Professional Documents

Culture Documents

E-Business & Supply Chain Management HANDOUT 2-Up

Uploaded by

Srinivasa KirankumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-Business & Supply Chain Management HANDOUT 2-Up

Uploaded by

Srinivasa KirankumarCopyright:

Available Formats

MMBA507 T1/11

Electronic Business & Supply Chain Management

Hans Lehmann 1

MMBA507 T1/11

More understanding of EB & SCM

Definition Wh t is What i the th problem? bl ? Demonstration of a simple case Example of the power of IT in SCM: WALMART and what about E-tailing?

Hans Lehmann 2

MMBA507 T1/11

The horizontal part is the

Supply Chain

Hans Lehmann

MMBA507 T1/11

Whats the problem?

In traditional supply chains, inventories build up at the interface between functions within an organization:

Purchasing

Production

Sales

and between organizations: g

Suppliers

Hans Lehmann

Firm

Customers

4

MMBA507 T1/11

What are the $$$?

Two types of Costs: Obvious Carrying Costs Not Not-so-obvious so obvious Carrying Costs

Hans Lehmann 5

MMBA507 T1/11

Supply Chain Strategies

Traditionally, firms manage internal supply chain and focus on immediate suppliers l and d customers. Now increasing focus further downstream and upstream in the supply chain.

Why?

Hans Lehmann 6

MMBA507 T1/11

Demand distortions

Empirical fact: demand variations amplify upstream p in the supply pp y chain. Manf. Wholesaler Distributor

Information flow (through orders)

Retailer

Product flow

Demand information is distorted: hence, every entity in the supply chain stockpiles too much product.

enter:

Hans Lehmann 7

MMBA507 T1/11

The Bullwhip Effect

Demand swings/ variations amplify upstream in the supply chain.

Demand at the Factory Warehouse Demand at the Distribution Centre level Demand at the Retail level

Hans Lehmann 8

MMBA507 T1/11

The Need for Supply Chain Management stems from the Realisation that

Businesses do not compete; their Supply Chains do.

Hans Lehmann 9

MMBA507 T1/11 INFO101

Lets look at an actual p of an example extraordinarily effective and successful S Supply l Chain Ch i Strategy:

Hans Lehmann 10

MMBA507 T1/11

Wal-Mart W l M t Stores, St I Inc. i is th the worlds ld l largest t retailer, t il with ith (USbn)$419 in sales in 2011. The company employs 2.25 million associates worldwide through nearly 9000 stores in the United States and in Argentina, Brazil, Canada, China, Costa Rica, El Salvador, Germany, Guatemala, Honduras, Japan Mexico, Japan, Mexico Nicaragua, Nicaragua Puerto Rico, Rico South Korea, Korea the United Kingdom and Continental and Eastern Europe. More than 200 million customers per week visit Wal-Mart stores worldwide.

Hans Lehmann 11

MMBA507 T1/11

Lets look at the $$$...

Hans Lehmann

Source: Walmart 2011Annual Report

12

MMBA507 T1/11

Consistently 1% better than UK SMs

Hans Lehmann Source: Walmart 2011Annual Report; Thanassoulis, UK Supermarket profitability, 2009 13

MMBA507 T1/11

Stock Turn

11.5 p.a.

Store Turnover

46.7$m

Hans Lehmann

Source: Walmart 2011Annual Report

14

MMBA507 T1/11

WALMARTs Core Competence:

Right Merchandise Negative Working Capital Shop Operations Good Discount Retailing;

...what else??

Hans Lehmann 15 MMBA507 T1/11

WALMARTs Core Capabilities

Network of Distribution Centers & g Cross Docking Dedicated Truck Fleet Decentralised, Pull-type merchandising management p y Motivation Employee

Enabled Processes

Hans Lehmann 16

MMBA507 T1/11

...how do you enable bl processes???

Crossdocking

Mapping Capabilities: Inventory replenishment at WALMART Stalk et al. HBR 3-4, 1992

Hans Lehmann

17 17

MMBA507 T1/11 INFO101

WALMART before major EB process enabling initiatives:

Demand flow

WALMART Value Chain

Supplier

Distributor Retail store 40 days Product flow

Consumer household

38 days

26 days

Hans Lehmann

18 18

MMBA507 T1/11 INFO101

WALMARTs enabling results:

Timely, accurate, paperless information flow Consumer household

Supplier

Before

Distributor Retail store

40 days

38 days

26 days

After 27 days

12 days

22 days

Savings 11 days

28 days

4 days

Smooth, continual, largely automated product flow matched to consumption

Hans Lehmann 19

MMBA507 T1/11

So whats that inventory reduction worth?

