Professional Documents

Culture Documents

Basler Electric TCC

Uploaded by

Galih Trisna NugrahaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basler Electric TCC

Uploaded by

Galih Trisna NugrahaCopyright:

Available Formats

Basler Electric

BE1 Numerical Systems Time Current Characteristic Curves and Time Dial Calculator (BNS-TCC-Rev_E.XLS)

Disclaimer This spreadsheet presents information about Basler Electric relays. It has been prepared as a convenience to our customers, and there is no expressed or implied commitment to maintain or update this file. In developing this software, Basler has attempted to offer the most accurate information possible, but Basler does not warrant that the software is free from bugs, errors or other program limitations. Users are encouraged to consult with a Basler Electric representative to determine the accuracy of the data and results for the specific use or purpose of the user. By use of this program, the user agrees that Basler disclaims all warranties of noninfringement of third party rights, quality, performance, merchantability, or fitness for a particular purpose. The user assumes the entire risk as to the quality and performance of the software. In no event will Basler be liable for any indirect, special, or consequential damages. In the event of any litigation regarding this software, the user agrees that the venue shall be the State of Illinois.

Purpose of this Spreadsheet The purpose of this spreadsheet is as a tool to inspect Basler Electric inverse time overcurrent relay time current curves (TCC's), develop programmable curve constants, and to serve as a tool for converting time dial settings for electro-mechanical (e-m) relays to the nearest equivalent time dial setting for your Basler Electric overcurrent relay. Basler Electric inverse time overcurrent relays provide TCC's that very closely emulate most of the common e-m induction disk relays that were manufactured in North America. To further improve proper relay coordination, selection of integrated reset or instantaneous reset characteristics is also provided in most Basler Electric relays. Even though the TCC curve shapes have been optimized to emulate various electro-mechanical (e-m) induction disk overcurrent relays, the e-m relay time dial settings and Basler Electric relay time dial settings are not perfectly equivalent and the user may need to perform a complete coordination study in cases where curve coordination timing is very tight. This tool applies to the following relays: The Basler CT Powered Protective Relay line: BE1-50/51B BE1-50/51M

CO, IAC Retrofit Line: BE1-50/51B -214, -218, -219, -225, -226, etc. BE3-GPR BE1-GPS

The following Basler Numerical Multifunction Protective Relay lines: BE1-851 BE1-951 BE1-1051 BE1-CDS220 Note: BE1-CDS240 BE1-IPS

Some versions of the CT powered BE1-50/51 products listed above do not provide all of the curve types covered in this spreadsheet. Programmable curves are not available in the BE1-50/51B, BE1-50/51M, and BE3-GPR relays. Please consult the appropriate bulletin or instruction manual for the capabilities of each individual device. This spreadsheet does not apply to the BE1-51 and 67 series relays. Please see the file "51-67TCC.XLS" for a tool to plot the characteristics of these relays (available @ www.basler.com). Instructions and Notes Using the spreadsheet to determine nearest equivalent e-m relay time dial. 1. Go to the sheet "TCC Curves and Graphs." Load in the curve for the relay you are trying to emulate by clicking on the appropriate button. 2. If you have a time and multiple of tap test point that you have previously calibrated the elecromechanical relay to, simply enter in these two values into the appropriate fields (cells H37, I37). The nearest Basler Electric time dial for the chosen curve will be calculated for you. 3. As an alternative approach, if you have a time dial setting for the electromechanical overcurrent relay, you may use the cross reference provided on the "EM Relay Cross Reference" sheet to obtain the nearest equivalent Basler Electric time dial. Notes on e-m curve equivalence: 1. The values in the cross reference table were obtained by inspection of the published electro-mechanical time current characteristic curve. The closest approximately equivalent Basler Electric time dial setting was then entered into the cross reference table. The match is not perfect; see further notes below. 2. If your electro-mechanical relay time dial setting is between the values provided in the table, it will be necessary to interpolate (estimate the correct intermediate value) between the electro-mechanical setting and the Basler Electric setting 3. The maximum time dial setting provided by Basler Electric relays is 9.9. The Basler Electric equivalent time dial setting for the maximum time dial setting provided in the electro-mechanical relay is provided in the cross reference table even if it is calculated to be above 9.9. This is provided for the purpose of allowing interpolation as noted above. 4. Basler Electric time/current characteristics are determined by a linear mathematical equation. An induction disk has a certain degree of non-linearity due to inertia and friction effects. For this reason, even though every effort has been made to provide equation constants that provide characteristic curves with minimum deviation from the published electromechanical curves, slight deviations can be observed between them. In applications where the time coordination between curves is extremely close, we recommend that you choose the optimal time dial setting by inspection of the coordination study. Also, in these applications where coordination is tight, it is recommended that you retrofit your circuits with Basler Electric solid state relays due to their high timing accuracy. Using the spreadsheet to plot curves. It is fairly straightforward, but simply click on the appropriate button on the "TCC Curves and Calcs" sheet, and a plot of the curve shows up. You may either print the entire sheet, or by clicking on the graph, print an enlarged graph the fills the page. Also, the TCC Curves and Calcs sheet provides a means of adding the specific time dial that one will be using to the plot. Please inspect the sheet for this and other features. Using the spreadsheet to develop the programmable curves constants.

