Professional Documents

Culture Documents

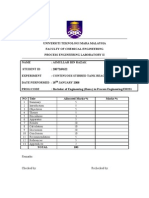

Tubular Flow Reactor: Solteq

Uploaded by

Raja MaizatulakmalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tubular Flow Reactor: Solteq

Uploaded by

Raja MaizatulakmalCopyright:

Available Formats

SOLTEQ

Equipment for Engineering Education & Research

TUBULAR FLOW REACTOR

MODEL: BP 101

his Tubular Flow Reactor (Model: BP 101) has been designed to introduce students of Chemical Engineering to the behaviour of a plug flow reactor by studying the second order reaction between dilute caustic soda and ethyl acetate. The unit is small in scale for ease of operation but capable of demonstrating the principles of industrial scale reactor behaviour. The unit includes a 10 litres reactor vessel as a water jacket, and is equipped with a variable speed stirrer, inlet and outlet ports for the feed and product streams, sampling, conductivity measurements and temperature measurements and control.

A cooling coil and immersion heater are provided inside the vessel to provide constant reaction temperature. The desired reaction temperature is achieved by controlling the heating using a digital temperature controller located on the front panel. Two non-corroding feed storage vessels are supplied, together with chemically resistant pumps and flowmeters. A product collection vessel is also provided and if necessary, the products are neutralised before

discharging to the laboratory drains. The tubular reactor is a coil of long tubing wound around a cylinder inside the vessel to give a total reactor volume of approximately 0.4 litres. The spiral design is practically the best approximation to plug flow conditions, as the secondary flow ensures good radial mixing while minimising longitudinal dispersion. The two reactants are pre-heated prior to mixing and entering the reactor.

SOLTEQ

Equipment for Engineering Education & Research

EXPERIMENTAL CAPABILITIES Comparison of predicted and experimental conversion in a continuous tubular flow reactor Effect of temperature on reaction rate Effect of flow velocity on conversion Residence time characteristics of the reactor Chemical analysis techniques Mathematical modelling of reactor systems

e) Feed Pumps: Capacity Electrical

: 1 LPM : 240VAC/1-phase/50-60Hz

f) Flow Control: Liquid Flowmeter : up to 500 ml/min; electronic Flow Control : needle valves

SPECIFICATIONS Bench-mounted apparatus designed to demonstrate tubular reactor behaviour comprising two 20 litre feed tanks, non-corrosive feed pumps and flowmeters. It includes a temperature controlled water jacket, a preheating coils and 0.4 litres reactor volume a) Reactor: Water Jacket

g) Instrumentations: The unit is fitted with all necessary sensors and digital indicators for measurements of temperature, flowrate and conductivity. All sensors are of electronic type to ensure compatibility with data acquisition system.

REQUIREMENTS Electrical supply Water supply Working area Chemicals

: 10 L; borosilicate glass; stainless steel top and bottom plate Cooling System : 3/8" stainless steel tube with connections for cooling water Heating System : 2 x 1 kW immersion heaters; temperature sensor; temperature controller Tubular Reactor : coiled tubing; 0.4 L Pre-heating : 2.5 L stainless steel vessel with coils and circulation pump

: 240VAC/1-phase/50-60Hz. : Laboratory mains supply with drainage points : ventilated; approx. 10 m2 : ethyl acetate and caustic soda are suggested Analytical equipment

OVERALL DIMENSIONS b) Stirrer System: Speed Range : 50 to 2000 rpm; with speed controller and digital indicator Electrical : 240VAC/1-phase/50-60Hz Impellers : 2" dia.; stainless steel c) Feed Tanks: Capacity Material Height Width Depth : 1.68 m : 1.22 m : 0.91 m

: 20 litre (cylindrical) : Stainless steel

SOLTEQ

d) Product Tanks: Capacity : 50 litre (rectangular) Material : Stainless steel

SOLTEQ

Equipment for Engineering Education & Research

SOFTWARE & E-LEARNING Our range of teaching equipment can be complemented with our SOLDAS and SOLCAL software.

SOLDAS - Supervisory Control & Data Acquisition - Data Logging - Signal Analysis - Process Control - Real-Time Display - Tabulated Results - Graph of Experiment Results

SOLCAL - Computer Aided Learning - Multimedia Features - Interactive - Graphic Simulation - Samples of Experiment Result - Full Experiment Manuals

Contact us for a catalog CD SOLUTION ENGINEERING SDN. BHD.

