Professional Documents

Culture Documents

Fire Test Cert API 607 6th Ed 8in 900cls Ball Valve

Uploaded by

strahor7492Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Test Cert API 607 6th Ed 8in 900cls Ball Valve

Uploaded by

strahor7492Copyright:

Available Formats

ANSI/API Standard 607 Sixth Edition 2010

ISO 10497: 2010

Fire Test Certificate

Name of Manufacturer:

Designation of Valve:

Size:

Body Material:

Trim Material:

ValvTechnologies, Inc.

Ball Valve V1 Series

V7C1-RF-RP-B080-024EMB01

8 inch

Carbon Steel SA-105

410SS

Test Date:

09/22/2011

Report/Certificate Number: 211088-8900

Pressure Rating:

Seat Material:

Stem Seal / Body Seal:

ANSI Class 900

SA-105 with RAM 31 coating

Graphite

The above valve was tested in accordance with the above stated fire test procedure. All of the applicable test parameters were met

and external and through leakage measurements were below the allowable limits. Other valves of the same construction may also

be qualified according to the requirements of the test specification, Section 7.

This certificate refers to the above mentioned product. This is to certify that the test specimen provided is in conformity with the

standard mentioned above. This certificate does not imply assessment of the production of the product.

Sizes Qualified:

8 inch and larger

Laboratory Information

Name:

Yarmouth Research and Technology, LLC

Address:

434 Walnut Hill Road

North Yarmouth, ME 04097 USA

Tester:

Matthew Wasielewski, PE

info@yarmouthresearch.com

www.yarmouthresearch.com

(207) 829-5359

Pressure Ranges Qualified:

900#, 1500# & PN 150, 260

Fire Test Report

ANSI/API Standard 607, Sixth Edition, 2010

ISO 10497:2010

Performed for

ValvTechnologies, Inc.

www.valv.com

8 inch Class 900 Metal-Seated Ball Valve

Product Code: V7C1-RF-RP-B080-024EM-B01

Project Number: 211088

Test Date: September 21, 2011

Performed by

YARMOUTH RESEARCH AND TECHNOLOGY, LLC

434 Walnut Hill Road

North Yarmouth, ME 04097 USA

(207) 829-5359

info@yarmouthresearch.com

www.yarmouthresearch.com

Yarmouth Research and Technology, LLC

Customer: ValvTechnologies

Date:

9/21/2011

Specification: ANSI/API Standard 607, Sixth Edition, 2010

ISO 10497: 2010

Product Description: 8 inch Class 900 Metal-seated Ball Valve

Project Number: PN211088

Comments: Product Code: V7C1-RF-RP-B080-024EM-B01

0

Yarmouth Engineer: Matthew J. Wasielewski, P.E.

Equipment Confirmed to be in Calibration to NIST Standards: Yes

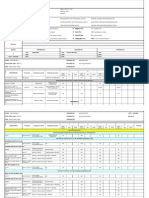

Burn and Cool Down Test

Burn Start Time:

Average Pressure During Burn:

Seat Leak Rate During Burn:

Allowable Seat Leak Rate:

External Leak Rate During Burn/Cool Down:

Allowable External Leak Rate:

13:07:00

1684

0

3200

1

800

Amount of Time of Avg. Cal. Blocks > 650 deg. C:

Were Test Conditions Within Compliance?

22.3

Yes

Were the Valve Leakages Below the Allowables?

Yes

psig

ml/min

ml/min

ml/min

ml/min

minutes

Post-burn Seat Test Not Required for Pressure Class 900

Operational Test

Did Valve Unseat and Open Fully?:

Average Pressure During Test:

External Leak Rate After Operating:

Allowable External Leak Rate:

Yes

1671

0

200

Was the Leakage Below the Allowable?

Yes

s Valve Pass or Fail the Test Standard?

psig

ml/min

ml/min

PASS

Witnesses

________________________________

www.yarmouthresearch.com

Page 2 of 16

YARMOUTH RESEARCH AND TECHNOLOGY, LLC

Fire Test Information Sheet

Valve Manufacturers Name:

ValvTechnologies

Valve Manufacturers Address:

5904 Bingle Road

Houston, TX 77092

Yes

Did valve meet all required hydrostatic,

leakage and other production pressure

tests?