4/9/2013

138797566.xls.ms_office

The sheet "Programmable Curve Calcs" provides a means to develop a programmable curve from a set of points from your existing target TCC curve that you may wish to emulate. See that sheet for instructions. This spreadsheet is best viewed at 1024x768 or higher resolution. Revision Notes: Rev. A (2/6/98) Corrected error in S2 curve constant B, which was set to 0.0280 rather than the correct 0.0208. Rev. B (2/18/98) Corrected drawing number reference for M curve. Rev. C Added graph page to TCC curves. Added some ability for users to plot programmable curves. Rev. D0 (09/03) General update. Added IEC curves A, B, C, and G. Added method to determine programmable curve constants via the Excel Solver Routine. Removed the multiple Rev E (05/09) Added Curves F, 46, A1, B1,C1, D1, E3, F1, P, T and updated drawing numbers. Rev F (05/09) Removed reference to Publication 9-2520-00-999 which is obsolete

Basler Electric Company, P.O. Box 269, Highland, Illinois USA 62249 Phone: 618/654-2341 - Fax: 618/654-2351 - Website: http://www.basler.com

4/9/2013

138797566.xls.ms_office

Curve Plotting and Time Dial Calculations

Short Inverse Long Inverse Definite Time Moderately Inverse Inverse Very Inverse Extremely Inverse Programmable

S, S1 S2 1000.00

Curve Type V or V1 -- Time Characteristic Curves

L, L1

D M I, I1 V, V1

L2

Click the appropriate button to plot a graph of the time current characteristic.

I2 V2

A B

E, E1 P

E2

Good viewing: It is intended that the most important data on this sheet will fit onto a screen with a monitor set at 1024x768 resolution, with Excel's zoom set at 75%. It may be helpful for one to experiment with zoom settings for best viewing on the monitor being used.

100.00

10.00

Time, Sec

Displayed Curve Name:

V or V1

Approximately Equivalent to: ABB CO -9 Curve Name V, Very Inverse Drawing No. 99-1374 T=(A*D)/(M^N-C)+B*D+K Curve Constants A B C N K 5.46780 0.10814 1.000 2.04690 0.0280

9.9 7 5

3

1.00

1.5 1 0.7

0.5

Curve V or V1: Time delay T at your time dial D and multiples of pickup M: Select a curve using buttons above, then enter a time dial (D) and multiple of pickup (M). The trip time (T) will be calculated.

Time Dial Mult of PU Trip Time (D) (M) (T) 1.0 2.000 1.882

0.10

0.3 0.2 0.1

0.0 4.0

Curve V or V1: Finding Time Dial D closest to your test data or old E-M relay response: To find a setting nearest your old E-M relay, a) select nearest curve type Trip Time Mult of PU Time Dial from buttons above, then b) enter a set of T and M points from your old (T) (M) (D) relay. D is shown to 2 decimal points, but the relays accept 1.000 3.000 1.29 increments of 0.1 only, in the range of 0.0 to 9.9. Want to add your selected time dial to the TCC curve? Enter the time dial (D) that you wish to add to the TCC curve. Relay accepts time dials in 0.0 to 9.9 in 0.1 increments.

