Professional Documents

Culture Documents

Awang

Uploaded by

Shahrudin van DzulkarnainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Awang

Uploaded by

Shahrudin van DzulkarnainCopyright:

Available Formats

INTRODUCTION

Ricardo Steel is an establish well-known company in Sabah and has been producing quality steels for constructions At Ricardo Steel, we are well known for our key values of safety, quality and productivity are the foundation of our business while character and integrity are the pillars of our success. The company strives to hold itself to the highest ethical standards in order to serve the long-term best interests of all of our stakeholders. As a world leader in the production of flat-rolled carbon, stainless and electrical steel products, RICADO Steel operates the most flexible facilities in the steel industry and that places us among the very best at adapting to ever-changing market conditions and customer needs. However, on a tour made by our Occupational Health Management Department, we found out that it is not as reported by the Management. Accidents in the workplace happen for a number of reasons. The results of a workplace accident can be minimal or tragic, causing minor injury, damage to equipment or even in some cases, major injury or death. Employees need to stay alert and aware at all times to avoid accidents, while managers need to know the most common causes for workplace accidents and be able to spot the risk factors early to prevent one. One of the challenges every employer faces is maintaining a safe workplace. Besides fines for failing to comply with federal and state workplace safety regulations, employers are in danger of injuring valuable employees or even lawsuits from employees who are inured on the job due to negligence or a failure to follow procedures. But employee actions also are key to keeping their environment safe. Employee safety is implemented in workplaces to keep workers safe from harm and danger. While safety measures are most often practiced in environments where heavy equipment and hazardous substances are used, safety procedures should also be established in office environments where other types of potential dangers can be found. Employee safety is not only about keeping employees safe as they work, but also about giving the company a credible reputation in employee safety standards and regulations. On the 13 and 15 of October, a tour made by the Occupational Health Manager team lead by me , in order to make sure the safety in the factory is in a good standard. The tour was made at 11.00

1

am with the assistance of the factory manager. It was found during plant visits that employees were not carrying portable carbon monoxide (CO) meters to detect gas leakage in the blast furnace area, which is a serious safety violation. The number of fixed online CO alarm monitors in the plant is also not clear. More attention needs to be paid on CO tracking and the accessibility of CO monitors for the steel plant .The plant also does not under the Ricado special health tests for coke oven battery workers. Existing safety monitoring and coordinating structures lack expertise or enforcement capacity to regulate safety measures in these steel plants. Workplace safety is the employer's and management's responsibility. It involves the formation and implementation of safety programs. Employee insurance schemes and employee safety policies help cover the risk an employee might suffer at work. Jobs, which require the employees to travel or stay out of their city or country, should cover the risks involved in the journey and the on-site stay. Certain jobs require the employees to engage in life-risking work; they require the employees to be part of dangerous industrial processes. Jobs, which put the safety of their employees at stake, should also provide the employees with the safety costs. No one can argue with the fact that workplace safety is important, yet its often unintentionally overlooked, leaving workers and others on the job site exposed to risk. Safety Management Groups trained safety advisors can identify unsafe acts and conditions and provide practical solutions for minimizing those risks. Additionally, Safety Management Groups safety professionals can help clients to develop a culture of safety on their job sites. The on- or off-site training that Safety Management Group provides can equip all the members of a construction team with the tools they need to perform their job safely, whether they need basic safety training or project-specific safety training

THE REPORT Referring to three accidents involving the workers in a span of three days in May and June 2012, the report had noted that 'it shows that occupational safety needs to be overhauled and improved particularly for the contractual staffs. As a number of contractual and daily wage laborers are employed in hazardous working areas, their health and safety aspects also need to be given equal

importance, the manager and workers in the factory were not aware of safety precautions or chose to ignore them. These factors should be handled in order to prevent accidents in the workplace to happen and to maintain the companys image on safety of workers in the workplace area. After a meeting with the Material and Handling board, safety in our factory has been the major agenda discussed and we had come out to a few conclusion on steps for solving and handling the safety of our workers. The present situation were identified and these are the major problems and careless situation that occurs in the factory : Workers are lack of training especially in handling dangerous materials and how to behave in the factory. They are found smoking in the area and handling the materials without proper safety clothing such as gloves, safety boots and helmets. They are also found eating and drinking in the area and behave carelessly. The worker sat on the chemical cans and some are using cell phones while working. These careless actions may lead to accidents in the workplace and should be prevented.

Knowledge of the worker on safety management was also found to be poor. Before the result of the rating was announced earlier this month, the technical advisory panel of Health Manager found that these comments and recommendations were totally ignored. The panel also included senior steel industry and pollution control experts. During the visits we were concerns of poor safety conditions were conveyed to highest management of the company, including the chairman, because we found that the management had not made any remedial measures on the lapses we had pointed out in July 2012.

