Professional Documents

Culture Documents

KW 105 4 PDF

Uploaded by

edwinramonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KW 105 4 PDF

Uploaded by

edwinramonCopyright:

Available Formats

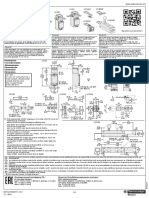

Maintenance Instruction Instruction de maintenance Manual para el mantenimiento

KW-105-4

Tightening Torques for Screw Fixings of Reciprocating Compressors

Content 1 Normal screw fixings 2 Special screw fixings 1 Normal screw fixings

Couples de serrage pour assemblages visss des compresseurs piston

Sommaire 1 Assemblages visss normals 2 Assemblages visss spcials 1 Assemblages visss normals M5 M6 7 lbf-ft (9 Nm) M8 17 lbf-ft (23 Nm)

Pares de apriete para uniones atornilladas de compresores a pistn

Contenido 1 Uniones atornilladas normales 2 Uniones atornilladas especiales 1 Uniones atornilladas normales M 10 31 lbf-ft (42 Nm) M 12 59 lbf-ft (80 Nm) M 16 111 lbf-ft (150 Nm) M 20

Without flat gasket Sans joint plat Sin junta plana With gasket and screw quality 10.9 Avec joints plats et qualit vis 10.9 Con juntas y calidad de tornillos 10.9 Notes Do not oil gaskets! Tighten screws crosswise and at least in two steps (50/100%). Tightening torques for aluminium housings see KW-550

5 lbf-ft (7 Nm)

12 lbf-ft (16 Nm)

30 lbf-ft (40 Nm)

59 lbf-ft (80 Nm)

100 lbf-ft (125 Nm)

162 lbf-ft (220 Nm)

162 lbf-ft (220 Nm)

Remarques Ne pas enduire dhuile les joints plats! Serrer les vis croix et au minimum en deux tapes (50/100%). Couples de serrage pour corps de aluminium voir KW-550

Notas No engrasar las juntas! Apretar los tornillos en forma de cruz y en mnimo dos pasos (50/100%). Pares de apriete para crteres de aluminio ver KW-550

2 Special screw fixings Sealing plug 1/8"-27 1/4"-18 3/8"-18 1/2"-14 3/4"-14

M = metric screw

2 Assemblages visss spcials Bouchon de fermeture NPTF NPTF NPTF NPTF NPTF

M = vis mtrique

2 Uniones atornilladas especiales Tapones de cierre Nm) Nm) Nm) Nm) Nm)

7 .. 10 lbf-ft (10 .. 13 15 .. 17 lbf-ft (20 .. 23 31 .. 35 lbf-ft (42 .. 47 47 .. 51 lbf-ft (64 .. 69 72 .. 80 lbf-ft (98 .. 108

M = tornillo mtrico

Oil drain M M M M Sight glass fixing M 6 (8.8) M 6 (10.9) Screwed sight glass 22 22 26 26 Al Cu Al Cu

Vidage d'huile 66 lbf-ft (90 100 .. 114 lbf-ft (135 .. 155 81 lbf-ft (110 114 .. 129 lbf-ft (155 .. 175 Fixation du voyant

Drenaje de aceite Nm) Nm) Nm) Nm) Fijacin del visor 61 lbf-ft (8 Nm) 81 lbf-ft (11 Nm)

Voyant vis 1 1/8"-18 UNEF (SW 36)

Visor atornillado 37 .. 44 lbf-ft (50 .. 60 Nm) Vlvula de cierre, contrabrida y brida ovalada 111 lbf-ft (150 Nm) 148 lbf-ft (200 Nm) 148 lbf-ft (200 Nm) Tornillos de contacto de la placa de bornes a 20C Nm) Nm) Nm) (2KC-05.2 .. 4CC-9.2: 10 lbf-ft [14 Nm]) Nm) Nm) Tornillos del rotor 15 lbf-ft (20 Nm) 15 lbf-ft (20 Nm) 44 lbf-ft (60 Nm)

80500102 Subject to change / Toutes modifications rsrves / Modicicaciones reservadas 01.09

Shut-off valve, compagnion flange and oval flange M 8 (8.8) M 10 (8.8) M 12 (8.8) Contact screws for terminal plate at 20C M4 M4 M6 M8 M10 Rotor screws M 10 (10.9) M 12 (10.9) M 16 (10.9) Connecting rod screws M 6 (10.9) M 8 (8.8) Oil pump M8 Oil centrifuge (for Octagons) M6 M8

M = metric screw with flat gasket with O-ring Clean and inspect the sealing surface, threads and sight glass. Tighten screws crosswise with a torque spanner. After pressurizing tighten the screws again with the torque spanner.