Valve Product Code:

V7C1-RF-RP-B080-024EMB01

8

900#

2220 psig

Seat-Supported Ball Valve

1,200 lbs

Reduced

SA-105

410SS

SA-105 with RAM 31 coating

A286/17-4

B7 Studs/2H Nuts

No

Valve Description

Size:

Pressure Rating:

Pressure Rating at 100F:

Type:

Weight:

Reduced or Full Bore:

Body/Bonnet Material:

Trim Material:

Seat Material:

Stem / Body Seal Material:

Bolting Material:

Is valve considered Soft-Seated?

Valve Markings

Nameplate Information: Size, Pressure Class

Casting Markings: N/A

Assembly Drawing Number / Revision /

Date of Issue:

111160-2/ Rev. 1/ 08/5/11

Assembly Drawing sent to Yarmouth:

Yes

If valve is fitted with gearbox, state gearbox

manufacturer, model number and

mechanical advantage:

If valve is non-symmetric, state direction of

flow for test:

For double-seated valves, state maximum

allowable cavity pressure:

Manufacturers Contact Name /Date:

Exeeco IW-6/420, mech.

Advantage of 132.

See flow direction as indicated

on drawing.

2220 psig

Becky Kowen / 9/2/11

www.yarmouthresearch.com

111160-2.dwg (Uncontrolled Current Copy as of 09/02/2011)

VALV TECHNOLOGIES

Yarmouth Research and Technology, LLC

Temperature verses Time Chart

1200

1000

Temperature - C

800

600

400

Average Cal.

Block

Average Flame

200

Test Time - min:sec

________________________________

www.yarmouthresearch.com

Page 5 of 16

Yarmouth Research and Technology, LLC

Pressure verses Time Chart

2000

1800

1600

Test Pressure-psig

1400

1200

1000

800

600

400

200

Test Time - min:sec

________________________________

www.yarmouthresearch.com

Page 6 of 16

Yarmouth Research and Technology, LLC

Valve During Burn

________________________________

www.yarmouthresearch.com

Yarmouth Research and Technology, LLC

Valve During Burn

________________________________

www.yarmouthresearch.com

Yarmouth Research and Technology, LLC

Fire Test Information

Customer: ValvTechnologies

Date: 9/21/2011

Product Code: 8 inch Class 900 Metal-seated Ball Valve

Project Number: PN211088

Fire Test Raw Data

Time

(EST)

13:07:00

13:07:15

13:07:30

13:07:45

13:08:00

13:08:15

13:08:30

13:08:45

13:09:00

13:09:15

13:09:30

13:09:45

13:10:00

13:10:15

13:10:30

13:10:45

13:11:00

13:11:15

13:11:30

13:11:45

13:12:00

13:12:15

13:12:30

13:12:45

13:13:00

13:13:15

13:13:30

13:13:45

13:14:00

13:14:15

13:14:30

13:14:45

13:15:00

Pressure

(psig)

1670

1670

1669

1667

1665

1676

1669

1664

1670

1674

1678

1681

1683

1686

1688

1690

1693

1697

1700

1694

1689

1684

1686

1683

1686

1695

1704

1714

1725

1716

1708

1711

1722

Water

Volume

(mls)

39939

39955

39953

39940

39933

39941

39946

39924

39937

39918

39921

39906

39924

39923

39962

39949

39937

39919

39910

39935

39952

39924

39907

39919

39924

39907

39911

39903

39932

39927

39929

39925

39920

Cal.

Block 1

Temp-C

50

51

61

75

89

103

113

123

139

168

205

247

283

315

343

368

390

411

432

450

466

481

496

510

522

534

546

555

562

568

574

579

583

Cal.

Block 2

Temp-C

44

51

81

109

136

184

237

286

331

368

399

428

453

477

499

521

541

558

575

591

606

619

632

643

654

664

673

682

690

698

706

713

719

Cal.

Avg.

