Professional Documents

Culture Documents

Burners Test Rig

Uploaded by

Tian JinayonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Burners Test Rig

Uploaded by

Tian JinayonCopyright:

Available Formats

International Combustion Equipment S.r.l.

Website : www.it-ice.com - E-mail : info@it-ice.com Burners Elevated/Ground flares Ignition / Flame detection systems Water bath heaters BMS systems / fuels skids

Horizontal cylindrical test heater

Box test heater

November 2009 edition

International Combustion Equipment S.r.l.

Website : www.it-ice.com - E-mail : info@it-ice.com Burners Elevated/Ground flares Ignition / Flame detection systems Water bath heaters BMS systems / fuels skids

INTRODUCTION

Constant updates on the production program is the basis to be constantly competitive. Moreover, stringent regulations on pollutant emissions in flue gases made imperative to lower NOx and CO levels in burner performance. Following this principle ICE, which has to goal to produce state of the art combustion equipment, built its own burners test rig. Our company has at its disposal a test area placed aside its production facility, in city of Cremosano (CR) A broad range of burners can be tested, ranging from standard round flame to flat flame shapes, from gas only to multiple firing burners. Also radiant wall burners, special burners for incinerators burners and firing tube burners can be tested. A number of variables can be recorded during the tests such as: Flame length and shape Emissions (NOx, CO, CO2, O2 etc) Temperature in combustion chamber Noise levels Flame stability at different draft and excess air It is also possible to test ancillary equipment such as pilot burners, flame detection equipment (ionisation amplifiers, UV scanners etc.) or ignition devices.

COMBUSTION CHAMBER CHARACTERISTICS

Max. heat release of burners to be tested is approx. 4,0 MMKcal/hr. Our furnace is horizontal cylindrical, with a length of 8,5m and external dia of 2,5m with wall thickness of 6 mm. Chimney is made of three section for a total height of 8,5 m. with a draft at burner level of approx. 5mm.w.c. To increase draft an electric fan with injector (placed inside chimney) can be added to reach 15 mmwc. Flame monitoring of length, shape and stability can be achieved by using one of the 9 sight ports provided on combustion chamber (6 on sides). 2 in front and 1 in the back). Sample ports are available for connection with flue gas analyzer or temperature transmitter Heater wall is insulated with 100mm of ceramic fibre and heater floor with 200mm of concrete cement to withstand a maximum continuous temperature of 1200C. To help simulating site conditions (heaters with radiant process pipes) a cooling system with water coil gas been added. This allow test at site temperature instead of higher temperature normally reached in furnaces without heat transfer. Recirculation of water inside cooling system is guaranteed by an electric pump connected with a recirculation bath of 12m3.

View of burners test rig

November 2009 edition

International Combustion Equipment S.r.l.

Website : www.it-ice.com - E-mail : info@it-ice.com Burners Elevated/Ground flares Ignition / Flame detection systems Water bath heaters BMS systems / fuels skids

FUEL COMPOSITION & VARIABLES

For burner tests a wide range of gaseous & liquid fuels can be used : CH4 (natural gas methane) C3H8 (L.P.G.) H2 (hydrogen) CO / CO2 (carbon monoxide/dioxide) O2 (oxygen) Any other mixture is available upon request. Heavy naphta Diesel Oil Liquid streams On fuels, following variables can be measured : Gas flowrate by means of a metering station with flowmeters.

Fuel gas pressure near burner by means of a pressure gauges.

Combustion air pressure drop thru the burner is measure by means of water column gauges. Flue gases composition will be measured by vol percentage of O2, CO, NO and NO2 by GREENLINE MK2 flue gas analyser equipped with electrochemical amperometric cells. The reading point is located at the end of the combustion chamber, before the connection to the stack. The temperature of the flue gases will be measured by Cr/Al thermocouple and temperature digital gauge from sample point of combustion chamber.

