 pagesFactory Acceptance Test Procedure for Pedestal Crane 1676Anonymous 1ykzuaxWgYNo ratings yet

- Instruction Manual: Board CraneDocument10 pagesInstruction Manual: Board CraneKL PetrachkovNo ratings yet

- Mecalac MWR BrochureDocument40 pagesMecalac MWR BrochureSamantha Marchand FirthNo ratings yet

- General Dimensions: R3850 Rear Rad IusDocument8 pagesGeneral Dimensions: R3850 Rear Rad IusHenry WijayaNo ratings yet

- Rt530e Grove CraneDocument12 pagesRt530e Grove Craneviju1981100% (1)

- Liebherr Datasheet 357 HC L 12 24 Litronic en 2019Document12 pagesLiebherr Datasheet 357 HC L 12 24 Litronic en 2019Rajkumar KNo ratings yet

- 1984 Nooteboom Osdb45vv 3 Axles Extendible Low Loader TrailerDocument1 page1984 Nooteboom Osdb45vv 3 Axles Extendible Low Loader TrailerdemulderNo ratings yet

- 200 Tonnes Liebherr LR1200Document0 pages200 Tonnes Liebherr LR1200Saure GnuNo ratings yet

- 20110928144103195Document12 pages20110928144103195Benny MarbunNo ratings yet

- TM 5 3810 300 10Document198 pagesTM 5 3810 300 10Денис ЧерныйNo ratings yet

- QUY150C 150t Crawler Crane BrochureDocument59 pagesQUY150C 150t Crawler Crane BrochureliftNo ratings yet

- CasappaDocument44 pagesCasappaback1949No ratings yet

- Tavola Esplosi MA 100 ID EngDocument5 pagesTavola Esplosi MA 100 ID EngDenisNo ratings yet

- Sandvik Ds210l VDocument4 pagesSandvik Ds210l Vlorenzo henerNo ratings yet

- Repair SD 100 5Document16 pagesRepair SD 100 5aytepeNo ratings yet

- Harken 40.2st 06Document2 pagesHarken 40.2st 06Stuartp1No ratings yet

- CraneDocument10 pagesCraneAvishek Sen Gupta100% (1)

- Hour Meter: Component Tracking - Lac Des Iles Mines LTDDocument7 pagesHour Meter: Component Tracking - Lac Des Iles Mines LTDgrtyyNo ratings yet

- Liebherr LR 1250 Crawler Crane Technical Data Sheet Specifications EnglishDocument40 pagesLiebherr LR 1250 Crawler Crane Technical Data Sheet Specifications EnglishtoppyhtunNo ratings yet

- KBB 1000 PDFDocument43 pagesKBB 1000 PDFJohan SanchezNo ratings yet

- 12 Standards - Technical Seminar For Cathodic Protection To GOGC DesignDocument13 pages12 Standards - Technical Seminar For Cathodic Protection To GOGC DesignkbenjikaNo ratings yet

- Chapter 5.1: Wave Impact Loads - Pressures and ForcesDocument45 pagesChapter 5.1: Wave Impact Loads - Pressures and ForcessNo ratings yet

- PPR Oumeraci WaveLoadsDocument116 pagesPPR Oumeraci WaveLoadsgeofounNo ratings yet

- Marine Outfall DesignDocument42 pagesMarine Outfall Designkbenjika100% (1)

- Coastal and MarineDocument8 pagesCoastal and MarinekbenjikaNo ratings yet

- Puerto Las Losas Ficha TecnicaDocument1 pagePuerto Las Losas Ficha TecnicakbenjikaNo ratings yet

- Interlocking Concrete Paving The State of The Art in AustraliaDocument8 pagesInterlocking Concrete Paving The State of The Art in AustraliakbenjikaNo ratings yet

- CBR IndexDocument204 pagesCBR IndexBoris CavarNo ratings yet

- 2013-03-15, Technical Data International, EDocument1 page2013-03-15, Technical Data International, EkbenjikaNo ratings yet

- PIANC N°88 1995 Movments of Ships in HarbourDocument36 pagesPIANC N°88 1995 Movments of Ships in HarbourkbenjikaNo ratings yet

- HB Wick and Earthquake Drain Case Study Oakland Bay Bridge1Document2 pagesHB Wick and Earthquake Drain Case Study Oakland Bay Bridge1kbenjikaNo ratings yet

- Naval Air StationDocument2 pagesNaval Air StationkbenjikaNo ratings yet

- 2013-03-15, Technical Data Switzerland, EDocument1 page2013-03-15, Technical Data Switzerland, EkbenjikaNo ratings yet

- Panzerbelt Cable Protection System CatalogueDocument16 pagesPanzerbelt Cable Protection System CataloguekbenjikaNo ratings yet

- Chile Presentation Hanping HongDocument42 pagesChile Presentation Hanping HongkbenjikaNo ratings yet

- GTD Trench Infill Data SheetDocument2 pagesGTD Trench Infill Data SheetkbenjikaNo ratings yet

- Rerouting The Idle Air PathwayDocument9 pagesRerouting The Idle Air PathwayTodd SandersNo ratings yet

- Mechanical Engineer Resume with Power Plant ExperienceDocument4 pagesMechanical Engineer Resume with Power Plant ExperienceMohamed FahmyNo ratings yet

- Caterpillar Marine EPA Tier 4 Sales PresentationDocument32 pagesCaterpillar Marine EPA Tier 4 Sales PresentationAnji Reddy DNo ratings yet

- Auburn Tune Up 14pagesDocument14 pagesAuburn Tune Up 14pagesjorge Angel LopeNo ratings yet

- Process Design Basis RevA - PLLSG CommentsDocument7 pagesProcess Design Basis RevA - PLLSG CommentschemjojoNo ratings yet

- Ignition LagDocument2 pagesIgnition Lageafz111No ratings yet

- Copic Color Wheel 358Document1 pageCopic Color Wheel 358kotoirNo ratings yet

- EFI-SystemDocument35 pagesEFI-SystemShrvan Hirde100% (2)

- Five-Spot Vs Crestal Waterflood PatternsDocument4 pagesFive-Spot Vs Crestal Waterflood PatternsWafindraNo ratings yet

- Sugar MillDocument6 pagesSugar MillgksaraffNo ratings yet

- Alfa Laval FCM - Kunshan SeminarDocument23 pagesAlfa Laval FCM - Kunshan Seminar麥香紅茶No ratings yet

- List of HW Transporter 12312018 For Posting Rev UpdatedDocument21 pagesList of HW Transporter 12312018 For Posting Rev UpdatedMaleahkat SantosNo ratings yet

- Waste Cook Oil To BiodieselDocument7 pagesWaste Cook Oil To Biodieselandri yulianyiNo ratings yet

- Gail Investor PresentationDocument31 pagesGail Investor Presentationsurya167No ratings yet

- Pipeline Network: Karachi-Mahmoodkot (KMK) PipelineDocument2 pagesPipeline Network: Karachi-Mahmoodkot (KMK) PipelineMichael LambNo ratings yet

- Lecture Plan - Petroleum Production Operations-IIDocument2 pagesLecture Plan - Petroleum Production Operations-IIJatin RamboNo ratings yet

- Bio EtOHDilutedAcidFinal PDFDocument44 pagesBio EtOHDilutedAcidFinal PDFRaul SoaresNo ratings yet