Professional Documents

Culture Documents

ACERO

Uploaded by

Renato BenavidesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACERO

Uploaded by

Renato BenavidesCopyright:

Available Formats

Introduction

This booklet was put together to familiarize the general reader with the terminology of suspension bridge components and to help the designer, builder or user of a small suspension bridge. Its use should enable him to make up preliminary calculations for determining the cable size as well as the various quantities of material required. Then, a comparative estimate can be made between the suspension bridge and any other type that may also be under consideration for a particular location. It is rather interesting to note that, in spite of the relative simplicity of design and erection of a suspension bridge, there are a number of cases where other types have been used, even though the suspension type might have been more economical. We think that this is because many engineers have been of the opinion that the cable analysis might be difficult and complicated as to its solution. However, the simple formulae used in the catalog should dispel this thought. ll we ask is that the imaginative engineer try the suspension type the ne!t time he contemplates building a bridge.

It is also our hope that the e!perienced designer of suspension bridges may find this booklet of use as a source of shortcut methods for arriving at his first appro!imations, and for the solution of many cable erection problems.

Terminology

Suspension Bridge Data

"alvanized #ridge Wire for $arallel Wire #ridge %ables. &ecommended diameter .'() inch. "alvanized #ridge *trand++consists of several bridge wires, of various diameters twisted together. "alvanized #ridge &ope++consists of si! strands twisted around a strand core.

Types of Suspension Bridge Cables

1. Parallel Wire Cables++This type of cable is made up of a large number of individual wires which are parallel to one another. ,either the cables nor the wires are twisted in any manner. The wire i) shipped to the site of the bridge on reels and the individual wires are installed or- .spun. on the bridge and later compacted together to form a round crosssection. %ables of this type are used on monumental structures, such as the "olden "ate #ridge and the "eorge Washington #ridge.

$arallel Wire %able

2. Parallel Strand Cables, Closed Construction++These consist of several prefabricated "alvanized #ridge *trands, all laid parallel and in contact with one another. Wood or aluminum fillers are used to bring the cable to a circular cross+section, after which the whole cable is wrapped with wire for protection. The cable may contain /, '( 0/, )', (' or '1/ strands.

2etail of 3ain %able and %able #and. The wrapping wire is omitted at the right for clarity. ,ote the closed construction and aluminum fillers.

. Parallel Strand Cables, !pen Construction++This type of cable consists of several prefabricated "alvanized bridge *trands which are all laid parallel to one another and not in contact. The strands are usually arranged in the form of a rectangle and the cable may contain 1, 4, ), (, '1, '), 15, 14 or 05 strands. ". Parallel #ope Cables, !pen Construction++These are the same as $arallel *trand %ables e!cept that "alvanized #ridge &ope is used in place of #ridge *trand.

%lose+up view of 3ain %able, %able #end and *uspender. ,ote the open construction.

$. Single #ope or Single Strand Cables++These are used for small structures.

%able with %lip Type %able #and and *uspender.

Prestretc%ing &al'ani(ed Bridge Strands and &al'ani(ed bridge #opes 6or many years the main cables of most suspension bridges, large and small, consisted of parallel wires installed individually at the site of the bridge. 7n small bridges this proved to be an e!pensive procedure and consequently placed the suspensiontype bridge at an economic disadvantage for the shorter span crossings. The use of prefabricated strands for these cables, although much less costly in erection, was restricted because the elastic properties of the strands could not he predicted and were not stabilized until the bridge had been in service for some time. In '(18, however, &oebling developed the process known as .$restretching,. whereby the elastic properties of a prefabricated strand or rope can he definitely established. This operation consists of sub9ecting the member to a tension above its working tension and holding it there until the desired results have been obtained. *ince the time this practice was initiated, it has been possible for the designer to depend on a length of prefabricated "alvanized #ridge *trand or #ridge &ope with the same confidence that he places in the

