Professional Documents

Culture Documents

1033079-KSS 050-Product Characteristic Classification

Uploaded by

vkmsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1033079-KSS 050-Product Characteristic Classification

Uploaded by

vkmsCopyright:

Available Formats

KSS Global Standard Product Characteristic Classification

KSS GLOBAL STANDARD

Product Characteristics Classification (CC/SC Guideline)

KSS 050

Document No: 1033079

Authors: Approved by: Approved by: Approved by: Approved by: Gnther Hilbich

Andreas Staub Jim Scarpa Tim Maly Dieter Hahn

(electronic signature on file) (electronic signature on file) (electronic signature on file) (electronic signature on file)

Document History Revision: 1 Release Date 22 Sep 2011 ECP No. 47830

Fully revised standard

Modification

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 1 of 9

KSS Global Standard Product Characteristic Classification

Table of Content

INTRODUCTION ................................................................................................................................................. 3 1 2 3 4 5 6 7 PURPOSE................................................................................................................................................... 3 SCOPE........................................................................................................................................................ 3 RESPONSIBILITY ...................................................................................................................................... 3 DEFINITION ................................................................................................................................................ 3 DETERMINATION OF SPECIAL CHARACTERISTICS ............................................................................ 4 REFERENCES (RELATED DOCUMENTS)............................................................................................... 9 APPENDICES ............................................................................................................................................. 9

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 2 of 9

KSS Global Standard Product Characteristic Classification

Introduction

This KSS Standard outlines requirements for how to control potential risks related to product and process through the identification and management of special product and process characteristics (named Critical Characteristics and Significant Characteristics).

Purpose

The purpose of this standard is to facilitate and to harmonize the use of special characteristics within drawings and other documentation throughout the KSS group. It explains the management and handling of special characteristics to fulfill functional and regulatory requirements.

Scope

All KSS sites, organizations, and suppliers must adhere to this standard.

Responsibility

The Engineering Manager or Director of each KSS engineering department is responsible to ensure that the CC/SC standard is followed, monitored and observed during development. The Product Engineer is responsible to define the CC/SC for all engineering documentation associated with development for the assigned programs. The Quality Manager/ Director is responsible to ensure that requirements defined in this standard are implemented. The Procurement Director and Director of Supplier Quality are responsible to communicate this standard and enforce compliance at the supplier level.

Definitions

A characteristic is a dimension or a physical, chemical, electrical, mechanical or visual property. A characteristic must be measurable, either directly or indirectly, either variable or attribute. Attribute characteristics are qualitative data that is measured or checked and results in conformance or non-conformance, pass or fail.

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 3 of 9

KSS Global Standard Product Characteristic Classification

Variable characteristics are quantitative data which can be measured, and the result is an absolute measurement reading eg. Millimeters, Inches, Newtons, etc. There are two different types of special characteristics: Critical Characteristics (CC) are product characteristics that may affect the safety of product or operator compliance with legal requirements environmental requirements. These characteristics are designated in the D- or PFMEA, having a causal relationship to the effect of potential failure modes rated 9-10 for severity. Significant Characteristics (SC) are product characteristics that may affect form, fit or function of the product the production (assembly) process These characteristics are designated in the D- or PFMEA having a causal relationship to the effect of potential failure modes rated 5-8 for severity, or where agreed by the cross-functional team, having severity rated less than 5. SC characteristics may be influenced by the manufacturing process (KSS and/or suppliers) and may require special control to maintain the required process capability and customer requirements.

5

5.1

Determination of Special Characteristics

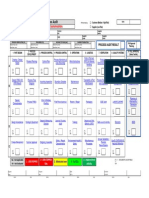

Identification Source of special characteristics DFMEA DFMEA PFMEA PFMEA Customer or internal requirements Legal, environmental requirements Criteria Severity rating = 9, 10 Severity Rating = 5 8 Occurrence= 4-10 Severity rating = 9, 10 Severity Rating = 5 8 Occurrence = 4 10 Outcome CC SC CC SC CC or SC CC

Note: A special characteristic (CC or SC) derived from DFMEA may not automatically be carried through to drawing and control plan.