Bonnet

Block 3 Cal Block Flame

Temp-C Temp-C Temp-C

60

104

158

210

251

293

327

362

390

414

437

455

476

491

508

523

536

548

561

571

581

592

600

609

617

623

631

638

644

651

658

661

664

52

69

100

131

159

193

226

257

286

317

347

377

404

428

450

471

489

506

522

537

551

564

576

588

598

607

617

625

632

639

646

651

655

________________________________

www.yarmouthresearch.com

92

332

334

395

471

561

693

716

788

863

872

867

907

892

876

923

893

913

874

897

919

948

944

933

923

892

914

892

893

909

845

837

838

Body

Flame

Temp-C

289

602

816

866

872

867

794

804

771

783

777

798

782

773

791

789

784

752

754

778

768

757

751

752

772

771

783

869

938

957

963

963

965

Average

Flame

Temp-C

190

467

575

630

671

714

743

760

779

823

824

833

844

833

834

856

838

833

814

837

844

853

848

843

847

831

848

881

916

933

904

900

902

Page 9 of 16

Yarmouth Research and Technology, LLC

Fire Test Data - continued

13:15:15

1705

39914

13:15:30

1682

39914

13:15:45

1683

39932

13:16:00

1694

39922

13:16:15

1693

39912

13:16:30

1694

39909

13:16:45

1692

39926

13:17:00

1692

39925

13:17:15

1697

39913

13:17:30

1694

39920

13:17:45

1697

39903

13:18:00

1696

39898

13:18:15

1688

39918

13:18:30

1685

39904

13:18:45

1685

39916

13:19:00

1690

39917

13:19:15

1683

39917

13:19:30

1688

39903

13:19:45

1696

39904

13:20:00

1685

39910

13:20:15

1676

39910

13:20:30

1670

39900

13:20:45

1667

39920

13:21:00

1666

39904

13:21:15

1666

39904

13:21:30

1667

39888

13:21:45

1670

39924

13:22:00

1683

39907

13:22:15

1684

39895

13:22:30

1684

39915

13:22:45

1684

39892

13:23:00

1685

39894

13:23:15

1687

39900

13:23:30

1687

39895

13:23:45

1690

39885

13:24:00

1692

39902

13:24:15

1695

39880

13:24:30

1698

39902

13:24:45

1702

39891

13:25:00

1707

39891

13:25:15

1713

39889

13:25:30

1720

39902

13:25:45

1728

39905

588

593

598

602

606

609

613

617

621

624

626

629

631

634

637

638

639

640

642

643

644

646

646

647

649

650

651

652

652

652

653

654

654

656

657

658

659

659

659

659

659

659

659

724

729

734

737

737

737

737

737

738

738

738

739

739

739

742

746

750

753

757

759

762

763

764

764

764

764

763

763

762

761

760

760

761

762

763

763

763

763

763

763

761

761

760

669

675

677

669

667

671

671

671

669

667

667

665

673

678

684

691

686

692

697

699

696

696

701

698

703

709

707

712

713

714

714

716

716

716

719

721

723

721

724

725

728

727

728

661

666

670

669

670

672

674

675

676

676

677

678

681

684

688

692

692

695

699

700

701

702

704

703

705

708

707

709

709

709

709

710

711

712

713

714

715

714

715

716

716

716

716

________________________________

www.yarmouthresearch.com

835

832

853

866

833

854

876

917

963

894

909

914

943

918

945

915

817

881

830

846

893

830

838

834

848

901

868

837

814

819

897

889

912

921

947

957

953

942

951

939

901

840

852

964

966

964

964

964

963

963

960

960

962

956

956

958

954

957

956

954

953

957

961

954

953

957

958

953

954

951

951

954

951

949

948

955

953

947

952

953

951

956

949

946

942

955

899

899

909

915

899

908

919

939

962

928

933

935

950

936

951

935

886

917

894

903

924

892

898

896

901

927

909

894

884

885

923

919

934

937

947

954

953

947

953

944

923

891

903

Page 10 of 16

Yarmouth Research and Technology, LLC

Fire Test Data - continued

13:26:00

1720

39897

13:26:15

1702

39899

13:26:30

1688

39892

13:26:45

1676

39887

13:27:00

1667

39895

13:27:15

1661

39893

13:27:30

1660

39888

13:27:45

1660

39902

13:28:00

1660

39885

13:28:15

1662

39887

13:28:30

1663

39891

13:28:45

1665

39881

13:29:00

1668

39893

13:29:15

1685

39865

13:29:30

1688

39876

13:29:45

1690

39882

13:30:00

1693

39881

13:30:15

1695

39874

13:30:30

1698

39910

13:30:45

1704

39880

13:31:00

1709

39858

13:31:15

1715

39876

13:31:30

1721

39872

13:31:45

1727

39873

13:32:00

1733

39879

13:32:15

1719

39890

13:32:30

1710

39871

13:32:45

1705

39883

13:33:00

1701

39855

13:33:15

1696

39875

13:33:30

