Professional Documents

Culture Documents

Heat Conduction Equation (Compatibility Mode)

Uploaded by

Salam AlbaradieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Conduction Equation (Compatibility Mode)

Uploaded by

Salam AlbaradieCopyright:

Available Formats

THERMAL TECHNOLOGY LABORATORY

INSTITUTE OF THERMAL TECHNOLOGY FACULTY OF ENERGY AND ENVIRONMENTAL ENGINEERING SILESIAN UNIVERSITY OF TECHNOLOGY

LABORATORY INSTRUCTION

Theme of the exercise: NATURAL CONVECTION

Laboratory Instruction: Measuring the Emissivity of a Surface

1 Introduction

Convection is one of three basic mechanisms of heat transfer. The mechanism of convection concerns fluids (gases and liquids) and is based both on heat conduction and on fluid motion. Fluid motion enhances heat transfer; heat convection is thus much more intensive than pure conduction [2]. Due to this intensity, in many engineering problems the temperature distribution in a fluid is assumed to be uniform and the mechanism of convenction is analyzed only in a boundary layer between the fluid and the adjacent solid surface. The phenomenon of convection is much more complex than conduction in solids. The rate of convection heat transfer between a solid surface and the fluid flowing over that surface depends both on fluid and flow properties, such as: 1. fluid thermal conductivity k (W/m-K); this parameter shows the role of heat conduction in the convection mechanism; 2. fluid dynamic viscosity (Pas), 3. fluid density , (kg/m3), 4. fluid specific heat Cp (J/kg-K), 5. flow velocity w (m/s), 6. flow area geometry identified by a characteristic dimension L (m), 7. type of flow (laminar, turbulent). It is also essential to note that the rate of convection heat transfer is proportional to the temperature difference between the surface and the fluid. This fact is known as the Newtons law of cooling:

& = hA (T T ) , Q s s

(1)

where h is the convection heat transfer coefficient expressed in (W/m2K), As is the heat transfer area, Ts is the temperature of the surface, and T is the temperature of the fluid sufficiently far from the surface. The convection heat transfer coefficent h depends on the factors (17) listed above. Numerous experimental studies were performed in the 20th century to find correlations suitable for a specific type of flow, fluid and geometry. Many such empirical correlations are given in heat transfer handbooks. In this exercise, you will also follow this approach.

However, you should remember that your specific engineering problem usually differs from the one investigated by the researcher, who gave an empirical formula that you wish to apply. If you need a more detailed solution of your convection problem, you should either perform problemspecific measurements, or simulate the problem using Computational Fluid Dynamics (CFD).

For typical flow and geometry patterns, empirical formulae are available in literature. Most of these formulae contain a dimensionless form of the convection heat transfer coefficient h, i.e. the Nusselt number, defined as:

Nu = hL , k (2)

where L is the characteristic object length, and k is the thermal conductivity of fluid. The Nusselt number compares the actual heat transfer by convection with heat transfer in the same fluid by pure conduction. When no fluid motion is present, then Nu = 1. Convection problems may be classified into two large groups:

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

Laboratory Instruction: Measuring the Emissivity of a Surface

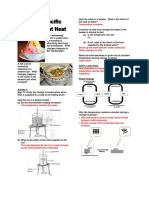

forced convection, when the fluid flow is forced by an external source such as a fan, pump or compressor; natural convection, when the fluid flow is only due to differences in fluid density; it is less intensive than forced convection in the same medium. Natural convection can occur due to the gravity and the buoyancy force. There is no natural convection inside a spacecraft, even if it is filled with atmospheric air [2]. In this exercise you will investigate a free convection problem using a test rig presented in Fig. 1. An electric heater (2) is placed inside a copper pipe (1); its thermal power can be adjusted using an autotransformer (7). High conductivity of copper ensures good temperature equalization along pipe walls. The electric heater is placed in the central part of the pipe so that both pipe ends are not heated, and heat losses through the ends can be neglected (their area is less than 0.5% compared to that of the side walls). Heat transfer to the pipe interior is thus not analyzed here. It can be assumed that the entire heat flux generated by the heater is transferred to the surrounding air through the pipe side surface.

