Professional Documents

Culture Documents

Maintaining Centrifugal Pumps

Uploaded by

aserf251Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintaining Centrifugal Pumps

Uploaded by

aserf251Copyright:

Available Formats

Maintenance and Repair of Centrifugal Pumps

written by: Willie Scott edited by: Lamar Stonecypher updated: 11/1/2011 Centrifugal pumps ha e been used in industry for a hundred and fifty years or more! "hey are used to con ert the energy from the pump dri er to #inetic and potential energy into the fluid$ ia the impeller! "hey are used aboard ships to circulate seawater and freshwater cooling for the main engine!

% ship&s engine room contains se eral different types of pumps including centrifugal pumps! 'n the ne(t few sections$ the maintenance of centrifugal pumps is e(plained! )ere we will ha e a loo# at the procedure to strip$ inspect and reassemble a centrifugal pump$ forming part of the planned maintenance schedule on board ships for the purpose of maintaining the e*uipment in optimum operating condition! "he first section gi es an o er iew of a typical centrifugal pump operation

Overview

%s we saw earlier+ the centrifugal pump was de eloped in the mid 1,00-s$ although it was used in a crude form before then! "he main design change was by .ohn %ppold in 1,/1+ he replaced the impeller straight anes by cur ed blades! "he pump con erts mechanical energy from the dri e to #inetic energy$ with this being transferred to the fluid as pressure! "his ta#es place due to the two main components of the pump: the impeller and the olute! "he rotating impeller con erts the input of mechanical energy to #inetic energy$ while the stationary olute con erts this to pressure! "he fluid to be pumped enters the pump through the suction pipe no00le$ where it is drawn directly to the impeller 1eye2 located in the center of the impeller! "he impeller spins the fluid tangentially and radially with centrifugal force outwards! "he cur ed blades create a low pressure at the eye that allows more fluid to be drawn from the suction no00le to the impeller! So basically$ the pump operates on the transfer of mechanical energy from the dri e motor from where it is con erted to #inetic energy that is transferred to the fluid as pressure energy! "he rotation of the impeller with its cur ed anes draws the fluid from the suction no00le+ throwing it outwards$ e(pelling it through centrifugal force from the discharge no00le! % s#etch of a hori0ontal pump is shown below!

Removal of Pump for Inspection and Maintenance

1 'solate pump electrical circuit brea#er on main switch board and attach a warning notice! 34o 5ot 6perate78en at Wor#9! 2! Switch off and loc# pump supply at its local supply panel! %ttach a warning notice to pump local supply panel! :! Close suction and discharge al es$ chain and loc# hand wheels! ;! 6pen pump suction and discharge pipe drain al es to bilge and when water ceases to flow+ crac# open the pipes / pump flange <oints carefully to ensure that pump has drained off and is safe for opening! /! =i( a shac#le to lifting pad eye abo e pump and hang chain bloc#+ ensuring SWL of bloc#$ slings and shac#les are satisfactory! >! ?se a center7punch to match/mar# coupling and casing$ then remo e the coupling bolts! @! 4isconnect$ fi( i/d tag and remo e motor supply cables+ taping o er bare ends with insulating tape! ,! Connect shac#le and sling to motor eyebolt and lift motor clear of pump using o erhead chain bloc#! Lay motor on its side out of harm-s way$ protecting machined surfaces on both pump and motor coupling hal es against damage! 3Cardboard and mas#ing tape is *uic# and efficient method!9 A! 4isconnect all e(ternal fittings from pump casing e!g! cooling pipe$ pressure gauge$ oil reser oirs and air coc#! 10! Bemo e bolting from top co er and remo e co er! Scrape off old gas#et and chec# mating surfaces$ and renew gas#et on assembly! 3Light smear of grease on gas#et / faces9 11! "he pump shaft with impeller can be lifted out of casing! 12! 4ismantle the impeller$ and remo e the wear ring! 1:! Bemo e the gland pac#ing and disregard+ replacing it on rebuild! Bemember to cut ends of pac#ing at ;/C and stagger <oints when repac#ing gland!