Safety rules were not displayed accordingly. The posters of rules and regulations in the factory were found in a poor condition. It was blocked from the factory workers by shelves and other furniture. The posters and pictures displaying safety rules were not displayed properly and some has been displayed in hidden areas.

3

During the visits, it was also found that employees were not carrying portable carbon monoxide (CO) meters. These meters are very important for detecting gas leakage in the blast furnace area. This is identified as a major problem that will lead to safety violation. We also found that some of the existing fixed online CO alarm monitors in the plant is also not clear. More attention needs to be paid on CO leakage tracking and the accessibility of CO monitors for the steel plant .

SUGGESTION ON ACTIONS Valuing your employees safety should be the number one priority of every business. The reasons behind valuing employee safety range from the mundane concerns about lawsuits, productivity and insurance premiums to the more humanitarian idea that employees are people and as such deserve the respect and treatment that does a soul good. Empathy is a great quality to practice even when it negatively affects the bottom line. Because of the very nature of manufacturing, managers of this type of business are always looking for ways to improve safety. Safety in the workplace should always be a high priority. The bottom line is that having accidents on the job, can lead to a loss in productivity, and can cost the company a lot of money. It can also have a huge effect on how your employees perform their work. This is because if they do not feel as if they are in a safe environment, they will not perform to their best potential. Below are some suggestion on how the company could help to manage the safety of the workers and prevent accidents from happening in the workplace. Visual reminders to improve safety can include everything from posters and count boards to videos and books. These visual reminders are important for those times in between when safety can be covered in a formal meeting and for during a formal meeting. The only thing is that management must use visual reminders in a smart way that does not make employees feel like they are being talked down to or like the company is wasting money on unneeded things.

4

Posters are the most commonly used visual reminders. One overlooked safety poster is in the bathroom that reminds people to wash their hands. Even with this reminder, men and women walk out of the bathroom with even so much looking at the sink. Someone else may even be at the sink washing his or her hands when the offender leaves without having done the same so much for peer pressure. Still all health is a matter of safety and that includes illness. Whether an employee is out because of an injury or an illness, the result is still loss productivity for the business and several unpleasant moments for the employee. Another popular safety poster involves the steps for first aid and safety. Of course, these procedures are applied after there has been one failure of safety protocol, so the posters may not be the best for keeping people from getting hurt. They are, however, useful in allowing people to remember how to deal with an emergency when it occurs. The visuals are handy and usually well-presented depending on where they were bought and how old they are. CPR and First Aid generally change every five years coinciding with the recommendations from the Emergency Cardiovascular Conference that takes place on the fives, i.e. 2005, 2010, 2015, etc. All employees should have workplace safety training before they begin a new job. Lifting injuries can happen to any employee, so proper instruction on the safe lifting of heavy materials should be part of basic safety training. Basic training should include how to report medical and fire emergencies. This includes the proper forms necessary to report accidents. Training in fire extinguisher usage should be mandatory. Employers should also hold periodic drills for evacuation of the building in case of emergency as well as where to shelter in the building in case of severe weather.

Depending on the type of work, specialized safety training should be available. For example, the United States Occupational Safety and Health Administration requires all lift truck operators to have specialized safety training. If employees work with hazardous materials, they should have training in how to handle them and how to react in case of an emergency around them. The safe use of an eye wash station or chemical shower is vital training for someone working around chemicals and other hazardous materials.

In order for the workplace to be safe for everyone, managers must enforce safety rules. Once employers set safety guidelines, they expect every employee to follow them with absolutely no exceptions. Instructions must be clear and readable:

i.

Supply new employees with reading material. The most critical part of employee training and development is retention of the training information. A new staff member has a great deal to absorb. The ability to refer back to printed information can help the process. Even if you don't have a company manual, custom-made worksheets outlining procedures and expectations can be a useful addition to your training program.

ii.

Walk through procedures several times. Explain each step thoroughly and encourage questions. When the new recruit is ready, have him or her perform the tasks as you watch. Correct mistakes kindly; it takes time to learn a new set of procedures.

iii.

Assign a mentor. The "sink or swim" approach rarely works among employee training techniques. Assigning a guide to ease the transition to independent working helps the new employee acclimate to the position while freeing your time for other duties.

iv.

Give credit where it's due. As your new employee masters job skills, praise his or her efforts. A feeling of appreciation can go a long way in employee training and development.