Fig. 1. The free convection test rig 1 pipe with air flow, 2 electric heater, 3 thermocouples for air inlet, 4 thermocouple switch, 5 temperature indicator,6 wattmeter, 7 autotransformer Pipe length: 830 mm, inner diameter: 13 mm Thermocouples (3 Ni-CrNi) soldered to the pipe surface; their indications can be used to verify if the wall temperature is equalized. Cold ends of the thermocouples are placed in the ambient temperature, the thermoelectric force is thus proportional to the temperature difference between the ambient and the pipe surface. The temperature indicator (5) automatically converts the thermocouple voltage into temperature and adds the ambient temperature measured with an additional sensor. The temperature you see on the display is thus directly the temperature at the given point. The thermocouple switch (4) can operate in a manual or automatic mode. The ambient temperature should be read from a common glass thermometer. The aim of the measurements is to determine the convection heat transfer coefficient h, which can be done using 2 independent methods describe in the subsections below.

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

Laboratory Instruction: Measuring the Emissivity of a Surface

1.1.

Method 1: Heat transfer effect

This method is based on a direct observation of cooling effects. It should be stressed that the pipe considered is cooled both by convection and by radiation. Radiative heat transfer can usually be neglected in forced convection problems, but should be considered in natural convection ones, since the latter are less intensive. In this exercise, it is possible to determine the total rate of heat transfer, however, it is not possible to evaluate which part of heat transfer is realized by convection or radiation, respectively. The Newtons law of cooling (Eq. 1) can be modified to account for radiation:

& =h Q combined As (Ts T ) ,

(1)

where hcombined is the combined heat transfer coefficient accounting both for convection and radiation. Mean values of the temperatures Ts and T result directly from measuerements. The area As can be calculated from pipe dimensions given to the Fig. 1.

1.2.

Method 2: Detailed analysis of natural convection

Within this analysis you will determine the convection heat transfer coefficient via Nusselt number (Eq. 2). In natural convection problems, the Nusselt number depends on the product of the Grashof and the Prandtl numbers:

Nu = C (Gr Pr ) ,

n

(1)

The product Gr Pr is sometimes referred to as the Rayleigh number Ra. As you know from the lectures, the Grashof number describes the ratio of the buoyancy force to the viscous force and is defined as:

Gr = where: g

g (Ts T )L3 c

(1)

= gravitational acceleration, m/s2 = coefficient of volume expansion 1/K (b = 1/T) for ideal gases = temperature of the surface, C = temperature of the fluid far from the surface, C = characteristic object length, m = kinematic viscosity of the fluid, m2/s

Ts T Lc

The Prandtl number describes the ratio of the molecular diffusivity of momentum to the molecular diffusivity of heat and is defined as: Pr =

C p

k

(1)

where is the dynamic viscosity of the fluid, Pa s. All fluid properties required for the calculation of the Grashof and Prandtl numbers should be calculated for the mean film temperature Tf:

Tf =

(Ts + T )

2

(1)

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

Laboratory Instruction: Measuring the Emissivity of a Surface In order to do find the convection heat transfer coefficient, you should: 1. 2. 3. 4. Find all the required fluid (air) properties for the average film temperature. Calculate the Grashof and the Prandtl number.

Find a formula for the Nusselt number suitable for natural convection in air and for the given geometry. Calculate the Nusselt number and the convection heat transfer coefficient.

2 Aim of exercise

The aim of the exercise is to demonstrate the phenomenon of the natural convection and to compare two ways of determining the convection heat transfer coefficient. The first method is based on analyzing the heat transfer effects (measured in the experiment) and does not go into details of the phenomenon. The second method uses the formulae given in the heat transfer literature to determine the coefficient value theoretically. From the first method you will obtain the combined heat transfer coefficient, accounting both for natural convection and for radiation. The second method allows you to find the convection heat transfer coefficient, accounting for convection and excluding thermal radiation.

