Professional Documents

Culture Documents

Cost Acc Vol. II

Uploaded by

SaibhumiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cost Acc Vol. II

Uploaded by

SaibhumiCopyright:

Available Formats

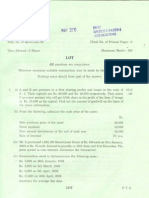

PRACTICE MANUAL

Integrated Professional Competence Course

PAPER : 3

COST ACCOUNTING AND

FINANCIAL MANAGEMENT

Part 1 : Cost Accounting

VOLUME II

BOARD OF STUDIES

THE INSTITUTE OF CHARTERED ACCOUNTANTS OF INDIA

This practice manual has been prepared by the faculty of the Board of Studies. The objective

of the practice manual is to provide teaching material to the students to enable them to obtain

knowledge and skills in the subject. Students should also supplement their study by reference

to the recommended text books. In case students need any clarifications or have any

suggestions to make for further improvement of the material contained herein, they may write

to the Director of Studies.

All care has been taken to provide interpretations and discussions in a manner useful for the

students. However, the practice manual has not been specifically discussed by the Council of

the Institute or any of its Committees and the views expressed herein may not be taken to

necessarily represent the views of the Council or any of its Committees.

Permission of the Institute is essential for reproduction of any portion of this material.

THE INSTITUTE OF CHARTERED ACCOUNTANTS OF INDIA

All rights reserved. No part of this book may be reproduced, stored in retrieval system, or

transmitted, in any form, or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without prior permission in writing from the publisher.

Revised Edition : July, 2012

Website : www.icai.org

E-mail : bosnoida@icai.org

Committee / : Board of Studies

Department

ISBN No. : 978-81-8441-302-1

Price : `

Published by : The Publication Department on behalf of The Institute of Chartered

Accountants of India, ICAI Bhawan, Post Box No. 7100,

Indraprastha Marg, New Delhi 110 002

Printed by : Sahitya Bhawan Publications, Hospital Road, Agra-282 003

July/2012/30,000 Copies (Revised)

A WORD ABOUT PRACTICE MANUAL

The study material has been divided into two parts, namely, Volume I dealing with conceptual

theoretical framework; and Volume II comprising of practice manual. The Study Material has been

designed having regard to the needs of home study and distance learning students in mind. The

students are expected to cover the entire syllabus and also do practice on their own while going

through the practice manual.

Volume I of the study material deals with the conceptual theoretical framework in detail. The main

features of Volume I are as under:

The entire syllabus has been divided into ten chapters.

In each chapter, learning objectives have been stated. The learning objectives would enable

you to understand the sequence of various aspects dealt within the chapter before going into

the details so that you know the direction of your studies.

In each chapter, the topic has been covered in a step by step approach. The text has been

explained, where appropriate, through illustrations and practical problems. You should go

through the chapter carefully ensuring that you understand the topic and then can tackle the

exercises.

A question bank has been included after each chapter in Volume I as well as many questions

for practice in Volume II.

Volume II of the Study Material comprises the Practice Manual. Main features of Volume II are

as under:

Compilation of questions appearing during last ten examinations.

Important Definition, equation and formulae have been given before each topic for quick

recapitulation. Students are expected to attempt the questions and then compare it with the

actual answers.

Exercises have been given at the end of each topic for independent practice.

Aims to provide guidance as to the manner of writing an answer in the examination.

Happy Reading and Best Wishes!

P

a

p

e

r

-

3

C

O

S

T

A

C

C

O

U

N

T

I

N

G

A

N

D

F

I

N

A

N

C

I

A

L

M

A

N

A

G

E

M

E

N

T

S

t

a

t

e

m

e

n

t

s

h

o

w

i

n

g

t

o

p

i

c

-

w

i

s

e

d

i

s

t

r

i

b

u

t

i

o

n

o

f

E

x

a

m

i

n

a

t

i

o

n

Q

u

e

s

t

i

o

n

s

a

l

o

n

g

w

i

t

h

M

a

r

k

s

T

o

p

i

c

s

T

e

r

m

o

f

E

x

a

m

i

n

a

t

i

o

n

T

o

t

a

l

M

a

r

k

s

A

v

g

.

M

a

r

k

s

N

o

v

.

2

0

0

9

M

a

y

2

0

1

0

N

o

v

.

2

0

1

0

M

a

y

2

0

1

1

N

o

v

.

2

0

1

1

Q

M

Q

M

Q

M

Q

M

Q

M

P

A

R

T

-

I

:

C

O

S

T

A

C

C

O

U

N

T

I

N

G

C

h

a

p

t

e

r

-

1

B

a

s

i

c

C

o

n

c

e

p

t

s

1

(

i

)

1

(

i

i

i

)

22

1

(

i

)

2

6

(

b

)

(

i

)

4

6

(

b

)

4

5

(

i

)

4

1

8

3

.

6

C

h

a

p

t

e

r

-

2

M

a

t

e

r

i

a

l

4

(

i

i

i

)

3

1

(

i

i

i

)

2

1

(

b

)

5

1

(

c

)

5

7

(

c

)

4

1

9

3

.

8

C

h

a

p

t

e

r

-

3

L

a

b

o

u

r

4

(

i

)

3

4

(

i

i

i

)

3

7

(

e

)

4

1

(

b

)

7

(

c

)

54

1

(

b

)

5

2

4

4

.

8

C

h

a

p

t

e

r

-

4

O

v

e

r

h

e

a

d

s

1

(

i

i

)

4

(

i

i

)

23

6

(

b

)

(

i

i

)

7

(

a

)

44

2

(

a

)

7

(

a

)

84

2

(

a

)

8

3

3

6

.

6

C

h

a

p

t

e

r

-

5

N

o

n

I

n

t

e

g

r

a

t

e

d

A

c

c

o

u

n

t

s

1

(

v

i

)

2

1

(

v

)

2

5

(

a

)

8

5

(

a

)

12

4

(

b

)

8

3

2

6

.

4

C

h

a

p

t

e

r

-

6

J

o

b

C

o

s

t

i

n

g

&

B

a

t

c

h

C

o

s

t

i

n

g

-

-

-

-

-

0

0

.

0

C

h

a

p

t

e

r

-

7

C

o

n

t

r

a

c

t

C

o

s

t

i

n

g

1

(

i

v

)

2

2

7

2

(

a

)

8

7

(

c

)

4

7

(

d

)

4

2

5

5

.

0

C

h

a

p

t

e

r

-

8

O

p

e

r

a

t

i

n

g

C

o

s

t

i

n

g

4

(

i

i

)

3

3

(

b

)

8

1

1

2

.

2

C

h

a

p

t

e

r

-

9

P

r

o

c

e

s

s

&

O

p

e

r

a

t

i

o

n

C

o

s

t

i

n

g

3

(

a

)

8

3

(

a

)

8

3

(

a

)

8

3

(

a

)

8

3

2

6

.

4

C

h

a

p

t

e

r

-

1

0

J

o

i

n

t

P

r

o

d

u

c

t

s

&

B

y

P

r

o

d

u

c

t

s

7

(

b

)

4

4

0

.