It's impossible to hold workers accountable for workplace safety unless they understand what makes for a safe workplace and how to make changes to reduce the risks associated with their own workplace. This means that an accountability policy can only come once employees receive safety training. This training should

6

focus on specific common tasks, equipment and dangers in the workplace. For example, safety training for office workers should include information about ergonomics and repetitive stress injuries, while factory workers need training in electrical, chemical and fire hazards. Retraining employees as new risks arise, or to refresh their understanding of safety, will help prevent lax behavior and enhance accountability.

Employees are the experts on their own work spaces, which means they also are best able to report safety issues or violations that they observe. To encourage this type of accountability, provide incentives for workers who report safety hazards that result in a policy change or correction. Rewards may include bonus cash, gift cards, vacation time or company merchandise. This will help get employees in the habit of being on the lookout for dangers and reporting them to supervisors.

Under certain circumstances, maintenance workers may need to work on live electrical systems for the purpose of diagnostic testing or troubleshooting. If this is the case, workers must be qualified, trained in safe working practices and equipped with personal protective equipment. Electrical systems must be grounded to prevent the risk of hazardous voltage, which can result in shock or arc flash, leading to personal injury or possibly death. Maintenance workers may need to establish a temporary ground to work safely on a particular task.

The levels of dust and harmful gases in the factory should be closely monitored, but the workers in our factory may still be at risk of respiratory diseases, such as pneumoconiosis or silicosis, caused by metal and zink dust. The workers Safety and Health Administration stipulates that factory operators must provide protection, in the form of protective clothing and respirators, against any such hazards; workers also have the right to have their lungs X-rayed periodically at company expense.

7

Every employee should be made educated of the necessary steps to be adopted in case there is an emergency. As we know, most of the offices are located in high rise towers and the incidents like fire, elevator emergency, power cut have manifold impact at these places. Especially in incidents like fire, it is necessary for the employee to take some basic steps so as to arrest the magnitude of the casualty. In case of high-rise towers, it becomes difficult for fire-fighters to carry 100pund gears at the top of the buildings. In that case fire fighting devices like fire extinguishers should be kept within the reach of everyone.

CLOSURE

Hazards are considered to be potentially dangerous substances or behaviors that can cause harm or injury to an employee. There are several hazards employees can be exposed to in the workplace. Health hazards can range from infectious diseases spread from one worker to another to poisonous chemicals that are not properly stored and maintained. For example, some industries are exposed to dangerous gases such as carbon monoxide. These industries must follow specific safety procedures in the event of an emergency situation involving the substance. Workplace health and safety practices are important because they help prevent inter-office violence and raise employee awareness of the potential dangers they face. Violent acts and behaviors of employees and other individuals within the workplace are cause for concern because they threaten a companys overall well-being. Companies must take an active approach in educating workers on the importance of practicing safe habits in order to maintain a healthy and safe working environment. We are committed to our goal of ensuring zero harm to our employees, our contractors and the communities in which we operate. This is integral to our business process and is laid down in our companys wide health and safety policy that was implemented since it was operated. Our policy principles include amongst other that all injuries and work-related illness can and must be prevented and that excellence in health and safety

8

drives excellence in business results. Health and safety are integrated into all our business management systems and processes. Health and safety is a key performance indicator and one of the prime drivers of our corporate vision. On our journey towards an accident-free workplace, it is our goal to achieve a lost time injury frequency rate of less than 0.7 by the end of the reporting year 2012/13. Creating safe and healthy environment in the workplace benefits everybody. When people feel safe and are healthy their productivity at work increases. This in turn benefits the company. The number of work hours lost due to illness and injuries is also decreased in a safe and healthy workplace. Everyone will be more productive. Ensuring the safety at workplace does not require huge investment of time or money or other resources. All you need is to establish the basic framework and pathways to achieve the desired targets. Everyone working in the company should be made aware of their responsibility to follow the local policies, provided training with regular updates then the whole environment will become safe and healthy. When individuals practice the safety at workplace on daily basis it becomes a second nature. Workers should be encouraged to report near misses which are critical in developing new strategies and safeguards against possible mishaps. Safe and healthy workplace leads to confident and productive workers.

