Professional Documents

Culture Documents

VVVF Setup

Uploaded by

BAAAKOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VVVF Setup

Uploaded by

BAAAKCopyright:

Available Formats

AUTOMATIC DOORS FOR LIFTS

TECHNICAL MANUAL AND ELECTRONICAL MODULE REGULATION VVVF-4+

10

CABIN DOORS

AUTOMATIC DOORS FOR LIFTS

PROGRAMMING

1 2 3 4

O F F

DESCRIPTION OF SWITCHES The unit may be programmed using the DIL switches on the front of the unit. If any change is made to any of the above switch selections, the Mains Supply to the VVVF-4+ unit MUST be switched OFF and ON again to read the new programming. The switches functions are: 1 & 2 Inputs. 1.ON: 1 Input.

O N

The door control unit will be controlled by a single input. Any voltage between 12 to 250 volts AC or DC applied between terminals 8 & 10 will close the doors. Without input active the door opens. Open input is not used. OFF: 2 Inputs. The door control module will be controlled by two independent inputs. Any voltage between 12 to 250 volts AC or DC applied between terminals 8 & 10 will cause the doors to close. And between terminals 12 & 10 will cause the doors to open. In the absence of a signal, the doors will remain static. If both inputs are applied then the open signal has priority.

1 Inputs:

2 Inputs:

Without voltage 0 V OPEN With voltage 12...250 V, CLOSE

Close

Close

Voltage 12...250V, CLOSE Voltage 12...250V, OPEN

Open

2.- Automatic / Semiautomatic. ON: Automatic.

Open

Operators with skate (automatic landing). In this case a special movement is made for loocking and unlocking the skate OFF: Semiautomatic. Operators without skate (Semiautomatic landing door). 3.- Rotation sense. ON: The control unit is expecting to control left hand or centre opening doors. OFF: The control unit is expecting to control right hand opening doors. The sense is dened from the outside of the car, refering to the direction taken when the door is opening. 4.- Master and Slave. ON: Master. The door control unit will execute instructions directly. Example: operation of the Photoelectric Detector will cause the doors to re-open immediately under control of the door control unit. OFF: Slave. There is no automatic reopen movements. The doors will only react to instruction given by the main lift controller by the inputs. Example: operation of the Safety Edge Detector will cause the door operato module to give a signal to the main lift controller via the PHOTOCELL (36, 37, 38) output. The main lift controller then must remove the close signal and put the open signal.

CABIN DOORS 11

AUTOMATIC DOORS FOR LIFTS

INPUTS

POWER INPUTS 220-250 VOLTS SINGLE PHASE AC (5, 6, 7) The circuit has been designed to operate on a mains supply of 230 Volts AC (+10%,-15%, 50 or 60 Hz). The unit will consume approx 1 Amp from the supply. It is important that the Door Operator Module has a GOOD EARTH CONNECTION.

N L

7 6 5

230 V

Fig. 3. Power input connections. (5, 6, 7).

CONTROL INPUTS (8, 9, 10, 11, 12) The circuit can work with external voltage inputs or by means a volt free contact input. EXTERNAL VOLTAGE INPUT: VOLT FREE CONTACT INPUT:

Open

Close

Voltage 12...250 V, OPEN Voltage 12...250 V, CLOSE

Open 12

0 V 11 Com 10 12 V 9 Close 8

OPEN

CLOSE

12.- Opening Signal. Is a signal that orders the door to open. The tension to apply could be from 12 to 250 V., with an external supply between this input and common. (10) 11.- 0 Volts. Is the opposite pole to 12V, in the case of using internal tension should be connected by a common input. 10.- Common. Is the reference used for the two inputs. 9.12 Volt. Isolated 12 Volts output available to control the door via a volt free contact. Features are: a) This supply must only be used for this purpose. b) This contact must be isolated from any other power supply. Close signal. This signal is used for ordering to close the door.

8.-

SERIAL PORT (13, 14, 15, 16) The serial port is used to connect with external devices like the diagnostic console, interfaces and future expansion devices. Operating speed 1.200 Baud, current loop.

V- 16

Rx 15

Tx 14

V+ 13

Fig. 5. Serial Port connection. (13, 14, 15, 16).

12

CABIN DOORS

AUTOMATIC DOORS FOR LIFTS

INPUTS

PHOTOCELL (17, 18, 19, 20) One of the most relevant characteristics of this control is the optional incorporation of a photocell. It is composed by a emitter and receptor infrared.

