Professional Documents

Culture Documents

Tables

Uploaded by

Bilal Ahmed BarbhuiyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tables

Uploaded by

Bilal Ahmed BarbhuiyaCopyright:

Available Formats

Table 10.

4: Placing conditions

Desirable Workability of Concrete for Different Placing Conditions Degree of Workability Compacting factor or slump, mm Very low Strict control required with C.F. of 0.75 to 0.80

Blinding Concrete; Shallow sections; Pavements using pavers Mass Concrete; Lightly reinforced sections in slabs, beams, walls, columns; Floors ; Hand Placed pavements; Canal lining; Strip footings; Heavily reinforced sections in slabs, beams, walls, columns; Slip from work; Pumped concrete; Trench fill; In-Situ Piling; Tremie Concrete;

Low

25-75

Medium

50-100 75-100

High Very High (flowable)

100-150 200

Table 10.5: Level of Workability as measured by Different Test Methods Degree of a workability Values of workability in terms of Slump Vee-Bee time (mm) (sec) --30-20

Compacting factor < 0.70*

Drop table revolutions 96-48

Extremely Low (very stiff) Very low (stiff) Low (stiff plastic) Medium (plastic) High (flowing)

0.75-0.80 0.80-0.85 0.85-0.92 > 0.92

0-25 25-50 50-75 75-150

20-10 10-5 5-2 2-0

48-24 24-12 12-6 6-0

Table-10.6

Minimum Cement Content (kg/m 3 ). Maximum Water-Cement Ratio and Grade of Concrete to Ensure Durability under Specified Exposure with Aggregate of 20mm Nominal Maximum size. Exposure conditions Plain Concrete Minimum Maximum free Cement water- cement content, kg/m 3 ratio Minimum grade of concrete Reinforced Concrete Minimum Maximum free Cement water- cement content, kg/m 3 ratio 300 0.55 Minimum grade of concrete M20

General environment

Concrete surface protected against weather or 220 0.60 --aggressive conditions, except those situated in coastal area. Moderate Concrete surface sheltered from severe rain or freezing whilst wet. Concrete exposed to consideration and rain. Concrete continuously under water. 240 0.60 M15 Concrete in contact or buried under nonaggressive soil/ground water. Concrete surface sheltered from saturated salt air in costal area. Severe Concrete surfaces exposed to severe rain, alternate wetting and drying or occasional 250 0.50 M20 freezing whilst wet or severe condensation. Concrete completely immersed in sea water concrete exposed or coastal environment. Very severe Concrete surface exposed to sea water spray, corrosive fumes or severe freezing condition 260 0.45 M20 whilst wet. Concrete with or buried under aggressive subsoil/ground water. Extreme Members in direct contact with liquid/ solid 280 0.40 M25 aggressive chemicals. Note: The Cement content is irrespective of grades of cement. The Cement content and water-cement ratio include satisfy the stipulations of IS: 1489 (part-I) and IS: 455, etc. respectively.

Mild

300

0.50

M25

320

0.45

M30

340

0.45

M35

360

0.40

M40

mineral additives if they are desirable and

Table 10.9: Maximum size of aggregate, mm

Dry Bulk Volume of Coarse Aggregate (ACI 211-1-91) Bluk volume of dry-rodded coarse aggregate per unit volume of concrete, for fineness modulus of fine aggregate 2.40 2.60 0.48 0.57 0.64 0.69 0.74 0.76 2.80 0.46 0.55 0.62 67.00 0.72 0.74 3.00 0.44 0.53 0.60 0.65 0.70 0.72

10.00 12.50 20.00 25.00 37.50 50.00

0.50 0.59 0.66 0.71 0.76 0.78

Table 10.10: Factors to be Applied to the Volume of Coarse Aggregate Calculated ob the Basis of Table 10.9 for Mixes of Consistancy other than Plastic Factors for maximum size of aggregates Consistency 10mm 12.5 mm 20 mm 25 mm 37.5 mm Extremely dry Very stiff Stiff Stiff-plastic Plastic (reference) Fluid or flowing 1.90 1.60 1.35 1.08 1.00 0.97 1.70 1.45 1.30 1.06 1.00 0.98 1.45 1.30 1.15 1.04 1.00 1.00 1.40 1.25 1.15 1.06 1.00 1.00 1.30 1.25 1.20 1.09 1.00 1.00

Table 10.11 Approximate Water Requirements for Different Slumps and Maximum Size Coarse Aggregate (ACI Manual of Concrete Practice, Part-I) Slump, mm Compacting Factor Relative water contant, per cent 10 Non-air entrained concrete Stiff-Plastic: 0.85 92 25-50 Plastic: 0.91 100 75-100 Flowing: 0.95 106 150-175 Approximate mean entrained air, per cent Air-entrained concrete Stiff-Plastic: 0.85 92 25-50 Plastic: 0.91 100 75-100 Flowing: 0.95 106 150-175 Recommended Mild exposure average total air Moderate exposure content, per cent Extreme exposure 207 228 243 3.0 182 203 212 4.5 6.0 7.5 Mixing water (kg/m3 of concrete) Maximum size of aggregate, mm 12.5 20 25 37.5 199 216 228 2.5 177 192 203 4.0 5.5 7.0 190 205 216 2.0 162 177 188 3.5 5.0 6.0 179 193 202 1.5 152 168 177 3.0 4.5 6.0 166 181 190 1.0 143 158 168 2.5 4.5 5.5