3 Measurement methodology

The test rig is highly sensible to external impulses, such as flow of air from an opened window or fluid motion caused by moving persons. Please try to ensure maximum stability of air during the experiment. During the experiment you should proceed as follows: 1. Check if the autotransformer power is 0. 2. Switch on the test rig equipment. 3. Set an electric heating power according to the tutors instructions. 4. Write down thermocouple indications and the electric power in time intervals of 1 minute. 5. Wait for equilibrium: two recent records should be in an acceptable agreement. 6. Check and write down the ambient (room) temperature. 7. Repeat the items 26 for different power settings.

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

Laboratory Instruction: Measuring the Emissivity of a Surface

4 Data sheet for measurement results

Page 1 Time Nel min 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 W T1a C T1b T1c T2a T2b T2c T3a T3b T3c

Indoor air temperature:

Atmospheric pressure:

Caution: this page has to be confirmed by tutors signature!

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

Laboratory Instruction: Measuring the Emissivity of a Surface Data sheet Page 2 Time Nel min 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 W T1a C T1b T1c T2a T2b T2c T3a T3b T3c

Indoor air temperature:

Atmospheric pressure:

Caution: this page has to be confirmed by tutors signature!

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

Laboratory Instruction: Measuring the Emissivity of a Surface Data sheet Page 3 Time Nel min 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 W T1a C T1b T1c T2a T2b T2c T3a T3b T3c

Indoor air temperature:

Atmospheric pressure:

Caution: this page has to be confirmed by tutors signature!

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

Laboratory Instruction: Measuring the Emissivity of a Surface

5 Guidelines for report preparation

The report should contain the following elements: 1. Calculation of the average combined heat transfer coefficient hcombined , performed for each value of flow rate, based on measurement results. 2. Discussion of results (compare results between the series). Please prepare a graph showing the dependency between the convection heat transfer coefficient and the temperature difference between the fluid and the surface. 3. Detailed process analysis: please include calculations as well as the formulae you applied. Ask the tutor for help if you encounter problems. 4. Comparison of results between the two methods of analysis. 5. Final conclusions (you can comment on the results or on the exercise, discuss the conditions in the laboratory room, find factors which might have influenced the results, or give your proposal how to improve the exercise to make it more valuable or more interesting).

References

[1] A. Bejan, A. D. Kraus Heat Transfer Handbook, J. Wiley & Sons, Hoboken NJ, 2003 [2] Y. A. engel Heat Transfer A Practical Approach, McGraw-Hill, New York 2003 [3] E. Kostowski Przepyw Ciepa (Heat Transfer, in Polish), Wydawnictwo Politechniki lskiej, Gliwice 2006. [4] R. Weber Lecture Notes in Heat Transfer, International Studies in Science and Engineering, IEVB TU Clausthal, 2008 [5] Laboratory instruction Konwekcja swobodna w powietrzu od rury (in Polish), ITC Gliwice, 2004, available at www.itc.polsl.pl

2010 W Kostowski, Institute of Thermal Technology, Silesian UT Gliwice

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Phet - Wave On A String Lab (Phet - Colorado.edu) : Research Question: How Does The Wave Behavior Change When The BoundaryDocument4 pagesPhet - Wave On A String Lab (Phet - Colorado.edu) : Research Question: How Does The Wave Behavior Change When The BoundaryFrancis DayanNo ratings yet

- Lecture 1BDocument14 pagesLecture 1BSalam AlbaradieNo ratings yet

- LibrariesDocument2 pagesLibrariesSalam AlbaradieNo ratings yet

- ETo Calculation MethodDocument8 pagesETo Calculation MethodSalam AlbaradieNo ratings yet

- Temperature, Buoyancy, and Vertical Motion What Air Temperature?Document7 pagesTemperature, Buoyancy, and Vertical Motion What Air Temperature?Salam AlbaradieNo ratings yet