8

C

h

a

p

t

e

r

-

1

1

S

t

a

n

d

a

r

d

C

o

s

t

i

n

g

3

(

b

)

8

2

8

1

(

a

)

5

6

(

b

)

8

2

9

5

.

8

C

h

a

p

t

e

r

-

1

2

M

a

r

g

i

n

a

l

C

o

s

t

i

n

g

1

(

v

)

2

4

(

i

v

)

28

3

1

(

i

v

)

4

(

i

)

23

4

(

b

)

8

1

(

a

)

5

3

1

6

.

2

C

h

a

p

t

e

r

-

1

3

B

u

d

g

e

t

a

n

d

B

u

d

g

e

t

a

r

y

C

o

n

t

r

o

l

1

(

i

i

)

2

5

(

i

i

)

7

(

e

)

(

i

i

)

42

8

1

.

6

N

o

t

e

:

r

e

p

r

e

s

e

n

t

s

q

u

e

s

t

i

o

n

n

u

m

b

e

r

s

a

s

t

h

e

y

a

p

p

e

a

r

e

d

i

n

t

h

e

q

u

e

s

t

i

o

n

p

a

p

e

r

o

f

r

e

s

p

e

c

t

i

v

e

e

x

a

m

i

n

a

t

i

o

n

.

M

r

e

p

r

e

s

e

n

t

s

t

h

e

m

a

r

k

s

w

h

i

c

h

e

a

c

h

q

u

e

s

t

i

o

n

c

a

r

r

i

e

s

.

T

h

e

q

u

e

s

t

i

o

n

p

a

p

e

r

s

o

f

a

l

l

t

h

e

p

a

s

t

a

t

t

e

m

p

t

s

o

f

I

P

C

C

c

a

n

b

e

a

c

c

e

s

s

e

d

f

r

o

m

t

h

e

B

O

S

K

n

o

w

l

e

d

g

e

P

o

r

t

a

l

o

n

t

h

e

I

n

s

t

i

t

u

t

e

s

w

e

b

s

i

t

e

w

w

w

.

i

c

a

i

.

o

r

g

.

CONTENTS

COST ACCOUNTING

CHAPTER 1 BASIC CONCEPTS ................................................................... 1.1 1.18

CHAPTER 2 MATERIAL ............................................................................... 2.1 2.50

CHAPTER 3 LABOUR .................................................................................. 3.1 3.52

CHAPTER 4 OVERHEADS ............................................................................ 4.1 4.70

CHAPTER 5 NON INTEGRATED ACCOUNTS ............................................... 5.1 5.56

CHAPTER 6 JOB COSTING & BATCH COSTING ............................................ 6.1 6.8

CHAPTER 7 CONTRACT COSTING ............................................................. 7.1 7.28

CHAPTER 8 OPERATING COSTING ............................................................. 8.1 8.22

CHAPTER 9 PROCESS & OPERATION COSTING ......................................... 9.1 9.42

CHAPTER 10 JOINT PRODUCTS & BY PRODUCTS ................................. 10.1 10.32

CHAPTER 11 STANDARD COSTING ........................................................ 11.1 11.20

CHAPTER 12 MARGINAL COSTING ........................................................ 12.1 12.18

CHAPTER 13 BUDGETS AND BUDGETARY CONTROL ............................ 13.1 13.14

1

BASIC CONCEPTS

BASIC CONCEPTS OF FORMULAE

BASIC CONCEPTS

Classification of Costs

1. Nature of Element

1.1 Material: Cost of Material used in production

1.2 Labour: Cost of Workers

1.3 Expenses: Costs other than Material and Labour

2. Traceability to Object

2.1 Direct Costs: Which can be allocated directly to the product

2.2 Indirect Costs: Which cannot be directly allocated to the product

3. Functions

3.1 Production Costs Cost of whole process of Production

3.2 Selling Costs: Cost for creating demand of the product produced

3.3 Distribution Costs: Costs starting from packing of the product till reconditioning

of empty products

3.4 Administrative Costs: Cost of formulating policy, controlling the organisation,

costs not directly related to production

3.5 Development Costs: Development Costs for trial Run

3.6 Pre- Production Costs: Costs starting with implementation of decisions and

ending with the commencement of the production process

3.7 Conversion Costs: Cost of transforming direct material into Finished Products

3.8 Product Costs: Costs necessary for production

4. Variability

4.1 Fixed Costs: Cost which remains constant in total

4.2 Variable Costs: Costs which changes with production

1.2 Cost Accounting

4.3 Semi- Variable Costs: Costs which are partly fixed and partly variable

5. Controllability

5.1 Controllable Costs: Costs which can be influenced by the action of a specific

member of an undertaking

5.2 Uncontrollable Costs: Costs which can not be influenced by the action of a

specific member.

6. Normality

6.1 Normal Costs: Costs which are expected to be incurred in normal routine

6.2 Abnormal Costs: Costs which are over and above normal costs

7. Decision Making

7.1 Relevant Costs (Marginal Costs, Differential Costs, Opportunity Costs, Out of

Pocket): Costs which are relevant and useful for decision making

7.2 Irrelevant Costs (Sunk costs, Committed costs, Fixed costs): Costs which are not

relevant or useful to decision making

8. Cash Outflow

8.1 Explicit Costs: Costs involving immediate payment of cash

8.2 Implicit Costs: Costs not involving immediate cash payment

Types of Costing

1. Uniform Costing: Standardised principles and practices of costing are used by a

number of different industries.

2. Marginal Costing: Only Variable Costs or costs directly linked are charged to the

product or process

3. Standard Costing:Standard Costs are compared with actual costs, to determine

variances

Historical Costing:Where costs are recorded after they have incurred

5. Direct Costing: Direct Costs are charged to the product or process, Indirect Costs are

charged to the profit from the product or process.

6. Absorption Costing: All costs (variable and Fixed) are charged to the product or

process

Methods of Costing

1. Job costing; Where all costs can be directly charged to a specific job

2. Batch Costing: Where all costs can be directly charged to a group of products

(batch)

Basic Concepts 1.3

3. Contract Costing: Similar to Job costing, but in this case the job is larger than job

costing.

4. Single or Output Costing: Cost ascertainment for a single product.

5. Process Costing:The cost of production at each stage is ascertained separately

6. Operating Costing : Ascertainment of Costs in cases where services are rendered

7. Multiple Costing:Combination of two or more methods of costing, used where the

nature of the product is complex and method cannot be ascertained

Question 1

Enumerate the main objectives of introduction of a Cost Accounting System in a

manufacturing organization

Answer

The main objectives of introduction of a Cost Accounting System in a manufacturing

organization are as follows:

(i) Ascertainment of cost

(ii) Determination of selling price

(iii) Cost control and cost reduction

(iv) Ascertainment of profit of each activity

(v) Assisting in managerial decision making

Question 2

Write short notes on any two of the following?

(i) Conversion cost (ii) Sunk cost (iii) Opportunity cost

Answer

(i) Conversion cost: It is the cost incurred to convert raw materials into finished goods. It is

the sum of direct wages, direct expenses and manufacturing overheads.