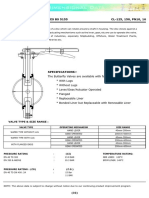

Centrifugal Pumps Fitted on Board (Images Taken from National Center for ppropriate Tec!nolog" #e$site%

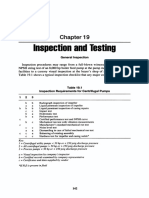

Inspection Procedure for Pump and Motor

Pump 1! 'mpeller$ pump shaft and internal olute/casing can now be inspected for erosion$ pitting and wear! 2! 'f re*uired rectify pitting or erosion in the impeller and casing with two D part alloy epo(y putty! 3See my article in the Beference section9 :! Chec# main dri e shaft bearings and thrust bearings for wear and replace if re*uired! ;! Chec# wear ring clearance using feeler gauges+ in my day at sea it was general practice is to replace with new rings at ma<or o erhaul! /! Chec# impeller / shaft #ey and #eyways for damage and undue wear$ ?nscrew impeller shaft securing nut and chec# threads are in satisfactory condition+ retighten to manufacturers tor*ue settings! >! Ei e all parts a good clean remo ing any dirt/ medium residue before re7 assembly using new parts as re*uired! @! Fnter date of o erhaul and parts renewed in the pump maintenance record card! &rive Motor 1! Erip motor dri e shaft /coupling firmly and chec# for e(cess a(ial and longitudinal mo ement! Botate shaft at speed by hand$ allowing it to run to a stop whilst listening for e(cess noise from bearings! %ny doubt on either counts$ the bearings should be replaced! 2! 8egger chec# motor windings to ensure no dampness is present and windings are in good condition! %ny suspect readings indicate a full motor strip to chec# condition of rotor and stator!

:! 'f these chec#s are satisfactory$ grease bearings as re*uired! Some bearings are now sealed for life and will not re*uire greasing!

Procedure to 'tart t!e Pump

1! ?nloc# and remo e chains from inlet/outlet al e wheels and open both al es full! 2! 6pen air coc# and e(pel air from line and pump while chec#ing for any lea#s :! "urn the shaft coupling and ensure shaft is free to rotate! ;! Beconnect motor! /! Bemo e danger notices from pump power supplies and reinstate brea#ers! >! Start and record current drawn by the motor under starting and running conditions! Chec# and record the discharge pressure!

You might also like

- Lesson Centrifugal PumpDocument14 pagesLesson Centrifugal Pumpmister pogiNo ratings yet

- Bevel Gear ManualDocument8 pagesBevel Gear ManualPiort ZelaskiNo ratings yet

- Operation Manual Horizontal Split CaseDocument24 pagesOperation Manual Horizontal Split CaseadiNo ratings yet

- DB 40-20 PDFDocument22 pagesDB 40-20 PDFMahendra AsawaleNo ratings yet

- VWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Document20 pagesVWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Kaushik ChakrabortyNo ratings yet

- Gear Drive Manual No. 702Document38 pagesGear Drive Manual No. 702MaintenanceNo ratings yet

- Centrifugal Pump ManualDocument16 pagesCentrifugal Pump Manualadam shaneNo ratings yet

- Generator Operation ManualDocument73 pagesGenerator Operation ManualFerdinand DescalzoNo ratings yet

- Process Pumps For Chemical and Industrial Application: Standards: Iso 2858 / Din en 22858Document22 pagesProcess Pumps For Chemical and Industrial Application: Standards: Iso 2858 / Din en 22858kztro066No ratings yet

- H.V Rectifier Device Use ManualDocument50 pagesH.V Rectifier Device Use Manualatulbrmhnkr100% (1)

- Type DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar PumpDocument43 pagesType DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar Pumpkprasad_56900No ratings yet

- H2 SystemDocument76 pagesH2 Systemkarma yasser100% (1)

- BPCL CYLINDER MANUFACTURINGDocument34 pagesBPCL CYLINDER MANUFACTURINGVishalVaishNo ratings yet