- 6DOF Control Lebedev MA PDFDocument92 pages6DOF Control Lebedev MA PDFavianbuNo ratings yet

- Fuzzy Fractional Order%2Document1 pageFuzzy Fractional Order%2Salam AlbaradieNo ratings yet

- Fulbright TEA LAFDocument1 pageFulbright TEA LAFSalam AlbaradieNo ratings yet

- Lecture 1ADocument12 pagesLecture 1ASalam AlbaradieNo ratings yet

- HW1Document18 pagesHW1Salam AlbaradieNo ratings yet

- 12 Chapter 4Document45 pages12 Chapter 4Salam AlbaradieNo ratings yet

- Important Experimental Designs: University of JordanDocument18 pagesImportant Experimental Designs: University of JordanSalam AlbaradieNo ratings yet

- Neuro-Adaptive Design - II:: A Robustifying Tool For Any DesignDocument46 pagesNeuro-Adaptive Design - II:: A Robustifying Tool For Any DesignSalam AlbaradieNo ratings yet

- Problem 1Document1 pageProblem 1Salam AlbaradieNo ratings yet

- Chap 5Document35 pagesChap 5Anonymous dWtqWj4qjNo ratings yet

- Introduction To Measurement Uncertainty: Date: 2006-3-02 AuthorsDocument27 pagesIntroduction To Measurement Uncertainty: Date: 2006-3-02 AuthorsSalam AlbaradieNo ratings yet

- Laplace's Equation in a Circular CylinderDocument11 pagesLaplace's Equation in a Circular CylinderSalam AlbaradieNo ratings yet

- Similarity Solutions For Boundary Layer Flows On A Moving Surface in Non-Newtonian Power-Law FluidsDocument10 pagesSimilarity Solutions For Boundary Layer Flows On A Moving Surface in Non-Newtonian Power-Law FluidsSalam AlbaradieNo ratings yet

- Lagrangian Dynamics: Virtual Work and Generalized ForcesDocument11 pagesLagrangian Dynamics: Virtual Work and Generalized ForcesAnonymous 2xjDjAcZNo ratings yet

- Lec24 JoseDocument5 pagesLec24 JoseJose D CostaNo ratings yet

- QuizDocument34 pagesQuizSalam AlbaradieNo ratings yet

- Trou W Borst 2014 BSCDocument36 pagesTrou W Borst 2014 BSCSalam AlbaradieNo ratings yet

- State Space Model Nptel ModDocument30 pagesState Space Model Nptel ModBarathNo ratings yet

- Lecture7 PDFDocument13 pagesLecture7 PDFSalam AlbaradieNo ratings yet

- ABET Syllabus HydraulicsDocument2 pagesABET Syllabus HydraulicsSalam AlbaradieNo ratings yet

- Java PrintingDocument6 pagesJava PrintingSalam AlbaradieNo ratings yet

- Fire Fighting Robot Detects & Extinguishes FiresDocument13 pagesFire Fighting Robot Detects & Extinguishes FiresSalam AlbaradieNo ratings yet

- The Geometry of Nature: FractalsDocument16 pagesThe Geometry of Nature: FractalsSalam Albaradie100% (1)

- A 04 V 9 N 2Document6 pagesA 04 V 9 N 2Salam AlbaradieNo ratings yet

- NEETprep admin dashboard provides 15 thermodynamics questionsDocument11 pagesNEETprep admin dashboard provides 15 thermodynamics questionsAshish RajNo ratings yet

- Some QuestionsDocument2 pagesSome QuestionsMd. Imran AhmedNo ratings yet

- Heat TransferDocument13 pagesHeat TransferJâîñ HïmåñßhûNo ratings yet

- Fall 2020 PHY-105 Mid Term ADocument1 pageFall 2020 PHY-105 Mid Term AMd. Imran AhmedNo ratings yet