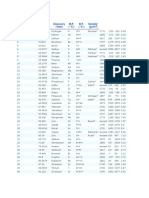

TEST RIG DETAILS

The test plant used for gas & oil burner demonstration includes near all equipment necessary to realize the requested working conditions: Combustion chamber, complete of stack and water coil system and recirculation pump to control temperature (limited, due to ceramic fibre internal lining, to 1200C max.) Double tank system for water cooling. Front plate for burner housing. Gasoil boiler to produce steam at 10 barg and 185C capable o 250 k/h of satured steam which is used as atomising medium with oil burners and gasification system system for CH4 and C3H8 packages.

Package of gas bottles for CH4 / H2 / LPG with pressure reducer and steam heater. Various sizes of combustion air fans (for forced draught burners). Air fan on stack to induce draft in combustion chamber. Due to the characteristics of combustion chamber, the burner can be tested only in horizontal position. The flame shape and dimensions can be easily checked through the existing sight ports (nr. 6 all around). The air pressure drop across the burner could be measured by differential pressure between burner windbox and combustion chamber.

Staged fuel burner gas

Heavy Oil flame

Raw burner gas flame

November 2009 edition

International Combustion Equipment S.r.l.

Website : www.it-ice.com - E-mail : info@it-ice.com Burners Elevated/Ground flares Ignition / Flame detection systems Water bath heaters BMS systems / fuels skids

Horizontal cylindrical combustion chamber

Vertical box combustion chamber

Gas metering equipment

H2 / C3H8 / CH4 gas bottles

CO2 gas bottle and vaporizer

International Combustion Equipment Srl

Office: Via Forlanini, 52 20043 Arcore (MI) Italy Tel. ++39 039 61.80.445 r.a. Fax ++39 039 61.68.84 Workshop: Via degli Artigiani 25/27 26010 Cremosano (CR) Italy Tel. ++39 0373 27-36.54 Fax ++39 0373 29.12.59 Website: www-it-ice.com e-mail : info@it-ice.com

November 2009 edition

You might also like

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Wobbe Index General Information Rev.1Document4 pagesWobbe Index General Information Rev.1Walid FattahNo ratings yet

- Efficiency of Waste Heat Boiler Calculation and SpecificationDocument13 pagesEfficiency of Waste Heat Boiler Calculation and SpecificationHasan Ahmed100% (1)

- SORG Glas - Melting TechnologyDocument27 pagesSORG Glas - Melting Technologymetalman_m100% (2)

- Gun Burner. Materi 1Document10 pagesGun Burner. Materi 1DwiIndraswari100% (1)

- 50-MW 18V-32-40 HFO 50-HZ 6-Units Technical ProposalDocument73 pages50-MW 18V-32-40 HFO 50-HZ 6-Units Technical ProposalRamesh Chandra Gupta86% (7)

- Stage 9 Science Paper 1Document5 pagesStage 9 Science Paper 1Tarek Faramawy75% (4)

- Chamber and Tube Furnaces 0001-G-EDocument64 pagesChamber and Tube Furnaces 0001-G-EMutsikamahwe BrianNo ratings yet

- Encon Thermal Engineers: Answer To The Continued Need For Energy ConservationDocument70 pagesEncon Thermal Engineers: Answer To The Continued Need For Energy ConservationAtul SaxenaNo ratings yet

- 2 BoilersDocument58 pages2 BoilersParameswararao BillaNo ratings yet

- Industrial Waste Fuel Options and Steam Generator Design ConsiderationsDocument21 pagesIndustrial Waste Fuel Options and Steam Generator Design ConsiderationsSathish PaulNo ratings yet

- Abma 9 00Document11 pagesAbma 9 00Matias MancillaNo ratings yet

- NT 664Y2500 B HeaMaster 71-101-201 EN PDFDocument44 pagesNT 664Y2500 B HeaMaster 71-101-201 EN PDFalex_cristiNo ratings yet