Time Dial (D) 4.0

0.01 1 10 100

The cell to the right checks that all time dials above are in the All time dials above are in the relay's range of 0.0 to 9.9. acceptable range

Multiple of PU

4/9/2013

138797566.xls.ms_office

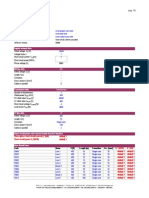

Time Dial Setting Cross Reference Rev. B

This list is to assist a person that is trying to emulate an old electromechanical relay time with a Basler relay. The table gives the time dial of a Basler relay that most closely matches the indicated time dial of the indicated relay. For instance, if one had a GE IAC 51 relay set at time dial 3, the appropriate curve in the Basler relay would be the I2 curve set at a time dial of 2.7. If one is using some time dial that is between two time dials given in the table, one must interpolate and pick an appropriate value between the two time dials. The valid range for Basler numerical relay time dials is 0 to 9.9 in steps of 0.1. The table indicates some time dials outside this range, indicating that the relay cannot reproduce the curve, but may be useful for interpolation purposes.

Electromechanical Relay Time Dial Setting Approximately Curve Name S, S1, Short Inverse L, L1, Long Inverse D, Definite Time M, Moderately Inverse I, I1, Inverse Time V, V1, Very Inverse E, E1, Extremely Inverse I2, Inverse Time V2, Very Inverse S2, Short Inverse L2, Long Inverse E2, Extremely Inverse Equivalent to ABB CO-2 ABB CO-5 ABB CO-6 ABB CO-7 ABB CO-8 ABB CO-9 ABB CO-11 GE IAC-51 GE IAC-53 GE IAC-55 GE IAC-66 GE IAC-77 Curve Dwg. Number 99-1369 99-1370 99-1371 99-1372 99-1373 99-1374 99-1375 99-1597 99-1596 99-1595 99-1594 99-1598 0.5 0.3 0.4 0.5 0.4 0.3 0.3 0.3 0.6 0.4 0.2 0.4 0.5 1.0 0.8 0.8 1.1 0.8 0.7 0.7 0.7 1.0 0.8 1.0 0.9 1.0 2.0 1.7 1.5 2.0 1.7 1.5 1.4 1.5 1.9 1.6 2.0 1.8 1.9 3.0 2.4 2.3 2.9 2.5 2.3 2.1 2.4 2.7 2.4 3.1 2.7 2.7 4.0 3.4 3.3 3.7 3.3 3.2 3.0 3.2 3.7 3.4 4.0 3.9 3.5 5.0 4.2 4.2 4.5 4.3 4.0 3.9 4.2 4.8 4.3 4.9 4.9 4.3 6.0 5.0 5.0 5.0 5.3 5.0 4.8 5.0 5.7 5.1 6.1 6.3 5.2 7.0 5.8 6.0 5.9 6.1 5.8 5.7 5.7 6.8 6.3 7.2 7.2 6.2 8.0 6.7 7.0 7.2 7.0 6.8 6.7 6.6 8.0 7.2 8.1 8.5 7.4 9.0 7.7 7.8 8.0 8.0 7.6 7.8 7.8 9.3 8.4 8.9 9.7 8.2 10.0 8.6 8.8 8.9 9.0 8.7 8.7 8.5 10.6 9.6 9.8 10.9 9.9 11.0 9.7 9.9 10.1 9.8 10.0 9.6 10.3 Basler Electric Approximately Equivalent Time Dial Setting

4/9/2013

138797566.xls.ms_office

Programmable Curve Constants Calculations

This Sheet calculates constants for the programmable curves given a user supplied set of time/current pairs and a target time dial setting.