(ii) Sunk cost: Historical costs or the costs incurred in the past are known as sunk cost.

They play no role in the current decision making process and are termed as irrelevant

costs. For example, in the case of a decision relating to the replacement of a machine,

the written down value of the existing machine is a sunk cost, and therefore, not

considered.

(iii) Opportunity cost: It refers to the value of sacrifice made or benefit of opportunity

foregone in accepting an alternative course of action. For example, a firm financing its

1.4 Cost Accounting

expansion plan by withdrawing money from its bank deposits. In such a case the loss of

interest on the bank deposit is the opportunity cost for carrying out the expansion plan.

Question 3

What is meant by cost centre?

Answer

Cost Centre : It is the smallest area of responsibility or segment of activity for which costs are

accumulated. It can be defined as a location; person or an item of equipment or a group of

these for which costs are ascertained and used for the purpose of cost control. Cost centres

are of two types viz.., personal and impersonal.

Personal cost centre: It is a cost centre which consists of a person or a group of persons.

Impersonal cost centre: It is a cost centre which consists of a location or an item of equipment

or a group of these.

In a manufacturing concern there are two types of cost centres viz., production and service

cost centres.

Question 4

Discuss cost classification based on variability and controllability.

Answer

Cost classification based on variability

Fixed cost These are costs, which do not change in total despite changes of a cost driver. A

fixed cost is fixed only in relation to a given relevant range of the cost driver and a given time

span. Rent, insurance, depreciation of factory building and equipment are examples of fixed

costs where the final product produced is the cost object.

Variable costs These are costs which change in total in proportion to changes of cost driver.

Direct material, direct labour are examples of variable costs, in cases where the final product

produced is the cost object.

Semi-variable costs These are partly fixed and partly variable in relation to output e.g.

telephone and electricity bill.

Cost classification based on controllability

Controllable costs Are incurred in a particular responsibility center and relate to a defined

time span. They can be influenced by the action of the executive heading the responsibility

center e.g. direct costs.

Uncontrollable costs Are costs are influenced by the action of the responsibility center

manager e.g. expenditure incurred by the tool room are controllable by the foreman in charge

Basic Concepts 1.5

of that section, but the share of tool room expenditure which are apportioned to the machine

shop are not controllable by machine shop foreman.

Question 5

Discuss the essential of a good cost accounting system?

Answer

Essentials of a good cost accounting system:

It should be tailor-made, practical, simple and capable of meeting the requirements of a

business concern.

The data used by the system should be accurate, otherwise it may distort the output of

system.

Cost of installing & operating the system should justify the results.

Cost accounting system should have the support of top management of the concern.

The system should have the necessary support from all the users departments.

Question 6

Explain:

(i) Sunk Costs

(ii) Pre-production Costs

(iii) Research and Development Costs

(iv) Training Costs

Answer

(i) Sunk Costs: These are historical costs which are incurred in the past. These costs were

incurred for a decision made in the past and cannot be changed by any decision that will

be made in future. In other words, these costs plays no role in decision making, in the

current period. While considering the replacement of a plant, the depreciated book value

of the old plant is irrelevant, as the amount is a sunk cost which is to be written off at the

time of replacement.

(ii) Pre-production Costs: These costs forms the part of development cost, incurred in

making a trial production run, preliminary to formal production. These costs are incurred

when a new factory is in the process of establishment or a new project is undertaken or a

new product line or product is taken up, but there is no established or formal production

to which such costs may be charged. These costs are normally treated as deferred

revenue expenditure (except the portion which has been capitalised) and charged to the

costs of future production.

1.6 Cost Accounting

(iii) Research and Development Costs: Research costs are the costs incurred for the

discovery of new ideas or processes by experiment or otherwise and for using the results

of such experimentation on a commercial basis. Research costs are defined as the costs

of searching for new or improved products, new applications of materials, or improved

methods, processes, systems or services.

Development costs, are the costs of the process which begins with the implementation of

the decision to produce a new or improved product or to employ a new or improved

method and ends with the commencement of formal production of that product by that

method.

(iv) Training Costs: These costs comprises of wages and salaries of the trainees or

learners, pay and allowances of the training and teaching staff, payment of fees etc, for

training or for attending courses of studies sponsored by outside agencies and cost of

materials, tools and equipments used for training. Costs incurred for running the training

department, the losses arising due to the initial lower production, extra spoilage etc.

occuring while providing training facilities to the new recruits.

All these costs are booked under separate standing order numbers for the various

functions. Usually there is a service cost centre, known as the Training Section, to which

all the training costs are allocated. The total cost of training section is thereafter

apportioned to production centers.

Question 7

Enumerate the factors which are to be considered before installing a system of cost

accounting in a manufacturing organization.

Answer

Factors which are to be considered before installing a system of cost accounting in a

manufacturing organization are:

(i) The objectives of installing a system of cost accounting should be defined, that is

whether the system is meant for control of cost or for price fixation

(ii) The organization of the company should be studied to understand the authority and

responsibilities of the managers.

(iii) The technical aspects and flow process should be taken into consideration.

(iv) The products to be manufactured should be studied.

(v) The marketing set up to be looked into for devising suitable control reports.

(vi) The possibility of integrating cost accounting system with financial accounting system

should be examined.

(vii) The procedure for collection and verification of reliability of the information should be

studied.

Basic Concepts 1.7

(viii) The degree of details of information required at each level of management should be

examined.

(ix) The maximum amount of information that would be sufficient and how the same should

be secured without too much clerical labour, especially the possibility of collection of data

on a separate printed form designed for each process; also the possibility of instruction

as regards filling up of the forms in writing to ensure that these would be faithfully carried

out.

(x) How the accuracy of the data collected can be verified? Who should be made

responsible for making such verification with regard to each operation and the form of

certification that should be given indicate verification that he has carried out.

(xi) The manner in which the benefits of introducing Cost Accounting could be explained to

various persons in the concern, specially those incharge of production department and

an awareness created for the necessity of promptitude, frequency and regularity in

collection of costing data.

Question 8

You have been asked to install a costing system in a manufacturing company. What practical

difficulties will you expect and how will you propose to overcome the same?

Answer

The practical difficulties with which a Cost Accountant is usually confronted with while

installing a costing system in a manufacturing company are as follows:

(i) Lack of top management support: Installation of a costing system do not receive the

support of top management. They consider it as an interference in their work. They

believe that such, a system will involve additional paperwork. They also have a

misconcept in their minds that the system is meant for keeping a check on their activities.

(ii) Resistance from cost accounting departmental staff: The staff resists because of fear of

loosing their jobs and importance after the implementation of the new system.

(iii) Non cooperation from user departments: The foremen, supervisor and other staff

members may not cooperate in providing requisite data, as this would not only add to

their responsibilities but will also increase paper work of the entire team as well.

(iv) Shortage of trained staff: Since cost accounting systems installation involves specialised

work, there may be a shortage of trained staff.

To overcome these practical difficulties, necessary steps required are:

To sell the idea to top management To convince them of the utility of the system.