- Oilon oil, gas, and dual fuel burners technical guideDocument32 pagesOilon oil, gas, and dual fuel burners technical guideHrishikesh RokadeNo ratings yet

- Boiler DesignJuly 2010Document44 pagesBoiler DesignJuly 2010dheerumgiNo ratings yet

- Energy Conservation: Topic "Boiler"Document38 pagesEnergy Conservation: Topic "Boiler"Ghazanfar GulNo ratings yet

- Black Gold Vegetable Oil HeaterDocument8 pagesBlack Gold Vegetable Oil HeateraaposxtoloNo ratings yet

- Oil & Gas BurnersDocument8 pagesOil & Gas BurnersgoelamitaNo ratings yet

- STF Industrial BoilersDocument20 pagesSTF Industrial BoilersDaniellzhangNo ratings yet

- Boiler Fuel Firing SystemDocument44 pagesBoiler Fuel Firing Systemrashm006ranjanNo ratings yet

- Cement and Lime KilnsDocument6 pagesCement and Lime KilnsbizarropNo ratings yet

- Encon Thermal Engineers: Answer To The Continued Need For Energy ConservationDocument73 pagesEncon Thermal Engineers: Answer To The Continued Need For Energy Conservationdawit mesfinNo ratings yet

- Cone Calorimeter Bench Scale Fire TestDocument12 pagesCone Calorimeter Bench Scale Fire TestGaurav KumarNo ratings yet

- Implementing Intelligent Sootblowing ControlDocument6 pagesImplementing Intelligent Sootblowing ControlenjineringNo ratings yet

- HC & HCS Heater Bro 8-09 - SM PDFDocument4 pagesHC & HCS Heater Bro 8-09 - SM PDFJozsef Magyari0% (1)

- Heat Treatment Processes in The Ceramics Industry: Edition 09.09 GBDocument8 pagesHeat Treatment Processes in The Ceramics Industry: Edition 09.09 GBKosphy Arden100% (1)

- TPV PDFDocument2 pagesTPV PDFAntyox StarkNo ratings yet

- Energy Conservation BoilerDocument38 pagesEnergy Conservation BoilerDeepak Kumar SinghNo ratings yet

- Fired HeatersDocument19 pagesFired HeatersCelestine OzokechiNo ratings yet

- Calor Installation Manual FINALDocument18 pagesCalor Installation Manual FINALPhil Yian100% (2)

- Brochure - Flownex Software Fired Heater Design PDFDocument11 pagesBrochure - Flownex Software Fired Heater Design PDFdatalogger123456No ratings yet

- Thermal Fluid Heaters Technical GuideDocument50 pagesThermal Fluid Heaters Technical GuideMuhamad Saukie100% (1)

- Alstom BFB PDFDocument18 pagesAlstom BFB PDFNaveed RabbaniNo ratings yet

- Instrukcja Pellets Fuzzy Logic - ENGDocument53 pagesInstrukcja Pellets Fuzzy Logic - ENGxilef84No ratings yet

- FGC Group LLC - Consulting & Engineering - Products - Thermal Processing Equipment - Activated Carbon Plant PDFDocument3 pagesFGC Group LLC - Consulting & Engineering - Products - Thermal Processing Equipment - Activated Carbon Plant PDFCleverSeyramKetekuNo ratings yet

- HM Technical File enDocument44 pagesHM Technical File enJosé MacedoNo ratings yet

- 118 - Package Boiler BrochureDocument8 pages118 - Package Boiler BrochureBayu Pramana PutraNo ratings yet

- 2012 Burner Range: Leaders in Combustion TechnologyDocument5 pages2012 Burner Range: Leaders in Combustion TechnologyBbaPbaNo ratings yet

- Three - Pass Fire Tube Boilers: Economizer AdvantagesDocument2 pagesThree - Pass Fire Tube Boilers: Economizer AdvantagesAmita PatelNo ratings yet