(+) White

PHOTOCELL

(-) Black (-) Black (+) White

Green

Receiver

Yellow Emitter

Fig. 6. Connection of the photoelectric detector. (17, 18, 19, 20).

OTHER INPUTS (26, 21, 25, 23)

FLOOR LEVEL RE-OPEN SLOW CLOSE

+ 12 V COM

26 21 25 23

Fig. 8. Connection of the other inputs. (26, 21, 25, 23).

26. Landing signal. This input is for connecting the external emergency current supplier that allows the opening manouvre in the case of power failure by a battery of 12V, able to give power during 15 seconds for a passengers rescue. 21. Reopening. This signal is for installing the cabin door swich or an external barrier. This signal has priority to the closing signal. Use contacts free on tension. For activating close one contact with the main supply +12V. (23).

25. Slow Closing. This input orders to the operator to close the door slowly regardless of the barrier and control signs. Is created for working with detection of re centres.

23. + 12 V. COM This terminal is used for giving with an isolated contact a reopening order or a slow closing. Always use contacts free of tension and usually open.

CABIN DOORS

13

AUTOMATIC DOORS FOR LIFTS

INPUTS

OUTPUT RELAYS AND LED INDICATORS (from 30 to 41) Output relays have been provided to give continuous information to the main lift controller concerning the status of the doors. One 2 Amp 150 Volts volt free change over contact is provided on each relay that may be used by the main lift controller to pilot such information as doors fully opened, doors fully closed, Photoelectric detection, obstruction in the doorway and door control O.K.. Opened. 30. Led indicator and relay activated when the doors are fully open. Closed.

31. 32.

OPENED

Led indicator and relay activated when the doors are fully closed and locked. Photocell. Led indicator and relay activated when the photocell or the reopening input is operated. Obstruction. Led indicator and relay activated when an obstacle is detected that stops the doors from closing. The signal will reset when the doors reach the opened or closed position. Status.

33. 34. 35.

CLOSED

PHOTOCELL

OBSTRUCTION

Blinking led indicating proper working conditions. TEST PUSHBUTTON (50) Operation of the Test pushbutton will cause a door open or close cycle. AUTOADJUSTMENT PUSHBUTTON (51) The Autoadjustment pushbutton is used to set up the doors. The doors will do 3 complete movements at rst the doors will close completly, then the doors will open slowly counting the pulses from the encoder built into the drive motor until they reach the open mechanical stop, and after a short delay the doors will close. From the information gained the microprocessor will calculate the acceleration and deceleration ramps and the bracking torque required to give the optimum control of the doors. Once the autoadjustment has been completed the parameter are stored in non- volatile EEPROM and will be used to calculate the optimum performance. The doors will open slowly for the rst operation after power has been removed from the door control unit. Autoadjustment only needs to be used when setting the initial parameters or when changes such as connecting or removing the Fermator Safety Detector are made. CLOSE SPEED (52) The door closing speed can be independently adjusted from 150 mm/s upto 600 mm/s. OPEN SPEED (53) The door opening speed can be independently adjusted from 200 mm/s upto 1.000 mm/s. SAFETY (54) This potentiometer is used to set the closing pressure onto an obstacle in the doorway. The closing pressure can be set between 40 and 150 Nw. ENCODER (55) An integral quadrature pulse encoder is connected to this input. The purpose of the encoder, which is situated inside the motor, is to inform the control of the exact position and speed of doors. MOTOR (56) Output to the 3 phase motor varying the voltage and frequency to control speed and torque. 14 CABIN DOORS

AUTOMATIC DOORS FOR LIFTS

INPUTS

ON / OFF SWITCH (57) Disconnects the unit from the 230 Volts AC mains supply. Caution: When the supply is switched off, capacitors in the control system will remain charged for a short time. Allow 60 seconds before handling the Control Card or Motor.

PROGRAMMING EXAMPLES

MASTER: 1 INPUT Conguration

O N

1 2 3 4

O F F

1. 2. 3. 4.

ON: 1 Input. Depends on type of door. Depends on type of door. ON: Master. Closes the doors with voltage between terminals 8 & 10. Open the doors when the voltage between terminals 8 & 10 is removed. Photocell. Doors will reopen if the photocell beam is broken. Reopening. Doors will not close if this signal is active. Obstacle. Door will open if an obstacle is detected by the motor ceasing to rotate. Slow Closing. Closes regardless of the state of the photocell. Reopening. Obstacle. Slow Closing. Photocell. Close. Close.