- Research - Kirloskar Fire Fighting Pumps PDFDocument8 pagesResearch - Kirloskar Fire Fighting Pumps PDFYogeshNo ratings yet

- Induction Motor Starting MethodsDocument4 pagesInduction Motor Starting Methodsعلي عايد عبدالشهيدNo ratings yet

- Vertical Turbine Canal Recirculation & CT Make-Up Water PumpDocument37 pagesVertical Turbine Canal Recirculation & CT Make-Up Water PumpSanto ENo ratings yet

- EOT crane maintenance guideDocument16 pagesEOT crane maintenance guideMohd Haidi100% (1)

- Chapter I General Information of Pump UnitDocument42 pagesChapter I General Information of Pump UnitRahmat Budi HartantoNo ratings yet

- KSB Centrifugal PumpsDocument12 pagesKSB Centrifugal Pumpswoodywheel100% (1)

- Technical Manual DBDocument27 pagesTechnical Manual DBRentu Philipose100% (2)

- Elecon Scoop Coupling Installation Maintenance ManualDocument21 pagesElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianNo ratings yet

- Lesson Globe Valves: Sub-ObjectiveDocument9 pagesLesson Globe Valves: Sub-Objectivemister pogiNo ratings yet

- Maintenance Manual VCP Upto 80mmDocument16 pagesMaintenance Manual VCP Upto 80mmKaushik Chakraborty0% (1)

- Maintenance BFPDocument28 pagesMaintenance BFPYulianto Kartono100% (1)

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- ESPDocument5 pagesESPKuntal SatpathiNo ratings yet

- Pumps Training Course OverviewDocument60 pagesPumps Training Course OverviewAuthers Raj SNo ratings yet

- Service & Maintenance Manual High Speed Separator: Product No. 881039-12-01/1 Book No. 568854-02 Rev. 2Document133 pagesService & Maintenance Manual High Speed Separator: Product No. 881039-12-01/1 Book No. 568854-02 Rev. 2امير الموسوي100% (1)

- Boiler Inspection Report TemplateDocument7 pagesBoiler Inspection Report TemplateBudi SantonyNo ratings yet

- Kirloskar Brothers LimitedDocument36 pagesKirloskar Brothers Limitedgopalakrishnannrm1202No ratings yet

- MAintenance Manual Progressive Cavity Pumps 1Document24 pagesMAintenance Manual Progressive Cavity Pumps 1mtfrvtNo ratings yet

- Emergency Lube Oil PumpDocument28 pagesEmergency Lube Oil Pumpdac3524No ratings yet

- Submersible Pump Moter Core Design PDFDocument7 pagesSubmersible Pump Moter Core Design PDFIjabiNo ratings yet

- Turbine Oil Flushing ProcedureDocument25 pagesTurbine Oil Flushing Proceduresrigirisetty208No ratings yet

- NEMA Motor Manual Section on AccessoriesDocument16 pagesNEMA Motor Manual Section on AccessoriesDelfinshNo ratings yet

- IK-525-DM3 IK-525-DM4 Dual Media Air Heater CleanersDocument135 pagesIK-525-DM3 IK-525-DM4 Dual Media Air Heater CleanersPhạm Hưng100% (1)

- EGB-1P and EGB-2P Governor - ActuatorDocument68 pagesEGB-1P and EGB-2P Governor - ActuatorMiguel SoteloNo ratings yet

- Pump MaintenanceDocument83 pagesPump MaintenanceSiva Kumar Tutika100% (3)

- Alignment of Steam Turbine Generator CouplingDocument5 pagesAlignment of Steam Turbine Generator CouplinganasNo ratings yet

- Rope Winches and Gearboxes PDFDocument20 pagesRope Winches and Gearboxes PDFannccknarime50% (2)

- Cooling Tower GearboxDocument12 pagesCooling Tower GearboxKaushik FalduNo ratings yet

- Overhauling of Centrifugal PumpDocument4 pagesOverhauling of Centrifugal Pumpanil thakur100% (1)

