Professional Documents

Culture Documents

ISO 9001 - 2008 Requirement

Uploaded by

Navnath TamhaneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 9001 - 2008 Requirement

Uploaded by

Navnath TamhaneCopyright:

Available Formats

ISO 9001 :2008 Requred Documentation

Quality Documents :

Quality policy (Clause 4.2.1 a ) Quality objectives (Clause 4.2.1 a ) Quality manual (Clause 4.2.1 b )

Documented Procedures :

4.2.3 Control of documents 4.2.4 Control of records 8.2.2 Internal Audit 8.3 Control of nonconforming product 8.5.2 Corrective action 8.5.3 Preventive action These documented procedured have to be controlled in accordance with the requirements of Clause 4.2.3

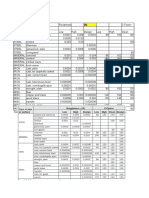

Records required by ISO 9001 : 2008

Clause 5.6.1 6.2.2 (e) Record Required Management review Education, training, skills and experience Must maintain records of education, training, skills and experience ; there is a procedure Evidence that the realization processes and resulting product fullfill requirements. records needed to provuded evidence that the realization (existing ) processe and resulting product (service) meet requirements. Results of the reviwe of requirements related to the product and actions arising form the review. The organiztion shall review the customer requirements of the service. This review must be conducted prior to commitment to customer. Nedd records of the results of the review. Design and development inputs relating to product requirements. Results of desing and development reviews and any necessary action. Results of desing and development verification and any necessary actions. Results of design and development validation and any necessary action. Results of the review of design and development changes and any necessry action. Results of supplier evaluations and any necessary actions arising from the evaluation Records of evaluating suppliers must be maintained. As required by the organization to demonstrate the validation of processes where the resulting output cannot be varified by subsequent monitoring or measurement Need records to validate a process where you cannot monitor or measure easily. The unique identification of the product, where traceability is a requirement. Customer property that is lost, damaged or otherwise found to be unsuitaqble for use Must maintain records re:customer property issues. Basis used for calibration or verification of measuring equipment where no internatinal or national measurement standards exist. Validity of the previous measuring results when the measuring equipment is found not to conform to requirements. Results of calibration and verification of measuring equipmen

7.1(d)

7.2.2

7.3.2 7.3.4 7.3.5 7.3.6 7.3.7 7.4.1 7.5.2 (d)

7.5.3 7.5.4 7.6 (a) 7.6 7.6

8.2.2 8.2.4

8.3 8.5.2 8.5.3

Internal audit results and follow-up actions Indication of the person(s) authorizing release of product. Need a record of how service gets released (approved). This could include daily inspection records, etc Nature of the product nonconformities and any subsequent actions taken, including concessions obtained Results of corrective action Results of preventive action

Documents which are not necessarily required but can be offered as supporting the organizations processes. This documentation should be minimized. Process maps, process flow charts and/or process descriptions Organization charts Specifications Work and/or test instructions Documents containing internal communications Production schedules Approved supplier lists Test and inspection plans Quality plans STEPS FOR ISO 9001: 2008 Registration Preparation: 1. Perform Gap analysis on required procedures and quality manual, policy, and objectives. 2. Write any procedures which are required 3. Perform gap analysis on required records 4. Work with staff to produce required records as necessary 5. Perform a gap analysis on the process(es) 6. Work with staff to ensure processes and work instructions are in place, up to date, used 7. Work with staff to do an internal audit, and correct non-conformances

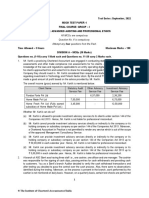

PROCESS STAGE Determine the goal

BASE CLAUSE 5.3 Establish organizations purpose 5.1 Establish Quality policy 5.4.1 Establish Quality objectives

RELATED CLAUSE 5.1 Management responsibility 5.3 Quality policy 5.1 Management responsibility 5.2 Customer focus 7.1 Planning of product realization 7.2.1 Determination of requirement related to the product 7.3.2 Design and development inputs 5.4.2 QMS planning 7.1 Planning of product realization 7.3.1 Design and development planning 7.1 Planning of product realization 7.3.1 Design and development planning 7.4.1 Purchasing process 7.5.1 Control of production and service provision 8.1 General 5.5.1 Responsibility and authority 5.5.2 Management representative 7.1 Planning of product realization 7.4.1 Purchasing process 7.5.1 Control of production and service provision 7.5.3 Identification and traceability 7.5.4 Customer property 7.5.5 Preservation of product 8.1 General 8.3 Control of nonconforming product 4.2.1 General documentation requirements 4.2.2 Quality manual 4.2.3 Control of documents 4.2.4 Control of records