Inputs 1. (8) 2. (17...20) 3. (21-23) 4. 5. (25-23) Priorities 1.(21-23) 2. 3.(25-23) 4.(17...20) 5.(8)

SLAVE: 2 INPUTS

O N

1 2 3 4

O F F

Conguration 1. OFF: 2 Inputs. 2. Depends on type door. 3. Depends on type door. 4. OFF: Eslave. Inputs 1. (8) Closes the doors with voltage between terminals 8 & 10. 2. (12) Open. Open the doors with voltage between terminals 12 & 10. Pryority to close. 3. (17...20) Photocell. Does not re-open the doors when activated but provides signal to main controller via the Photocell relay. 4. (21-23) Reopening. Doors will not close if this signal is active 5. Obstacle. Doors will not re-open if an obstacle is detected by the motor ceasing to rotate. 6. (25-23) Slow Closing. Closes regardless of the state of the photocell. Open. Reopening. Slow Closing. Close. 15 Close.

Priorities 1. (12) 2. (21-23) 3. (25-23) 4. (8) CABIN DOORS

AUTOMATIC DOORS FOR LIFTS

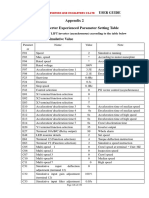

CHARACTERISTICS PAGE

POWER SUPPLY: MOTOR: Asynchronous three phase: Voltage supply: Power: Thermic class: Nominal speed: Impedance: Voltage: Contacts: R. contact: Swich time: Output current: Voltage: Open Speed: Close speed: Maximum acceleration: Safety force: Maintenance torque (Opened Door): 6 poles. 250 V. 250 W. B-130C. 900 RPM. 20 K. 12...230 V AC / DC. Switched. 50 mW. 5 ms. Mximum: 5A 250 V 200...1000 150...600 800...1500 80 N/ cm. mm/s. mm/s. mm/s. AC voltage range: Frequency supply: Minimum supply: Open door power: Nominal power: Maximum power: Carrier frequency: Frequency range: Voltage range: Maximum output current: Positional control: 230v +10%, -15%. AC/DC 50...60 Hz. 70 mA, 13W. 0,6 A 80W. 0,93 A 140W. 1,38 A 190W. 16 KHz. 0,5...100 Hz. 40...200 V AC III 4A Quadrature encoder.

INVERTER:

INPUTS:

OUTPUTS:

PERFORMANCE:

40...150 N adjustable.

16

CABIN DOORS

AUTOMATIC DOORS FOR LIFTS

EMERGENCY SUPPLIER*

CHARACTERISTICS: 1 - Control by microprocessor. 2 - Verication of the battery charge level. 3 - Output power Until 1.5 A / 110 Volts . 4 - Complete control of the rescue process. * NOTE: This system is only suitable for VVVF4+ circuits.

CABIN DOORS

17

AUTOMATIC DOORS FOR LIFTS

OPERATION

This equipment has a bypass relay that switches the supply for the VVVF control from the mains supply or from the internal converter if there is a mains power failure.

INSTALLATION

1 - It will be installed close to the VVVF, connected in the input side of the VVVF. 2 - The input supply to the VVVF will be connected to OUTPUT terminals 5/6/7 of the emergency supplier instead of being directly connected to the mains supply. 3 - The emergency supplier should be connected to a 230V AC mains supply on terminals 1/2/3 marked as SUPPLY 230V AC. 4 - A 12V rechargeable battery should be connected to terminals 28/29 marked BATTERY, special care should be given to the polarity (+29 and 28- ) when connecting. 5 - To enable the doors to open correctly when on emergency supply a volt free contact should be provided to the VVVF box on terminals 66 and 67. This contact should be normally closed only at oor level and can be operational on normal and when on emergency supply. As this input is only operational during the mains power failure, no synchronization with the mains supply is needed. 6 - The contacts 23(+12V) and the 6 (GND) in the emergency supplier have to be connected to the output terminals 23(+12V COM) and 6(GND) respectively in the VVVF. 7 - The terminal 26 (FLOOR) of the emergency supplier has to be connected to the terminal 26 input in the VVVF4+ (FLOOR) to inform it about the mains supply status.