50 154 169 178 0.5 139 145 155 2.0 4.0 5.0

Table 10.12: Relationship Between Water-Cement Ratio and average compressive strength (ACI Manual od Concrete Practice, Part-I) Compressive Strength at 28 days, Mpa 45 40 35 30 25 20 15 Water-Cement Ratio by Mass Non-air-entrained concrete 0.38 0.42 0.47 0.54 0.61 0.69 0.79 Air-entrained concrete ------0.39 0.45 0.52 0.60 0.71

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Wildlife Crossing Design Based On AASHTO-17th & ACI 318-14Document1 pageWildlife Crossing Design Based On AASHTO-17th & ACI 318-14Bilal Ahmed BarbhuiyaNo ratings yet

- Moment of Inertia ExplainedDocument18 pagesMoment of Inertia ExplainedSameOldHatNo ratings yet

- Estimate For Pitching & ApronDocument63 pagesEstimate For Pitching & ApronBilal Ahmed Barbhuiya67% (3)

- Drain DesignDocument106 pagesDrain DesignBilal Ahmed Barbhuiya100% (2)

- SP-017 (14) : The Reinforced Concrete Design Handbook Volumes 1 & 2 PackageDocument4 pagesSP-017 (14) : The Reinforced Concrete Design Handbook Volumes 1 & 2 PackageBrunoAmorim0% (1)

- Dost Jls S PrimerDocument17 pagesDost Jls S PrimerShaunrey SalimbagatNo ratings yet

- Pipeline Design For Onshore Pipelines: STD.4600 Engineering Standards and Specifications PipelineDocument23 pagesPipeline Design For Onshore Pipelines: STD.4600 Engineering Standards and Specifications PipelineEzequiel Guillermo Trejo NavasNo ratings yet

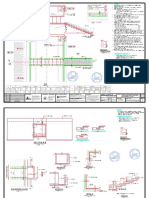

- Box Culvert 1.5 X 1.5Document2 pagesBox Culvert 1.5 X 1.5Bilal Ahmed Barbhuiya50% (2)

- PDA Testing Assess Pile CapacityDocument2 pagesPDA Testing Assess Pile Capacityphongmel50% (2)

- Design 12.9 X 22 MDocument214 pagesDesign 12.9 X 22 MBilal Ahmed BarbhuiyaNo ratings yet

- Design of A R.C.C Mountable Drain Slab CoverDocument4 pagesDesign of A R.C.C Mountable Drain Slab CoverBilal Ahmed Barbhuiya100% (8)

- CEng Career AssessmentDocument11 pagesCEng Career AssessmentKarthik Dhayalan50% (4)

- BS 1434 Copper For Electrical PurposesDocument14 pagesBS 1434 Copper For Electrical PurposesCristi Grosu0% (1)

- AS 3735 - Concrete Structures For Retaining LiquidsDocument27 pagesAS 3735 - Concrete Structures For Retaining LiquidslowiyaunNo ratings yet

- Slab Girder BridgeDocument42 pagesSlab Girder BridgeAslam Saifi100% (2)

- Drain DWGDocument1 pageDrain DWGBilal Ahmed BarbhuiyaNo ratings yet

- Staad Input File RCC Drain 3 M X 3 MDocument2 pagesStaad Input File RCC Drain 3 M X 3 MBilal Ahmed BarbhuiyaNo ratings yet

- Summary of Findings and Recommendations:: Appointment of A Safety ConsultantDocument2 pagesSummary of Findings and Recommendations:: Appointment of A Safety ConsultantBilal Ahmed BarbhuiyaNo ratings yet

- Election Commission of India Model Code of Conduct (2019)Document312 pagesElection Commission of India Model Code of Conduct (2019)Deepak Kumar VasudevanNo ratings yet

- Appendix C.26 D: Single Cell RCC Box Culvert of Size 2 X 3 (U/S & D/S Pitching)Document7 pagesAppendix C.26 D: Single Cell RCC Box Culvert of Size 2 X 3 (U/S & D/S Pitching)Bilal Ahmed Barbhuiya100% (1)

- Box Culver 1 X 4 X 3Document97 pagesBox Culver 1 X 4 X 3Bilal Ahmed BarbhuiyaNo ratings yet

- MX PresentationDocument48 pagesMX PresentationBilal Ahmed BarbhuiyaNo ratings yet

- Analysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporDocument4 pagesAnalysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporBilal Ahmed BarbhuiyaNo ratings yet

- 13Document18 pages13api-3696315No ratings yet

- Highway DDocument1 pageHighway DBilal Ahmed BarbhuiyaNo ratings yet

- River Training WorksDocument34 pagesRiver Training WorksBia MughalNo ratings yet