Develop processes to achieve the goal

4.1a Identify processes

4.1b Determine sequence and interaction of processes

4.1c Develop criteria and methods

4.1d Provide information

5.1 Management commitment 5.5.3 Internal communication 7.1 Planning of product realization 7.2.3 Customer communication 7.3.3 Design and development outputs 7.4.2 Purchasing information 4.1d Provide resources 6.1 Provision of resources 6.2 Human resources 6.3 Infrastructure 6.4 Work environment 7.1 Planning of product realization 4.2.2 Quality manual 4.2.3 Control of documents 5.1 Management commitment 5.4.2 Quality management system planning 5.5.2 Management representative 6.3 Infrastructure 7.2.3 Customer communication 7.5.1 Control of product and service provision 7.2.2 Review of requirements related to the product 7.3.4 Design and development review 7.3.5 Design and development verification 7.3.6 Design and development validation 7.4.3 Verification of purchased product 7.5.1 Control of production and service provision 7.6 Control of monitoring and measuring devices 8.1 General 8.2.1 Customer satisfaction 8.2.2 Internal audit 8.1 General 8.5.2 Corrective action 8.5.3 Preventive action 8.3 Control of nonconforming product

Operate and maintain processes

4.1 Implement and maintain QMS

Establish that goal is being achieved

8.2.4 Monitor and measure product

Establish that goal is being achieved (continued)

8.4 Analyse product

4.1f Implement actions to achieve planned results

5.6 Management review 7.3.7 Control of design and development changes 8.1 General 8.2.3 Monitoring and measurement of processes 8.5.1 Continual improvement 8.5.2 Corrective action 8.5.3 Preventive action 5.6 Management review 7.5.2 Validation of processes for production and service provision 7.6 Control of monitoring and measuring devices 8.1 General 8.2.2 Internal audit 8.2.3 Monitoring and measurement of processes 8.1 General 8.4 Analysis of data 8.1 General 8.5.1 Continual improvement 5.6.2 Review input 7.6 Control of monitoring and measuring devices 5.6 Management review 8.5.1 Continual improvement

Establish goal is achieved in the best way

4.1e Monitor and measure processes

4.1e Analyse processes

4.1f Continually improve processe Establish if its the right goal 8.4 Analyse suitability, adequacy and effectiveness 5.6.1 Review system effectiveness 4.1f Continually improve processes

QUALITY POLICY

JP Engg. is committed to providing superior quality products and services by adhering to a quality management sys benefits our customers & employees. To meet our commitment, we must;

V alue our Customers through open communication, timely responses and continual improvement.

in all positions throughout the company.

A ppreciate and foster an environment of trust, integrity, challenge and reward that attracts and retains the best em L everage efficient technology applied to all business processes in order to maintain a competitive advantage. U nderstand that our ultimate purpose is customer satisfaction. E nsure that our Quality Management System serves our customers needs.

QUALITY POLICY

Expectations with those of our suppliers, employees, investors and society and endeavour to give full satisfaction to all parties.

QUALITY POLICY

On continual improvement We will provide an environment in which every person is motivated to continually improve the efficiency and effectiveness of our products, processes and our management system.

Quality Policy

We are committed to providing products that we are delivered on time. and meet customer requirements. while yielding a profit and increasing sales We accomplish this through product and process innovation, Cost reduction activities.

Quality Objective

98% on time delivery s measured by the customer 99.9% of monthly output to be defect free as measured by customer returns 5% profict on annual sales 25% increase in annual sales volume 20% of out product reange will contain new product and 50 improvement teams will be set up to seek process improvement 15% reduction in cost of poor quality as a precentage of sales

JP Engg. Will provide products and services to global markets that will meet or

exceed customer expectations through people, teamwork, and continuous improvement.

We are committed for an entire satisfaction of each & every customer by supplying consistent Quality Product by way at continual improvement in process / technology & in time delivery.