- Low NOx Burners Folder. LRDocument6 pagesLow NOx Burners Folder. LRLTE002No ratings yet

- BERKES - Energy DivisionDocument10 pagesBERKES - Energy DivisionalfredopinillosNo ratings yet

- Delta Performance MVDocument36 pagesDelta Performance MVJosé MacedoNo ratings yet

- Krom Schroder 1Document10 pagesKrom Schroder 1Sujanto WidjajaNo ratings yet

- Combustion Laboratory Unit C492: P.A.Hilton LTDDocument6 pagesCombustion Laboratory Unit C492: P.A.Hilton LTDVictor Hugo Valqui LopezNo ratings yet

- Waste Heat Recovery BoilerDocument28 pagesWaste Heat Recovery BoilerNath Boyapati100% (2)

- CFBC Boiler Training PresentationDocument86 pagesCFBC Boiler Training Presentationmojitoa100% (3)

- Boiler Design SoftwareDocument9 pagesBoiler Design SoftwareRaja T0% (1)

- Agasti Energy Boiler Factory Address and Team DetailsDocument10 pagesAgasti Energy Boiler Factory Address and Team DetailsYogesh KumarNo ratings yet

- Chimney Flue Size Rules - Flue Diameter and Height Requirements For Category I Draft Hood and Fan Assisted AppliancesDocument9 pagesChimney Flue Size Rules - Flue Diameter and Height Requirements For Category I Draft Hood and Fan Assisted ApplianceschichavlajaNo ratings yet

- Esl Ie 85 05 120Document10 pagesEsl Ie 85 05 120losmoscasbrNo ratings yet

- Carbolite Furnace (Leading Heat Technology)Document100 pagesCarbolite Furnace (Leading Heat Technology)Anonymous Wi2Pd2UgPINo ratings yet

- Power Generation From Combustion NEWDocument49 pagesPower Generation From Combustion NEWhridita purbaNo ratings yet

- BKC On Economizer & WHRDocument56 pagesBKC On Economizer & WHRB K. ChoudhuryNo ratings yet

- Tata Steel ProjectDocument12 pagesTata Steel Projectsp32483No ratings yet

- Price list for energy efficiency productsDocument88 pagesPrice list for energy efficiency productsFran IgledominguezNo ratings yet

- Co HenDocument40 pagesCo HenHiltonNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- 6510 0240-48-60TS 2 Stage TurbochargingDocument6 pages6510 0240-48-60TS 2 Stage TurbochargingTian JinayonNo ratings yet

- Puberty StageDocument1 pagePuberty StageTian JinayonNo ratings yet

- Chapter 8: Relational Calculus and Algebra EquivalenceDocument23 pagesChapter 8: Relational Calculus and Algebra EquivalenceTian JinayonNo ratings yet

- Heat Engine - Power Engg - LabDocument2 pagesHeat Engine - Power Engg - LabTian JinayonNo ratings yet

- Ice Plant FisheriesDocument14 pagesIce Plant FisheriesmadhusudhansNo ratings yet

- DC 1066 DataDocument11 pagesDC 1066 DataTian JinayonNo ratings yet

- High Capacity / High Quality - State of The Art Portable Ice Plant Available For PurchaseDocument12 pagesHigh Capacity / High Quality - State of The Art Portable Ice Plant Available For PurchaseTian JinayonNo ratings yet

- PT4 FluidDocument10 pagesPT4 FluidTian JinayonNo ratings yet

- Reifschneider 100405Document16 pagesReifschneider 100405Tian JinayonNo ratings yet

- Technical ElectiveDocument3 pagesTechnical ElectiveTian JinayonNo ratings yet

- Energy: Haifeng Liu, Xin Wang, Zunqing Zheng, Jingbo Gu, Hu Wang, Mingfa YaoDocument12 pagesEnergy: Haifeng Liu, Xin Wang, Zunqing Zheng, Jingbo Gu, Hu Wang, Mingfa YaoBắc Phạm LêNo ratings yet

