Professional Documents

Culture Documents

Calculo de Separadores Horizontales

Uploaded by

Ramber Andrade FloresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculo de Separadores Horizontales

Uploaded by

Ramber Andrade FloresCopyright:

Available Formats

VERTICAL SEPARATOR CALCULATIONS Gas handling Capacity Calculation Qs= 67,824 Ks dxd Fg ( P/Ps)( Ts/ T)(1/Z) (L - g / g )^0.5 d = 0.

0188 ( m / Fg Ks )^0.5 / [ ( L - g ) g ]^0.25,ft internal vessel diameter

For vertical separators with vane pack or wire mist extractors :

0.23 < Ks < 0.35 ft/sec

Vt = Terminal particle velocity . ft/sec m = mas flow rate = 110 ( MMscfd) MW , lbm/hr Dp = Average particle diameter , ft . m = 10^(-6) m = 3.3 x 10^( - 6) ft L = Density of liquid particle , lbm/ft3 SGl = 141.5 / ( 131.5 + API) g = Density of gas particle , lbm/ft3. g = MW x P/( 10.73 x T x Z) g = Gas viscosity, lbm/ ft-sec ., Cp= 0.001 Kg/ m -s = 6.72 x 10^(-4) lbm/ ft-sec o = Oil viscosity , Cp w = Water viscosity , Cp g = Gravity = 32.2 ft/sec2 Cd = Drag coefficient Ks = Sizing coefficient , ft/sec Fg = Fracction of cross sectional area for gas flow P = Actual separator pressure , psia T = Actual separator temperature, R Ps = Standard pressure, psia Ts = Standard temperature, R Z = Gas compressibility factor Re = Reynold number Re = 1,488 x Dp x Vt x g / g(Cp) DATA: Qs = 10 MMscfd SGg = 0.6 g = 0.0135 Cp 9.072E-06 lbm/ft-sec P= 1000 psia T= 60 F 520 R Z= 0.83 Qo = 2000 Bbl/day of oil Dp = 100.00 m 3.300E-04 ft API = 40 0.825 SGl Qw = 0 Bbl/day of water MWg = 17.38 lb/mole m= 19116.24 lb/hr L = 51.410 lb/ft3 g = 3.753 lb/ft3 g= 32.2 ft/sec2 Trw = Tro 3 min. resident time of water and oil Vt = 1488x gxDp^2 x (L-g)/ 18 g , Stoke's Law for particles from 10 to 100 Vt= 1.02 ft/sec and Re < 2 Vt=Ks[(L-g)/g]^0.5 ft/sec for vertical separator

Donald Rivero11/16/2013

Ks=

0.287 ft/sec 746.59

Gas capacity constraints : d^2 = 500x KsxTxQs/P= d = 27.32 inch, minimum for gas Liquid capacity constraint : d^2xh = Tr( Qo+Qw)/0.12 h= 66.97 Height of liquid volume,inch Ls-s = ( h+76)/12 Ls-s = 11.91 ft Liquid capacity constrain for vertical separator Tr 3 3 3 3 3 3 2 2 2 2 1 1 1 d(inch) 27 24 30 36 42 48 24 30 36 42 24 30 36 h(inch) 66.97 86.81 55.56 38.58 28.34 21.70 57.87 37.04 25.72 18.90 28.94 18.52 12.86 Ls-s(ft) 11.91 13.57 10.96 9.55 8.70 8.14 11.16 9.42 8.48 7.91 8.74 7.88 7.41 12 Ls-s/d 5.23 6.78 4.39 3.18 2.48 2.04 5.58 3.77 2.83 2.26 4.37 3.15 2.47

3<12Ls-s/d<4

it does not meet liquid capacity constrain

OK

OK

OK

Donald Rivero11/16/2013

HORIZONTAL 3 PHASE SEPARATOR CALCULATIONS

For horizontal separators with vane pack or wire mist extractors :

0.23 < Ks < 0.5 ft/sec

Vt = Terminal particle velocity . ft/sec m = mas flow rate, lbm/hr Dp = Average particle diameter , ft . m = 10^(-6) m = 3.28.08 x 10^( - 6) ft Dp= 150 micron = 4.92E-04 ft L = Density of liquid particle , lbm/ft3 SGL = 141.5 / ( 131.5 + API), L = SGLx62.38 lb/ft^3 g = Density of gas particle , lbm/ft3. g = MW x P/( 10.73 x T x Z) g = Gas viscosity, lbm/ ft-sec . Cp= 0.001 Kg/ m -s = 6.72 x 10^(-4) lbm/ ft-sec o = Oil viscosity , Cp w = Water viscosity , Cp g = Gravity = 32.2 ft/sec2 Cd = Drag coefficient Ks = Sizing coefficient , ft/sec Fg = Fracction of cross sectional area for gas flow P = Actual separator pressure , psia T = Actual separator temperature, R Ps = Standard pressure, psia Ts = Standard temperature, R Z = Gas compressibility factor Re = Reynold number DATA: Qgs = SGg = Qactual g = o = P= T= Z= Qo = Dp = SGo SG Qw = SGw MWg = SGg = m= L = g =