Quality Objectives

1) Timely Delivery 2) Minimize Customer Complaint 3) Increase Turnover QUALITY POLICY

"JP Engg. Is dedicated to Customer Satisfaction by providing Quality Products in a Timely Manner through Teamwork and a commitment to continual Improvement."

. JP Quality Management System Objectives for quality are to ..strive to be the supplier of choice for JP customers.

(External PPM, customer quality concerns, on time PPAP, first time PPAP approval, customer surveys, internal and external quality audits. )

..establish zero defects as the goal of procudtion.

(Internal PPM, scrap as a precentage of production.)

meet customer expectations for on-time delivery.

(Ford SIM, GM Report, Chrysler EBSC, premium freight)

.avoid waste and excessive cost without jeopardizing quality.

(WOW, Cost of Poor Quality)

.provide a safe environment for employees.

(Reduction or turnover, elimination of accidents)

a quality management system that

rovement.

cts and retains the best employees

ompetitive advantage.

uct &

You might also like

- Expansion Tank Capacity Calculation SheetDocument5 pagesExpansion Tank Capacity Calculation SheetDEX TERRNo ratings yet

- CP (T) DT: AIR FuelDocument3 pagesCP (T) DT: AIR FuelPriambudi PujihatmaNo ratings yet

- TOP For Water SystemDocument35 pagesTOP For Water SystemNaresh PattanaikNo ratings yet

- DBA CalculationDocument4 pagesDBA CalculationKevin J. MillsNo ratings yet

- Displacement CompressorDocument14 pagesDisplacement Compressorharsh_1582No ratings yet

- Tri P10Document10 pagesTri P10Dvd Davide La CruzNo ratings yet

- HVACPow Den InstructionsDocument5 pagesHVACPow Den InstructionsadamyzcNo ratings yet

- A Study On Energy Audit of A Cold StorageDocument5 pagesA Study On Energy Audit of A Cold StorageAshfaq Ali KhanNo ratings yet

- Cooling Capacity Calculation PrintingDocument1 pageCooling Capacity Calculation PrintingJay PatelNo ratings yet

- Concept Design Review Report Template: Project TitleDocument8 pagesConcept Design Review Report Template: Project Titlennamdi nwoyeNo ratings yet

- Homework #03: U.S. Standard Sieve SizesDocument11 pagesHomework #03: U.S. Standard Sieve SizesVikaas SagerNo ratings yet

- Volume Control Damper Specifications and PerformanceDocument6 pagesVolume Control Damper Specifications and Performancejames_chan2178No ratings yet

- Greenheck Relief DamperDocument2 pagesGreenheck Relief DamperguythaiNo ratings yet

- Excel MSDS Database - Pressmans Pride - Chemgon CommercialDocument38 pagesExcel MSDS Database - Pressmans Pride - Chemgon CommercialAboo Khan100% (1)

- CIS7:2014Document66 pagesCIS7:2014Ken ChuahNo ratings yet

- NBC Part 7Document72 pagesNBC Part 7Shubham AggarwalNo ratings yet

- Steam Tracing Specification ChartDocument1 pageSteam Tracing Specification Chartgpskumar22No ratings yet

- Master CIP Technical Specification Check ListDocument3 pagesMaster CIP Technical Specification Check ListYogesh NikamNo ratings yet

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFArshath FleminNo ratings yet

- Instructions: TLD Applicant - Financial ProjectionsDocument5 pagesInstructions: TLD Applicant - Financial ProjectionsMichael AdalikwuNo ratings yet

- ESP Calculation for Multiple Duct RunsDocument11 pagesESP Calculation for Multiple Duct RunsJitheesh Sahadevan100% (1)

- Fire Hydrant CalculatorDocument4 pagesFire Hydrant CalculatorTri SubaktiNo ratings yet

- Energy Savings Calculator For Boiler ReplacementsDocument14 pagesEnergy Savings Calculator For Boiler ReplacementsSanjeev KachharaNo ratings yet

- Pipe Roughness and C-Factors TableDocument48 pagesPipe Roughness and C-Factors Tablesaroat moongwattanaNo ratings yet

- PumpsDocument11 pagesPumpsamk3745No ratings yet

- Chiller ComparisonDocument2 pagesChiller ComparisonMohit SharmaNo ratings yet

- An Introduction To QFMEADocument9 pagesAn Introduction To QFMEAchiragparekhNo ratings yet