Vanne d'arrt, contre-bride et bride ovale M 16 (8.8) M 18 (8.8) M 20 (8.8)

18.5 lbf-ft (25 Nm) 37 lbf-ft (50 Nm) 74 lbf-ft (100 Nm)

Vis contactes de la plaque bornes 20C (brass / laiton / latn) (steel / acier / acero) (steel / acier / acero (steel / acier / acero) (steel / acier / acero) Vis du rotor 1 lbf-ft (1.2 1.5 lbf-ft (2 5 lbf-ft (6 7 lbf-ft (10 15 lbf-ft (20

Vis de tte de bielle

Tornillos de la biela 12 lbf-ft (16 Nm) 19 lbf-ft (25.5 Nm

Pompe d'huile

Bomba de aceite 17 lbf-ft (23 Nm)

Centrifugeuse d'huile (Octagon) 12 lbf-ft (16 Nm) 17 lbf-ft (23 Nm)

M = vis mtrique avec joint plat avec joint annulaire Purifier et contrler la surface d'tanchit, les filetages et le voyant. Serrer les vis croix avec un cl dynamomtrique. Daprs la mise sous pression serrer les vis encore avec un cl dynamomtrique.

Centrfuga de aceite (marca Ocagons)

2KC-05.2(Y) .. 4CC-9.2(Y) 4VC(S)-6.2(Y) .. 4NC(S)-20.2(Y)

M = tornillo mtrico con junta plana con junta trica Limpiar y controlar la superficie de obturacin, la rosca y el visor. Apretar los tornillos en forma de cruz utilizando una llave dinamomtrica. Despus de la prueba hidrulica apretarlos de nuevo utilizando la llave dinamomtrica.

Bitzer Khlmaschinenbau GmbH Eschenbrnnlestrae 15 71065 Sindelfingen, Germany fon +49 (0) 70 31 932-0 fax +49 (0) 70 31 932-146 & -147

www.bitzer.de bitzer@bitzer.de

You might also like

- TECHinfo 1.2 PureTech AtmoDocument19 pagesTECHinfo 1.2 PureTech AtmoSimon FigueiredoNo ratings yet

- Moteur Renault K4MDocument75 pagesMoteur Renault K4Mserge_bonvalot100% (5)

- 4 Train MoteurDocument8 pages4 Train MoteurloloNo ratings yet

- 1600Document51 pages1600Cezar FlorinNo ratings yet

- Peugeot MoteurDw10 (2,0LHdi) PDFDocument28 pagesPeugeot MoteurDw10 (2,0LHdi) PDFjoker63000No ratings yet

- Vdma-C85 FRDocument38 pagesVdma-C85 FRyouri594900% (1)

- BTS2005 2 ComplementsDocument17 pagesBTS2005 2 Complementssaded05No ratings yet

- 3JH4Document131 pages3JH4Olivier35300No ratings yet

- Bow ThrusterDocument50 pagesBow Thrusterjagarov4954100% (2)

- Laguna MRMOTK4M PDFDocument75 pagesLaguna MRMOTK4M PDFtriadouNo ratings yet

- Vannes Guillotine Et OperculeDocument12 pagesVannes Guillotine Et Operculeanon_323299199No ratings yet

- 12.07 DGBFDocument4 pages12.07 DGBFdenysfilipov26No ratings yet

- Yamaha YZF-R6 2016 Gytr Kitmanual FRDocument68 pagesYamaha YZF-R6 2016 Gytr Kitmanual FRHenrik FalkNo ratings yet

- MR Moteur F4R Clio RSDocument149 pagesMR Moteur F4R Clio RSnenogz100% (19)

- Caracteristiques 2CV 1985-1990Document9 pagesCaracteristiques 2CV 1985-1990Jan MaňasNo ratings yet

- Turbocompresseur PDFDocument7 pagesTurbocompresseur PDFJulien Lauvergnier100% (1)

- Reglamento Técnico 206 SprintDocument22 pagesReglamento Técnico 206 SprintblancohccNo ratings yet

- Peugeot MoteurDw10 (2,0LHdi)Document28 pagesPeugeot MoteurDw10 (2,0LHdi)Rodolphe Sandrine VoisyNo ratings yet