length of a structural steel member. The immediate result was to make the suspension bridge economically advantageous for much shorter span lengths. $restretched "alvanized #ridge *trand can he depended on to have a minimum modulus of elasticity of 14,555,555 lbs. per sq. in. and the minimum modulus of $restretched "alvanized #ridge &ope is 15,555,555 lbs. per sq. in. The prestretching procedure also makes it possible to measure the prefabricated members to e!act lengths in the shop under their working tension. 6urthermore, the location of the centerline of the main tower saddle can he established and marked on each main cable. The location of each cable band can also be established and marked on one member for each main cable. )otes on Suspension Bridge Design The suspension bridge is inherently a fle!ible structure and in the ma9ority of cases some form of stiffening must he incorporated in the design. 7n highway or walkway bridges, stiffness may he obtained with a stiffening truss or by a properly designed diagonal cable system. In statically loaded bridges, such as pipe lines or belt conveyors, the stiffening truss may be omitted. The effect of heavy transverse winds on a suspension bridge necessitates the incorporation of a properly designed wind bracing system. This wind bracing system can be incorporated in the floor system design or the necessary stiffness may he obtained more economically in some cases by the use of a wind cable system. The choice of main cable size can be made after the total dead and live loads have been determined. quick, appro!imate estimate of the cable size can be made as follows :see figure '; <

The proportions of the stiffening truss may be appro!imated with sufficient accuracy for a rough estimate by designing a weightless truss which will support the uniform live

load over a simple span equal to 45-.* of the main span of the bridge. The wind bracing system may also be appro!imated by using conventional design methods. The design of the wind cable system is similar to the design of the main cable. However, the design of a diagonal cable stiffening system requires a different analysis and &oebling-s #ridge 2ivision is available to assist in the design. Inquiries in connection with the design of specific pro9ects are invited. 6or the final design of the bridge an accurate analysis should be made and the complete coverage of this sub9ect would require a booklength discussion. The reader who wishes to acquaint himself with this branch of engineering, however, is referred to the published literature. 3any such sources of information are listed in the following publication . History of *uspension #ridges in #ibliographical 6orm. by . . =akkula, a #ulletin of the gricultural > 3echanical %ollege of Te!as. )otes on Suspension Bridge *rection Calculations n important item to be determined by the computer of suspension bridge calculations is the free cable sag+the elevation at which the cables must be set when hanging under their own weight only, to make certain that the fullyloaded bridge will come k? rest at the right elevation. 7bviously, the cable has one length under dead load tension and a shorter length under free cable tension due to elastic contraction. However, it always has the same unstressed length from anchor to anchor. If this one constant, common characteristic is kept in mind, the problem of finding the free cable sag is reduced to a simple form of applied mechanics. The unstressed length is found for each span of the bridge from the dead load condition. #y trial and error a free cable HF is found which is equal for all spans and yields the proper unstressed length in each span. The free cable curves may be computed accurately by the use of catenary formulas, such as shown in figure ', or appro!imated by the use of the parabolic formulas :equations ''4; listed under . ppro!imate 6ormulas for 2etermining %able and *uspender lengths and %able Tensions.. rapid appro!imation of free cable characteristics may be made as follows< '. 6ind stretch due to dead load H in each span.

where @ A %able length in any span, ft B A %able span in same span, ft. A %able area, sq. in. C A 3odulus of Clasticity, p.s.i.

1. 6ind unstressed length :D.@.; in each span.