- M 389 ContentDocument52 pagesM 389 ContentokahertaberNo ratings yet

- Project: Doha Metro - Major Station Pump Friction Loss AnalysisDocument5 pagesProject: Doha Metro - Major Station Pump Friction Loss AnalysisAdnan AttishNo ratings yet

- TCVN - English VersionDocument4 pagesTCVN - English Versionambition1340cnNo ratings yet

- Simplex 4100-0033Document2 pagesSimplex 4100-0033vlaya1984No ratings yet

- Design Notes FireDocument6 pagesDesign Notes FirempwasaNo ratings yet

- Geberit Piping Systems Catalogue 2010/2011Document95 pagesGeberit Piping Systems Catalogue 2010/2011Catalin Frincu0% (1)

- FPA Good Practice Guide Baseline DataDocument42 pagesFPA Good Practice Guide Baseline DataPeter ThomsonNo ratings yet

- Concrete Volume CalculationDocument17 pagesConcrete Volume CalculationRamuAlagappanNo ratings yet

- UPVC Pipe SizeDocument2 pagesUPVC Pipe Sizeahmedomar_953724702No ratings yet

- 7-Ottawa County Farms CP 7-Vi Pipe-Stress-Calculations 530131 7Document91 pages7-Ottawa County Farms CP 7-Vi Pipe-Stress-Calculations 530131 7Juan Carlos RiveraNo ratings yet

- Chapter3 CompressorDocument36 pagesChapter3 CompressorSaiful AzrieNo ratings yet

- Camusat Hazardous Waste Disposal PolicyDocument8 pagesCamusat Hazardous Waste Disposal PolicyThein Zaw OoNo ratings yet

- Water Treatment Catalogue GuideDocument12 pagesWater Treatment Catalogue GuideJim TsikasNo ratings yet

- Imir - Incomming Material Inspection ReportDocument2 pagesImir - Incomming Material Inspection Reportmitendra singhNo ratings yet

- Air Change RateDocument18 pagesAir Change Ratemumbaimale20009776No ratings yet

- MDB Resume KsaDocument2 pagesMDB Resume KsamarkNo ratings yet

- Chilled Water Pump CalculationsDocument4 pagesChilled Water Pump CalculationsNitesh SinghNo ratings yet

- B+P - Maintenance Strategies Update - 17-June-10 - FINALDocument52 pagesB+P - Maintenance Strategies Update - 17-June-10 - FINALRaghu NathaNo ratings yet

- Return Air Square: Ceiling DiffuserDocument1 pageReturn Air Square: Ceiling DiffuserEnak Cenir100% (1)

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- Work Book HVACDocument24 pagesWork Book HVACmohamednavaviNo ratings yet

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- Fcu Selection For Vitamin RoomDocument2 pagesFcu Selection For Vitamin RoomArjay SalgadoNo ratings yet

- WS CalculationDocument29 pagesWS CalculationMac ShaikNo ratings yet

- Enclosure Cooling DesignDocument9 pagesEnclosure Cooling Designrajpre1213No ratings yet

- Fan ESP CalculationDocument6 pagesFan ESP CalculationAyesha SiddiquaNo ratings yet

- Productivity and Reliability-Based Maintenance Management, Second EditionFrom EverandProductivity and Reliability-Based Maintenance Management, Second EditionNo ratings yet

- Effective Implementation of an ISO 50001 Energy Management System (EnMS)From EverandEffective Implementation of an ISO 50001 Energy Management System (EnMS)Rating: 4 out of 5 stars4/5 (1)

- Iso 9001 Document RequirementsDocument47 pagesIso 9001 Document Requirementsksbbs100% (1)

- ISO 9001 - Documentaion Requirement SummaryDocument7 pagesISO 9001 - Documentaion Requirement SummaryminhajurrehmanNo ratings yet

- 9001 2008 Iso OrientationDocument27 pages9001 2008 Iso OrientationFernanda Palacios ReyesNo ratings yet

- Quality Management System Principle 3 Engagement of PeopleDocument4 pagesQuality Management System Principle 3 Engagement of PeopleNavnath TamhaneNo ratings yet

- ISO 9001 Leadership PrinciplesDocument3 pagesISO 9001 Leadership PrinciplesNavnath TamhaneNo ratings yet

- 8.1 Operational Planning and ControlDocument6 pages8.1 Operational Planning and ControlNavnath TamhaneNo ratings yet