- Turbine ErectionDocument49 pagesTurbine Erectionazeemmet9924No ratings yet

- Mechanical Technician Resume - 3+ Yrs ExperienceDocument3 pagesMechanical Technician Resume - 3+ Yrs Experiencemohammad QutubuddinNo ratings yet

- Turbair Blower (Type RC)Document2 pagesTurbair Blower (Type RC)Amir AbbaszadehNo ratings yet

- Hydraulic Actuator SpecificationsDocument3 pagesHydraulic Actuator SpecificationsRizky RamadhaniNo ratings yet

- Pump inspection and testing proceduresDocument4 pagesPump inspection and testing proceduresAmal KaNo ratings yet

- Vertical Pumps Repairs Standards VPRSDocument44 pagesVertical Pumps Repairs Standards VPRSAlvialvarez100% (1)

- O&M ManualDocument20 pagesO&M ManualUmair AhmedNo ratings yet

- Compact Range Installation ManualDocument79 pagesCompact Range Installation ManualIgor Balic0% (1)

- TG Lube Oil FlushingDocument3 pagesTG Lube Oil FlushingS V NAGESHNo ratings yet

- Install, operate and maintain VCP pumpsDocument21 pagesInstall, operate and maintain VCP pumpsKaushik ChakrabortyNo ratings yet

- Chemical Dosing SystemsDocument6 pagesChemical Dosing Systemsnaveenbaskaran1989100% (2)

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- 1.06-Mechanical Seal Installation and Maintenance Instructions - IOMDocument16 pages1.06-Mechanical Seal Installation and Maintenance Instructions - IOMcavillalobosb8167No ratings yet

- Fabrication of Hydraulic Pipie Bending MachineDocument50 pagesFabrication of Hydraulic Pipie Bending MachineElakkiya Karthic100% (4)

- Maintenance and Repair of Centrifugal PumpsDocument4 pagesMaintenance and Repair of Centrifugal PumpsKavishNo ratings yet

- Maintain Centrifugal PumpsDocument3 pagesMaintain Centrifugal PumpsRohan NaikNo ratings yet

- What Is A Centrifugal Pump?Document3 pagesWhat Is A Centrifugal Pump?ravi_92No ratings yet

- Phase II Steering Gear Q&ADocument11 pagesPhase II Steering Gear Q&ANithin Varghese100% (2)

- Endorsement DetailsDocument5 pagesEndorsement Detailsaserf251No ratings yet

- Adv PlansssDocument164 pagesAdv Planssspuri π badshahNo ratings yet

- Bash Beginners GuideDocument173 pagesBash Beginners GuideCarin IoanaNo ratings yet

- 20 Possible Causes For Reduction in Ship's Auxiliary Engine PerformanceDocument4 pages20 Possible Causes For Reduction in Ship's Auxiliary Engine Performanceaserf251No ratings yet

- Kali Linux Revealed 1st EditionDocument5 pagesKali Linux Revealed 1st Editionaserf251No ratings yet

- 10 Ways To Ensure Safe Slow Steaming Operation of Old Marine Propulsion EnginesDocument4 pages10 Ways To Ensure Safe Slow Steaming Operation of Old Marine Propulsion Enginesaserf251No ratings yet

- Kali LinuxxxxxxxxxxxxRevealed 1st EditionDocument341 pagesKali LinuxxxxxxxxxxxxRevealed 1st EditionWalid UmarNo ratings yet

- Linuxfun PDFDocument365 pagesLinuxfun PDFrmarques_30164No ratings yet

- PC Advisor - November 2015Document148 pagesPC Advisor - November 2015aserf251100% (1)

- Steam Turbine Rotor Vibration Failures - Causes and Solutions - POWER Magazine 1Document11 pagesSteam Turbine Rotor Vibration Failures - Causes and Solutions - POWER Magazine 1aserf251No ratings yet

- 10 Harmful Effects of Impure Air On Ship's MachineryDocument5 pages10 Harmful Effects of Impure Air On Ship's Machineryaserf251No ratings yet

- 10 Situations When Ship's Generator Must Be Stopped ImmediatelyDocument7 pages10 Situations When Ship's Generator Must Be Stopped Immediatelyaserf251No ratings yet