- Fiche Technique Vanne A Sphere Inox 3 Pieces AdlerDocument12 pagesFiche Technique Vanne A Sphere Inox 3 Pieces AdlerBenny 37No ratings yet

- Vérin SMC Série C96Document44 pagesVérin SMC Série C96youri59490No ratings yet

- 00 1 Couples - SerrageDocument11 pages00 1 Couples - SerrageKenji ReinhardtNo ratings yet

- Etude Carburateur BVF 30n3-1Document8 pagesEtude Carburateur BVF 30n3-1Marcos GoodNo ratings yet

- Vue Eclatee Compresseur Vmu015100100 D Vmu015100200 D 22503rDocument2 pagesVue Eclatee Compresseur Vmu015100100 D Vmu015100200 D 22503rgaecdugrandvillageNo ratings yet

- Stihl MS290 Farm Boss Parts ListDocument38 pagesStihl MS290 Farm Boss Parts ListrvpilotNo ratings yet

- 11C Moteur F9Q1Document33 pages11C Moteur F9Q1morinNo ratings yet

- Aprietes KubotaDocument78 pagesAprietes KubotaJOSEALBERICH80% (5)

- dv6 BerDocument8 pagesdv6 Beradsl.20063190No ratings yet

- Couples Serrage Moteur 9hz 9hyDocument10 pagesCouples Serrage Moteur 9hz 9hyDANIEL2060% (2)

- Dossier Technique Transept - OptDocument104 pagesDossier Technique Transept - OptbottiotherNo ratings yet

- Calc CourroiesDocument1 pageCalc CourroiesTriki BilelNo ratings yet

- Fiche Technique Clio II PDFDocument0 pagesFiche Technique Clio II PDFDavagusta6988% (17)

- Stihl MS250 - MS250CDocument48 pagesStihl MS250 - MS250CSasko PrangovskiNo ratings yet

- Mr339laguna2 PDFDocument105 pagesMr339laguna2 PDFLudovic LoudièreNo ratings yet

- Caracteristiques 2CV 1963-1970Document6 pagesCaracteristiques 2CV 1963-1970Jan MaňasNo ratings yet

- KD481.05 Préconisations Montage Démontage - FRDocument9 pagesKD481.05 Préconisations Montage Démontage - FRTamata Benebig100% (1)

- MR Mot k4mDocument75 pagesMR Mot k4mIslam CidNo ratings yet

- IPL-piece 021 023 025 PDFDocument56 pagesIPL-piece 021 023 025 PDFNigelNo ratings yet

- MASTER - ChâssisDocument127 pagesMASTER - ChâssisLotfi Ben SlimNo ratings yet

- Tech T120Document82 pagesTech T120BNUNo ratings yet

- SYMFR 18753 MaMio50-100Document63 pagesSYMFR 18753 MaMio50-100Nicolas TailladeNo ratings yet

- TD4 Chaines de SolidesDocument5 pagesTD4 Chaines de SolidesfabisotresNo ratings yet

- RTA 130 Renault B90 B110 Low DefDocument60 pagesRTA 130 Renault B90 B110 Low Defjosé delmote100% (1)

- TransmissionDocument220 pagesTransmissionEd DuconNo ratings yet

- 1975 CitroenDocument6 pages1975 CitroenRafael SadiNo ratings yet

- 3790ADocument3 pages3790Anicoj30No ratings yet

- Elster Emetteur Impulsion in s12 Compteur Turbines - Compteur Energie - ComDocument4 pagesElster Emetteur Impulsion in s12 Compteur Turbines - Compteur Energie - Comhacene omarNo ratings yet

- PMT FRDocument24 pagesPMT FRTomas Blik50% (2)

- FS48 FS52 FS56 305Document22 pagesFS48 FS52 FS56 305Philippe MartinNo ratings yet

- Reductores Coaxiales VarvelDocument0 pagesReductores Coaxiales VarvelGonzalo Arturo Bobadilla CastroNo ratings yet

- Moteur Kawasaki Fj180v Am58 Vue Eclatee Liste Des PiecesDocument29 pagesMoteur Kawasaki Fj180v Am58 Vue Eclatee Liste Des Piecesjf.carouge11410No ratings yet

- Clio R3 Maxi EVO - Notice de Montage Moteur - XCDDocument65 pagesClio R3 Maxi EVO - Notice de Montage Moteur - XCDVisseq Michel100% (4)