- Summary of Each Section of ISO 90012015 RequirementsDocument4 pagesSummary of Each Section of ISO 90012015 RequirementsShailesh GuptaNo ratings yet

- Clause 7.5 of ISO 9001 Documented InformationDocument3 pagesClause 7.5 of ISO 9001 Documented InformationNavnath TamhaneNo ratings yet

- 21 148Document1 page21 148Navnath TamhaneNo ratings yet

- ISO 9001 - Clause 7 Support ExplainedDocument5 pagesISO 9001 - Clause 7 Support ExplainedNavnath TamhaneNo ratings yet

- Mplement A QMS and Achieve ISO 9001 Certification With Customer FocusDocument2 pagesMplement A QMS and Achieve ISO 9001 Certification With Customer FocusNavnath TamhaneNo ratings yet

- 8.7 Control of Nonconforming Process Outputs, Products, and ServiceDocument2 pages8.7 Control of Nonconforming Process Outputs, Products, and ServiceNavnath TamhaneNo ratings yet

- CLAUSE 8.5 Production and Service ProvisionDocument10 pagesCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNo ratings yet

- Why A New Version of ISO 9001 2015Document5 pagesWhy A New Version of ISO 9001 2015Navnath TamhaneNo ratings yet

- 4 Main Differences Between ISO 90012008 and ISO 90012015Document4 pages4 Main Differences Between ISO 90012008 and ISO 90012015Navnath TamhaneNo ratings yet

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneNo ratings yet

- ISO 9001 Requirements and StructureDocument4 pagesISO 9001 Requirements and StructureNavnath TamhaneNo ratings yet

- DeskRef9K1 2015 Transition0 10Document89 pagesDeskRef9K1 2015 Transition0 10Navnath TamhaneNo ratings yet

- IATF 16949:2016 Clause 4 Context of The Organization: FD-440-001 Flow Diagram Process InteractionsDocument1 pageIATF 16949:2016 Clause 4 Context of The Organization: FD-440-001 Flow Diagram Process InteractionsNavnath TamhaneNo ratings yet

- Iso 9001 CRMDocument6 pagesIso 9001 CRMNavnath TamhaneNo ratings yet

- 05 Guidance On Outsourced ProcessesDocument4 pages05 Guidance On Outsourced ProcessesNavnath TamhaneNo ratings yet

- Documented InformationDocument5 pagesDocumented InformationbkssdgNo ratings yet

- 9 Ncert Solutions Social Science Pol CH 4Document7 pages9 Ncert Solutions Social Science Pol CH 4Navnath TamhaneNo ratings yet

- 9 Ncert Solutions Social Science Pol CH 4Document7 pages9 Ncert Solutions Social Science Pol CH 4Navnath TamhaneNo ratings yet

- 9 Social His Ch1 1Document6 pages9 Social His Ch1 1Navnath TamhaneNo ratings yet

- 9 Ncert Solutions Soc Sci Eco The Story of Village PalampurDocument5 pages9 Ncert Solutions Soc Sci Eco The Story of Village PalampurNavnath TamhaneNo ratings yet

- 9 Ncert Solutions Soc Sci Eco The Story of Village PalampurDocument5 pages9 Ncert Solutions Soc Sci Eco The Story of Village PalampurVaibhav ChouhanNo ratings yet

- Mycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Document6 pagesMycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Navnath TamhaneNo ratings yet

- Quality Manual Template: WWW - Iso-9001-Checklist - Co.ukDocument10 pagesQuality Manual Template: WWW - Iso-9001-Checklist - Co.ukNavnath TamhaneNo ratings yet

- Mycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Document6 pagesMycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Navnath TamhaneNo ratings yet

- 9 Ncert Solutions Social Science Pol CH 4Document7 pages9 Ncert Solutions Social Science Pol CH 4Navnath TamhaneNo ratings yet

- RTN Connect Pfmea PDFDocument23 pagesRTN Connect Pfmea PDFNavnath TamhaneNo ratings yet

- Quality ManualDocument22 pagesQuality ManualRajeeb MohammedNo ratings yet

- Binding Letter of Intent Trend Technology Corp and American Energy CompanyDocument4 pagesBinding Letter of Intent Trend Technology Corp and American Energy CompanyJose Antonio BarrosoNo ratings yet