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 4 of 9

KSS Global Standard Product Characteristic Classification

5.2 CC/SC List Each DFMEA/PFMEA requires a CC/SC list as a controlled document (see appendix) and is to be understood as a subset of the DFMEA. The purpose of the CC/SC list is to monitor and assure that all special characteristics are effectively controlled and documented during development and ongoing production. It is a mandatory document and shall be used for each product. Task Owner of the CC/SC List *) List all CC/SC (column A to M) Input of Data (column N-R) Suppliers Input of data (ppk, cpk, column N,O) Input of data (column N-R) KSS Process Responsible Product Engineer Product Engineer SQE SQA, (SQE) Process Engineer

*): In case of not timely deliverable of data, immediate escalation to Program Manager (PM) is indicated. PM to escalate latest in TG review. 5.3 Control of CC/SC

5.3.1 During Development All special characteristics determined as CC/SC during FMEA process shall be carried forward to the CC/SC list, the drawings, the control plans, and to standard work instructions. All CC/SC shall be verified and validated during Design Validation (DV). The supplier shall evaluate and implement the measurement method approved by KSS and other appropriate controls on characteristics related to their processes. The supplier shall evaluate their processes and further identify, document, and control additional contributing characteristics. All CC/SC shall be verified prior to any DV or customer builds. 5.3.2 During PPAP and Product Validation (PV) All CC/SC on the drawings, control plans and other documents shall be referenced in the PPAP documentation and proven capable. Process capability must be proven for each special characteristic

KSS 050 / 1033079 rev. 1

If capability cannot be demonstrated, 100% check must be performed with proven detection of non-compliance If this is not possible other methods must be applied (e.g Poka-yoke) Compliance of attribute characteristics can be proven by using a certificate.

Uncontrolled copy printed: 22/09/2011 Page 5 of 9

KSS Global Standard Product Characteristic Classification

The initial process capability study is to evaluate: The conformity of characteristics to the specified requirement and the effect of tool/process variation on these characteristics. If material is identified as a CC a material certificate must be included in PPAP submission and must be available for each batch/lot during mass production. Capability studies shall be performed according to the AIAG manual Statistical Process Control (SPC), and measurement equipment shall be proven acceptable according to the AIAG manual Measurement Systems Analysis (MSA)/ ISO/TS 16949, latest editions. Suppliers shall demonstrate their ability to perform capable measurement of special characteristics according to methods agreed by KSS. Evidence shall be provided during supplier APQP process. 5.3.3 During Serial Production All CC/SC on the drawings, D- and PFMEA, and/or specifications shall be verified during serial production and reflected in approved control plans. 5.4 CC/SC List Management

5.4.1 All CC/SC lists shall be written in English. Dual language (local language and English) can be applied as applicable. 5.4.2 Distribution of the complete CC/SC list data outside of KSS (customer or supplier) is prohibited, as well as PFMEA, but can be presented upon request. The supplier shall be provided with the CC/SC list for his component.

5.5

Documentation of Special Characteristics CC/SCs must be marked on the drawing according to the global KSS drafting standard. General numbering of characteristics (dimensions) or

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 6 of 9

KSS Global Standard Product Characteristic Classification

Table on the drawing specifying the identification number of the characteristics

Some more examples

5.6

Documentation/Record retention All documents referring to special characteristics shall be written in English or in dual language (local language and english) Record Retention is mandatory for each document and/or report referring to special characteristics.

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 7 of 9

KSS Global Standard Product Characteristic Classification

5.7 Summary and FAQ

CC

1 When to apply a CC/ SC Affects product and operator safety and/or compliance with regulatory requirements.

SC

Affects product form, fit or function (other than safety and regulatory) or has other valid reasons to classify significant Yes, temporarily

3 3.1

Is a deviation approval possible in case out of spec.? For new design and new tool after 31 Oct 2011 Evidence for PPAP approval

No

3.2

Evidence in serial production

Initial capability Ppk>2.0 or Poka-Yoke or 100% detection If the CC applies to material, a material certificate is required Continuous capability Cpk >1.67, if verification indicated by SPC (Statistical Process Control) or Poka-Yoke or 100% detection If the CC applies to material, a material certificate is required on request.