(Co. No. 174876-M) Sales Office : No.3, Jalan TPK 2/4, Taman Perindustrian Kinrara, 47100 Puchong, Selangor Darul Ehsan, Malaysia. Tel. No. : +(603) 80758000 Fax. No. : +(603) 80755784 R&D Office : G-2A, Incubator 3, Technology Park Malaysia, Bukit Jalil, 57000 Kuala Lumpur, Malaysia. Tel. No. : +(603) 8996 0023 MSC- Status Email : solution@solution.com.my Web site : http//www.solution.com.my/

BUATAN MALAYSIA

AGENT:

Company

You might also like

- LS-32001-BCR Bench Top Chemical ReactorsDocument5 pagesLS-32001-BCR Bench Top Chemical ReactorsAhmed AliNo ratings yet

- BP107 (A4) 1Document4 pagesBP107 (A4) 1Huda TajuddinNo ratings yet

- LAB 2 CSTR in Series - Expected ResultsDocument4 pagesLAB 2 CSTR in Series - Expected ResultsArfa Zulkifli01No ratings yet

- LiquidLiquid Extraction Unit BP60Document2 pagesLiquidLiquid Extraction Unit BP60Nurakmal SyuhAdaNo ratings yet

- Gas UnitDocument4 pagesGas UnitZalina SamsuddinNo ratings yet

- Vle SolteqDocument3 pagesVle SolteqFarhan AhmadNo ratings yet

- Water Hydraulic TestDocument5 pagesWater Hydraulic TestcomyahoothanhNo ratings yet

- CPE5005-B Reaction Engineering: Tubular Reactor Lab ExperimentDocument22 pagesCPE5005-B Reaction Engineering: Tubular Reactor Lab ExperimentJuan CalderonNo ratings yet

- Climb Film EvaporationDocument4 pagesClimb Film EvaporationSachinNo ratings yet

- He158 (A4)Document4 pagesHe158 (A4)MUzair5No ratings yet

- He165 (A4) PDFDocument4 pagesHe165 (A4) PDFLina ShakirNo ratings yet

- Air Compressor Study Unit: SolteqDocument4 pagesAir Compressor Study Unit: Solteqrahulpatel07No ratings yet

- He158c (A4)Document4 pagesHe158c (A4)Mohd Hafizil Mat YasinNo ratings yet

- CEB2072 Chemical Engineering Lab 2: Experiment Group Group MembersDocument36 pagesCEB2072 Chemical Engineering Lab 2: Experiment Group Group MembersGrace ChowNo ratings yet

- Engineering Services & Solutions for DaVision Proiect SRLDocument11 pagesEngineering Services & Solutions for DaVision Proiect SRLAdriana BanyaiNo ratings yet

- Isothermal Batch ReacterDocument1 pageIsothermal Batch ReacterVirender RanaNo ratings yet

- Flow Instrumentation BenchDocument3 pagesFlow Instrumentation Benchadnan0% (1)

- Gas Flow Measurement Bench FM120Document3 pagesGas Flow Measurement Bench FM120daus_kimiNo ratings yet

- ConvectionDocument4 pagesConvectionNur AishaNo ratings yet

- 5 VsDocument4 pages5 VsAdhitomoWirawanNo ratings yet

- Plate Heat Exchanger: SolteqDocument0 pagesPlate Heat Exchanger: SolteqbabeNo ratings yet

- Loughborough University Process Control Lab ManualDocument16 pagesLoughborough University Process Control Lab Manualabmuqeet2No ratings yet

- EXP 2 - Plug Flow Tubular ReactorDocument18 pagesEXP 2 - Plug Flow Tubular ReactorOng Jia YeeNo ratings yet

- QDTLDocument3 pagesQDTLsady1967No ratings yet

- Lab RPRT (CSTR)Document21 pagesLab RPRT (CSTR)Black White80% (5)

- Cooling TowerDocument4 pagesCooling TowerNurakmal SyuhAdaNo ratings yet

- BP143 (A4)Document4 pagesBP143 (A4)Siti Hajar JamaluddinNo ratings yet

- Clibration Laboratory LayoutDocument16 pagesClibration Laboratory Layoutjrlr65No ratings yet

- SEPARACIÓN INTERFASE: LIQUIDO – LIQUIDODocument3 pagesSEPARACIÓN INTERFASE: LIQUIDO – LIQUIDOMiguel VelazcoNo ratings yet

- Chemical reactors teaching equipmentDocument8 pagesChemical reactors teaching equipmentMaque Cimafranca GabianaNo ratings yet

- Banco Hidraulico ReporteDocument5 pagesBanco Hidraulico ReporteJuan Diego Citalan AguilarNo ratings yet

- Water Treatment and Chemical CleaningDocument5 pagesWater Treatment and Chemical CleaningtonylyfNo ratings yet

- Marcet BoilerDocument4 pagesMarcet Boilerpure14No ratings yet

- Chme 401 Chemical Engineering Laboratory Ii Experiment 401-4 Chemical Reactors ObjectiveDocument4 pagesChme 401 Chemical Engineering Laboratory Ii Experiment 401-4 Chemical Reactors ObjectiveDyako D TaherNo ratings yet