- 07 10 15Document4 pages07 10 15Bilal Ahmed BarbhuiyaNo ratings yet

- Tbeambridge 07092015Document4 pagesTbeambridge 07092015Bilal Ahmed BarbhuiyaNo ratings yet

- Solid SlabDocument4 pagesSolid SlabBilal Ahmed BarbhuiyaNo ratings yet

- Culvert EssttDocument51 pagesCulvert EssttBilal Ahmed BarbhuiyaNo ratings yet

- Beam Output From StaddDocument4 pagesBeam Output From StaddBilal Ahmed BarbhuiyaNo ratings yet

- Eq. DesignDocument15 pagesEq. DesignBilal Ahmed BarbhuiyaNo ratings yet

- Statement of Qty. Drain Ghy. ByepassDocument12 pagesStatement of Qty. Drain Ghy. ByepassBilal Ahmed BarbhuiyaNo ratings yet

- Staad Input File RCC Drain 3 M X 3 MDocument2 pagesStaad Input File RCC Drain 3 M X 3 MBilal Ahmed BarbhuiyaNo ratings yet

- Eq. DesignDocument15 pagesEq. DesignBilal Ahmed BarbhuiyaNo ratings yet

- Drain DesignDPRDocument94 pagesDrain DesignDPRBilal Ahmed Barbhuiya100% (1)

- Eq. DesignDocument15 pagesEq. DesignBilal Ahmed BarbhuiyaNo ratings yet

- Eq. DesignDocument15 pagesEq. DesignBilal Ahmed BarbhuiyaNo ratings yet

- 2 Nov 15 Guidelines On Supervision of Steelworks Fabricated Overseas PDFDocument12 pages2 Nov 15 Guidelines On Supervision of Steelworks Fabricated Overseas PDFSadok KzadriNo ratings yet

- Hilti HvaDocument14 pagesHilti Hvaceca_89No ratings yet

- Proposal Ccs e WeekDocument5 pagesProposal Ccs e WeekXandra LeeNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- Climaveneta - 350 Euston RoadDocument20 pagesClimaveneta - 350 Euston RoadrobasiNo ratings yet

- Culvert 1x2x2 0.50 CushionDocument22 pagesCulvert 1x2x2 0.50 CushionubiakashNo ratings yet

- CIVIL ENGINEERING prEN 1995-2 2004 (Final Draft) - Design of Timber Structures - Bridges PDFDocument29 pagesCIVIL ENGINEERING prEN 1995-2 2004 (Final Draft) - Design of Timber Structures - Bridges PDFcaballerolangNo ratings yet

- PVPE Pneumatic Valve Packing EquipmentDocument12 pagesPVPE Pneumatic Valve Packing EquipmentAustralian Weighing EquipmentNo ratings yet

- International Journal of Science and Business ISSN 2520-4750Document2 pagesInternational Journal of Science and Business ISSN 2520-4750ijsab.comNo ratings yet

- Forthcoming TitlesDocument116 pagesForthcoming TitlesSanket RoutNo ratings yet

- Buet Prospectus 2022-23 FinalDocument10 pagesBuet Prospectus 2022-23 FinalProttoy BhattacharyaNo ratings yet

- Load Attaching Points On Loads in Nuclear Power PlantsDocument59 pagesLoad Attaching Points On Loads in Nuclear Power PlantsmaomontesNo ratings yet

- 00 Basement Foundation LayoutDocument1 page00 Basement Foundation LayoutrendaninNo ratings yet

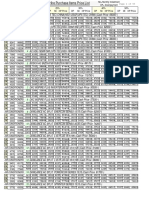

- PriceListHirePurchase Normal 1Document55 pagesPriceListHirePurchase Normal 1Muhammad HajiNo ratings yet

- Voltage Profile Improvement, Transmission Line Loss Reduction in Rajasthan Power System: A Case StudyDocument12 pagesVoltage Profile Improvement, Transmission Line Loss Reduction in Rajasthan Power System: A Case StudyAdvanced Research PublicationsNo ratings yet

- Final TT-End Sem - Spring Sem2022-23 - 13.04.2023Document4 pagesFinal TT-End Sem - Spring Sem2022-23 - 13.04.2023Ritwik NandiNo ratings yet

- PostDocument203 pagesPostMichael NasiefNo ratings yet

- Supertall Building Chilled Water Distribution SI May 30 2015Document10 pagesSupertall Building Chilled Water Distribution SI May 30 2015185412No ratings yet

- The Easily Mounted Floor System For Large Spans: Hoesch Additive Floor Technical InformationDocument16 pagesThe Easily Mounted Floor System For Large Spans: Hoesch Additive Floor Technical InformationIvan ŠpacNo ratings yet

- Capstone - Design, Installations and Testing of Electrical Systems in BuildingDocument10 pagesCapstone - Design, Installations and Testing of Electrical Systems in BuildingHaziq10101No ratings yet

- HELLER 4 Axis Machining Centres H enDocument28 pagesHELLER 4 Axis Machining Centres H enAbdullah ANo ratings yet