- KP 155 3 PDFDocument0 pagesKP 155 3 PDFedwinramonNo ratings yet

- SH 100 3 PDFDocument0 pagesSH 100 3 PDFedwinramonNo ratings yet

- Esh 130 12 PDFDocument56 pagesEsh 130 12 PDFedwinramonNo ratings yet

- KP 115 2 PDFDocument0 pagesKP 115 2 PDFedwinramonNo ratings yet

- SH 100 3 PDFDocument0 pagesSH 100 3 PDFedwinramonNo ratings yet

- ExtincteurDocument8 pagesExtincteurBenaoumeur FNo ratings yet

- Centrale SolaireDocument14 pagesCentrale SolaireHassan B'ouNo ratings yet

- Zaaoui m1 Construction Mecanique Technique de SoudageDocument2 pagesZaaoui m1 Construction Mecanique Technique de SoudageAdnane Es-saiydyNo ratings yet

- Programme SaganeDocument18 pagesProgramme Saganedonglejack83No ratings yet

- CCTP Tce GobckDocument153 pagesCCTP Tce GobckFrançoisToulouse100% (1)

- 14 Guide Technique PDFDocument24 pages14 Guide Technique PDFDahim OualiNo ratings yet

- LIEGEDocument3 pagesLIEGEAyoub VbNo ratings yet

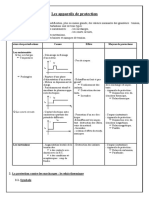

- Appareils de Protection PDFDocument34 pagesAppareils de Protection PDFHadil Sellami100% (2)

- Evaluation BFM Rapport Final 11072016 PDFDocument125 pagesEvaluation BFM Rapport Final 11072016 PDFjoel arnaud sambouNo ratings yet

- TDocument122 pagesTMohamadsfNo ratings yet

- Corrige s2 2014Document7 pagesCorrige s2 2014GueyeNo ratings yet

- Cours Et Initiation en DimensionnementDocument20 pagesCours Et Initiation en Dimensionnementshilulu598No ratings yet

- Communique de Presse - Keolis Adapte Son Comite Executif A Ses Enjeux StrategiquesDocument3 pagesCommunique de Presse - Keolis Adapte Son Comite Executif A Ses Enjeux StrategiquesBob MoraneNo ratings yet

- XCS ABC W915275050111 A14 - WebDocument4 pagesXCS ABC W915275050111 A14 - WebIhcene BoudaliNo ratings yet

- Modélisation Machine CC ParDocument23 pagesModélisation Machine CC ParomarNo ratings yet

- 896 PDFDocument6 pages896 PDFlounes2007No ratings yet

- 09 - Chapitre - 2 - Controle de La CorrosionDocument11 pages09 - Chapitre - 2 - Controle de La CorrosionYamina BEGHRINo ratings yet

- Exposer CMCDocument13 pagesExposer CMCJennifer SenouvorNo ratings yet

- Conduite Des Chaudieres Industrielles Au Gaz Naturel Perfectionner Sa PratiqueDocument2 pagesConduite Des Chaudieres Industrielles Au Gaz Naturel Perfectionner Sa PratiqueMoustapha AbdouNo ratings yet

- L'entreprise Et Son Environnement LoucifDocument19 pagesL'entreprise Et Son Environnement LoucifAMIROUCHE LoucifNo ratings yet

- RapportDocument25 pagesRapportMolka Ayechi100% (1)

- 2-Gammes de Maintenance PreventiveDocument162 pages2-Gammes de Maintenance PreventiveAnaibar TarikNo ratings yet

- Espace 4 - Octobre 2010Document11 pagesEspace 4 - Octobre 2010pascal75012No ratings yet

- Le Beton Bitumineux A Froid Cle224eafDocument44 pagesLe Beton Bitumineux A Froid Cle224eafMANERER100% (1)

- Essais Sur L'acier 2021dDocument67 pagesEssais Sur L'acier 2021dFisso Ben BenNo ratings yet

- Rapport - Stage Conduite de TravauxDocument31 pagesRapport - Stage Conduite de TravauxIlyas KamiNo ratings yet

- Définition de TransformateurDocument2 pagesDéfinition de Transformateurzakri azeddineNo ratings yet

- Fiche Synoptique-Barrage GAMGOUMDocument2 pagesFiche Synoptique-Barrage GAMGOUMhajlaouiNo ratings yet

- Transport Chapitre 02Document10 pagesTransport Chapitre 02TRAORENo ratings yet

- Dossier Technique Photovoltaique BT STEGDocument21 pagesDossier Technique Photovoltaique BT STEGhoucineNo ratings yet