Init. capability Ppk >1.67 or Poka-Yoke or 100% detection (material spec. applies to CC classification) Continuous capability Cpk >1.33, if verification indicated by SPC (Statistical Process Control) or Poka-Yoke or 100% detection (material spec applies to CC classification)

4 4.1

Existing design or tools before 31 Oct. 2011 Evidence for PPAP approval

Initial capability Ppk>1,67 Init. capability Ppk >1.33 or or Poka-Yoke Poka-Yoke or or 100% detection 100% detection If the CC applies to (material spec. applies to material, a material CC classification) certificate is required

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 8 of 9

KSS Global Standard Product Characteristic Classification

4.2 Evidence in serial production Continuous capability Cpk >1.33, if verification indicated by SPC (Statistical Process Control) or Poka-Yoke or 100% detection If the CC applies to material, a material certificate is required on request. Continuous capability Cpk >1.33, if verification indicated by SPC (Statistical Process Control) or Poka-Yoke or 100% detection (material spec applies to CC classification)

References (Related Documents)

- KSS Quality First Manual - KSS Global Drafting Standard

Appendices

Attachment: CC/SC list template

KSS 050 / 1033079 rev. 1

Uncontrolled copy printed: 22/09/2011

Page 9 of 9

You might also like

- SCCAF Handbook - LetterDocument42 pagesSCCAF Handbook - LetterBruno Debonnet78% (9)

- GM 1805Document33 pagesGM 1805Hector Calle100% (1)

- SP-1171 Specification For Quality Assurance Requirements For Product and Service - Rev2Document26 pagesSP-1171 Specification For Quality Assurance Requirements For Product and Service - Rev2shashi_nsp100% (2)

- Design Qualification Protocol - Finish Product Cold RoomDocument8 pagesDesign Qualification Protocol - Finish Product Cold RoomApoloTrevino50% (2)

- Warehouse Assessment QuestionaireDocument18 pagesWarehouse Assessment Questionairebgmenotman0% (1)

- Quality Assurance Manual: MIL-STD-45208ADocument37 pagesQuality Assurance Manual: MIL-STD-45208AJessica JamesNo ratings yet

- SCCAF Handbook A4Document37 pagesSCCAF Handbook A4William Autometal100% (1)

- Quality Assurance ManualDocument51 pagesQuality Assurance ManualMadhan RamamoorthyNo ratings yet

- QualityPlan FPSO TopsideDocument36 pagesQualityPlan FPSO Topsidedndudc100% (4)

- Quality Management SystemDocument36 pagesQuality Management SystemAgung RiyadiNo ratings yet

- Solution Manual - RANTE COST ACCDocument127 pagesSolution Manual - RANTE COST ACCray57% (7)

- KSS Global Standard for Product Characteristics ClassificationDocument9 pagesKSS Global Standard for Product Characteristics Classification80ALLA86iNo ratings yet

- Special Characteristics PDFDocument11 pagesSpecial Characteristics PDFKristof MCNo ratings yet

- AS052Document12 pagesAS052krishna kumarNo ratings yet

- QA QC Manual 2008Document86 pagesQA QC Manual 2008netomeller100% (2)

- Fit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) DefinitionsDocument3 pagesFit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) Definitions57641No ratings yet

- Autoliv Special Characteristics Classification June 2016Document13 pagesAutoliv Special Characteristics Classification June 2016David GarafutdinovNo ratings yet

- Fmea Alignment Aiag and VdaDocument14 pagesFmea Alignment Aiag and Vdahaitem100% (1)

- Designating Special CharacteristicsDocument14 pagesDesignating Special CharacteristicsIoana AlexandraNo ratings yet

- Process Audit Check ListDocument24 pagesProcess Audit Check ListSorin FrentoniNo ratings yet

- Standard STD 105-0007: Special CharacteristicsDocument12 pagesStandard STD 105-0007: Special Characteristics57641No ratings yet

- Key Product Characteristic Definitions and ControlsDocument2 pagesKey Product Characteristic Definitions and Controls57641100% (2)

- Quality Control SpecificationDocument31 pagesQuality Control Specificationم.ذكى فضل ذكى100% (2)

- UFGS 01 45 00.00 40 Quality ControlDocument9 pagesUFGS 01 45 00.00 40 Quality Controlrhunter2010No ratings yet