The eW Walmart Supply Supp y C Chain wou would d save because they would have to buy less stock. Lets assume that they buy their stuff with a bank loan Lets further assume they manage to get an overdraft interest of 10%: How much would they save?

Hans Lehmann 20 20

10

MMBA507 T1/11

Using 2011 figures:

Gross profit margin: 24.7% ergo: cost of sales: $315,471m Inventories: $36,318m Sales/day: $419bn/365=$1.15bn ergo: 31.6 31 6 days d worth h of f inventory

Source: Walmart 2011Annual Report

Hans Lehmann 21

MMBA507 T1/11

So whats that worth in $$$s?

Cost of Sales $315,471m Cost of Sales p.d. $864m Interest p.d. @ 10% $86.4m

Suppliers saved Distr.Centre saved Stores saved

11 days 28 days 4 days

$951m $2,420m $346m

WalMart saved

Hans Lehmann

$2,766bn

22 22

11

MMBA507 T1/11

So whats that worth in $$$s?

Cost of Sales $307,024m Cost of Sales p.d. $841.16m Interest p.d. @ 10% $84.1m

Suppliers saved Distr.Centre saved Stores saved

11 days 28 days 4 days

$925m $2,355m $336m

WalMart saved

Hans Lehmann

$2,691bn

23 23

MMBA507 T1/11

Role of Information Technology? Obvious glue for the enabled processes but will develop into much more : Enabling closer co-operation Transform collaboration In manufacturing and logistics

Hans Lehmann

And what about the SC for E-tailers?

24

12

MMBA507 T1/11

Hans Lehmann

25

MMBA507 T1/11

Hans Lehmann

26

13

MMBA507 T1/11

So: how has AMAZON been b doing since its IPO in 1997?

http://finance.yahoo.com/q?s=AMZN http://www.wikinvest.com/stock/Amazon.com_%28AMZN%29/Data/Market_Capitalization/2012/Q1

27 Hans Lehmann

MMBA507 T1/11

How Amazon Fulfills Orders

The Problem When Amazon.com was launched in 1995, the business model was virtual retailingno warehouse, no inventory, no shipments The idea was to take orders and receive payments electronically and then let others fill the orders However, it soon became clear, that while this model may be appropriate for a small company, it does not work for The earths Largest E-tailer

Hans Lehmann 28

14

MMBA507 T1/11

How Amazon Fulfills Orders

The Solution Amazon.com decided to change its business model and h dl it handle its own inventory; i t but b t Maintaining inventory and shipping costs money and takes time: The company spent $3.5 billion to build world-class warehouses around the US and the world to become a l d in leader i warehouse h management, t warehouse h automation, packaging, and inventory management The actual shipment of products to customers is outsourced to UPS and/or the local Postal Service

Hans Lehmann 29

MMBA507 T1/11

Materials Handling - Generation 1

Hans Lehmann

30

15

MMBA507 T1/11

still unchanged!

Hans Lehmann

http://www.buzzfeed.com/mjs538/what-it-looks-like-inside-amazoncom

31

MMBA507 T1/11 ELCM311 T2/2010

The stuff to remember: B2B-EB technology is the glue in the Supply Chain; and Its Supply Chains that compete not single companies; also: Web-enabled organisation and processes, connected with IT, are fast becoming standard operating practice for businesses; but Learning curve is still steep

32

Hans Lehmann

16

You might also like

- Implementation of Supply Chain Logistics Process Reengineering and E-Business Solution For A Chain Store BusinessDocument11 pagesImplementation of Supply Chain Logistics Process Reengineering and E-Business Solution For A Chain Store BusinessSrinivasa KirankumarNo ratings yet

- Introduction CMSCDocument11 pagesIntroduction CMSCSrinivasa KirankumarNo ratings yet

- Guidelines For Sustainable Supply Chain ManagementDocument21 pagesGuidelines For Sustainable Supply Chain ManagementSrinivasa KirankumarNo ratings yet

- MSSCMcurriculum 100110Document6 pagesMSSCMcurriculum 100110Srinivasa KirankumarNo ratings yet