50.00 MMscfd 0.638 0.66 0.0106 1.2 1009.70 93 0.86 1500 150.00 60.5 0.283 200.00 1.02 18.48 0.64 101426.69 45.921 3.664 42.257 32.20 10.00

NOTA: Multiplicar Qgs por 1.20 para tomar en cuenta los slugs en terreno plano y por 1.5 para terrenos ondulados con subidas y bajadas (J M Campbell) Qa= (PsxQgs/TsxZs)(ToxZo/Po) 7.123E-06 lb/ft sec 8.064E-04 lb/ft sec 553.00 R

MMacfd Cp Cp psia F

Bbl/day of oil m 4.921E-04 API 0.737 SGw - SGo Bbl/day of water lb/mole lb/hr lb/ft3 lb/ft3

ft

L-g

g= Trw = Tro

ft/sec2 min. resident time of water and oil

Gas handling capacity for a separator m = 3600x K x [(L-g) x g ]^0.5 , lb/hr, and w = 4 x m /( x d^2 x Fg), lb/ft^2-hr, equating these two eq. d = [ 0.0188 x (m/FgxK)] / [L-g) x g ]^0.5 normally 0.23 ft/sec.< K < 0.5 ft/sec for horizontal separators Select K= 0.5 ft/sec, and Fg =0.5 for liquid level at 50% of the diameter d= 3.795 ft 45.54 inches ( internal diameter of separator) GAS CAPACITY CONSTRAINTS dxLeff. = 42 x K x T x Qg/P, and 3.0 > 12Ls-s/d < 5.0, and Ls-s=Leff/0.75 dxLeff. = 575.07 d(inch) 45.54 36.00 42.00 48.00 54.00 Leff.(ft) 12.63 15.97 13.69 11.98 10.65 Ls-s(ft) 16.84 21.30 18.26 15.97 14.20 12Ls-s/d 4.44 7.10 5.22 3.99 3.16

OK NO NO OK OK

Gas handling Capacity Calculation Qs= 67,824x Ksx d^2xFgx ( P/Ps)x( Ts/ T)x(1/Z)x( L - g / g )^0.5 Qs= 6.2E+07 MMscfd for d = 3.889 ft diameter Va= K(L-g/g)^0.5 Allowable gas velocity Va= 1.70 ft/sec Re = 1,488 x Dp x Vt x g / g(Cp) Re = 429.82 Cross sectional area calculation to degas de liquid, assuming that larger than 200-300 micron gas bubbles leaves the V = gxDp^2x(L-g)/18o V= 6.31E-02 ft/sec Qo = 1500 Bbls/d = A = Qo/V 7.14 ft^2 Dp=250 microns = 8.20E-04 ft Normally max. settling velocity = 1.39x10^-2 ft/sec 0.45 Ft^3/sec

RETENTION TIME CONSTRAINTS FOR LIQUIDS d^2xLefff. = 2.6x[(Qw x Trw) + (Qo x Tro)] , and 3.0 > 12Ls-s/d < 5.0, and Ls-s=Leff/0.75 d^2xLefff. = 44200.00 d(inch) 42.00 46.00 48.00 54.00 56.00 58.00 Leff.(ft) 25.06 20.89 19.18 15.16 14.09 13.14 Ls-s(ft) 33.41 27.85 25.58 20.21 18.79 17.52 12Ls-s/d 9.55 7.27 6.39 4.49 4.03 3.62 NO NO NO OK OK OK

Z coeff.to calculate max.separato allow 500 water droplet to settle o

CALCULATE MAXIMUM OIL PAD THICKNESS (ho)max. = 320xTrox(SGw - Sgo)/o (ho)max. = 754.72 inches CALCULATE MAXIMUM DIAMETER FOR OIL PAD THICKNESS CONSTRANT Aw/Avessel = 0.5xQwxTrw / [QoxTro+QwxTrw] Aw/A = 0.0588 by interpolation Z= 0.420 ho = 22.68 inch or 42% of D (d)max = (ho)max/Z 1796.96 inches( internal diameter of separator) Conclusion: 1.Gas capacity does not govern 2.Oil pad thickness does not govern 3.Liquid retention constraint govern!