REFFERENCES

http://www.safetymanagementgroup.com/why-safety.aspx

http://safetyandworkplace.com/safety-and-workplace.html

http://www.utem.edu.my/fkp/images/format%20penulisan%20psm.pdf

http://www.linkedin.com/skills/skill/Report_Writing

http://www.spartacus.schoolnet.co.uk/IRaccidents.htm

10

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Leading and Lagging Indicators PDFDocument35 pagesLeading and Lagging Indicators PDFtatony100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lifting Risk AssessmentDocument5 pagesLifting Risk AssessmentimranNo ratings yet

- Construction Safety ManagementDocument32 pagesConstruction Safety ManagementBanala shivaniNo ratings yet

- Standards and SpecificationDocument35 pagesStandards and SpecificationBhaswati PandaNo ratings yet

- An Overview of FM 200, Carbon Dioxide, Wet Chemical, and Dry Chemical Fire Suppression SystemsDocument5 pagesAn Overview of FM 200, Carbon Dioxide, Wet Chemical, and Dry Chemical Fire Suppression SystemsAlex ChinNo ratings yet

- National Hospital StandardsDocument267 pagesNational Hospital Standardsقمةالثقه100% (1)

- PEJABAT PENDIDIKAN DAERAH BETONG STATUS PENERIMAAN ID SISTEM 1GFMAS & SAP GUIDocument6 pagesPEJABAT PENDIDIKAN DAERAH BETONG STATUS PENERIMAAN ID SISTEM 1GFMAS & SAP GUIShahrudin van DzulkarnainNo ratings yet

- Lesson Plan Week 2Document6 pagesLesson Plan Week 2Sha ImanNo ratings yet

- Resume 2020Document2 pagesResume 2020Shahrudin van DzulkarnainNo ratings yet

- Daily Lesso Plan 13-16Document9 pagesDaily Lesso Plan 13-16Shahrudin van DzulkarnainNo ratings yet

- Diocese of Kuching-2015Document1 pageDiocese of Kuching-2015Shahrudin van DzulkarnainNo ratings yet

- Teach OnDocument5 pagesTeach OnShahrudin van DzulkarnainNo ratings yet

- Zon Betong 2019Document4 pagesZon Betong 2019Shahrudin van DzulkarnainNo ratings yet

- Zon Betong 2019Document4 pagesZon Betong 2019Shahrudin van DzulkarnainNo ratings yet

- Biweekly Report 4: Please Refer To The Pictures Attach With The Report For Your ReferenceDocument2 pagesBiweekly Report 4: Please Refer To The Pictures Attach With The Report For Your ReferenceShahrudin van DzulkarnainNo ratings yet

- KBSR WRITING (Sentence Construction)Document1 pageKBSR WRITING (Sentence Construction)Shahrudin van DzulkarnainNo ratings yet

- Lesson ReportDocument13 pagesLesson ReportShahrudin van DzulkarnainNo ratings yet

- Korea Lesson Plan 2017Document1 pageKorea Lesson Plan 2017Shahrudin van DzulkarnainNo ratings yet

- Korea Lesson PlanDocument1 pageKorea Lesson PlanShahrudin van DzulkarnainNo ratings yet

- New Doc 2017-04-10 11.06.28Document1 pageNew Doc 2017-04-10 11.06.28Shahrudin van DzulkarnainNo ratings yet

- Daily Lesson Plan Sekolah Kebangsaan Supa, Pusa AprilDocument14 pagesDaily Lesson Plan Sekolah Kebangsaan Supa, Pusa AprilShahrudin van DzulkarnainNo ratings yet

- Peserta Karnival Transformasi Belia Bahagian BetongDocument3 pagesPeserta Karnival Transformasi Belia Bahagian BetongShahrudin van DzulkarnainNo ratings yet

- Keperluan asas manusiaDocument1 pageKeperluan asas manusiaShahrudin van DzulkarnainNo ratings yet

- Asembly TextDocument2 pagesAsembly TextShahrudin van DzulkarnainNo ratings yet

- Analisis Item BI Paper 2Document10 pagesAnalisis Item BI Paper 2Shahrudin van DzulkarnainNo ratings yet

- Analisis Item BI Paper 1Document16 pagesAnalisis Item BI Paper 1Shahrudin van DzulkarnainNo ratings yet

- Kemahiran/ Subtopik/ Konteks Pencapaian Murid Catatan: Matapelajaran: Bahasa Inggeris Kertas: Kertas 2Document2 pagesKemahiran/ Subtopik/ Konteks Pencapaian Murid Catatan: Matapelajaran: Bahasa Inggeris Kertas: Kertas 2Shahrudin van DzulkarnainNo ratings yet

- Daily Lesson Plan Sekolah Kebangsaan Supa PusaDocument7 pagesDaily Lesson Plan Sekolah Kebangsaan Supa PusaShahrudin van DzulkarnainNo ratings yet

- Mozi AssignmentDocument22 pagesMozi AssignmentShahrudin van DzulkarnainNo ratings yet

- Daily Lesson Plan Sekolah Kebangsaan Supa PusaDocument7 pagesDaily Lesson Plan Sekolah Kebangsaan Supa PusaShahrudin van DzulkarnainNo ratings yet