Notes: 1) To calculate the Programmable Curve constants, this sheet makes use of the Excel "Solver" Add-In. Solver is supplied with Excel, but may not be installed in a partial installation of Excel, and even if installed, it needs to be enabled. You enable the Solver Add-In by the clicking on the appropriate box in the Excel Menu: TOOLS / ADD-INS. 1b) Even if one cannot load and run the Solver Add-In, or if one has specific constants that need to be evaluated, one may enter constants directly into the "Solution" fields below and plot the curves in the TCC Curves and Calcs Sheet. 2) When the Solver routine is run, the program minmizes cell G24, which is the RMS of "time error x sqrt(MOP)". The sqrt(MOP) factor forces improved error at high MOP for higher accuracy at the fast end of the TOC curve. 3) Though an inspection of the time delay equation may at first make it appear there are 5 user-adjustable constants in the time equation (A, B, C, N, and K), there are actually only 3 constants that can be varied: A, B, and N. The value of C is fixed at 1 so that curves will give a time delay that rises to infinity at 1 multiple of pickup, and K is fixed at 0.028 in all Basler relays. Desired Step 1) a: Enter 5 data points from the time-current Multiple of Time Delay Time Dial (D) of Basler Relay to curve of interest in the fields to the right. Pickup (M): (T) be used in calculations: b: Enter in the Time Dial (D) of the Basler relay that Point 1 (Low MOP) 1.300 10.6580 1.0 you want to match to these points. Point 2 2.000 2.4300 Point 3 4.000 0.5060 Point 4 10.000 0.1190 Point 5 (High MOP) 20.000 0.0700 Step 2) a: Run the Excel "Solver" routine by clicking on the Excel Menu: TOOLS / SOLVER. b: Accept the Solver settings that you will see and click on "SOLVE." c: When Solver is done, a dialog box will pop up. Select the option, "Keep Solver Solutions." d: Go to the "TCC Curves and Calcs" sheet to plot the results. Equation for time delay: Curve Coefficient Definitions: T: Time to Trip. Allowed Curve Constants Ranges. If any of cells C17 to G17 below are red, D: Time Dial Setting. user has entered a constant that is out of range. M: Multiples of Pickup. A B C N K A, B: Curve Coefficients. Have a large role in 0 0 1.00 0.50 0.028 Time Dial effects. 600 25 1.00 2.50 0.028 C: Fixed at 1. Affects where curve rises to infinite time. 7.762688 0.027509 1.000000 2.093918 0.028000 N: Curve coefficient. Has a major role in Desired Calculated Error Error x inverseness of relay curve. MOP Time Time (seconds) sqrt(MOP) K: A fixed time delay adder. 10.6580 0.0000 0.0001 1.300 10.6580 2.4301 -0.0001 -0.0001 2.000 2.4300 0.5062 -0.0002 -0.0004 4.000 0.5060 0.1185 0.0005 0.0014 10.000 0.1190 0.0702 -0.0002 -0.0008 20.000 0.0700 RMS Error: 0.0002 0.0008 T = A*D / ((M^N)-C) + B*D + K 4/9/2013 138797566.xls.ms_office

Constant: Min Max Solution (Solver), or user data entry: Comparison:

Curve Descriptions and Constants List

Equation T=(A*D)/(M^N-C)+B*D+K Where Parameter Description T Time to Trip D M A B C Time Dial Setting Multiple of pickup Coefficient specific to selected curve Coefficient specific to selected curve Coefficient specific to selected curve Exponent specific to selected curve Constant Explanation Time that the 51 function will take to time out and trip. Time dial setting for the 51 function. Measured current in multiples of pickup. Timing algorithm has a dynamic range of 0 to 40 time pickup. Affects the effective range of the time dial. Affects a constant term in the timing equation. Has greatest affect on curve shape at high multiples of tap. Affects the multiple of PU where the curve would approach infinity if allowed to continue below pickup. Has greatest affect on curve shape near pickup. Affects the inverseness of the characteristic. Has greatest affect on curve shape at low to medium multiples of tap. Characteristic minimum delay term