- PhysicsDocument170 pagesPhysicsW PremsonNo ratings yet

- Unit 2 Thermal Physics CIEDocument27 pagesUnit 2 Thermal Physics CIEShrirang ChandankhedeNo ratings yet

- Answer Key ThermodynamicsDocument18 pagesAnswer Key ThermodynamicsAnant DwivediNo ratings yet

- Textbook of Heat Transfer Sukhatme S PDocument122 pagesTextbook of Heat Transfer Sukhatme S PSamer HouzaynNo ratings yet

- ECE Mock Board Exam April 2022 GEASDocument7 pagesECE Mock Board Exam April 2022 GEASx8t2w5ngjcNo ratings yet

- Problemas de Estudio Sobre Sonido (Parte 1)Document3 pagesProblemas de Estudio Sobre Sonido (Parte 1)Jose Ignacio Negrete TamayoNo ratings yet

- Wave Motion Practice ProblemsDocument4 pagesWave Motion Practice ProblemsPawowNo ratings yet

- Models - Woptics.photonic CrystalDocument8 pagesModels - Woptics.photonic CrystalAhsan MuhammadNo ratings yet

- Physics G8 2021-22 3RD Term Revision SheetDocument14 pagesPhysics G8 2021-22 3RD Term Revision SheetAya ChoucairNo ratings yet

- Tube Secara Metode Matematis Dan Simulasi Software: Perancangan Heat Exchanger Tipe Shell DanDocument8 pagesTube Secara Metode Matematis Dan Simulasi Software: Perancangan Heat Exchanger Tipe Shell DanMulya AzhariNo ratings yet

- Wave OpticsDocument7 pagesWave OpticsHarsh GuptaNo ratings yet

- Inbreathing Outbreathing of TanksDocument30 pagesInbreathing Outbreathing of Tanksomesh2008No ratings yet

- 4.3 Answer Specific Latent Heat Module 2021Document12 pages4.3 Answer Specific Latent Heat Module 2021黎珮琴No ratings yet

- COMPARISON of Helical Coil Versus Straight Tube HXdocumentDocument7 pagesCOMPARISON of Helical Coil Versus Straight Tube HXdocumentlram70No ratings yet

- Science8 Q1 MOD4of8 Sound V2Document26 pagesScience8 Q1 MOD4of8 Sound V2Marc Jone ArengaNo ratings yet

- HGDocument4 pagesHGdcopperfeild195No ratings yet

- Daftar Pustaka Pratikum PTKDocument2 pagesDaftar Pustaka Pratikum PTKLopen JelinNo ratings yet

- LP2 PropertiesOfEMWavesDocument2 pagesLP2 PropertiesOfEMWavesMarco GNo ratings yet

- S5 Chemistry Revision QuestionsDocument4 pagesS5 Chemistry Revision Questionshadadikigambo58No ratings yet

- B.E (IV SEM) MECH - ENGG / Tutorial - 4 B.E (IV SEM) MECH - ENGG / Tutorial - 4Document2 pagesB.E (IV SEM) MECH - ENGG / Tutorial - 4 B.E (IV SEM) MECH - ENGG / Tutorial - 4Kumaran RNo ratings yet

- 2020 Year 9 Physics Waves Success CriteriaDocument2 pages2020 Year 9 Physics Waves Success Criteriaapi-356655652No ratings yet

- Dll-Science 10 - Nov 14-18,2022Document3 pagesDll-Science 10 - Nov 14-18,2022Precious SanianoNo ratings yet

- HEAT TRANSFER PROBLEMS AND SOLUTIONSDocument5 pagesHEAT TRANSFER PROBLEMS AND SOLUTIONSIntanbyzuri ARNo ratings yet

- Cheatsheet Mechanical VibrationsDocument16 pagesCheatsheet Mechanical VibrationsTatik JuwariyahNo ratings yet

- Physics Mdcat: D) 4 L A) Sine WaveDocument6 pagesPhysics Mdcat: D) 4 L A) Sine WaveahmedNo ratings yet