- Analisis Item ScoringDocument15 pagesAnalisis Item ScoringShahrudin van DzulkarnainNo ratings yet

- 29052Document10 pages29052norkamayanaNo ratings yet

- Travel Reservation September 10 For AWANGKU SYAHRUDINDocument1 pageTravel Reservation September 10 For AWANGKU SYAHRUDINShahrudin van DzulkarnainNo ratings yet

- Jadual Tugas KhasDocument1 pageJadual Tugas KhasShahrudin van DzulkarnainNo ratings yet

- Safety Data Sheet for LUBLIGHT #500-WDDocument4 pagesSafety Data Sheet for LUBLIGHT #500-WDAzuan MABKNo ratings yet

- Health Program (Dole)Document2 pagesHealth Program (Dole)catrynkat100% (1)

- HSE - EEMUA 160. Safety Related Instrument Systems Forthe Process IndustriesDocument2 pagesHSE - EEMUA 160. Safety Related Instrument Systems Forthe Process IndustriesAndrew BaileyNo ratings yet

- KM-C2630 Service ManualDocument460 pagesKM-C2630 Service ManualAnonymous egTruyVdxvNo ratings yet

- Dimethyl Disulfide: Safety Data SheetDocument13 pagesDimethyl Disulfide: Safety Data SheetbondsivamaniNo ratings yet

- Earthquake Contingency PlanDocument27 pagesEarthquake Contingency PlanCristopher Saraum Benegian100% (2)

- Flygt 2640 PDFDocument28 pagesFlygt 2640 PDFAlberto Roca M100% (1)

- SC-5004 SDSDocument9 pagesSC-5004 SDSarurNo ratings yet

- NFPA 1710 Fact SheetDocument2 pagesNFPA 1710 Fact SheetMarius BuysNo ratings yet

- Rescue Plan Thickener New PDFDocument7 pagesRescue Plan Thickener New PDFHafdi NawfalNo ratings yet

- OptiSelect GM03 E enDocument41 pagesOptiSelect GM03 E enqa.wnyNo ratings yet

- Disaster Management PPT NEWDocument11 pagesDisaster Management PPT NEWshikhabhanot2059No ratings yet

- Risk Identification and Assessment for Safety Improvement in ManufacturingDocument7 pagesRisk Identification and Assessment for Safety Improvement in ManufacturingBastian CristNo ratings yet

- Iic Pub G4 V1.00 PB-3Document173 pagesIic Pub G4 V1.00 PB-3blaljNo ratings yet

- Annual Report 2021 2022Document312 pagesAnnual Report 2021 2022PRIYA TIWARINo ratings yet

- Hazard Exposure & Vulnerability Narative EssayDocument3 pagesHazard Exposure & Vulnerability Narative EssayTrixie MatanguihanNo ratings yet

- DELTA - User Manual CellD APS 1500A-230-3 SSW enDocument32 pagesDELTA - User Manual CellD APS 1500A-230-3 SSW enMuhammad Adeel KhanNo ratings yet

- S&M 1Document8 pagesS&M 1Mohamed AlaaNo ratings yet

- SDS - Barrier 90 - Comp. B - Marine - Protective - English (Uk) - Australia - 2524 - 30.10.2012Document7 pagesSDS - Barrier 90 - Comp. B - Marine - Protective - English (Uk) - Australia - 2524 - 30.10.2012DonNo ratings yet

- Operating Instructions SITRANS Probe LU (HART) 08/2017 Edition Ultrasonic TransmittersDocument837 pagesOperating Instructions SITRANS Probe LU (HART) 08/2017 Edition Ultrasonic TransmittersvladimirNo ratings yet

- Bahaya Potensial Fisik Pada Proses Pengolahan Kelapa Sawit PT Perkebunan Nusantara Vii Tahun 2019Document9 pagesBahaya Potensial Fisik Pada Proses Pengolahan Kelapa Sawit PT Perkebunan Nusantara Vii Tahun 2019Yazid NtsNo ratings yet

- Natural and Artificial Apple Jacks Flavor MSDSDocument3 pagesNatural and Artificial Apple Jacks Flavor MSDSBill RichardsonNo ratings yet

- 02-2-Toxicological StudiesDocument24 pages02-2-Toxicological StudiesAstra BeckettNo ratings yet

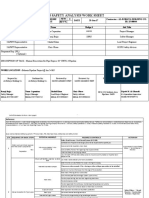

- Job Safety Analysis Work SheetDocument3 pagesJob Safety Analysis Work SheetHaleemUrRashidBangashNo ratings yet