If the polarity is reversed the 20 A fuse will blow and damage to the electronic board could occur. The battery should have a minimum capacity of 2 Ah. Special care has to be taken with the cable and battery connector. The wire connecting the battery to the terminals 28/29 must be as short as possible and terminated properly, because the current can reach a peak level of 15A. 18 CABIN DOORS

AUTOMATIC DOORS FOR LIFTS

LED STATUS

Once the system is installed, the ON led shows the system status: 1 - Always ON: means that the battery is not charged. The charge process of the battery can last about 48 hours, so after this time the Normal status should be achieved. If not, the battery is drained and not functioning. 2 - Blinking: means Normal status. The system is Ok and the battery is charged. 3 - Blinking every 15s: means that there is no 230V AC mains supply and the unit is waiting for the Floor signal to commence the emergency open process.

BATTERY CONTROL

As long as the emergency supplier is connected to the mains supply and with a battery connected, it charges the battery until 100% charge is achieved. When the charge level is lower than 70%, the charge process starts again. If there is a mains power failure, the system waits for the Floor signal to open the door. This open cycle lasts for a xed time after which the system starts a low power status waiting for the mains supply to be reinstated.

SCHEME

VVVF Circuit

MOTOR 56.U MOTOR 56.V MOTOR 56.W MOTOR

55.1 55.2 55.3 55.4

Emergency Supplier

N GND F 5 6 7 12 11 10 9 8 26 21 25 23 20 19 18 17 16 RX 14 13 7 6 L1' 5 GND L2' 23 26 +12V COM PISO / FLOOR

ON BAT

Mains Supply

230V AC

CON3 1 1 2 3 66 67 29 28 2 1 2 3

ALIMENTACION MAINS SUPPLY ENTRADAS INPUTS

L2 GND L1 RELLANO PISO FLOOR BAT+ BAT-

GND FASE1 FASE2 +12V

ENCODER

ABRIR/OPEN 0 Volt COM +12V CERRAR/CLOSE

Rellano / Floor

ENTRADAS PRIORITARIAS PISO/FLOOR PRIORITY INPUTS REOPEN FOTOCELULA PHOTOCELL PUERTO SERIE SERIAL PORT

BT1

SLOWCLOSE +12V COM REC GND GND EMI VRX TX V+

Bateria 12V. 2Ah

CABIN DOORS

19

You might also like

- VF7 Electronic Module InstructionsDocument25 pagesVF7 Electronic Module InstructionsEdgar ZamoraNo ratings yet

- TECHNICAL MANUAL FOR VVVF-4+ ELECTRONICAL MODULE REGULATIONDocument7 pagesTECHNICAL MANUAL FOR VVVF-4+ ELECTRONICAL MODULE REGULATIONMohammed Qaid AlathwaryNo ratings yet

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Operating Instruction ZETADYN 2CF2SY PDFDocument121 pagesOperating Instruction ZETADYN 2CF2SY PDForioldelgado100% (3)

- ENG LiSA20-Fehlermeldungen R111Document36 pagesENG LiSA20-Fehlermeldungen R111Adarsh Manoharan100% (1)

- Operation Manual: Rcf-1 Door Operator ControllerDocument31 pagesOperation Manual: Rcf-1 Door Operator ControllerKen LeeNo ratings yet

- O1 Prisma Fox Door Drive PDFDocument11 pagesO1 Prisma Fox Door Drive PDFfirasalthiyabyNo ratings yet

- ALGI BA-AZ 2 (E) - Elevator Control Blocks and Mounted ValvesDocument41 pagesALGI BA-AZ 2 (E) - Elevator Control Blocks and Mounted ValvesJonathan Bryant78% (9)

- F21aau4 8 PDFDocument34 pagesF21aau4 8 PDFjhfbty100% (1)

- SG Frenic Lift en 1 8 0Document42 pagesSG Frenic Lift en 1 8 0محمدحمادNo ratings yet

- Lisa-Operation Manual: Installation and Operation Instructions (Part B)Document41 pagesLisa-Operation Manual: Installation and Operation Instructions (Part B)majdNo ratings yet

- ILC2 Installation and Programming Guide (9 StepsDocument1 pageILC2 Installation and Programming Guide (9 StepsJuanNo ratings yet

- Group Control System MPK 400 DescriptionDocument34 pagesGroup Control System MPK 400 DescriptionElevator & Escalator EngineeringNo ratings yet

- Fuji Starting Guide G11S-LE2 - Lift - 7Document54 pagesFuji Starting Guide G11S-LE2 - Lift - 7Nguyen Anh Tu100% (3)