- 8 Common Problems of Ship's Incinerator Mariners Should KnowDocument6 pages8 Common Problems of Ship's Incinerator Mariners Should Knowaserf251No ratings yet

- 8 Things Marine Engineers Must Know About Starting Air System On ShipDocument5 pages8 Things Marine Engineers Must Know About Starting Air System On Shipaserf251No ratings yet

- IMO Inert Gas SystemsDocument82 pagesIMO Inert Gas SystemsManuel100% (3)

- Water Treatment Handbook UNITORDocument46 pagesWater Treatment Handbook UNITORplatastur100% (26)

- 2002 FWG and Heat Recovery SystemDocument7 pages2002 FWG and Heat Recovery Systemaserf251No ratings yet

- Introduction To Practical Marine EngineeringDocument7 pagesIntroduction To Practical Marine Engineeringndlongnd0% (6)

- PlanetSim RatesDocument10 pagesPlanetSim Ratesaserf251No ratings yet

- Abb CountriesDocument3 pagesAbb Countriesaserf251No ratings yet

- Prot Warrior Skills v1.09Document8 pagesProt Warrior Skills v1.09aserf251No ratings yet

- PlanetSim GPRS UpdatedDocument8 pagesPlanetSim GPRS Updatedaserf251No ratings yet

- Site Visit Risk Assessment FormDocument3 pagesSite Visit Risk Assessment FormAmanuelGirmaNo ratings yet

- August 03 2017 Recalls Mls (Ascpi)Document6 pagesAugust 03 2017 Recalls Mls (Ascpi)Joanna Carel Lopez100% (3)

- Exercises 6 Workshops 9001 - WBP1Document1 pageExercises 6 Workshops 9001 - WBP1rameshqcNo ratings yet

- Hindustan Motors Case StudyDocument50 pagesHindustan Motors Case Studyashitshekhar100% (4)

- Sarvali On DigbalaDocument14 pagesSarvali On DigbalapiyushNo ratings yet

- AATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsDocument3 pagesAATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsAdrian CNo ratings yet

- Exp 8 - GPG - D12B - 74 PDFDocument4 pagesExp 8 - GPG - D12B - 74 PDFPRATIKSHA WADIBHASMENo ratings yet

- ITU SURVEY ON RADIO SPECTRUM MANAGEMENT 17 01 07 Final PDFDocument280 pagesITU SURVEY ON RADIO SPECTRUM MANAGEMENT 17 01 07 Final PDFMohamed AliNo ratings yet

- System: Boehringer Mannheim/Hitachi AnalysisDocument20 pagesSystem: Boehringer Mannheim/Hitachi Analysismaran.suguNo ratings yet

- DLP in Health 4Document15 pagesDLP in Health 4Nina Claire Bustamante100% (1)

- Us Virgin Island WWWWDocument166 pagesUs Virgin Island WWWWErickvannNo ratings yet

- Log File Records Startup Sequence and Rendering CallsDocument334 pagesLog File Records Startup Sequence and Rendering CallsKossay BelkhammarNo ratings yet

- Pita Cyrel R. Activity 7Document5 pagesPita Cyrel R. Activity 7Lucky Lynn AbreraNo ratings yet

- India: Kerala Sustainable Urban Development Project (KSUDP)Document28 pagesIndia: Kerala Sustainable Urban Development Project (KSUDP)ADBGADNo ratings yet

- Memo Roll Out Workplace and Monitoring Apps Monitoring Apps 1Document6 pagesMemo Roll Out Workplace and Monitoring Apps Monitoring Apps 1MigaeaNo ratings yet

- Trading As A BusinessDocument169 pagesTrading As A Businesspetefader100% (1)

- Annamalai International Journal of Business Studies and Research AijbsrDocument2 pagesAnnamalai International Journal of Business Studies and Research AijbsrNisha NishaNo ratings yet

- STAT455 Assignment 1 - Part ADocument2 pagesSTAT455 Assignment 1 - Part AAndyNo ratings yet

