Professional Documents

Culture Documents

Cooling Towers

Uploaded by

Mohan KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling Towers

Uploaded by

Mohan KumarCopyright:

Available Formats

* Drift - Water droplets that are carried out of the cooling tower with the exhaust air.

Drift droplets have the same concentration of impurities as the water entering the tower. The drift rate is typically reduced by employing baffle-like devices, called dri ft eliminators, through which the air must travel after leaving the fill and spray zones of the tower. Drift can also be reduced by using warmer entering cooling tower temperatures. * Blow-out - Water droplets blown out of the cooling tower by wind, generall y at the air inlet openings. Water may also be lost, in the absence of wind, through splashin g or misting. Devices such as wind screens, louvers, splash deflectors and water diverters ar e used to limit these losses. * Plume - The stream of saturated exhaust air leaving the cooling tower. The plume is visible when water vapor it contains condenses in contact with cooler ambient air, like the saturated air in one's breath fogs on a cold day. Under certain conditions, a cooling tower p lume may present fogging or icing hazards to its surroundings. Note that the water evaporated in the cooling process is "pure" water, in contrast to the very small percentage of drift droplets or water blown out of the air inlets. * Blow-down - The portion of the circulating water flow that is removed in o rder to maintain the amount of dissolved solids and other impurities at an acceptable level. It may b e noted that higher TDS (total dissolved solids) concentration in solution results in greater potent ial cooling tower efficiency. However the higher the TDS concentration, the greater the risk of sc ale, biological growth and corrosion. * Leaching - The loss of wood preservative chemicals by the washing action o f the water flowing through a wood structure cooling tower. * Noise - Sound energy emitted by a cooling tower and heard (recorded) at a given distance and direction. The sound is generated by the impact of falling water, by the mo vement of air by fans , the fan blades moving in the structure, and the motors, gearboxes or drive bel ts. * Approach - The approach is the difference in temperature between the coole d-water temperature and the entering-air wet bulb temperature (twb). Since the cooling towers are ba sed on the principles of evaporative cooling, the maximum cooling tower efficiency depends on the wet bulb temperature of the air. The wet-bulb temperature is a type of temperature measurement that reflects the physical properties of a system with a mixture of a gas and a vapor, usually air and water vapor

* Range - The range is the temperature difference between the water inlet an d water exit. * Fill - Inside the tower, fills are added to increase contact surface as we ll as contact time between air and water. Thus they provide better heat transfer. The efficiency of the tower also depends on them. There are two types of fills that may be used: o Film type fill (causes water to spread into a thin film) o Splash type fill (breaks up water and interrupts its vertical progre ss)

You might also like

- Army Public School Bareilly Requires Teachers & StaffDocument1 pageArmy Public School Bareilly Requires Teachers & StaffMohan KumarNo ratings yet

- Product Profitability Analysis TemplateDocument6 pagesProduct Profitability Analysis Templatenobi26No ratings yet

- The Person in Control and Possession of The Vehicle Under An Agreement of Hypothecation Should Be Construed As The Owner and Not Alone The Registered OwnerDocument29 pagesThe Person in Control and Possession of The Vehicle Under An Agreement of Hypothecation Should Be Construed As The Owner and Not Alone The Registered OwnerLive Law100% (2)

- DG 1600 (D) Question Paper IDocument28 pagesDG 1600 (D) Question Paper IMohan KumarNo ratings yet

- Calculating boat speeds on streams and riversDocument45 pagesCalculating boat speeds on streams and riverssudipta88No ratings yet

- F 30Document4 pagesF 30Mohan KumarNo ratings yet

- Form of Assignment of Life PolicyDocument5 pagesForm of Assignment of Life PolicyMohan KumarNo ratings yet