- Spec Characteristics GdlnesDocument2 pagesSpec Characteristics Gdlnessathyabalaraman0% (1)

- Validation Master Plan SummaryDocument11 pagesValidation Master Plan SummaryAjay GangakhedkarNo ratings yet

- SQR 10000Document36 pagesSQR 10000Pedro Tavares MurakameNo ratings yet

- 2294E2-0000-DA00-SPC-0002 Rev 0Document14 pages2294E2-0000-DA00-SPC-0002 Rev 0amirNo ratings yet

- Burns Quality ManualDocument30 pagesBurns Quality ManualjaydiiphajraNo ratings yet

- URS, Validation Phases ConceptDocument41 pagesURS, Validation Phases ConceptSyed Ghazanfar AliNo ratings yet

- Supplier Parts Quality ManualDocument41 pagesSupplier Parts Quality Manualkyu999950% (2)

- Jig and Tool Instruction: Acceptance, Testing, Release and Inspection Marks of Special ToolingDocument8 pagesJig and Tool Instruction: Acceptance, Testing, Release and Inspection Marks of Special ToolingRafaelNo ratings yet

- VAL-030 Equipment Specification and Qualification SampleDocument2 pagesVAL-030 Equipment Specification and Qualification SampleVizit31No ratings yet

- Lear-70-SSD Spec Characteristics GdlnesDocument10 pagesLear-70-SSD Spec Characteristics Gdlnesrpagarwal2No ratings yet

- Global Supplier Standards Manual Quality Expectations SectionDocument18 pagesGlobal Supplier Standards Manual Quality Expectations Sectionamhosny64No ratings yet

- Construction SupervisionDocument18 pagesConstruction Supervisionfhsn8480% (5)

- Standard STD 105-0007: Special CharacteristicsDocument11 pagesStandard STD 105-0007: Special CharacteristicsKrunal PandyaNo ratings yet

- Process AuditDocument15 pagesProcess Auditdesurkarb100% (2)

- Validation Commissioning DocumentsDocument4 pagesValidation Commissioning DocumentsPrashansa ShresthaNo ratings yet

- 5.2.3 CofC 21 JAN 15Document6 pages5.2.3 CofC 21 JAN 15Mani Rathinam Rajamani100% (1)

- Quality Plan for Dahej Standby Jetty ProjectDocument40 pagesQuality Plan for Dahej Standby Jetty ProjectPuneet Vikram Singh100% (5)

- YCPTI03 Process Control Functional DescriptionDocument48 pagesYCPTI03 Process Control Functional DescriptionarmdsfNo ratings yet

- Supplier Quality Manual Rev FDocument23 pagesSupplier Quality Manual Rev Fisrael afolayan mayomiNo ratings yet

- Technical Instruction No.17 Functions of Quality Control Cell in Bro 1Document46 pagesTechnical Instruction No.17 Functions of Quality Control Cell in Bro 1Aaron WilsonNo ratings yet

- Standard HVAC Control SystemsDocument127 pagesStandard HVAC Control Systemsdash_caddiesNo ratings yet

- 00-10-001 - F - Nov.2000Document0 pages00-10-001 - F - Nov.2000Levi MurdokNo ratings yet

- VAL 005 Validation Concept and Procedure SampleDocument4 pagesVAL 005 Validation Concept and Procedure SampleSameh MostafaNo ratings yet

- 01 Quality Procedure - Document Control Ver.1Document9 pages01 Quality Procedure - Document Control Ver.1Mohamed SultanNo ratings yet

- CDOT Bridge Fabrication ManualDocument12 pagesCDOT Bridge Fabrication Manualnurul ain talibNo ratings yet

- Quality Assurance ProceduresDocument35 pagesQuality Assurance ProcedurestrikjohNo ratings yet

- 13 JLR-HTG-119188 Guide To Control Plans For CCDSDocument6 pages13 JLR-HTG-119188 Guide To Control Plans For CCDSSOSTENIBILIDAD SINERGIAS Y SOLUCIONES SLNo ratings yet

- C5 Gearbox Design AnalysisDocument151 pagesC5 Gearbox Design AnalysisaakashtrivediNo ratings yet