- 4-Variable Advanced Process Control Training System Plus - 603-PACEHDocument6 pages4-Variable Advanced Process Control Training System Plus - 603-PACEHاحمد المرشديNo ratings yet

- Thermo Scientific Dionex Integrion HPIC SystemDocument5 pagesThermo Scientific Dionex Integrion HPIC SystemYan RiveraNo ratings yet

- 35,000 kg/hr Water-Tube Boiler Design & Construction SpecDocument7 pages35,000 kg/hr Water-Tube Boiler Design & Construction SpecRabindranath Hendy TagoreNo ratings yet

- Hydraulic & FM LabDocument4 pagesHydraulic & FM LabJaishree ChauhanNo ratings yet

- Designing of Controllers For PH NeutralizationDocument6 pagesDesigning of Controllers For PH NeutralizationvargasNo ratings yet

- HE 178 - Solution EngineeringDocument4 pagesHE 178 - Solution EngineeringMuhammad TufailNo ratings yet

- Liquid Diffusion Coefficient Apparatus BP09Document4 pagesLiquid Diffusion Coefficient Apparatus BP09Ahmed AliNo ratings yet

- M.tech Lab ManualDocument94 pagesM.tech Lab ManualSHINUMMNo ratings yet

- Final PresentationDocument15 pagesFinal PresentationkamalNo ratings yet

- UTM Chemical Engineering Lab Report OptimizationDocument15 pagesUTM Chemical Engineering Lab Report OptimizationNabilah SyaheeraNo ratings yet

- MICROCERVECERIA - InglesDocument23 pagesMICROCERVECERIA - InglesdavidNo ratings yet

- Aeration Apparatus: SolteqDocument3 pagesAeration Apparatus: Solteqafiq_akashah1264No ratings yet

- LabTech water chiller cooling solutions for analytical labsDocument6 pagesLabTech water chiller cooling solutions for analytical labsrajesh_rbpNo ratings yet

- Gujarat State Electricity Corporation LimitedDocument5 pagesGujarat State Electricity Corporation LimitedSylab InstrumentsNo ratings yet

- Temperature Effects On The Performance of Tunable Diode Laser Moisture AnalyzersDocument18 pagesTemperature Effects On The Performance of Tunable Diode Laser Moisture AnalyzersVictor Enrique Rosales ParadaNo ratings yet

- SOLTEQ® Reactor Service Unit (Model: BP 150) WasDocument4 pagesSOLTEQ® Reactor Service Unit (Model: BP 150) WasDivaan Raj KarunakaranNo ratings yet

- HVAC Water TreatmentDocument9 pagesHVAC Water TreatmentDudyFredy100% (1)

- C TLL HD Control Loop HardwareDocument20 pagesC TLL HD Control Loop Hardwareenigmaticmind23No ratings yet

- EPC Quotation-15th May 2011Document95 pagesEPC Quotation-15th May 2011Michael Parohinog Gregas100% (2)

- SOLTEQDocument4 pagesSOLTEQRobert GilmoreNo ratings yet

- Instrumentation and ControlDocument13 pagesInstrumentation and ControlAdilaAnbreenNo ratings yet

- Plug Flow Tubular ReactorDocument23 pagesPlug Flow Tubular Reactorzulkhairi100% (1)

- Power Electronics: Switches and ConvertersFrom EverandPower Electronics: Switches and ConvertersRating: 2 out of 5 stars2/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Avasoo PDFDocument66 pagesAvasoo PDFRaja MaizatulakmalNo ratings yet

- Hyperbranched Polymers: New Selective Solvents For Extractive Distillation and Solvent ExtractionDocument19 pagesHyperbranched Polymers: New Selective Solvents For Extractive Distillation and Solvent ExtractionRaja Maizatulakmal0% (1)

- Topic 9-Liquid Chromatography (Part II)Document41 pagesTopic 9-Liquid Chromatography (Part II)Raja MaizatulakmalNo ratings yet

- ADF Health Manual Vol 20, Part8, Chp2Document18 pagesADF Health Manual Vol 20, Part8, Chp2Ahmad Usman Tahir100% (2)

- 1 s2.0 S0141022903002060 MainDocument7 pages1 s2.0 S0141022903002060 MainRaja MaizatulakmalNo ratings yet

- Topic 1-Intro To Bioproducts and BioseparationsDocument30 pagesTopic 1-Intro To Bioproducts and BioseparationsRaja Maizatulakmal100% (4)

- Cell Distruption: (Downstream Processing)Document10 pagesCell Distruption: (Downstream Processing)Raja MaizatulakmalNo ratings yet

- Chapter 8 - Cost of ManufacturingDocument28 pagesChapter 8 - Cost of ManufacturingRaja MaizatulakmalNo ratings yet