1694

39872

13:33:45

1691

39874

13:34:00

1689

39866

13:34:15

1688

39872

13:34:30

1687

39868

13:34:45

1686

39869

13:35:00

1686

39880

13:35:15

1685

39873

13:35:30

1685

39860

13:35:45

1686

39849

13:36:00

1686

39874

13:36:15

1686

39870

13:36:30

1687

39858

659

659

660

661

661

661

661

660

661

660

661

661

660

659

659

658

658

658

659

659

659

659

658

658

657

656

655

655

654

655

655

654

654

653

653

652

652

651

651

651

649

648

647

760

759

758

758

758

757

757

757

757

757

757

757

757

756

752

749

750

752

752

751

748

744

741

737

734

730

726

723

722

719

717

713

709

704

699

697

696

693

689

688

687

686

685

728

727

729

730

730

729

731

731

731

729

730

732

730

713

703

709

711

715

720

724

728

729

732

734

735

736

738

736

739

742

743

745

746

747

748

750

750

750

750

750

750

750

750

716

715

716

716

716

716

716

716

716

715

716

717

715

709

705

706

707

708

710

711

711

711

710

710

709

707

706

705

705

705

705

704

703

701

700

700

699

698

696

696

695

695

694

________________________________

www.yarmouthresearch.com

818

926

916

944

936

944

926

882

883

895

901

901

847

841

794

876

908

903

939

950

938

922

918

859

810

797

843

872

872

848

827

785

793

837

824

795

799

778

782

781

793

801

797

954

953

957

959

960

958

955

946

941

946

941

940

944

948

937

941

950

945

953

954

955

956

946

942

938

931

934

933

943

942

929

931

936

921

925

944

949

951

942

936

926

913

938

886

939

937

952

948

951

941

914

912

921

921

920

896

894

866

908

929

924

946

952

947

939

932

901

874

864

889

902

908

895

878

858

864

879

875

870

874

864

862

859

859

857

868

Page 11 of 16

Yarmouth Research and Technology, LLC

Fire Test Data - continued

13:36:45

1687

39881

13:37:00

1688

39862

13:37:15

1694

39859

13:37:30

1698

39803

13:37:45

1698

39826

13:38:00

1695

39908

13:38:15

1689

39847

13:38:30

1676

39851

13:38:45

1660

39882

13:39:00

1655

39925

13:39:15

1655

39827

13:39:30

1673

39830

13:39:45

1663

39862

13:40:00

1660

39820

13:40:15

1660

39848

13:40:30

1671

39806

13:40:45

1662

39885

13:41:00

1661

39887

13:41:15

1674

39776

13:41:30

1662

39839

13:41:45

1660

39783

13:42:00

1673

39788

13:42:15

1661

39787

13:42:30

1660

39752

13:42:45

1668

39828

13:43:00

1660

39814

13:43:15

1661

39802

13:43:30

1662

39764

13:43:45

1660

39787

13:44:00

1669

39811

13:44:15

1659

39799

13:44:30

1671

39747

13:44:45

1659

39748

13:45:00

1673

39717

13:45:15

1664

39795

13:45:30

1663

39736

13:45:45

1663

39748

13:46:00

1666

39718

13:46:15

1662

39767

13:46:30

1665

39671

13:46:45

1674

39687

13:47:00

1664

39684

646

646

643

614

535

263

211

186

148

112

81

57

49

39

38

38

33

31

31

37

36

33

29

33

35

28

36

33

30

31

30

27

31

25

24

33

27

29

24

27

26

28

682

680

676

665

617

490

399

329

257

187

127

88

68

58

51

47

43

45

49

49

44

41

37

34

33

32

31

29

29

28

27

27

27

27

26

26

26

25

25

25

25

25

751

750

713

659

567

498

443

407

362

324

283

268

260

243

215

170

114

61

50

40

48

50

53

55

54

53

50

50

50

51

51

49

47

49

46

45

44

44

42

42

39

39

693

692

677

646

573

417

351

307

256

208

164

138

126

113

101

85

63

46

43

42

43

41

40

41

41

37

39

37

36

37

36

34

35

33

32

34

32

33

30

31

30

31

________________________________

www.yarmouthresearch.com

790

791

582

423

323

192

68

66

61

60

59

58

57

58

58

56

54

52

51

49

49

51

49

48

46

45

44

45

45

44

44

43

41

41

41

40

39

37

39

38

38

38

936

935

690

410

196

63

66

61

54

48

44

42

41

39

37

37

37

36

36

35

35

34

34

35

34

33

33

33

32

33

33

32

32

32

32

32

31

31

32

31

32

30

863

863

636

417

259

128

67

63

58

54

52

50

49

49

48

46

46

44

43

42

42

43

42

41

40

39

39

39

39

38

39

38

36

36

37

36

35

34

36

35

35

34

Page 12 of 16

Yarmouth Research and Technology, LLC

Leakage Summary for Burn and Cool Down Periods

All pressure transducers and thermocouples are in calibration per YRT's QA program.