N K

Curve Description: Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: 6

S or S1 ABB CO-2 S, Short Inverse D1089-10 S2 GE IAC-55 S2, Short Inverse D2307-02 L or L1 ABB CO-5 L, Long Inverse D1089-11 L2 GE IAC-66 L2, Long Inverse D2307-01 D ABB CO-6 D, Definite Time D1089-09 M ABB CO-7 M, Moderately Inverse D1089-01 I or I1 ABB CO-8 I1, Inverse Time D1089-02 I2 GE IAC-51 I2, Inverse Time D2307-04 V or V1 ABB CO -9 V, Very Inverse D1090-03 V2

Curve Constants: A B 0.26630 0.03393

C 1.000

N 1.2969

K 0.028

R 0.5000

A 0.02860

B 0.02080

C 1.000

N 0.9844

K 0.028

R 0.0940

A 5.61430

B 2.18592

C 1.000

N 1.0000

K R 0.028 15.7500

A 2.39550

B 0.00000

C 1.000

N 0.3125

K 0.028

R 7.8001

A 0.47970

B 0.21359

C 1.000

N 1.5625

K 0.028

R 0.8750

A 0.30220

B 0.12840

C 1.000

N 0.5000

K 0.028

R 1.7500

A 8.93410

B 0.17966

C 1.000

N 2.0938

K 0.028

R 9.0000

A 0.27470

B 0.10426

C 1.000

N 0.4375

K 0.028

R 0.8888

A 5.46780

B 0.10814

C 1.000

N 2.0469

K 0.028

R 5.5000

4/9/2013

138797566.xls.ms_office

Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation: Approximately Equivalent to: Curve Name Drawing No. Curve Short Designation:

GE IAC-53 V2, Very Inverse D2307-03 E or E1 ABB CO-11 E, Extremely Inverse D1090-04 E2 GE IAC-77 E2, Extremely Inverse D2307-05 A N/A BS/IEC Standard Inverse D2570-06 B N/A BS/IEC Very Inverse D1089-07 C N/A BS/IEC Extremely Inverse D1089-05 G N/A BS/IEC Long Time Inverse D2570-07 P N/A Programmable - User N/A F

4.43090

0.09910

1.000

1.9531

0.028

5.8231

A 7.76240

B 0.02758

C 1.000

N 2.0938

K 0.028

R 7.7500

A 4.98830

B 0.01290

C 1.000

N 2.0469

K 0.028

R 4.7742

A 0.01414

B 0.00000

C 1.000

N 0.0200

K 0.028

R 2.0000

A 1.46360

B 0.00000

C 1.000

N 1.0469

K 0.028

R 3.2500

A 8.25060

B 0.00000

C 1.000

N 2.0469

K 0.028

R 8.0000

A 12.12120

B 0.00000

C 1.000

N 1.0000

K R 0.028 28.0000

A 7.76269

B 0.02751

C 1.00000

N 2.09392

K 0.02800

4/9/2013

138797566.xls.ms_office

You might also like

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet

- ECI082206 (Short Circuit) Ver0000DDocument5 pagesECI082206 (Short Circuit) Ver0000Dyasararafat12010No ratings yet

- Sizing Calculation of Generator Step up TransformerDocument3 pagesSizing Calculation of Generator Step up TransformerMadhabNo ratings yet

- ECI082206 (Short Circuit) Ver0000DDocument5 pagesECI082206 (Short Circuit) Ver0000DElsayed Abdelmagid MohamedNo ratings yet

- 03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)Document12 pages03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)juliancansenNo ratings yet

- Power Cables & Wires Technical ManualDocument163 pagesPower Cables & Wires Technical Manualbharatsehgal00@gmail.comNo ratings yet

- Battery Sizing Temperature Correction Factor PDFDocument1 pageBattery Sizing Temperature Correction Factor PDFgilbertomjcNo ratings yet

- EDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFDocument14 pagesEDS 05-2010 Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFLimuel EspirituNo ratings yet

- 13.MCB For Motor ProtectionDocument48 pages13.MCB For Motor Protectionrajinipre-1No ratings yet

- Gemss e 30 r01 (0) MV CablesDocument6 pagesGemss e 30 r01 (0) MV CablesAdel KlkNo ratings yet

- Testing Risk DocumentDocument15 pagesTesting Risk Documentapi-3831102No ratings yet