Resistance and non cooperation can be overcome by behavioral approach. To deal with

the staff concerned effectively.

1.8 Cost Accounting

Proper training should be given to the staff at each level

Regular meetings should be held with the cost accounting staff, user departments, staff

and top management to clarify their doubts / misgivings.

Question 9

Distinguish between controllable & uncontrollable costs?

Answer

Controllable costs and Uncontrollable costs: Controllable costs are the costs which can be

influenced by the action of a specified member of the undertaking. Controllable costs incurred

in a particular responsibility centre can be influenced by the action of the executive heading

that responsibility centre.

Uncontrollable costs are the costs which cannot be influenced by the action of a specified

member of an undertaking.

Question 10

Define Explicit costs. How is it different from implicit costs?

Answer

Explicit costs: These costs are also known as out of pocket costs. They refer to those costs

which involves immediate payment of cash. Salaries, wages, postage and telegram, interest

on loan etc. are some examples of explicit costs because they involve immediate cash

payment. These payments are recorded in the books of account and can be easily measured.

Main points of difference: The following are the main points of difference between explicit and

implicit costs.

(i) Implicit costs do not involve any immediate cash payment. As such they are also known

as imputed costs or economic costs.

(ii) Implicit costs are not recorded in the books of account but yet, they are important for

certain types of managerial decisions such as equipment replacement and relative

profitability of two alternative courses of action.

Question 11

What are the main objectives of Cost Accounting?

Answer

The main objectives of Cost Accounting are as follows:

(i) Ascertainment of cost.

(ii) Determination of selling price.

Basic Concepts 1.9

(iii) Cost control and cost reduction.

(iv) Ascertainment of profit of each activity.

(v) Assisting management in decision making.

Question 12

Explain controllable and non-controllable costs with illustrations.

Answer

Controllable and non-Controllable costs

Controllable costs: These are the costs which can be influenced by the action of a specified

person in an organisation. In every organisation, there are a number of departments which are

called responsibility centres, each under the charge of a specified level of management. Costs

incurred in these responsibility centres are influenced by he action of the incharge of the

responsibility centre. Thus any cost that an organisational unit has the authority to incur may

be identified as controllable cost.

Non-controllable costs: These are the costs which cannot be influenced by the action of a

specified member of an undertaking. For example, expenditure incurred by the Tool Room is

controllable by the Tool Room Manager but the share of Tool Room expenditure, which is

apportioned to the Machine Shop cannot be controlled by the manager of the Machine Shop.

However, the distinction between controllable and non-controllable costs is not very sharp and

is sometimes left to individual judgment to specify a cost as controllable or non-controllable in

relation to a particular individual manager.

Question 13

Discuss the four different methods of costing alongwith their applicability to concerned

industry?

Answer

Four different methods of costing along with their applicability to concerned industry have

been discussed as below:

1. Job Costing: The objective under this method of costing is to ascertain the cost of each

job order. A job card is prepared for each job to accumulate costs. The cost of the job is

determined by adding all costs against the job it is incurred. This method of costing is

used in printing press, foundries and general engineering workshops, advertising etc.

2. Batch Costing: This system of costing is used where small components/parts of the same

kind are required to be manufactured in large quantities. Here batch of similar products is

treated as a job and cost of such a job is ascertained as discussed under 1, above. If in a

1.10 Cost Accounting

cycle manufacturing unit, rims are produced in batches of 2,500 units each, then the cost

will be determined in relation to a batch of 2,500 units.

3. Contract Costing: If a job is very big and takes a long time for its completion, then

method used for costing is known as Contract Costing. Here the cost of each contract is

ascertained separately. It is suitable for firms engaged in the construction of bridges,

roads, buildings etc.

4. Operating Costing: The method of Costing used in service rendering undertakings is

known as operating costing. This method of costing is used in undertakings like

transport, supply of water, telephone services, hospitals, nursing homes etc.

Question 14

Distinguish between Marginal Costing and Differential Costing

Answer

Marginal Costing and Differential Costing

Marginal Costing is defined as the Ascertainment of marginal costs and of the effect on profit

of changes in volume or type of output by differentiating between fixed costs and variable

costs.

Differential Costing is defined as the technique of costing which uses differential costs

and/or differential revenues for ascertaining the acceptability of an alternative. The technique

may be termed as incremental costing when the difference is increase in costs and

decremental costing when the difference is decrease in costs. The main points of distinction

between marginal costing and differential costing are as below:

(a) The technique of marginal costing requires a clear distinction between variable costs and

fixed costs whereas no such distinction is made in the case of differential costing.

(b) In marginal costing, margin of contribution and contribution ratio are the main yard sticks

for performance evaluation and for decision making whereas under differential costs

analysis, differential costs are compared with the incremental or decremental revenue (as

the case may be) for arriving at a decision.

(c) Differential cost analysis is possible in both absorption costing and marginal costing,

where as marginal costing in itself is a distinct technique.

(d) Marginal cost may be incorporated in the cost accounting system whereas differential

costs are worked out separately.

Question 15

Answer any the following:

(i) Explicit and Implicit Costs

Basic Concepts 1.11

(ii) Period Costs and Discretionary Costs

Answer

(i) Explicit and Implicit cost:

Explicit costs, which are also known as out of pocket costs, refer to costs involving

immediate payment of cash. Salaries, wages, interest on loan etc. are examples of

explicit costs. They can be easily measured.

The main points of difference between explicit and implicit costs are:

Implicit costs do not involve immediate cash payment.

They are not recorded in the books of account.

They are also known as economic costs.

(ii) Period and Discretionary costs

There are the costs, which are not assigned to the products but are charged as expenses

against the revenue of the period in which they are incurred. All non-manufacturing costs

such as general and administrative expenses, selling and distribution expenses are

period costs.

Such costs are not tied to a clear cause and effect relationship between inputs and

outputs. They arise from periodic decisions regarding the maximum outlay to be

incurred. Examples are advertising, public relations, training etc.

Question 16

Explain Profit centres and investment centres.

Answer

Profit Centres and Investment Centres:

Centres which have the responsibility of generating and maximizing profits are called profit

centres.

Those centres which are concerned with earning an adequate return on investment are known

as Investment centres.

Question 17

Briefly discuss, how the synergetic effect help in reduction in costs.

Answer

Two or more products are produced and managed together.

The result of combined efforts are higher than sum of the results of individual products.

1.12 Cost Accounting

Analysis of synergetic effect is helpful in cost control.

Question 18

What items are generally included in good uniform costing manual?

Answer

Uniform costing manual includes essential informations and instructions to implement

accounting procedures.

(a) Introduction: It includes objects and scope of the planning.

(b) Accounting procedure and planning includes rules, and general principle to be followed.

(c) Cost accounting planning includes methods of costing, relation between cost and

financial accounts and methods of integration.

Question 19

Explain in brief the explicit cost with examples.

Answer

Out of pocket cost, involving immediate payment of Cash. Salaries, Wages, Postage and

Telegram, Printing and Stationery, Interest on Loan are some examples of Explicit Costs.

Question 20

Discuss briefly the relevant costs with examples.