- The Supply Chain Management Article4Document24 pagesThe Supply Chain Management Article4Elzein Amir ElzeinNo ratings yet

- Guidelines For Sustainable Supply Chain ManagementDocument21 pagesGuidelines For Sustainable Supply Chain ManagementSrinivasa KirankumarNo ratings yet

- Tools and Techniques For Impl. Chain ManagementDocument37 pagesTools and Techniques For Impl. Chain ManagementAravind MaitreyaNo ratings yet

- Introduction CMSCDocument11 pagesIntroduction CMSCSrinivasa KirankumarNo ratings yet

- Bonnici India PRESENTATION PDFDocument19 pagesBonnici India PRESENTATION PDFshivam_dubey4004No ratings yet

- Guidelines For Sustainable Supply Chain ManagementDocument21 pagesGuidelines For Sustainable Supply Chain ManagementSrinivasa KirankumarNo ratings yet

- The Use of IT in Supply ChainsDocument8 pagesThe Use of IT in Supply ChainsSrinivasa KirankumarNo ratings yet

- Export PackagingDocument32 pagesExport PackagingSrinivasa KirankumarNo ratings yet

- Guidelines For Sustainable Supply Chain ManagementDocument21 pagesGuidelines For Sustainable Supply Chain ManagementSrinivasa KirankumarNo ratings yet

- The Use of IT in Supply ChainsDocument8 pagesThe Use of IT in Supply ChainsSrinivasa KirankumarNo ratings yet

- Imp Dec GuideDocument68 pagesImp Dec GuideSrinivasa KirankumarNo ratings yet

- Karnatka Vat RulesDocument77 pagesKarnatka Vat RulesSrinivasa KirankumarNo ratings yet

- Freight Clearing and Forwarding ProceduresDocument285 pagesFreight Clearing and Forwarding ProceduresSerdar Kontaş88% (17)

- Vat - Rate of TaxDocument16 pagesVat - Rate of TaxSrinivasa KirankumarNo ratings yet

- Forms KvatDocument63 pagesForms KvatShashi KanthNo ratings yet

- Lux FormsDocument1 pageLux FormsSrinivasa KirankumarNo ratings yet

- Karnataka VAT Return FormDocument2 pagesKarnataka VAT Return FormSrinivasa KirankumarNo ratings yet

- Sap SD Exclusive Study Materials - Sap SD Interview Questions and AnswersDocument17 pagesSap SD Exclusive Study Materials - Sap SD Interview Questions and AnswersSrinivasa Kirankumar100% (1)

- Karnatka Vat RulesDocument77 pagesKarnatka Vat RulesSrinivasa KirankumarNo ratings yet

- Profession Tax Act Form Due Dates Under 40 CharactersDocument1 pageProfession Tax Act Form Due Dates Under 40 CharactersSrinivasa KirankumarNo ratings yet

- Bangalore Vat OfficesDocument3 pagesBangalore Vat OfficesSrinivasa KirankumarNo ratings yet

- Karnataka Value Added Tax NotificationDocument3 pagesKarnataka Value Added Tax NotificationSrinivasa KirankumarNo ratings yet

- Vat - Rate of TaxDocument16 pagesVat - Rate of TaxSrinivasa KirankumarNo ratings yet

- Sap SD PPT-1Document47 pagesSap SD PPT-1vijaykumarNo ratings yet

- CST FormsDocument28 pagesCST FormsSrinivasa KirankumarNo ratings yet

- SAP FICO Shortcut Keysc36005c8 1cc9 4837 B29a 7388a1ca2ec1Document9 pagesSAP FICO Shortcut Keysc36005c8 1cc9 4837 B29a 7388a1ca2ec1Srinivasa KirankumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Business Plan Revised 1Document18 pagesBusiness Plan Revised 1Irin SoniaNo ratings yet

- Know your insurance claim process in case of major car lossDocument3 pagesKnow your insurance claim process in case of major car lossRavi PandeyNo ratings yet

- Assignment1 10%Document3 pagesAssignment1 10%Felicia ChinNo ratings yet

- Investors PerceptionDocument30 pagesInvestors PerceptionAmanNagaliaNo ratings yet

- Final Project On Brands (1) ............................................................Document35 pagesFinal Project On Brands (1) ............................................................AbhinandanMalhotraNo ratings yet