lugs en terreno plano M Campbell)

these two eq. or horizontal separators

icron gas bubbles leaves the liquid phase.

coeff.to calculate max.separator diameter to water droplet to settle out of oil pad

Aw/A

Z=ho/d

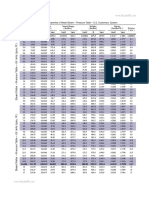

0.000 0.025 0.050 0.100 0.150 0.200 0.250 0.300 0.350 0.400 0.450 0.500

0.500 0.450 0.400 0.348 0.300 0.249 0.210 0.165 0.145 0.075 0.048 0.000

Ao Aw

ho hw

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 2018 01 30 p3fh Ms 4000 PRC 1005 RC Hydrostatic Test ProcedureDocument7 pages2018 01 30 p3fh Ms 4000 PRC 1005 RC Hydrostatic Test ProcedureavriamandaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Lab 1. Experiment 2. Fluid Properties: ViscosityDocument2 pagesLab 1. Experiment 2. Fluid Properties: ViscosityPapi JackNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 4 Way ValveDocument2 pages4 Way Valvedarthvader_1388No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document9 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pumpentechnik Screwpumps Product Range en - New - 1Document9 pagesPumpentechnik Screwpumps Product Range en - New - 1AhmdSbhyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- BHXDocument26 pagesBHXrob.careyNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Marcet Boiler ReportDocument20 pagesMarcet Boiler Reportgabrielhii1995No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- AMINE UNIT EVALUATION FORM Metric UnitDocument4 pagesAMINE UNIT EVALUATION FORM Metric Unitandrey.glinskyNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Water-Steam Saturation Properties (By Pressure in US Units)Document5 pagesWater-Steam Saturation Properties (By Pressure in US Units)Juan Carlos Ramirez DariasNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Fluid Mechanics Lab AssignmnentDocument8 pagesFluid Mechanics Lab AssignmnentMuhammad AbdullahNo ratings yet

- Activated Carbon Adsorber (L1000V L8200V) BEKODocument48 pagesActivated Carbon Adsorber (L1000V L8200V) BEKOdj22500No ratings yet

- Unit-4 Control of Gaseous PollutantsDocument40 pagesUnit-4 Control of Gaseous Pollutantspthangarasu sctengNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Steam Valve Nominal Size Selection PRVDocument6 pagesSteam Valve Nominal Size Selection PRVFahad NaveedNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Homework - 07-Dimensional - Analysis-FmDocument1 pageHomework - 07-Dimensional - Analysis-FmSALVADOR VARGAS DIAZNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 2420 Pressure Reducing PilotDocument14 pages2420 Pressure Reducing PilotRyan VelezNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hydraulics: Prepared by Ajesh Kumar.T Si/FireDocument18 pagesHydraulics: Prepared by Ajesh Kumar.T Si/FireSuriya Das100% (2)

- Dead Weight Pressure Gauge TestersDocument2 pagesDead Weight Pressure Gauge Testersmhatresameer0% (1)

- Gas TestingDocument51 pagesGas Testingfauziot100% (1)

- 1 Colmac DX Ammonia Piping Handbook 4th EdDocument64 pages1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoNo ratings yet

- Fieldpiece SSX34 Superheat and Subcooling MeterDocument2 pagesFieldpiece SSX34 Superheat and Subcooling MeterjrrguitarNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Compressed Substances ProcedureDocument8 pagesCompressed Substances ProcedureAditya Raj MishraNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- High Pressure Mud PumpDocument4 pagesHigh Pressure Mud PumpMihai OpreaNo ratings yet

- CFBC Boilers: Quest Professional CircleDocument31 pagesCFBC Boilers: Quest Professional CircleMayur Patel100% (1)

- Expanded Air Valve Program 1Document8 pagesExpanded Air Valve Program 1Capital Diesel SASNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Chapter 5 LectureDocument23 pagesChapter 5 Lecturediegopena100% (1)

- Pump Selection and Design GuideDocument178 pagesPump Selection and Design GuideSudhanshu ShekharNo ratings yet

- V5X VRF Service Manual 380V-3Ph-60HzgfjDocument105 pagesV5X VRF Service Manual 380V-3Ph-60HzgfjSam RVNo ratings yet

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDocument84 pagesDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Types of FlowsDocument24 pagesTypes of FlowsSyed MuneebNo ratings yet

- CEVE 101 Fluid Mechanics 2 The Bernoulli EquationDocument49 pagesCEVE 101 Fluid Mechanics 2 The Bernoulli EquationSenthilkumar Veeraiah0% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)