Answer

Relevant costs are those expected future cost which are essential but differ for alternative

course or action.

(a) Historical cost or sunk costs are irrelevant as they do not play any role in the decision

making process.

(b) Variable costs which will not differ under various alternatives are irrelevant.

Question 21

State the unit of cost for the following industries

(a) Transport (b) Power

(c) Hotel (d) Hospital

Basic Concepts 1.13

Answer

Industry Unit of Cost

(a) Transport Per passenger k.m. or per tonne. k.m.

(b) Power Per Kilo watt (kw) hour

(c) Hotel Per room day / or per meal

(d) Hospital Per patient day

Question 22

Distinguish between product cost and period cost.

Answer

Product Cost vis--vis Period cost

Product costs are associated with the purchase and sale of goods. In the production scenario,

such costs are associated with the acquisition and conversion of materials and all other

manufacturing inputs into finished product for sale. Hence under absorption cost, total

manufacturing costs constitute inventoriable or product cost.

Periods costs are the costs, which are not assigned to the products but are charged as

expense against revenue of the period in which they are incurred. General Administration,

marketing, sales and distributor overheads are recognized as period costs.

Question 23

Discuss accounting treatment of spoilage and defectives in cost accounting.

Answer

Accounting of Spoilage and Defectives:

Spoilage is the tem used for materials which are badly damaged in manufacturing operations,

and it cannot rectified economically and hence taken out of the process to be disposed of in

some manner without further processing.

Normal spoilage costs are included in costs either charging it to production order or by charging

it to production overheads so that it is spread over all products. Any value realized from spoilage

is credited to production order or production overhead account as the case may be.

Cost of abnormal spoilage is charged to costing P/L A/c.

Defectives: Signifies those units or portions of production which can be rectified and turned

cut as good units by application of additional material, labour or other service. Defectives are

charged to general overheads or department overheads depending upon their traceability.

1.14 Cost Accounting

They are charged to good production, when second have a normal value and defective

rectified into second or first are normal.

Costing P/L A/c in case of abnormal nature

Question 24

Define the following:

(a) Imputed cost (b) Capitalised cost

Answer

(a) Imputed Cost: These costs are notional costs which do not involve any cash outlay.

Interest on capital, the payment for which is not actually made, is an example of Imputed

Cost. These costs are similar to opportunity costs.

(b) Captialised Cost: These are costs which are initially recorded as assets and

subsequently treated as expenses.

Question25

What is Cost accounting? Enumerate its important objectives.

Answer

Cost Accounting is defined as "the process of accounting for cost which begins with the

recording of income and expenditure or the bases on which they are calculated and ends with

the preparation of periodical statements and reports for ascertaining and controlling costs."

The main objectives of the cost accounting are as follows:

(a) Ascertainment of cost: There are two methods of ascertaining costs, viz., Post Costing

and Continuous Costing. Post Costing means, analysis of actual information as recorded

in financial books. Continuous Costing, aims at collecting information about cost as and

when the activity takes place so that as soon as a job is completed the cost of completion

would be known.

(b) Determination of selling price: Business enterprises run on a profit making basis. It is

thus necessary that the revenue should be greater than the costs incurred. Cost

accounting provides the information regarding the cost to make and sell the product or

services produced.

(c) Cost control and cost reduction: To exercise cost control, the following steps should be

observed:

(i) Determine clearly the objective.

(ii) Measure the actual performance.

(iii) Investigate into the causes of failure to perform according to plan;

Basic Concepts 1.15

(iv) Institute corrective action.

(d) Cost Reduction may be defined as the achievement of real and permanent reduction in

the unit cost of goods manufactured or services rendered without impairing their

suitability for the use intended or diminution in the quality of the product.

(e) Ascertaining the profit of each activity: The profit of any activity can be ascertained by

matching cost with the revenue of that activity. The purpose under this step is to

determine costing profit or loss of any activity on an objective basis.

(f) Assisting management in decision making: Decision making is defined as a process of

selecting a course of action out of two or more alternative courses. For making a choice

between different courses of action, it is necessary to make a comparison of the

outcomes, which may be arrived under different alternatives.

Question 26

Write short note on essential factors for installing a Cost Accounting system.

Answer

Essential Factors for installing a Cost Accounting System

Before setting up a system of cost accounting following factors should be studied:

(a) Objective : The objective of costing system, for example whether it is being introduced

for fixing prices or for insisting a system of cost control.

(b) Type of Business: The areas of operation of business wherein the managements

action will be most beneficial. For instance, in a concern, which is anxious to expand its

operations, increase in production would require maximum attention. On the other hand

for a concern, which is not able, to sell the whole of its production the selling effort would

require greater attention. The system of costing in each case should be designed to

highlight, in significant areas, factors considered important for improving the efficiency of

operations in that area.

(c) General organisation: The business, with a view of finding out the manner in which the

system of cost control could be introduced without altering or extending the organisation

appreciably.

(d) The Technical Details: Technical aspects of the concern and the attitude and behaviour

that will be successful in winning sympathetic assistance or support of the supervisory

staff and workmen.

(e) Change in operations: The manner in which different variable expenses would be

affected with expansion or cessation of different operations

(f) Method of maintenance of cost records: The manner in which Cost and Financial

accounts could be inter-locked into a single integral accounting system and in which

1.16 Cost Accounting

results of separate sets of accounts, cost and financial, could be reconciled by means of

control accounts.

(g) Information: The maximum amount of information that would be sufficient and how the

same should be secured without too much clerical labour, especially the possibility of

collection of data on a separate printed form designed for each process; also the

possibility of instruction as regards filling up of the forms in writing to ensure that these

would be faithfully carried out.

(h) Accuracy : How the accuracy of the data collected can be verified? Who should be

made responsible for making such verification in regard to each operation and the form of

certificate that he should give to indicate the verification that he has carried out?

(i) Informative and Simple: The manner in which the benefits of introducing Cost

Accounting could be explained to various persons in the concern, especially those in

charge of production department and awareness created for the necessity of

promptitude, frequency and regularity in collection of costing data.

(j) Support : Support of top management and employees are essential for installing a Cost

Accounting System in any organisation.

EXERCISE

1. SV Ltd. Is a manufacturing company which has a sound system of financial accounting. The management of

the company therefore feels that there is no need for the installation of a cost accounting system. Prepare a

report to the management bringing out the distinction between cost and financial accounting system and the

need for the introduction of a sound cost accounting system.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

2 (a) Define the terms cost centre and cost unit.

(b) Given below is a list of ten industries. Give the method of costing and the unit of cost against each

industry.

(a) Nursing Home (b) Road Transport

(c) Steel (d) Coal

(e) Bicycles (f) Bridge Construction

(g) Interior Decoration (h) Advertising

(i) Furniture (j) Sugar company having its own

sugarcane fields.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

3 Distinguish between

(i) Cost Unit and Cost Centre

(ii) Cost Centre and Profit Centre

Basic Concepts 1.17

(iii) Bill of material from a material requisition note.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

4 (a) Match the following

(i) Total fixed cost 1. What cost should be?