- C6 RS6 Engine Wiring DiagramsDocument30 pagesC6 RS6 Engine Wiring DiagramsArtur Arturowski100% (3)

- Ujian Madrasah Kelas VIDocument6 pagesUjian Madrasah Kelas VIrahniez faurizkaNo ratings yet

- CAS-GEC04 Module11 Food-SecurityDocument6 pagesCAS-GEC04 Module11 Food-SecurityPermalino Borja Rose AnneNo ratings yet

- Chapter 3 of David CrystalDocument3 pagesChapter 3 of David CrystalKritika RamchurnNo ratings yet

- Break Even AnalysisDocument4 pagesBreak Even Analysiscyper zoonNo ratings yet

- 5511Document29 pages5511Ckaal74No ratings yet

- Logic and Set Theory PropositionDocument3 pagesLogic and Set Theory PropositionVince OjedaNo ratings yet

- MODULE+4+ +Continuous+Probability+Distributions+2022+Document41 pagesMODULE+4+ +Continuous+Probability+Distributions+2022+Hemis ResdNo ratings yet

- Game Rules PDFDocument12 pagesGame Rules PDFEric WaddellNo ratings yet

- Write UpDocument5 pagesWrite Upmourad baNo ratings yet

- House Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Document4 pagesHouse Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Raphael Eyitayor TyNo ratings yet

- Bulletproof Seduction: How to Be the Man That Women Really WantFrom EverandBulletproof Seduction: How to Be the Man That Women Really WantRating: 4.5 out of 5 stars4.5/5 (168)

- Fabric Manipulation: 150 Creative Sewing TechniquesFrom EverandFabric Manipulation: 150 Creative Sewing TechniquesRating: 4.5 out of 5 stars4.5/5 (13)

- DIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!From EverandDIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Rating: 3.5 out of 5 stars3.5/5 (7)

- Crystal Basics: The Energetic, Healing, and Spiritual Power of 200 GemstonesFrom EverandCrystal Basics: The Energetic, Healing, and Spiritual Power of 200 GemstonesRating: 5 out of 5 stars5/5 (3)

- Knitting for Anarchists: The What, Why and How of KnittingFrom EverandKnitting for Anarchists: The What, Why and How of KnittingRating: 4 out of 5 stars4/5 (51)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- The Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewFrom EverandThe Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewRating: 4.5 out of 5 stars4.5/5 (25)

- Famous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsFrom EverandFamous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsRating: 4 out of 5 stars4/5 (4)

- Liberated Threads: Black Women, Style, and the Global Politics of SoulFrom EverandLiberated Threads: Black Women, Style, and the Global Politics of SoulRating: 4 out of 5 stars4/5 (1)

- How to Dress: Secret styling tips from a fashion insiderFrom EverandHow to Dress: Secret styling tips from a fashion insiderRating: 4 out of 5 stars4/5 (1)

- Playful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsFrom EverandPlayful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsRating: 3.5 out of 5 stars3.5/5 (3)

- How Patterns Work: The Fundamental Principles of Pattern Making and Sewing in Fashion DesignFrom EverandHow Patterns Work: The Fundamental Principles of Pattern Making and Sewing in Fashion DesignRating: 4 out of 5 stars4/5 (17)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsFrom EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsRating: 4.5 out of 5 stars4.5/5 (4)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- My Crocheted Closet: 22 Styles for Every Day of the WeekFrom EverandMy Crocheted Closet: 22 Styles for Every Day of the WeekRating: 4.5 out of 5 stars4.5/5 (20)

- Metric Pattern Cutting for Women's WearFrom EverandMetric Pattern Cutting for Women's WearRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Necklines & Collars: A Directory of Design Details and TechniquesFrom EverandNecklines & Collars: A Directory of Design Details and TechniquesRating: 3.5 out of 5 stars3.5/5 (3)

- Creative Fashion Drawing: A complete guide to design and illustration stylesFrom EverandCreative Fashion Drawing: A complete guide to design and illustration stylesRating: 4 out of 5 stars4/5 (17)