- Ts 240 SQMM Cable JSPLDocument4 pagesTs 240 SQMM Cable JSPLAnonymous vcadX45TD7100% (1)

- Cable Sizing ToolDocument6 pagesCable Sizing ToolmipanosNo ratings yet

- Lanco 8.5 Mva GTP Rv.01Document14 pagesLanco 8.5 Mva GTP Rv.01Pankaj TiwariNo ratings yet

- Modelling and Simulation of Power Quality IssuesDocument27 pagesModelling and Simulation of Power Quality IssuesMayaNo ratings yet

- CYMTCC For Windows: User's Guide and Reference ManualDocument290 pagesCYMTCC For Windows: User's Guide and Reference ManualJosselynGalloMuñozNo ratings yet

- Current Transformer Requirements Fro VA Tech RelaysDocument7 pagesCurrent Transformer Requirements Fro VA Tech Relayskkamal600No ratings yet

- Battery Sizing 3 Trafo (Latest)Document20 pagesBattery Sizing 3 Trafo (Latest)jm.mankavil6230No ratings yet

- Harmonics Transformer de RatingDocument6 pagesHarmonics Transformer de RatingFabricio Dias CoimbraNo ratings yet

- MasterThesis Basem Idlbi (Document119 pagesMasterThesis Basem Idlbi (GuruxyzNo ratings yet

- Reference DAPPERDocument124 pagesReference DAPPERVictor Luiz MerlinNo ratings yet

- Types and Applications of Overcurrent Relay Part 1Document10 pagesTypes and Applications of Overcurrent Relay Part 1carlos vidalNo ratings yet

- Selective Coordination Breaker Application ChartDocument5 pagesSelective Coordination Breaker Application Charthanner90No ratings yet

- Saudi 33/13.8kV Transformer ProtectionDocument8 pagesSaudi 33/13.8kV Transformer Protectiondaniel.cabasa2577No ratings yet

- How Does Your Capacitor Work?: PanelsDocument4 pagesHow Does Your Capacitor Work?: PanelsNavneet SinghNo ratings yet

- Determining Burden For CTDocument2 pagesDetermining Burden For CTajaysitaula8478No ratings yet

- Electrical Data Manual: Document Number: EN 4.04 P10Document141 pagesElectrical Data Manual: Document Number: EN 4.04 P10Santosh BagadeNo ratings yet

- Trfo Voltage DropDocument16 pagesTrfo Voltage Dropshivvaram100% (1)

- Arc Flash Hazard Standards The Burning Question SeshaDocument0 pagesArc Flash Hazard Standards The Burning Question SeshaFikret VelagicNo ratings yet

- Load Flow Analysis of An Eht Network Using Etap ®: June 2016Document7 pagesLoad Flow Analysis of An Eht Network Using Etap ®: June 2016vjvijay88No ratings yet

- Technical Guide No 7Document20 pagesTechnical Guide No 7peloduro1010No ratings yet

- Verification of The Calculation Procedures For Evaluation of Short-Circuit PDFDocument5 pagesVerification of The Calculation Procedures For Evaluation of Short-Circuit PDFbrobataNo ratings yet

- CT SizingDocument62 pagesCT SizingNoli OtebaNo ratings yet

- Nepal DrawingsDocument13 pagesNepal Drawingsnarinder kumarNo ratings yet

- Section 9Document43 pagesSection 9Yahya AsiriNo ratings yet

- Mepe 3 3W, 11kV: Project Title: Site Name: Bago StationDocument2 pagesMepe 3 3W, 11kV: Project Title: Site Name: Bago StationAung Thein OoNo ratings yet

- Selection Guide For Transformer-Primary Fuses in Mediumand High-Voltage Utility and Industrial SubstationDocument124 pagesSelection Guide For Transformer-Primary Fuses in Mediumand High-Voltage Utility and Industrial SubstationNicol Belén EscobarNo ratings yet

- Energy Loss at 11kv Rural Distribution Feeders in Anand District A Case Study - Confer Paper - 2011 - Prajapati Et AlDocument3 pagesEnergy Loss at 11kv Rural Distribution Feeders in Anand District A Case Study - Confer Paper - 2011 - Prajapati Et AlBBJINo ratings yet