- Cost Control Measures and Profitability of Vitafoam Nigeria PLCDocument8 pagesCost Control Measures and Profitability of Vitafoam Nigeria PLCInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Rohith C H's Operations Management ResumeDocument2 pagesRohith C H's Operations Management ResumeVijay N ManjunathNo ratings yet

- 2020 21 RGICL Annual ReportDocument113 pages2020 21 RGICL Annual ReportShubrojyoti ChowdhuryNo ratings yet

- Audit of Cash and Cash Equivalents QuizDocument16 pagesAudit of Cash and Cash Equivalents QuizBienvenido JmNo ratings yet

- The Asset Management Landscape: Second EditionDocument57 pagesThe Asset Management Landscape: Second EditionEduardo Estrada100% (1)

- Annual-Report-Financial-Statements-2020 Heart FoundationDocument40 pagesAnnual-Report-Financial-Statements-2020 Heart Foundationwr KheruNo ratings yet

- EIS-Enterprise Information SystemsDocument3 pagesEIS-Enterprise Information SystemsKeyur JoshiNo ratings yet

- Auditing and Reporting Social Performance 1Document12 pagesAuditing and Reporting Social Performance 1ROMAR A. PIGANo ratings yet

- PCPPI - May 30, 2019 SEC Form I-ACGR For 2018Document48 pagesPCPPI - May 30, 2019 SEC Form I-ACGR For 2018Ronald MalicdemNo ratings yet

- DBATU Civil Engg Syllabus 2023-24Document29 pagesDBATU Civil Engg Syllabus 2023-24Panchasheela कावळेNo ratings yet

- 2018 Compensation DisclosureDocument114 pages2018 Compensation DisclosureElishaDacey50% (2)

- Audit MTP Nov'22Document22 pagesAudit MTP Nov'22Kushagra SoniNo ratings yet

- T Gas Dik MP Lkan Hari Selasa, 27 April 2020 !!!Document11 pagesT Gas Dik MP Lkan Hari Selasa, 27 April 2020 !!!Rut LumbantobingNo ratings yet

- Reference Form 2014 Version 1.0Document365 pagesReference Form 2014 Version 1.0MPXE_RINo ratings yet

- Essar Steel India Limited Board and Annual ReportDocument188 pagesEssar Steel India Limited Board and Annual ReportoguNo ratings yet

- VP Finance CAO Controller in Houston TX Resume Donald HelmerDocument3 pagesVP Finance CAO Controller in Houston TX Resume Donald HelmerDonaldHelmerNo ratings yet

- This Study Resource WasDocument4 pagesThis Study Resource WasKim TanNo ratings yet

- Introduction To MASDocument10 pagesIntroduction To MASErika Mae UmaliNo ratings yet

- Phased Introduction of An Environmental Management System, Acorn Factsheet, BS8555Document3 pagesPhased Introduction of An Environmental Management System, Acorn Factsheet, BS8555richardshearwoodporterNo ratings yet

- Clarification Note Guidelines Valuation Basis For Liabilities of Labuan General - 16112016Document2 pagesClarification Note Guidelines Valuation Basis For Liabilities of Labuan General - 16112016Azman IsmailNo ratings yet

- Johnstone 9e Auditing 1Document98 pagesJohnstone 9e Auditing 1didiNo ratings yet

- Ias 38Document6 pagesIas 38nychan99No ratings yet

- Skills Auditing & Personality Development Submit To: Submit By: Ms. Suman Lata MamDocument15 pagesSkills Auditing & Personality Development Submit To: Submit By: Ms. Suman Lata MamSiti FarhanaNo ratings yet

- DBD Accounting ManualDocument47 pagesDBD Accounting ManualFarrukh TouheedNo ratings yet

- Audit Working Papers ReceivablesDocument4 pagesAudit Working Papers ReceivablesIra YbanezNo ratings yet

- Overview of Ops Aud Part 2 - MARPDocument25 pagesOverview of Ops Aud Part 2 - MARPRNo ratings yet

- CMA 19 II-Section-DDocument22 pagesCMA 19 II-Section-DAkash GuptaNo ratings yet

- Pending Points To Be DiscussedDocument6 pagesPending Points To Be DiscussedGaurav ModiNo ratings yet

- Consolidated Mines Inc. v. CTADocument22 pagesConsolidated Mines Inc. v. CTAJenNo ratings yet