Seat leakages were collected manually. External leakage was collected electronically.

Total Through Seat Leakage Collected Over 30 Minute Duration:

Average Leak Rate Over 30 Minute Duration:

Allowable Leak Rate:

Total Through Seat Leakage Collected Over 10 Minute Cool Down:

Total Water Volume Lost Over 40 Minute Burn and Cool Down:

Water Collected in System Relief Valve:

Calculated External Leakage During 40 Minute Duration:

Average Leak Rate Over 40 Minute Duration:

Allowable Leak Rate:

Were the Valve Leakages Below the Allowables?

0

0

3200

0

255

220

35

1

800

mls

mls

mls

mls

ml/min

ml/min

Yes

________________________________

www.yarmouthresearch.com

mls

ml/min

ml/min

Page 13 of 16

Yarmouth Research and Technology, LLC

Summary of Test Parameters During Burn and Cool Down Periods

Amount of Time Pressure Dropped Below 50%:

Maximum Allowable Low Pressure Time:

Maximum Pressure During Burn/Cool Down:

Average Pressure During Burn/Cool Down:

Minimum Pressure During Burn/Cool Down:

0.0

2.0

1733

1684

1655

minutes

minutes

psig

psig

psig

Amount of Time of Avg. Cal Block > 650 deg.C:

Minimum Allowable Time at Temperature:

Maximum Avg Cal Block Temperature:

Average Cal Block Temperature:

Lowest Avg Cal. Block Temperature:

22.3

15.0

717

504

30

minutes

minutes

deg. C

deg. C

deg. C

Maximum Body Flame Temperature During Burn:

Average Body Flame Temperature During Burn:

966

906

deg. C

deg. C

Maximum Bonnet Flame Temperature During Burn:

Average Bonnet Flame Temperature During Burn:

963

847

deg. C

deg. C

Average of Both Flame Temperatures During Burn:

877

deg. C

Note

Were Test Conditions Within Compliance?

Yes

________________________________

www.yarmouthresearch.com

Page 14 of 16

Yarmouth Research and Technology, LLC

Post-Burn Seat Test Information

Customer: ValvTechnologies

Product Code: 8 inch Class 900 Metal-seated Ball Valve

Project Number: PN211088

Date:

9/21/2011

Test Not Required for Pressure Class 900

________________________________

www.yarmouthresearch.com

Page 15 of 16

Yarmouth Research and Technology, LLC

Operational Test Information

Customer: ValvTechnologies

Product Code: 8 inch Class 900 Metal-seated Ball Valve

Project Number: PN211088

Date:

9/21/2011

Test Data

Time

Pressure

(psig)

Cal Block

Temp - C

13:53:52

13:54:07

13:54:22

13:54:37

13:54:52

13:55:07

13:55:22

13:55:37

13:55:52

13:56:07

13:56:22

13:56:37

13:56:52

13:57:07

13:57:22

13:57:37

13:57:52

13:58:07

13:58:22

13:58:37

13:58:52

1675

1668

1665

1665

1665

1668

1671

1673

1674

1676

1679

1679

1679

1679

1679

1675

1672

1672

1666

1663

1658

28

28

28

28

28

28

29

28

28

28

29

29

28

29

28

29

29

29

29

29

29

Leakages were collected manually.

Total External Leakage Collected Over 5 Minute Duration:

Average Leak Rate Over 5 Minute Duration:

Allowable Leak Rate:

0.0

0.0

200

Was the Valve Leakage Below the Allowable?