- Arem Mobile User Manual.V101.enDocument8 pagesArem Mobile User Manual.V101.enmicrocherietNo ratings yet

- Delcon - 300 I 9010270 e 04Document47 pagesDelcon - 300 I 9010270 e 04sd23No ratings yet

- ADL300 SYN FPRev0.603052016 PDFDocument144 pagesADL300 SYN FPRev0.603052016 PDFEvandro PavesiNo ratings yet

- User Guide NICE900 Series Integrated Door Operator ControllerDocument99 pagesUser Guide NICE900 Series Integrated Door Operator ControllerCoil98No ratings yet

- Wittur d27gmgb Eco Operating ManualDocument28 pagesWittur d27gmgb Eco Operating ManualCarlos RamosNo ratings yet

- ICT Bill Acceptor Test Tool Diagnostic SoftwareDocument7 pagesICT Bill Acceptor Test Tool Diagnostic SoftwareismifaizulNo ratings yet

- Instruction Manual for OPC-LM1-PR Encoder Interface CardDocument14 pagesInstruction Manual for OPC-LM1-PR Encoder Interface CardMahran Mastouri100% (1)

- AS3 Manual E PDFDocument23 pagesAS3 Manual E PDFMinh Luong100% (3)

- Right choice for maximum yieldDocument223 pagesRight choice for maximum yieldRobert Mohovic100% (1)

- Autodialler PTU 8028 V2 and PTU 8028 D06 Installation ManualDocument19 pagesAutodialler PTU 8028 V2 and PTU 8028 D06 Installation ManualderbalijalelNo ratings yet

- ARKEL Catalogue enDocument56 pagesARKEL Catalogue enmkyoda100% (1)

- T10019EN 5.0 QuickstartDocument12 pagesT10019EN 5.0 Quickstartalex1807100% (1)

- Irc Regulation and Control Instructions: Control System Cmc-3 SeriesDocument10 pagesIrc Regulation and Control Instructions: Control System Cmc-3 SeriesAshraful Shohag100% (1)

- MACPUARSA - FAULT CODES OF MICROBASIC CONTROLLER AS-21.99.900-MFS000005 - en - .1 - AS-21.99.900-MFS000005Document10 pagesMACPUARSA - FAULT CODES OF MICROBASIC CONTROLLER AS-21.99.900-MFS000005 - en - .1 - AS-21.99.900-MFS000005Christophe TaglioneNo ratings yet

- CT Unidrive SP Elevator Solution Software User Guide - Issue 3 PDFDocument222 pagesCT Unidrive SP Elevator Solution Software User Guide - Issue 3 PDFjayb1984No ratings yet

- PLANODocument1 pagePLANOJavier MartínezNo ratings yet

- User Manual. Automatic Horizontal Sliding Car Door. Component: VF7 Relay Electronic Module. V7.01.06-00Document32 pagesUser Manual. Automatic Horizontal Sliding Car Door. Component: VF7 Relay Electronic Module. V7.01.06-00Aidolan UlrichNo ratings yet

- 《NICE3000new电梯一体化控制器用户手册》英文19010735 A00Document367 pages《NICE3000new电梯一体化控制器用户手册》英文19010735 A00Иван АндреевNo ratings yet

- 3300 AP ReportDocument14 pages3300 AP ReportWiratama PutraNo ratings yet

- Mikronik SX Opman V2.00 EngDocument69 pagesMikronik SX Opman V2.00 EngKhaled ZakariaNo ratings yet

- Otis TCB Guide LinesDocument38 pagesOtis TCB Guide LinesAnonymous EstxH750% (2)

- Fermator Door Operator VF7 Relay User Manual SW V7.01.04 - 05 - 2018Document28 pagesFermator Door Operator VF7 Relay User Manual SW V7.01.04 - 05 - 2018alfrelia80% (5)

- MicroZed v33Document18 pagesMicroZed v33Ken LeeNo ratings yet

- EN Programming ELCO Micro-ANTS LEB02 Basic Encoder V2.2 26-10-2020Document35 pagesEN Programming ELCO Micro-ANTS LEB02 Basic Encoder V2.2 26-10-2020Renny Barragan100% (1)

- Reference Manual: INR-SI47-1909-EDocument246 pagesReference Manual: INR-SI47-1909-EAtaur RahamanNo ratings yet

- Fermator vvvf-4+Document20 pagesFermator vvvf-4+paul100% (3)