(ii) Total variable cost 2. Incurred cost

(iii) Unit variable cost 3. Increase in proportion to output

(iv) Unit fixed cost 4. Cost of conversion

(v) Standard cost 5. What costs are expected to be

(vi) Period cost 6. Decreases with rise in output

(vii) Actual cost 7. Remains constant in total

(viii) Labour and overhead 8. Remains constant per unit

(ix) Incremental cost 9. Cost not assigned to products

(x) Budgeted cost 10. Added value of a new product.

(b) Indicate whether the following statements are True or False:

(a) All costs are controllable.

(b) Conversion cost is equal to direct wages plus factory overhead.

(c) Variable cost per unit varies with the increase or decrease in the volume of output.

(d) Depreciation is an out of pocket cost.

(e) An item of cost that is direct for one business may be indirect for another

(f) Fixed cost per unit remains fixed.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

5. List down any eight factors that you will consider before installing a costing system.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

6. Outline the steps involved in installing a costing system in a manufacturing unit. What are the essentials of

an effective costing system?

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

7 Distinguish between Controllable costs and uncontrollable costs.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

8. (a) Describe briefly the role of the cost accountant in a manufacturing organisation.

(b) Distinguish between:

(i) Variable cost and direct cost

(ii) Estimated cost and standard cost.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

1.18 Cost Accounting

9 Write short notes on Cost Centre

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

10 Name the various reports (Elaboration not needed) that may be provided by the Cost Accounting

Department of a big manufacturing company for the use of its executives.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

11 State the unit of cost and method of costing generally used for accounting purpose in the following cases:

(i) Brick-works (ii) Bi-cycle

(iii) Oil refining mill and (iv) Road transport company

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

12 What is meant by Profit Centre?

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

13 (a) What are the essentials of a Cost Accounting System?

(b) Narrate the essential factors to be considered while designing and installing a Cost Accounting

System.

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

14 Specify the methods of costing and cost units applicable to the following industries:

(i) Toy making (ii) Cement

(iii) Radio (iv) Bicycle

(v) Ship building (vi) Hospital

Answer Refer to Chapter No. 1 i.e. Basic Concepts of Study Material.

2

MATERIALS

BASIC CONCEPTS AND FORMULAE

1. Maximum Level: It indicates the maximum figure of inventory quantity held in stock

at any time.

2. Minimum Level: It indicates the lowest figure of inventory balance, which must be

maintained in hand at all times, so that there is no stoppage of production due to

non-availability of inventory.

3. Re-order level: This level lies between minimum and the maximum levels in such a

way that before the material ordered is received into the stores, there is sufficient

quantity on hand to cover both normal and abnormal consumption situations.

4. Danger level: It is the level at which normal issues of the raw material inventory are

stopped and emergency issues are only made.

5. ABC Analysis: It is a system of inventory control. It exercises discriminating control

over different items of stores classified on the basis of the investment involved. Items

are classified into the following categories:

A Category: Quantity less than 10 % but value more than 70 %

B Category; Quantiy less than 20 % but value about 20 %

C Category: Quantity about 70 % but value less than 10%

6. Two bin system: Under this system each bin is divided into two parts - one, smaller

part, should stock the quantity equal to the minimum stock or even the re-ordering

level, and the other to keep the remaining quantity. Issues are made out of the larger

part; but as soon as it becomes necessary to use quantity out of the smaller part of

the bin, fresh order is placed.

7. System of budgets: The exact quantity of various types of inventories and the time

when they would be required can be known by studying carefully production plans

and production schedules. Based on this, inventories requirement budget can be

prepared. Such a budget will discourage the unnecessary investment in inventories.

8. Perpetual inventory: Perpetual inventory represents a system of records maintained by

the stores department. It in fact comprises: (i) Bin Cards, and (ii) Stores Ledger.

9. Continuous stock verification: Continuous stock taking means the physical checking of

those records (which are maintained under perpetual inventory) with actual stock.

2.2 Cost Accounting

10. Economic Order Quantity (EOQ): It is the calculation of optimum level quantity

which minimizes the total cost of Ordering and Delivery Cost and Carrying Cost.

11. Review of slow and non-moving items: Disposing of as early as possible slow

moving items, in return with items needed for production to avoid unnecessary

blockage of resources.

12. Input output ratio : Inventory control can also be exercised by the use of input

output ratio analysis. Input-output ratio is the ratio of the quantity of input of material

to production and the standard material content of the actual output.

13. Inventory turnover ratio: Computation of inventory turnover ratios for different

items of material and comparison of the turnover rates provides a useful guidance for

measuring inventory performance. High inventory turnover ratio indicates that the

material in the question is a fast moving one. A low turnover ratio indicates over-

investment and locking up of the working capital in inventories

14. Valuation of Material Issues: Several methods of pricing material issues have been

evolved which are as follows:

a) First-in First-out method: The materials received first are to be issued first

when material requisition is received. Materials left as closing stock will be at

the price of latest purchases.

b) Last-in First-out method: The materials purchased last are to be issued first

when material requisition is received. Closing stock is valued at the oldest stock

price.

c) Simple Average Method:

Total of unit price of each purchase

Material Issue Price =

Total Numbers of purchases

d) Weighted Average Price Method: This method gives due weightage to

quantities purchased and the purchase price to determine the issue price.

Total cost of Materials received

Weighted Average Price =

Total Quantity purchases

15. Various Material Losses

a) Wastage: Portion of basic raw material lost in processing having no

recoverable value

b) Scrap: The incidental material residue coming out of certain manufacturing

operations having low recoverable value.

c) Spoilage: Goods damaged beyond rectification to be sold without further

processing.

Materials 2.3

d) Defectives: Goods which can be rectified and turned out as good units by the

application of additional labour or other services.

Basic Formulas

1. Maximum Level = Reorder Level + Reordering Quantity Minimum Consumption

during

the period required to obtain delivery.

Or

RL + RQ MnC

Or

Safety Stock + EOQ

2. Minimum Level = Reorder Level (Normal usage per period Average

delivery time)

3. Average Stock Level =

2

Level Minimum Level Maximum +

Minimum Level + Reorder Quantity

4. Reorder Level = Maximum Reorder period Maximum Usage

= Normal Usage (Minimum Stock Period + Average Delivery

Time)

= Safety Stock + Lead Time Consumption

5. Danger Level = Minimum Consumption Emergency Delivery Time

6. EOQ =

year one for inventory of unit one carrying of Cost

order per t cos Buying n Consumptio Annual 2

7. Ordering Cost =

Ordered Quantity

Order per Cost Fixed usage Annual

8. Carrying Cost =

2

ordered Quantity

Purchase Price for Inventory Carrying

Cost expressed as % of average

inventory

9. Inventory Turnover Ratio =

Inventory Average

Consumed Material

2.4 Cost Accounting

10. Inventory Turnover Period = 365 Inventory Turnover Ratio

11. To decide whether discount on purchase of material should be availed or not,

compare total inventory cost before discount and after discount. Total inventory cost

will include ordering cost, carrying cost and purchase cost.