- Quality Manual ExampleDocument15 pagesQuality Manual ExampleHagit Givati100% (1)

- Pharmaceutical Qualification2023Document40 pagesPharmaceutical Qualification2023sahil mansuriNo ratings yet

- Procedure - Special CharacteristicsDocument13 pagesProcedure - Special Characteristicsalexandru.ghiniaNo ratings yet

- Tooling Management SummaryDocument10 pagesTooling Management SummaryabraNo ratings yet

- Automotive Supplier Quality RequirementsDocument13 pagesAutomotive Supplier Quality RequirementsmilanstrNo ratings yet

- Mission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsFrom EverandMission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsRating: 5 out of 5 stars5/5 (1)

- PVF Pps-Mesh en 2017Document2 pagesPVF Pps-Mesh en 2017vkmsNo ratings yet

- 739 Plastic AdhesiveDocument4 pages739 Plastic AdhesivevkmsNo ratings yet

- MIL-DTL-17 Attenuation PDFDocument1 pageMIL-DTL-17 Attenuation PDFvkmsNo ratings yet

- Bare Solid Soft Drawn Copper WireDocument1 pageBare Solid Soft Drawn Copper WirevkmsNo ratings yet

- Transition Boot - Strain Relief & Boots For Harness Systems PDFDocument1 pageTransition Boot - Strain Relief & Boots For Harness Systems PDFvkmsNo ratings yet

- Top Ten 07Document4 pagesTop Ten 07PiroinnovationNo ratings yet

- MIL DTL 17 Cable DescriptionsDocument1 pageMIL DTL 17 Cable DescriptionsvkmsNo ratings yet

- Full Time Postgraduate Program Highlights 2018Document1 pageFull Time Postgraduate Program Highlights 2018vkmsNo ratings yet

- Health Effects of Lead ExposureDocument2 pagesHealth Effects of Lead ExposurevkmsNo ratings yet

- Application: Business Group Automotive CablesDocument1 pageApplication: Business Group Automotive CablesvkmsNo ratings yet

- Class H Shielded & Jacketed Type E Cables PDFDocument1 pageClass H Shielded & Jacketed Type E Cables PDFvkmsNo ratings yet

- Inside Telephone Multi-Pair PDFDocument1 pageInside Telephone Multi-Pair PDFvkmsNo ratings yet

- Multiple Pair Control Cable, PDFDocument1 pageMultiple Pair Control Cable, PDFvkmsNo ratings yet

- Nylon - Defects - StudyDocument2 pagesNylon - Defects - StudyvkmsNo ratings yet

- Flexoprene® Portable Cord PDFDocument1 pageFlexoprene® Portable Cord PDFvkmsNo ratings yet

- Multiple Pair Control Cable, PDFDocument1 pageMultiple Pair Control Cable, PDFvkmsNo ratings yet

- Inside Telephone Multi-Pair PDFDocument1 pageInside Telephone Multi-Pair PDFvkmsNo ratings yet

- Mil DTL 22759,16Document1 pageMil DTL 22759,16vkmsNo ratings yet

- Inside Telephone Multi-Pair CABLE PDFDocument1 pageInside Telephone Multi-Pair CABLE PDFvkmsNo ratings yet

- Low smoke PVC shielded multi-conductor cable for air plenumsDocument1 pageLow smoke PVC shielded multi-conductor cable for air plenumsvkmsNo ratings yet

- Econoseal J Series (Mark II+)Document1 pageEconoseal J Series (Mark II+)vkmsNo ratings yet

- Standard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)Document1 pageStandard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)vkmsNo ratings yet

- Process Engineers - CONCEPT DETAILS (Plating)Document1 pageProcess Engineers - CONCEPT DETAILS (Plating)vkmsNo ratings yet

- National Electric CodeDocument1 pageNational Electric CodevkmsNo ratings yet

- The Fmea Method Used in Process Approach To TheDocument7 pagesThe Fmea Method Used in Process Approach To ThevkmsNo ratings yet

- NTSE2014Document5 pagesNTSE2014Sanjeev KumarNo ratings yet

- Reeed Switch Automotive Application ExamplDocument1 pageReeed Switch Automotive Application ExamplvkmsNo ratings yet