- University Departments: Anna University Chennai:: Chennai 600 025Document30 pagesUniversity Departments: Anna University Chennai:: Chennai 600 025Manju Satpo50% (2)

- Calculating transformer loss cost ratesDocument3 pagesCalculating transformer loss cost ratesRatana KemNo ratings yet

- 14 IntergraphDocument60 pages14 Intergraphphanibhaskar100% (1)

- CT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5Document20 pagesCT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5goalex100% (1)

- Nigeria Grid 330kvDocument9 pagesNigeria Grid 330kvemmas90No ratings yet

- Regenerative Power DissipationDocument9 pagesRegenerative Power DissipationPramod B.Wankhade100% (1)

- Fault Analysis On LVDocument15 pagesFault Analysis On LVVENKATESAN RNo ratings yet

- Voltage Drop and Circuit Sizing CalculatorsDocument5 pagesVoltage Drop and Circuit Sizing Calculatorsdarsh2001patelNo ratings yet

- TR0902: Report On Matched-Melt Co-Ordination As Used For Selecting Wind Farm FusesDocument7 pagesTR0902: Report On Matched-Melt Co-Ordination As Used For Selecting Wind Farm FusesPCTMarketingNo ratings yet

- Electrical Thumb Rules (Part-2) - Electrical Notes & ArticlesDocument4 pagesElectrical Thumb Rules (Part-2) - Electrical Notes & Articlesanon_306841143No ratings yet

- Power Plant Drawing Reviewed with CommentsDocument2 pagesPower Plant Drawing Reviewed with Commentstvpham123No ratings yet

- SVC Abb Case StudyDocument2 pagesSVC Abb Case StudybhsujanNo ratings yet

- Medium Voltage Capacitor Bank SpecificationsDocument4 pagesMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaNo ratings yet

- JD-132-QA-E41-01 - TUBE SIZING 50 DGRDocument14 pagesJD-132-QA-E41-01 - TUBE SIZING 50 DGRRami The OneNo ratings yet

- Bns TCCDocument8 pagesBns TCCanupam789No ratings yet

- BNS-TCC Basler Time CurvesDocument8 pagesBNS-TCC Basler Time CurvesFelipeMoriNo ratings yet

- Sag and Tension Calculations Refinements and Enhancements Made by TrimbleDocument8 pagesSag and Tension Calculations Refinements and Enhancements Made by TrimbleChirantan GuptaNo ratings yet

- ACCC/TW Conductors Stress-Strain Polynomial DevelopmentDocument56 pagesACCC/TW Conductors Stress-Strain Polynomial DevelopmentCarlos Mario LopezNo ratings yet

- Advancing The Accuracy of Sag-Tension Calculations For Enhanced Line Designs and PerformanceDocument7 pagesAdvancing The Accuracy of Sag-Tension Calculations For Enhanced Line Designs and PerformanceJitendraNo ratings yet

- Electrical CalculationsDocument20 pagesElectrical CalculationssesabcdNo ratings yet

- Cummins Generator Technologies Power Portfolio OverviewDocument1 pageCummins Generator Technologies Power Portfolio OverviewGalih Trisna NugrahaNo ratings yet

- IEEE STD 519-1992 Harmonic Limits - 07 - TMBDocument9 pagesIEEE STD 519-1992 Harmonic Limits - 07 - TMBAN.ADAMMSNo ratings yet

- Piano TheoriDocument86 pagesPiano TheoriGalih Trisna Nugraha88% (8)

- Smart Grid Standards GuideDocument11 pagesSmart Grid Standards GuideKeyboardMan19600% (1)

- InfoDocument1 pageInfoEdwin WardhanaNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- IEEE C57.12.00 Test Tables 1 & 2Document6 pagesIEEE C57.12.00 Test Tables 1 & 2Galih Trisna NugrahaNo ratings yet

- Contract Engineering 07Document6 pagesContract Engineering 07Galih Trisna NugrahaNo ratings yet