- Lipid nanoparticles may serve as glue between metals and nucleic acidsDocument8 pagesLipid nanoparticles may serve as glue between metals and nucleic acidsÓscar SánchezNo ratings yet

- 8 Msds MSDSDocument21 pages8 Msds MSDSoddyNo ratings yet

- SDS Hydrochloric Acid InhibitorDocument4 pagesSDS Hydrochloric Acid InhibitorJahidul IslamNo ratings yet

- Ikatan Kovalen Polar Dan Asam Basa - Kimor 2Document29 pagesIkatan Kovalen Polar Dan Asam Basa - Kimor 2akbar_rozaaqNo ratings yet

- Symbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Document79 pagesSymbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Kameswar MandhataNo ratings yet

- Srinadh18560-ES312 Assignment 1Document10 pagesSrinadh18560-ES312 Assignment 1Jammigumpula PriyankaNo ratings yet

- Chapter - Vii: Moringa Oleifera Seed PowderDocument18 pagesChapter - Vii: Moringa Oleifera Seed PowderDrVishwanatha HNNo ratings yet

- PaperDocument48 pagesPaperAnonymous MHKrd6RNo ratings yet

- IP 3. Protocol - Chemical Principles II LaboratoryDocument9 pagesIP 3. Protocol - Chemical Principles II LaboratoryJavier PratdesabaNo ratings yet

- Polyester Fiber Production Flow ChartDocument2 pagesPolyester Fiber Production Flow ChartMuhammad Jafor IqbalNo ratings yet

- The History of ExplosivesDocument6 pagesThe History of ExplosivesprateekpandyaNo ratings yet

- PE PPBrochure - v1 - A4 - 110717Document8 pagesPE PPBrochure - v1 - A4 - 110717jamil ahmedNo ratings yet

- Coa - Argan Oil Organic PDFDocument1 pageCoa - Argan Oil Organic PDFDhaval SoniNo ratings yet

- Treating Technologies of Shell Global Solutions For Natural Gas and Refinery Gas StreamsDocument19 pagesTreating Technologies of Shell Global Solutions For Natural Gas and Refinery Gas StreamsPrasad ChakkrapaniNo ratings yet

- SST3005 Soil Science GuideDocument39 pagesSST3005 Soil Science GuideSleeping BeautyNo ratings yet

- Complexometrictitration-Ppt Part III A 2Document21 pagesComplexometrictitration-Ppt Part III A 2Anand NanavatyNo ratings yet

- PHPA TestDocument2 pagesPHPA TestRagha RagNo ratings yet

- Review Organic AcidsDocument27 pagesReview Organic Acidscleon79100% (2)

- Questions - Homework - 10th - Science - 2021-11-21T08 - 31Document6 pagesQuestions - Homework - 10th - Science - 2021-11-21T08 - 31Nisha SinghNo ratings yet

- Organic Chemistry Some Basic Principles and Techniques - WatermarkDocument29 pagesOrganic Chemistry Some Basic Principles and Techniques - WatermarkPrathviraj SinghNo ratings yet

- Use of N2 Gas For Purging in GTAW of SSDocument4 pagesUse of N2 Gas For Purging in GTAW of SSrondulf goNo ratings yet

- DSM-0279.0 Fe SpecialityDocument3 pagesDSM-0279.0 Fe SpecialityStefanoNo ratings yet

- TLE9 Q1 WK1-editedDocument26 pagesTLE9 Q1 WK1-editedMichael AmoresNo ratings yet

- Seimens PS 555Document26 pagesSeimens PS 555HoangNo ratings yet

- Applications of Redox ReactionsDocument6 pagesApplications of Redox ReactionsAndreiFoxNo ratings yet

- Recipes For MilletsDocument20 pagesRecipes For MilletsRavi TejaNo ratings yet

- Im Dissociation PDFDocument10 pagesIm Dissociation PDFRamesh SNo ratings yet