- Maintaining and error parsing now faster and easier with new LED and WiFiDocument16 pagesMaintaining and error parsing now faster and easier with new LED and WiFiwilderness_666No ratings yet

- BL3-U User Manual English Version 2011.07.12 - Revis...Document162 pagesBL3-U User Manual English Version 2011.07.12 - Revis...Luisa BlancoNo ratings yet

- Lift Monitoring & Diagnostics: SystemDocument53 pagesLift Monitoring & Diagnostics: SystemMohd Abu AjajNo ratings yet

- Hidral Maintenance HandbookDocument32 pagesHidral Maintenance HandbookBaltija MechanikasNo ratings yet

- IM SEC TM en 11 03Document46 pagesIM SEC TM en 11 03pedrokingpin100% (1)

- Has-Dc Automatic Door Control CardDocument5 pagesHas-Dc Automatic Door Control CardsundarNo ratings yet

- ECO-MPU Application GuideDocument23 pagesECO-MPU Application GuideAssir El DjazairiNo ratings yet

- Operation and Maintenance Manual DianaDocument20 pagesOperation and Maintenance Manual Dianagrenui50% (2)

- Complete Diagram of EC100 SystemDocument26 pagesComplete Diagram of EC100 SystemMitro Je100% (1)

- FB10, FB11, FB12 User Manual Version 8.5Document49 pagesFB10, FB11, FB12 User Manual Version 8.5paul3178No ratings yet

- Sec Electronics: G - Type Lift ControllerDocument56 pagesSec Electronics: G - Type Lift Controllermohammad ghassanNo ratings yet

- Unidrive SP Elevator Issue 2Document174 pagesUnidrive SP Elevator Issue 2Andrew Lachica JacangNo ratings yet

- ARCODE Fire Evacuation and Firefighters Modes V10.EnDocument17 pagesARCODE Fire Evacuation and Firefighters Modes V10.EnHenri KleineNo ratings yet

- KM-10 User Guide.V111.enDocument18 pagesKM-10 User Guide.V111.enSalah SalahNo ratings yet

- HB32 (BG15) - Manuel D'installation - GB - Du 30 11 00 (7261) 1 PDFDocument226 pagesHB32 (BG15) - Manuel D'installation - GB - Du 30 11 00 (7261) 1 PDFasif mahmoodNo ratings yet

- Sar Plus Com Auto Dialler PDFDocument20 pagesSar Plus Com Auto Dialler PDFHenrique NogueiraNo ratings yet

- NICE3000new Elevator Controller FeaturesDocument209 pagesNICE3000new Elevator Controller Featureskolwin .chindwin100% (1)

- Elevator Door Controller - NSFC01-01Document14 pagesElevator Door Controller - NSFC01-01احمد المقرمي100% (1)

- IG5A Europe ManualDocument93 pagesIG5A Europe ManualBAAAKNo ratings yet

- Varispeed-F7 Manual PDFDocument463 pagesVarispeed-F7 Manual PDFIsradani MjNo ratings yet

- 78 Fuji SanyoDocument4 pages78 Fuji SanyoBAAAK100% (2)

- 3G3FV Parameters PDFDocument47 pages3G3FV Parameters PDFBAAAKNo ratings yet

- ARL-300 Lift Controller User Manual Setup GuideDocument42 pagesARL-300 Lift Controller User Manual Setup GuideBAAAK78% (98)

- LCBII菜单Document59 pagesLCBII菜单BAAAK100% (5)

- NATIONAL Service Manual SchematicDocument6 pagesNATIONAL Service Manual SchematicBAAAKNo ratings yet

- Villa Lift-NICE 1000-220V Single PhaseDocument14 pagesVilla Lift-NICE 1000-220V Single PhaseBAAAK100% (1)

- Philips Xh3 HP l1502 l1523 Compaq Fp5315Document65 pagesPhilips Xh3 HP l1502 l1523 Compaq Fp5315BAAAKNo ratings yet

- Principles of LCD DisplaysDocument32 pagesPrinciples of LCD DisplaysHoàng NguyễnNo ratings yet

- Transistores THS TOSHIBADocument24 pagesTransistores THS TOSHIBAJulio Chuquilin BecerraNo ratings yet

- CT21Q66 ServisDocument3 pagesCT21Q66 ServisBAAAKNo ratings yet

- SF Analyzer 973: Operation Manual Version 973-SFDocument43 pagesSF Analyzer 973: Operation Manual Version 973-SFbcqbaoNo ratings yet