12. Safety Stock =

Annual Demand

365

(Max. lead time Normal / Average lead time)

13. Total Inventory Cost = Ordering Cost + Carrying Cost + Purchase Cost

Note: For calculation of total inventory carrying cost, average inventory should betaken

as half of EOQ. Average inventory cost is normally given as a percentage of cost per unit

Question 1

How are normal and abnormal loss of material arising during storage treated in Cost

Accounts?

Answer

Cost Accounts treatment of normal and abnormal loss of material arising during

storage.

The difference between the book balance and actual physical stock, which may either be gain

or loss, should be transferred to Inventory Adjustment Account pending scrutiny to ascertain

the reason for the difference.

If on scrutiny, the difference arrived at is considered as normal, then such a difference should

be transferred to overhead control account and if abnormal, it should be debited to costing

profit and loss account.

In the case of normal losses, an alternative method may be used. Under this method the price

of the material issued to production may be inflated so as to cover the normal loss.

Question 2

Distinguish clearly Bincards and Sores Ledger.

Answer

Both bin cards and stores ledger are perpetual inventory records. None of them is a substitute

for the other. These two records may be distinguished from the following points of view:

(i) Bin card is maintained by the store keeper, while the stores ledger is maintained by the

cost accounting department.

(ii) Bin card is the stores recording document whereas the stores ledger is an accounting

record.

Materials 2.5

(iii) Bin card contains information with regard to quantities i.e. their receipt, issue and

balance while the stores ledger contains both quantitative and value information in

respect of their receipts, issue and balance.

(iv) In the bin card entries are made at the time when transaction takes place. But in the

stores ledger entries are made only after the transaction has taken place.

(v) Inter departmental transfer of materials appear only in stores ledger.

(vi) Bin cards record each transaction but stores ledger records the same information in a

summarized form.

Question 3

What is Just in Time (JIT) purchases? What are the advantages of such purchases?

Answer

Just in time (JIT) purchases means the purchase of goods or materials such that delivery

immediately precedes their use.

Advantages of JIT purchases:

Main advantages of JIT purchases are as follows:

1. The suppliers of goods or materials cooperates with the company and supply requisite

quantity of goods or materials for which order is placed before the start of production.

2. JIT purchases results in cost savings for example, the costs of stock out, inventory

carrying, materials handling and breakage are reduced.

3. Due to frequent purchases of raw materials, its issue price is likely to be very close to the

replacement price. Consequently the method of pricing to be followed for valuing material

issues becomes less important for companies using JIT purchasing.

4. JIT purchasing are now attempting to extend daily deliveries to as many areas as

possible so that the goods spend less time in warehouses or on store shelves before

they are exhausted.

Question 4

Discuss the accounting treatment of defectives in cost accounts

Answer

Accounting treatment of defectives in cost accounts:

Defectives refers to those units or portions of production, which do not meet the prescribed

specifications. Such units can be reworked or re-conditioned by the use of additional material,

labour and /or processing and brought to the point of either standard or sub-standard units.

The possible way of treating defectives in cost accounts are as below:

2.6 Cost Accounting

1. When defectives are normal and it is not beneficial to identity them job-wise, then the

following methods may be used.

(a) Charged to good products: The cost of rectification of normal defectives is charged to

good units. This method is used when defectives rectified are normal.

(b) Charged to general overheads. If the department responsible for defectives cannot be

identified, the rework costs are charged to general overheads.

(c) Charged to departmental overheads: If the department responsible for defectives can

be correctly identified, the rectification costs should be charged to that department.

2. When normal defectives are easily identifiable with specific job the rework costs are

debited to the identified job.

3. When defectives are abnormal and are due to causes within the control of the

organisation, the rework cost should be charged to the Costing Profit and Loss Account.

Question 5

Discuss the concept of Economic Batch Quantity (EBQ)

Answer

Economic batch quantity: Production is usually done in batches and each batch can have

any number of units of a component in it. The optimum quantity for a batch is that quantity for

which the setting up and carrying costs are minimum. Such an optimum quantity is known as

"Economic batch quantity". The formula used to determine the economic batch quantity (EBQ)

is:

EBQ =

C

DS 2

where, EBQ = Economic batch quantity

D = Demand of the components in a year

S = Setting up cost per batch

C = Carrying cost p.u. per annum

Question 6

Explain the concept of "ABC Analysis" as a technique of inventory control

Answer

ABC Analysis: It is a system of selective inventory control whereby the measure of control

over an item of inventory varies with its usage value. It exercises discriminatory control over

different items of stores grouped on the basis of the investment involved,. Usually the items of

Materials 2.7

material are grouped into three categories viz; A, B and C according to their use value during

a period. In other words, the high use value items are controlled more closely than the items of

low use value.

(i) 'A' Category of items consists of only a small percentage i.e., about 10 % of the total

items of material handled by the stores but require heavy investment i.e., about 70% of

inventory value, because of their high prices and heavy requirement.

(ii) 'B' Category of items comprises of about 20% of the total items of material handled by

stores. The percentage of investment required is about 20% of the total investment in

inventories.

(iii) 'C category of items does not require much investment. It may be about 10% of total

inventory value but they are nearly 70% of the total items handled by stores.

'A' category of items can be controlled effectively by using a regular system, which ensures

neither over- stocking nor shortage of materials for production. Such a system plans its total

material requirements by making budgets. The stocks of materials are controlled by fixing

certain levels like maximum level, minimum level and re-order level. A reduction in inventory

management costs is achieved by determining economic order quantities after taking into

account ordering cost and carrying cost. To avoid shortages and to minimize heavy

investment of funds in inventories, the techniques of value analysis, variety reduction,

standardization etc. are used along with aforesaid techniques.

In the case of

'

B' category of items, as the sum involved is moderate, therefore, the same

degree of control as applied in 'A' category of items is not warranted. The order for the items,

belonging to this category may be placed after reviewing their situation periodically. This

category of items can be controlled by routine control measures.

For 'C' category of items, there is no need of exercising constant control. Orders for items in

this group may be placed either after six months or once in a year, after ascertaining

consumption requirements.

Question 7

Distinguish between Re-order level and Re-order quantity

Answer

Re-order level & Re-order quantity: Re-order level is defined as that level of an inventory item

where a fresh order for its replenishment is placed. Mathematically it can be determined by

using the following formulas:

Re-order level (ROL) = [Maximum consumption x Maximum re-order period]

Alternatively: = Minimum level +

n consumptio

of rate Average

period order re

Average

2.8 Cost Accounting

Re-order quantity (ROQ) is defined as that quantity of an inventory item for which order is

placed again and again. Economic order quantity is a re-order quantity but not vice-a-versa. It

can be determined by using the following mathematical expression:

EOQ = ROQ =

annum per unit per t cos carrying Annual

order per t cos Ordering units in item inventory of t requiremen Annual 2

Question 8

Describe perpetual inventory records and continuous stock verification.

Answer

Perpetual inventory records and continuous stock verification:

Perpetual inventory records represents a system of records maintained by the stores

department. It in fact comprises of (i) Bin cards, and (ii) Stores Ledger.