- Cambridge Primary Computing: Mulit-Component SampleDocument28 pagesCambridge Primary Computing: Mulit-Component SampleMuhammed Muhammed0% (1)

- Instalação Unificontroler Debian 10Document4 pagesInstalação Unificontroler Debian 10PatrickNo ratings yet

- Spring Security Saml ReferenceDocument36 pagesSpring Security Saml ReferenceebazzanaNo ratings yet

- Document SummaryDocument13 pagesDocument SummaryjagannathNo ratings yet

- ML Projects For Final YearDocument7 pagesML Projects For Final YearAlia KhanNo ratings yet

- ISO27k Controls (2005 2013 NIST)Document29 pagesISO27k Controls (2005 2013 NIST)Hemant Sudhir WavhalNo ratings yet

- A-008559-1642179507704-119701-New Microsoft Word Document (2) DIKESHI WICKRAMASURIYADocument63 pagesA-008559-1642179507704-119701-New Microsoft Word Document (2) DIKESHI WICKRAMASURIYAelearn myNo ratings yet

- ADVANCE STANDALONE Yamaha Z1 (EN) PDFDocument10 pagesADVANCE STANDALONE Yamaha Z1 (EN) PDFTechno TechNo ratings yet

- The Five Steps of Gemba KAIZENDocument1 pageThe Five Steps of Gemba KAIZENAbhinaya RamdassNo ratings yet

- Summer Training Project ReportDocument121 pagesSummer Training Project ReportNehaNo ratings yet

- MM2 Creativity and Idea Generation HisrichDocument47 pagesMM2 Creativity and Idea Generation HisrichMaria Kanishia SantosNo ratings yet

- OTS80 60PB DS en V01Document4 pagesOTS80 60PB DS en V01Vicente R. Edano Jr.No ratings yet

- VLSI DESIGN Lab Manual Verilog+l-EditDocument55 pagesVLSI DESIGN Lab Manual Verilog+l-Editmario sanchezNo ratings yet

- Davis ColorsDocument10 pagesDavis ColorsRafael SoaresNo ratings yet

- Question Combi - 082410Document43 pagesQuestion Combi - 082410JuhNo ratings yet

- RTSD Introduction Ch1Document10 pagesRTSD Introduction Ch1Dandza PradityaNo ratings yet

- W970suw PDFDocument104 pagesW970suw PDFEdu Kees MorelloNo ratings yet

- Beta 15A PDFDocument2 pagesBeta 15A PDFJosé Luis AlegriaNo ratings yet

- Informacion Tecnica Del Relé OrionDocument57 pagesInformacion Tecnica Del Relé OrionivanNo ratings yet

- Operation Manual For: MS3 Magnetic Susceptibility MeterDocument15 pagesOperation Manual For: MS3 Magnetic Susceptibility Meterait ijjaNo ratings yet

- Filing NOTEDDocument57 pagesFiling NOTEDoki mora100% (1)

- Automated Railway Ticket Issuing System For Sri LankaDocument85 pagesAutomated Railway Ticket Issuing System For Sri LankaSutharshan Sivasankar100% (1)

- Nsdi21spring Liu XinDocument15 pagesNsdi21spring Liu XinYang RuiyuanNo ratings yet

- Folded Cascode Operational Transconductance Amplifier ThesisDocument6 pagesFolded Cascode Operational Transconductance Amplifier Thesismelissawardbaltimore100% (1)

- Cutting Master5 Manual EngDocument85 pagesCutting Master5 Manual Engdiegodaer77No ratings yet

- XML File UploadDocument5 pagesXML File Uploadkanhaiya_priyadarshiNo ratings yet

- Network and Control ConsiderationDocument14 pagesNetwork and Control ConsiderationIndika WithanachchiNo ratings yet

- Led TV Led TV: Service Manual Service ManualDocument101 pagesLed TV Led TV: Service Manual Service Manualboroda2410100% (4)

- Java Source Code EditorDocument45 pagesJava Source Code EditorKush BhargavaNo ratings yet

- Checklist 1 After Recon - Beginner Friendly ChecklistDocument2 pagesChecklist 1 After Recon - Beginner Friendly Checklistsidhant TechNo ratings yet