- CMV 22 ADocument1 pageCMV 22 ARohit JainNo ratings yet

- Form 34Document2 pagesForm 34Rohit JainNo ratings yet

- (WWW - Entrance Exam - Net) IRDA 2Document4 pages(WWW - Entrance Exam - Net) IRDA 2sbsathishnewNo ratings yet

- Science and TechnologyDocument9 pagesScience and TechnologyMohan KumarNo ratings yet

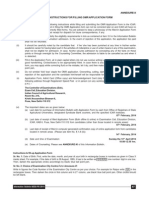

- Detailed Instructions For Filling Omr Application Form: Annexure-XDocument5 pagesDetailed Instructions For Filling Omr Application Form: Annexure-XMohan KumarNo ratings yet

- F 30Document4 pagesF 30Mohan KumarNo ratings yet

- Child Development-15!02!2015 General StudiesDocument40 pagesChild Development-15!02!2015 General StudiesRaghu RamNo ratings yet

- NotificatinDocument28 pagesNotificatinMohan KumarNo ratings yet

- Apparel retailers need bold steps to emerge as winnersDocument1 pageApparel retailers need bold steps to emerge as winnersMohan KumarNo ratings yet

- CaMV Particle StructureDocument2 pagesCaMV Particle StructureMohan KumarNo ratings yet

- 8.0 Instructions To Candidates For Examination 8.1 Filling of Application Form A. Offline OMR ApplicationDocument4 pages8.0 Instructions To Candidates For Examination 8.1 Filling of Application Form A. Offline OMR ApplicationMohan KumarNo ratings yet

- Etd 2013 11 28 17Document1 pageEtd 2013 11 28 17Mohan KumarNo ratings yet

- REPORT Udhaya Solar PVDocument5 pagesREPORT Udhaya Solar PVMohan KumarNo ratings yet

- More of The Same: The Difference The Aam Aadmi Party Will MakeDocument1 pageMore of The Same: The Difference The Aam Aadmi Party Will MakeMohan KumarNo ratings yet

- PaperDocument13 pagesPaperMohan KumarNo ratings yet

- Thermochemicalpractical ManualDocument56 pagesThermochemicalpractical ManualMohan KumarNo ratings yet

- Herbal Bath SoapDocument4 pagesHerbal Bath SoapMohan KumarNo ratings yet

- Preparation of SoapDocument17 pagesPreparation of SoapMohan KumarNo ratings yet

- Reviewed By: John Luick: TidesDocument9 pagesReviewed By: John Luick: TidesMohan KumarNo ratings yet

- Therapeutic Garden Design Recommended Reading ListDocument16 pagesTherapeutic Garden Design Recommended Reading ListKritikou1547100% (1)

- Waves: Reviewed By: Ivan Lebedev and Yin SoongDocument10 pagesWaves: Reviewed By: Ivan Lebedev and Yin SoongMohan KumarNo ratings yet

- How Do You Copy A Whole Page On A ComputerDocument1 pageHow Do You Copy A Whole Page On A ComputerMohan KumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Transmission Line TowersDocument3 pagesTransmission Line TowersSoumik Dandapat100% (2)

- Journal of Cleaner Production: A. Vinod, M.R. Sanjay, Siengchin Suchart, Parameswaranpillai JyotishkumarDocument27 pagesJournal of Cleaner Production: A. Vinod, M.R. Sanjay, Siengchin Suchart, Parameswaranpillai JyotishkumarSiddharthBhasneyNo ratings yet

- Kidneys and renal system overviewDocument40 pagesKidneys and renal system overviewFasie DragosNo ratings yet

- Connecting You to EmploymentDocument29 pagesConnecting You to EmploymenthaticeNo ratings yet

- The Big Bang Theory - S05E01 - The Skank Reflex Analysis - RPGDocument36 pagesThe Big Bang Theory - S05E01 - The Skank Reflex Analysis - RPGghanasyam970No ratings yet

- POTT Echo Back - RWG R19 Rev3Document5 pagesPOTT Echo Back - RWG R19 Rev3hikaru20No ratings yet