Yes

________________________________

www.yarmouthresearch.com

mls

ml/min

ml/min

Page 16 of 16

You might also like

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- DrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsDocument1 pageDrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsmarcotplNo ratings yet

- Grados Termicos TN55TH y TN80THDocument10 pagesGrados Termicos TN55TH y TN80THgfwtNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- 00 PR SP 00001 - 2 Wet Hydrogen Sulphide (H2S) Service SpecificationDocument12 pages00 PR SP 00001 - 2 Wet Hydrogen Sulphide (H2S) Service SpecificationStevanNikolicNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- PMS-V32-Ball Valves - FlangedDocument2 pagesPMS-V32-Ball Valves - FlangedMB Azharudeen100% (1)

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Document8 pagesInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaNo ratings yet

- Design and Analysis of Disc Plate in Hot Blast Valve #DN1800Document8 pagesDesign and Analysis of Disc Plate in Hot Blast Valve #DN1800MounicaRasagyaPallaNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Utility Boiler Inspection PlanDocument3 pagesUtility Boiler Inspection PlanGanesh EshwarNo ratings yet

- Flash Report-2016-2-15Document3 pagesFlash Report-2016-2-15sujinlongNo ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- NDE Requirements for Header Box WeldsDocument9 pagesNDE Requirements for Header Box Weldsrony16novNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- A234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFDocument9 pagesA234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFRony YudaNo ratings yet

- ASME CertificationDocument3 pagesASME Certificationtamim2014No ratings yet

- Pipe, Valves & Fittings Specification GuideDocument136 pagesPipe, Valves & Fittings Specification GuideTefa MartinezNo ratings yet

- Piping Materials Match Chart (ASTM) - ProjectmaterialsDocument14 pagesPiping Materials Match Chart (ASTM) - ProjectmaterialsdhurjatibhuteshNo ratings yet

- Pt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesDocument0 pagesPt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesZoebairNo ratings yet

- Thermal Power Project Weld Inspection ReportDocument1 pageThermal Power Project Weld Inspection ReportAshwani DograNo ratings yet

- Supplier Pre-Qualification Document - September 2020Document23 pagesSupplier Pre-Qualification Document - September 2020cephas ventures enterprisesNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- FactoryDocument72 pagesFactorywhitebrosNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17ziaNo ratings yet

- SP 2094Document48 pagesSP 2094ArshadNo ratings yet

- M 4 D1.1 2015 Form PDFDocument1 pageM 4 D1.1 2015 Form PDFDabbar TaherNo ratings yet

- Inspection Report for JS-04 Rig UnitDocument52 pagesInspection Report for JS-04 Rig Unitjohnj_ramirezNo ratings yet

- 175 000003 PDFDocument1 page175 000003 PDFSohail TisekarNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 pagesItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- Pressure Vessel CertificationDocument3 pagesPressure Vessel CertificationYetkin ErdoğanNo ratings yet

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedDocument4 pagesStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- I08-028-000J-TS093 - 0 Knife Gate ValvesDocument7 pagesI08-028-000J-TS093 - 0 Knife Gate ValvesCristian RománNo ratings yet

- Visual Inspection Checklist PipingDocument2 pagesVisual Inspection Checklist PipingshifaNo ratings yet

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocument15 pages4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriNo ratings yet

- Resume Suda Mara IDocument5 pagesResume Suda Mara IMd AkhtarNo ratings yet

- ANSI B16.5 Flange ToleranceDocument2 pagesANSI B16.5 Flange TolerancevmrameshbeNo ratings yet

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

- Paint For SteelDocument11 pagesPaint For SteelSaud PathiranaNo ratings yet

- Antony Mervin - SR - qa.QC EngineerDocument6 pagesAntony Mervin - SR - qa.QC EngineerantonyNo ratings yet

- LOWER FARS HEAVY OIL DEVELOPMENT PHASE-1 PIPING TEST PLANDocument4 pagesLOWER FARS HEAVY OIL DEVELOPMENT PHASE-1 PIPING TEST PLANmuralidmurthyNo ratings yet

- OCTGDocument1 pageOCTGMurugananthamParamasivam100% (1)

- API SPEC 6D Pipeline Valves SpecDocument1 pageAPI SPEC 6D Pipeline Valves SpecVictor MeltonNo ratings yet

- BS3076 Na18Document4 pagesBS3076 Na18BHARGAVNo ratings yet

- 12 Storage of Parent MaterialsDocument3 pages12 Storage of Parent MaterialselmiraNo ratings yet

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsDocument6 pagesConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanNo ratings yet

- GTS-PP-120: 3 LayerDocument2 pagesGTS-PP-120: 3 Layershoaib1985100% (1)