- ReportDocument17 pagesReportHafiniHambaliNo ratings yet

- Absorption Tutorial 1Document1 pageAbsorption Tutorial 1Raja MaizatulakmalNo ratings yet

- Introduction to Leaching ProcessesDocument47 pagesIntroduction to Leaching ProcessesRaja Maizatulakmal100% (3)

- Residence Time Distribution: Expt. MT 401Document5 pagesResidence Time Distribution: Expt. MT 401Javidh SeyedNo ratings yet

- EntropyDocument6 pagesEntropyRaja MaizatulakmalNo ratings yet

- Chapter 12, Problem 9P: CommentDocument1 pageChapter 12, Problem 9P: Commentmahdi najafzadehNo ratings yet

- Metal Stamping GlossaryDocument5 pagesMetal Stamping GlossarynikitaNo ratings yet

- Stress Analysis Report ABS Plastic PartDocument40 pagesStress Analysis Report ABS Plastic PartIhsan SamohNo ratings yet

- General Theory of Elastic Stability - SouthwellDocument59 pagesGeneral Theory of Elastic Stability - SouthwelltpadhyNo ratings yet

- Synthesis and Characterization of Carbazole DerivativeDocument7 pagesSynthesis and Characterization of Carbazole DerivativeDavid MoralesNo ratings yet

- 1986 HermiaDocument7 pages1986 HermianevenkanikNo ratings yet

- Pierre-André Schnegg, University of Neuchâtel, Switzerland: Groundwater and Human DevelopmentDocument5 pagesPierre-André Schnegg, University of Neuchâtel, Switzerland: Groundwater and Human Developmentsurbakti_unsriNo ratings yet

- Alberty (2002) Thermodynamics of Systems of Biochemical ReactionsDocument11 pagesAlberty (2002) Thermodynamics of Systems of Biochemical ReactionsSultan ShaikhNo ratings yet

- Docol Welding Handbook v2 2018 WEBDocument56 pagesDocol Welding Handbook v2 2018 WEBFeratNo ratings yet

- SN1 Vs SN2 PDFDocument1 pageSN1 Vs SN2 PDFAlphaNo ratings yet

- Burrows2e Solutions Ch01Document42 pagesBurrows2e Solutions Ch01mnemoniaNo ratings yet

- Experimental Study of Bamboo Reinforced Concrete Beams Having Various Frictional PropertiesDocument9 pagesExperimental Study of Bamboo Reinforced Concrete Beams Having Various Frictional PropertiesSARA ISABEL BURBANO MOSQUERANo ratings yet

- Aluminium WeldingDocument2 pagesAluminium WeldingARYANo ratings yet

- Modelling The Seismic Response of An Unreinforced Masonry StructureDocument152 pagesModelling The Seismic Response of An Unreinforced Masonry Structurecandsbanda100% (1)

- MSDS Tape Safety DataDocument5 pagesMSDS Tape Safety Dataalex6inNo ratings yet

- Fiit Jee Jee All India Test Series Answer KeyDocument14 pagesFiit Jee Jee All India Test Series Answer KeyDheeraj PradeepNo ratings yet

- ModelQuestion Ch23Document3 pagesModelQuestion Ch23Yasmeen ElsawafNo ratings yet

- Comparing Environmental Impacts of Electric and Stovetop KettlesDocument10 pagesComparing Environmental Impacts of Electric and Stovetop KettlesAliAyoubNo ratings yet

- Compressed Gases ChecklistDocument3 pagesCompressed Gases ChecklistImam FirdausNo ratings yet

- Nicofer Alloy625 PDFDocument13 pagesNicofer Alloy625 PDFbigsteve9088No ratings yet

- Optimal AgricultureDocument9 pagesOptimal AgriculturesamNo ratings yet

- Air Pollution Treatment MethodsDocument64 pagesAir Pollution Treatment Methodssagbvn100% (1)

- Applied OpticsDocument55 pagesApplied OpticsDevesh AgrawalNo ratings yet

- Interzone 954 enDocument4 pagesInterzone 954 engrootwNo ratings yet

- Draw Chemical Structures with Chemfig LaTeX PackageDocument46 pagesDraw Chemical Structures with Chemfig LaTeX PackageCygnus ConstellationNo ratings yet

- Human Skin Temperature CalculationDocument14 pagesHuman Skin Temperature CalculationRaymond FuentesNo ratings yet

- Santogard PviDocument2 pagesSantogard PviMimiaguilNo ratings yet

- IFA Atex WoodDocument7 pagesIFA Atex Woodrafabustamante7651No ratings yet

- CPE 1ST YR CHEM ENGDocument3 pagesCPE 1ST YR CHEM ENGKhairie MahadiNo ratings yet

- DARACLAR 9000HP Silica Brewery Case Study 2016-WebDocument7 pagesDARACLAR 9000HP Silica Brewery Case Study 2016-WebAlia ShabbirNo ratings yet