- Product Datasheet: BRIGTEZ - Building Vicinity LuminairesDocument3 pagesProduct Datasheet: BRIGTEZ - Building Vicinity LuminairesMijail Villanueva Escalante100% (1)

- ProSine 1800Document88 pagesProSine 1800thecupkasNo ratings yet

- Operating Instructions for DD 150-U Diamond Core Drilling MachineDocument32 pagesOperating Instructions for DD 150-U Diamond Core Drilling MachineGANG MEINo ratings yet

- Communications Systems - Ple 1mexx0 XX Plena Mixer AmplifierDocument3 pagesCommunications Systems - Ple 1mexx0 XX Plena Mixer AmplifierAbdul AhadNo ratings yet

- ATS2018 Installation ManualDocument28 pagesATS2018 Installation ManualJohnny BravooNo ratings yet

- EEq MMMOBTqcnf KveDocument96 pagesEEq MMMOBTqcnf KveHomeroPerezNo ratings yet

- Everlast: PowertigDocument37 pagesEverlast: PowertigAndrew PsalidasNo ratings yet

- Product Manual: Panel Mounted ControllerDocument271 pagesProduct Manual: Panel Mounted ControllerLEONARDO FREITAS COSTANo ratings yet

- Growatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyDocument2 pagesGrowatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyjimmyNo ratings yet

- Em2e SM 3122-785-10310Document98 pagesEm2e SM 3122-785-10310Татьяна ГарецNo ratings yet

- 6EP13331LD00 Datasheet enDocument3 pages6EP13331LD00 Datasheet enGilles Roland KamgnoNo ratings yet

- Ameren Service Manual 11-21-2022Document275 pagesAmeren Service Manual 11-21-2022Vince AceyNo ratings yet

- PL 1290 ManualDocument46 pagesPL 1290 ManualvictandNo ratings yet

- Emergency LightingDocument18 pagesEmergency Lightingkarim karimNo ratings yet

- Onan Accessories & Service Support CatalogDocument46 pagesOnan Accessories & Service Support CatalogJohn Larson100% (1)

- 133R6017 HLP-SK Series Operating Manual V2018-01 (20180814)Document259 pages133R6017 HLP-SK Series Operating Manual V2018-01 (20180814)nardobizungaNo ratings yet

- CEB-MKIII Issue 2 Instruction ManualDocument49 pagesCEB-MKIII Issue 2 Instruction ManualAlejandra SantosNo ratings yet

- DKG 705 User ManualDocument58 pagesDKG 705 User ManualMarioEnriqueAlcocerÁvila100% (1)

- SH320 Ventilator User ManualDocument80 pagesSH320 Ventilator User Manualrobiatula1506No ratings yet

- Service Manual Alpha RTDocument216 pagesService Manual Alpha RTRubén Cadima Barrientos100% (1)

- Datasheet 25 50KTL V3Document2 pagesDatasheet 25 50KTL V3Houssem KhelilNo ratings yet

- ALR Compact Repeater - Installation and Service Manual - 044 - 05252 Rev A February 2007Document54 pagesALR Compact Repeater - Installation and Service Manual - 044 - 05252 Rev A February 2007Virgil PeiulescuNo ratings yet

- L&T MX Contactor Catalogue PDFDocument9 pagesL&T MX Contactor Catalogue PDFAnonymous lFFnnXmjUuNo ratings yet

- Catalog of HAILI Welder MMA MIG TIG and Plasma CutterDocument41 pagesCatalog of HAILI Welder MMA MIG TIG and Plasma CutterHugo AlvarezNo ratings yet

- Agilent 8453E UV-visible Spectroscopy System: Operator's ManualDocument160 pagesAgilent 8453E UV-visible Spectroscopy System: Operator's ManualLaura RosalesNo ratings yet

- AK 96 dialysis machine technical data chapterDocument22 pagesAK 96 dialysis machine technical data chapterMounir AngadNo ratings yet

- Dse 530 Manual PDFDocument25 pagesDse 530 Manual PDFjonatan samuel huamanNo ratings yet

- Wheel Balancer: Service ManualDocument51 pagesWheel Balancer: Service ManualOscar Eduardo Viertel DufflocqNo ratings yet

- HF-320 Series Inverter Instruction ManualDocument103 pagesHF-320 Series Inverter Instruction Manualmoshik99100% (8)