- Financial Accounting 9th Edition Libby Solutions Manual 1Document36 pagesFinancial Accounting 9th Edition Libby Solutions Manual 1jenniferallenoigcyajdtx100% (23)

- Designing A Microsoft SharePoint 2010 Infrastructure Vol 2Document419 pagesDesigning A Microsoft SharePoint 2010 Infrastructure Vol 2Angel Iulian PopescuNo ratings yet

- Unit 32 QCF Quality Management in BusinessDocument6 pagesUnit 32 QCF Quality Management in BusinessdrakhtaraliNo ratings yet

- Business Practices of CommunitiesDocument11 pagesBusiness Practices of CommunitiesKanishk VermaNo ratings yet

- Hinduja Ventures Annual Report 2015Document157 pagesHinduja Ventures Annual Report 2015ajey_p1270No ratings yet

- OPIM 101 Midterm Exam QuestionsDocument12 pagesOPIM 101 Midterm Exam Questionsjoe91bmw0% (1)

- New TeDocument9 pagesNew Tephillip19wa88No ratings yet

- Wipro Midas MDM - Partner Solution - 6094 PDFDocument2 pagesWipro Midas MDM - Partner Solution - 6094 PDFShiva CHNo ratings yet

- P - Issn: 2503-4413 E - Issn: 2654-5837, Hal 78 - 85 Studi Brand Positioning Toko Kopi Kekinian Di IndonesiaDocument8 pagesP - Issn: 2503-4413 E - Issn: 2654-5837, Hal 78 - 85 Studi Brand Positioning Toko Kopi Kekinian Di IndonesiaNurul SyafitriiNo ratings yet

- Cooperative Training ModuleDocument38 pagesCooperative Training ModuleAndreline AnsulaNo ratings yet

- Taxation Management AssignmentDocument12 pagesTaxation Management AssignmentJaspreetBajajNo ratings yet

- Types of Organizational Resources - MONICA BUSCATODocument3 pagesTypes of Organizational Resources - MONICA BUSCATOMonica Buscato100% (4)

- PDF Created With Pdffactory Pro Trial Version: Sps1000 Schematic Ac - inDocument1 pagePDF Created With Pdffactory Pro Trial Version: Sps1000 Schematic Ac - inTiago RechNo ratings yet

- Postpaid Postpaid Plans & ServicesDocument8 pagesPostpaid Postpaid Plans & ServicesTrinnah Rose ReyesNo ratings yet

- Employees Come FirstDocument4 pagesEmployees Come FirstLeonWilfanNo ratings yet

- Theresa Martin v. Shaw's Supermarkets, Inc., 105 F.3d 40, 1st Cir. (1997)Document8 pagesTheresa Martin v. Shaw's Supermarkets, Inc., 105 F.3d 40, 1st Cir. (1997)Scribd Government DocsNo ratings yet

- Survey of Current Business Documents Convergence in State Per Capita IncomesDocument13 pagesSurvey of Current Business Documents Convergence in State Per Capita IncomesViverNo ratings yet

- Bar Exam Questions Income TaxationDocument11 pagesBar Exam Questions Income TaxationG.B. SevillaNo ratings yet

- Ghani Glass AccountsDocument28 pagesGhani Glass Accountsumer2118No ratings yet

- Heavy Engineering Corporation Presented by RajeevDocument13 pagesHeavy Engineering Corporation Presented by RajeevrajeevforyouNo ratings yet

- Advanced Accounting Fischer11e - SMChap21Document24 pagesAdvanced Accounting Fischer11e - SMChap21sellertbsm2014No ratings yet

- Huge Collection of 900s Finacle Menu - Finacle Commands - Finacle Wiki, Finacle Tutorial & Finacle Training For BankersDocument27 pagesHuge Collection of 900s Finacle Menu - Finacle Commands - Finacle Wiki, Finacle Tutorial & Finacle Training For BankersShadab ArfiNo ratings yet

- Eir January2018Document1,071 pagesEir January2018AbhishekNo ratings yet

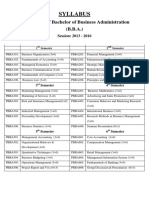

- BBA Syllabus 2013-2016Document59 pagesBBA Syllabus 2013-2016GauravsNo ratings yet

- ARIA Telecom Company - DialerDocument9 pagesARIA Telecom Company - DialerAnkit MittalNo ratings yet