- What is a Transformer and How Does it WorkDocument48 pagesWhat is a Transformer and How Does it WorkPraveen ChandranNo ratings yet

- Placare HPL Prin Lipire Pag 38 PDFDocument108 pagesPlacare HPL Prin Lipire Pag 38 PDFMaria ArionNo ratings yet

- Bournvita Project ReportDocument43 pagesBournvita Project Reportlatikalatika100% (6)

- Comments Response Sheet: Ain Tsila DevelopmentDocument11 pagesComments Response Sheet: Ain Tsila DevelopmentSaid Massinissa Elhadj AliNo ratings yet

- About Nestle IndiaDocument5 pagesAbout Nestle IndiaSAMBHAVI SINGH 1827653No ratings yet

- Locomotor Movements: NAME: Dannie Anne T. Paynago Year & Section: Bsm-1A Subject: Physical EducationDocument3 pagesLocomotor Movements: NAME: Dannie Anne T. Paynago Year & Section: Bsm-1A Subject: Physical EducationDannie Anne PaynagoNo ratings yet

- BS BuzzDocument6 pagesBS BuzzBS Central, Inc. "The Buzz"No ratings yet

- Class06 - NCRMD and Automatism - 2023Document23 pagesClass06 - NCRMD and Automatism - 2023Dora LopezNo ratings yet

- Governmentality and risk in the new NHSDocument21 pagesGovernmentality and risk in the new NHSS A SouravNo ratings yet

- Travel Guide - San Francisco by SlidesgoDocument56 pagesTravel Guide - San Francisco by SlidesgoVydheh SumodNo ratings yet

- 2017, 9999, N/a-N/a 9999 : Icole Odriguez Egan Evesque Ictoria Ohrs AND Essica IemeierDocument16 pages2017, 9999, N/a-N/a 9999 : Icole Odriguez Egan Evesque Ictoria Ohrs AND Essica IemeierAndré Luíz FerreiraNo ratings yet

- Installation and programming guide for alarm control panelDocument28 pagesInstallation and programming guide for alarm control panelewie52No ratings yet

- Cantonment Bye Law 2019 Dated 09 12 2019Document160 pagesCantonment Bye Law 2019 Dated 09 12 2019omerumeromer100% (2)

- Pesticides Standards QFWDocument12 pagesPesticides Standards QFWRita RahmawatiNo ratings yet

- H Calculations - Enthalpy of SolutionDocument3 pagesH Calculations - Enthalpy of SolutionArif PurwadanaNo ratings yet

- Concentration of SolutionsDocument42 pagesConcentration of SolutionsAien RonquilloNo ratings yet

- KEYWORDS: Precipitation, Analytics, Volhard'S Method: AbstractDocument2 pagesKEYWORDS: Precipitation, Analytics, Volhard'S Method: AbstractThania GonzlezNo ratings yet

- Nano-Ipriflavone for OsteoporosisDocument9 pagesNano-Ipriflavone for OsteoporosisChaitrashree GururajNo ratings yet

- WOTCDocument2 pagesWOTCrobert marleyNo ratings yet

- A Single-Cell Atlas and Lineage Analysis of The AdultDocument17 pagesA Single-Cell Atlas and Lineage Analysis of The Adult奕蓁陳No ratings yet

- Esicm Lives 2018: Meetingabstracts Open AccessDocument690 pagesEsicm Lives 2018: Meetingabstracts Open AccessjasbvbfitnessNo ratings yet

- Clymer Pe175 Pe250 Pe400 ManualDocument207 pagesClymer Pe175 Pe250 Pe400 ManualXTERRANo ratings yet

- Instruction Det 5 - 3D PDFDocument59 pagesInstruction Det 5 - 3D PDFhafiziNo ratings yet

- Change Management v1.0Document12 pagesChange Management v1.0pushpendrasbNo ratings yet