- TenarisCatalogue Casing&Tubing PDFDocument118 pagesTenarisCatalogue Casing&Tubing PDFHenry Carreno MesaNo ratings yet

- Fire Test Cert 2Document17 pagesFire Test Cert 2jamil voraNo ratings yet

- Fire Test Cert API 607 6th Ed 2in 150cls V1 Series Ball PDFDocument18 pagesFire Test Cert API 607 6th Ed 2in 150cls V1 Series Ball PDFKo NSNo ratings yet

- Fire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010Document16 pagesFire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010jamil voraNo ratings yet

- VENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSDocument8 pagesVENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSMichael HaiseNo ratings yet

- ISO 17000 2004 Terms & DefintionsDocument6 pagesISO 17000 2004 Terms & DefintionsSelvaraj SimiyonNo ratings yet

- Unit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDocument15 pagesUnit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDoc Joey100% (3)

- CHM 127 Exp 1Document4 pagesCHM 127 Exp 1shelby hartwigNo ratings yet

- By Emile Alline: Technical Art by Fred WolffDocument4 pagesBy Emile Alline: Technical Art by Fred WolffJim100% (3)

- Sci9 Q4 Mod8.2Document24 pagesSci9 Q4 Mod8.2John Christian RamosNo ratings yet

- Internal Controls and Risk Management: Learning ObjectivesDocument24 pagesInternal Controls and Risk Management: Learning ObjectivesRamil SagubanNo ratings yet

- Managerial Performance Evaluation ProceduresDocument3 pagesManagerial Performance Evaluation Procedures1robcortesNo ratings yet

- CA Module Franklin Gari RDocument28 pagesCA Module Franklin Gari RFranklin GariNo ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 pagesManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- Th255, Th255c Axle Cat ServiceDocument280 pagesTh255, Th255c Axle Cat ServiceKevine KhaledNo ratings yet

- Individual Moving Range (I-MR) Charts ExplainedDocument18 pagesIndividual Moving Range (I-MR) Charts ExplainedRam Ramanathan0% (1)

- Transportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDocument11 pagesTransportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDaniel Juan De Dios OchoaNo ratings yet

- Radiograph Evaluation ChecklistDocument2 pagesRadiograph Evaluation ChecklistZulfadli Haron100% (1)

- Effect of Social Media On The Academic PerformanceDocument55 pagesEffect of Social Media On The Academic PerformanceFJ Asufra100% (2)

- Stylistic and DiscourseDocument4 pagesStylistic and Discourseeunhye carisNo ratings yet

- Philippine Popular Culture in HEIsDocument9 pagesPhilippine Popular Culture in HEIsNokie TunayNo ratings yet

- Love Your Design Getting Started GuideDocument14 pagesLove Your Design Getting Started GuideOnalevel100% (9)

- Plenaristas León 2022xDocument6 pagesPlenaristas León 2022xGloria MontielNo ratings yet

- 9.tools and Equipment 1Document13 pages9.tools and Equipment 1NKH Mega GasNo ratings yet

- Subject and Content NotesDocument52 pagesSubject and Content NotesJoe Carl CastilloNo ratings yet

- AsdfgDocument2 pagesAsdfgTejendra PachhaiNo ratings yet

- TSR Cyl Tilt Cab LD 110Document2 pagesTSR Cyl Tilt Cab LD 110Ferry AndisNo ratings yet

- Dball-Gm5 en Ig Cp20110328aDocument18 pagesDball-Gm5 en Ig Cp20110328aMichael MartinezNo ratings yet

- Studying Supply and Demand of Software Maintenance and Evolution ServicesDocument6 pagesStudying Supply and Demand of Software Maintenance and Evolution ServicesJorge Arturo Moreno VeasNo ratings yet

- C172M QRH (VH-JZJ) v1.1Document49 pagesC172M QRH (VH-JZJ) v1.1alphaNo ratings yet

- Face To Face Pre-Intermediate B1Document162 pagesFace To Face Pre-Intermediate B1Andra OlariNo ratings yet

- Reflecting on UPHSD's Mission, Vision, and Core ValuesDocument3 pagesReflecting on UPHSD's Mission, Vision, and Core ValuesBia N Cz100% (1)

- ERC12864-12 DemoCode 4wire SPI 2Document18 pagesERC12864-12 DemoCode 4wire SPI 2DVTNo ratings yet

- Chemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Document226 pagesChemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Kabwela MwapeNo ratings yet