- HDPE Vs LDPE ArticleDocument2 pagesHDPE Vs LDPE ArticleJanene DenilaNo ratings yet

- HDPE - Specification and DetailsDocument1 pageHDPE - Specification and DetailsvkmsNo ratings yet

- Water Hindi PPT-FinalDocument38 pagesWater Hindi PPT-FinalMonika AgarwalNo ratings yet

- Question Bank KTQT 2Document90 pagesQuestion Bank KTQT 2Minh NguyenNo ratings yet

- Delivering The Goods: Benefits of Reusable Shipping ContainersDocument36 pagesDelivering The Goods: Benefits of Reusable Shipping ContainersbaraharbNo ratings yet

- PIS Stores Managment Inventory Control Synopsis)Document9 pagesPIS Stores Managment Inventory Control Synopsis)Vikram AroraNo ratings yet

- SCM: Managing supply chain flows boosts profitsDocument9 pagesSCM: Managing supply chain flows boosts profitsbalajigandhirajanNo ratings yet

- Notes - JIT and Backflush CostingDocument19 pagesNotes - JIT and Backflush CostingKaren CaelNo ratings yet

- Glossary: Andon (J) Availability Failure Modes and Effects Analysis (FMEA)Document3 pagesGlossary: Andon (J) Availability Failure Modes and Effects Analysis (FMEA)Juan Camilo MolanoNo ratings yet

- Supply Chain Managment Chap 124Document104 pagesSupply Chain Managment Chap 124phươngNo ratings yet

- To Pull or Not To PullDocument17 pagesTo Pull or Not To PullJabri JuhininNo ratings yet

- Week 11 - English Muhammad Rizky RamadhanDocument44 pagesWeek 11 - English Muhammad Rizky RamadhanMuhammad Rizky RamadhanNo ratings yet

- Environmental Benefits of RecyclingDocument2 pagesEnvironmental Benefits of RecyclingMBA103003No ratings yet

- Fabless WhitepaperDocument9 pagesFabless WhitepaperspaulsNo ratings yet

- LSCM ProjectDocument25 pagesLSCM ProjectManish KumarNo ratings yet

- B473 07Document7 pagesB473 07Srinivasan KrishnamoorthyNo ratings yet

- Introduction To Operations Management: © Wiley 2010 1Document26 pagesIntroduction To Operations Management: © Wiley 2010 1Dr. Sandeep KautishNo ratings yet

- Life Cycle PV Approach PDADocument9 pagesLife Cycle PV Approach PDAK.m. Ehsan Morshed RanaNo ratings yet

- 3-01 KanbanDocument58 pages3-01 KanbanJuan PabloNo ratings yet

- Quiz Production CycleDocument2 pagesQuiz Production CycleAira Jaimee GonzalesNo ratings yet

- Transaction Types GuideDocument8 pagesTransaction Types GuideSayedabdul batenNo ratings yet

- Practical Guide To Blow MouldingDocument216 pagesPractical Guide To Blow Mouldingamitav.datta80% (5)

- Kaizen FormsDocument25 pagesKaizen FormsAbdel Nasser AdamNo ratings yet

- Chapter3 CHopraDocument47 pagesChapter3 CHopraDivyesh ParmarNo ratings yet

- Cost AccountingDocument19 pagesCost AccountingPixxel HubNo ratings yet

- Weekly Report on Installation of Cartridge FilterDocument21 pagesWeekly Report on Installation of Cartridge FilterThirukkumaranBalasubramanian100% (1)

- Best Practices in Bearing Reliability - CIWG Minutes PDFDocument23 pagesBest Practices in Bearing Reliability - CIWG Minutes PDFAnonymous ffje1rpaNo ratings yet

- Process CostingDocument46 pagesProcess CostingRasyikah FitriaNo ratings yet

- CAD CAM RoboticsDocument4 pagesCAD CAM RoboticsAshish MahatoNo ratings yet

- Tablas FmeaDocument4 pagesTablas FmeaPalmer Dionicio100% (1)

- N Quality Management System Planning Section 14Document3 pagesN Quality Management System Planning Section 14Ngonidzashe ZvarevasheNo ratings yet