Bin cards maintains a quantitative record of receipts, issues and closing balances of each item

of stores. Separate bin cards are maintained for each item. Each card is filled up with the

physical movement of goods i.e. on its receipt and issue.

Like bin cards the stores ledger is maintained to record all receipts and issues in respect of

materials. Entries in it are made with the help of goods received notes and material issue

requisitions.

A perpetual inventory record is usually checked by a programme of continuous stock

verification. Continuous stock verification means the physical checking of those inventory

records (which are maintained under perpetual inventory) with actual stock.

Perpetual inventory records helps in proper material control as discrepancies in physical stock

and book figures are regularly reconciled through continuous stock verification.

Question 9

How is slow moving and non-moving item of stores detected and what steps are necessary to

reduce such stocks?

Answer

Detection of slow moving and non-moving item of stores:

The existence of slow moving and non-moving item of stores can be detected in the following

ways.

(i) By preparing and scanning periodic reports showing the status of different items or

stores.

(ii) By calculating the stock holding of various items in terms of number of days/ months of

consumption.

Materials 2.9

(iii) By computing ratios periodically, relating to the issues as a percentage of average stock

held.

(iv) By implementing the use of a well designed information system.

Necessary steps to reduce stock of slow moving and non-moving item of stores:

(i) Proper procedure and guidelines should be laid down for the disposal of non-moving

items, before they further deteriorates in value.

(ii) Diversify production to use up such materials.

(iii) Use these materials as substitute, in place of other materials.

Question 10

Distinguish between Bin Card and Stores Ledger.

Answer

Bin Card Stores Ledger

Bincards are maintained in the stores and are

serving the purpose of stock register.

Entries in it are posted by the issue clerk. He

records the quantity about receipts, issues and

closing balance along with code number of

material, maximum, minimum and reorder

levels.

Here transactions are posted individually.

Posting is done at the time of issue of material.

Stores ledger is maintained in the cost accounts

department.

Here entries are posted by the stores ledger

clerk. He records the quantities and value about

receipts, issues and closing balance along with

code number of material, maximum, minimum

and reorder levels.

Here transactions can be posted periodically.

Posting . is done after the issue of materials.

Question 11

Explain the advantages that would accrue in

Using the LIFO method of pricing for the valuation of raw material stock

Answer

LIFO- Last-in-first-out: A method of pricing for the valuation of raw material stock. It is based

on the assumption that the items of the last batch(lot) purchased are the first to be issued.

Therefore, under this method, the price of the last batch(lot) of raw material is used for pricing

raw material issues until it is exhausted. If, however, the quantity of raw material issued is

more than the quantity of the latest lot, the price of the last but one lot and so on will be taken

for pricing the raw material issues.

The advantages that would accrue from the use of LIFO method of pricing the valuation of raw

materials, are as follows:-

2.10 Cost Accounting

(i) The cost of materials used is nearer to the current market price. Thus the cost of goods

produced depends upon the trend of the market price of materials. This enables the

matching of cost of production with current sales revenues.

(ii) Use of LIFO during the period of rising prices does not depict unnecessarily high profit in

the income statement; compared to the first-in-first-out or average methods. The profit

shown by the use of LIFO is relatively lower, because the cost of production takes into

account the rising trend of material prices.

(iii) When price of materials fall, the use of LIFO method accounts for rising the profits due

to lower material cost. Inspite of this finished product appears to be more competitive and

at market prices.

(iv) Over a period, the use of LIFO will iron out the fluctuations in profit.

(v) During inflationary period, the use of LIFO will show the correct profit and thus avoid

paying unduly high taxes to some extent.

Question 12

(a) Discuss briefly the considerations governing the fixation of the maximum and minimum

levels of inventory.

(b) A company uses three raw materials A, B and C for a particular product for which the

following data apply :

Raw

Material

Usage

per unit

of

product

(Kgs)

Re-

order

Quantity

(Kgs)

Price

per

Kg.

`

Delivery period

(in weeks)

Re-

order

level

(Kgs)

Minimum

level

(Kgs)

Minimum Average Maximum

A 10 10,000 0.10 1 2 3 8,000

B 4 5,000 0.30 3 4 5 4,750

C 6 10,000 0.15 2 3 4 2.000

Weekly production varies from 175 to 225 units, averaging 200 units of the said product.

What would be the following quantities:

(i) Minimum Stock of A?

(ii) Maximum Stock of B?

(iii) Re-order level of C?

(iv) Average stock level of A?

Materials 2.11

Answer

(a) Considerations for the fixation of maximum level of inventory.

Maximum level of an inventory item is its maximum quantity held in stock at any time.

The mathematical formula used for its determination is as follows:

Maximum level = Re-order level (Minimum Consumption Minimum Re-order period) +

Re-order quantity.

The important considerations which should govern the fixation of maximum level for

various inventory items are as follows:

(1) The fixation of maximum level of an inventory item requires information about re-

order level. The re-order level itself depends upon its maximum rate of consumption

and maximum delivery period. It in fact is the product of maximum consumption of

inventory item and its maximum delivery period.

(2) Knowledge about minimum consumption and minimum delivery period for each

inventory item should also be known.

(3) The determination of maximum level also requires the figure of economic order

quantity. Economic order quantity means the quantity of inventory to be ordered so

that total ordering and storage cost is minimum.

(4) Availability of funds, storage capacity, nature of items and their price also are

important for the fixation of minimum level.

(5) In the case of important materials due to their irregular supply, the maximum level

should be high.

Considerations for the fixation of minimum level of inventory

Minimum level indicates the lowest figures of inventory balance, which must be

maintained in hand at all times, so that there is no stoppage of production due to non-

availability of inventory. The formula used for its calculation is as follows:

Minimum level of inventory = Re-order level (Average rate of consumption Average

time of inventory delivery).

The main considerations for the fixation of minimum level of inventory are as

follows:

1. Information about maximum consumption and maximum delivery period in respect

of each item to determine its re-order level.

2. Average rate of consumption for each inventory item.

3. Average delivery period for each item. The period can be calculated by averaging

the maximum and minimum period.

2.12 Cost Accounting

(b) (i) Minimum stock of A

Re-order level (Average rate of consumption Average time required to obtain

fresh delivery)

= 8,000 (2,000 2) = 4,000 kgs.

(ii) Maximum stock of B

Re-order level (Minimum Consumption Minimum Re-order period) + Re-order

quantity

= 4,750 (4 175 3) + 5,000

= 9,750 2,100 = 7,650 kgs.

(iii) Re-order level of C

Maximum re-order period Maximum Usage

= 4 1,350 = 5,400 kgs.

OR

Re-order level of C

= Minimum stock of C+(Average rate of consumption Average time required to

obtain fresh delivery)

= 2,000 + [(2006)3] kgs.

= 5,600 kgs.

(iv) Average stock level of A

= Minimum stock level of A +

2

1

Re-order quantity

= 4,000 +

2

1

10,000 = 4,000 + 5,000 = 9,000 kgs.

OR

Average Stock level of A

=

2

stock Maximum stock Minimum +

(Refer to working note)

=

2

250 , 16 000 , 4 +

= 10,125 kgs.

Working note