0. 6ind total unstressed length for all spans from anchor to anchor. 4. *elect a trial free cable H6 and proceed with tabular computation, as outlined in figure 1, to find for this H6. In this table there will be a column for each span and each trial will involve the use of a group of columns representing all the spans from anchor to anchor. E. When an H6 has been found which yields a equal to that found in step 0, it is the correct value for H6. ). 6ind free cable sag in any span or other de+sired characteristics by using the parabolic or catenary relations mentioned above. /. It will be noted that the unstressed lengths of the individual free cable spans do not equal those obtained from dead load. The differences represent the amount of motion of the tower top from the dead load to the free cable positions. method of arriving at tower motions from these differences is indicated at the bottom of figure 1. 7n larger bridges it is also necessary to make computations for sag temperature charts. These charts define the line of sight necessary to estab+lish the proper sag of the free hanging strand in any span for any temperature and tower position. In recent years an alternative method of manufacture and erection procedure for the prefabric+ated main cable strands has been evolved which eliminates the time+consuming and voluminous computations necessary to prepare the sag temp+erature charts. Dnder this new method the first strands are+erected with normal shims at the an+chorages and with the centerline of main tower saddle marks placed e!actly on the prescribed position. Thereafter additional strands are simply ad9usted to the first strand. This method requires particular care to be taken to check the e!act location of the main towers and anchorages. It also requires the cable manufacturer to take special precautions in the measuring and handling of the main cable strands. It is suggested that this method of erection be discussed with &oebling before being adopted.

C%arts, Tables, and Tec%nical Data

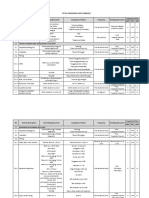

*tandard "alvanized *teel #ridge &ope *tandard "alvanized *teel #ridge *trand ppro!imate 6ormulas for 2etermining %able and

)/B# =$C" E)B# =$C" 1(B# =$C"

*uspender @engths and %able Tensions 3ain *pan *uspender @engths *ide *pan *uspender @engths %atenary 6ormulas :6igure '; ppro!imate %omputation of 6ree %able H %hart ' %hart '# %hart '%

E5B# =$C" 15B# =$C" 10B# =$C" 1(B# =$C" 4EB# =$C" '58B# =$C" /)B# =$C" '15B# =$C"

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ITP for Bridge Expansion Joint InspectionDocument4 pagesITP for Bridge Expansion Joint Inspectionm2biz05No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Fireproofing Requirements GuideDocument16 pagesFireproofing Requirements GuideAnonymous yCpjZF1rFNo ratings yet

- Instrumentation EarthingDocument13 pagesInstrumentation EarthingTrung TrầnNo ratings yet

- REVIEW INNOVATIONS CE BOARD EXAMDocument3 pagesREVIEW INNOVATIONS CE BOARD EXAMKian Inductivo100% (1)

- Introduction To MeasurementDocument20 pagesIntroduction To MeasurementAamaniVeeranam100% (1)

- Method Statement Marble Fixing - Quality and ConstructionDocument13 pagesMethod Statement Marble Fixing - Quality and ConstructionumitNo ratings yet

- 11.7 States of Matter PhET LabDocument2 pages11.7 States of Matter PhET LabCoacytTucumanNo ratings yet

- Economiser & DrumDocument75 pagesEconomiser & DrumGaurav ChauhanNo ratings yet

- Precast Post Tentioned TanksDocument20 pagesPrecast Post Tentioned TanksMarcel SteoleaNo ratings yet

- Grundfosliterature 776429Document96 pagesGrundfosliterature 776429Орце АндовNo ratings yet

- Thi Công Chống Thấm Chop MBS Marina-Bay-SandsDocument5 pagesThi Công Chống Thấm Chop MBS Marina-Bay-SandsTrần KhươngNo ratings yet

- Fas-11 Typical Device Equipment Installation PDFDocument1 pageFas-11 Typical Device Equipment Installation PDFMØhãmmed ØwięsNo ratings yet

- Univer Eng Digitale2 PDFDocument76 pagesUniver Eng Digitale2 PDFMohsin MukulNo ratings yet

- Gundu Rao Sanc Plan - A2 SizeDocument1 pageGundu Rao Sanc Plan - A2 SizeBHARATH KUMARNo ratings yet

- LED Lighting CatalogDocument10 pagesLED Lighting CatalogNguyen Anh TuNo ratings yet

- Liebert HimodDocument71 pagesLiebert HimodlincolnNo ratings yet

- OHT DesignDocument55 pagesOHT Designdheeraj tiwariNo ratings yet

- A Comparative Study On Cutting Tool Performance PDFDocument6 pagesA Comparative Study On Cutting Tool Performance PDFdevmecz2696No ratings yet

- MS Plate 2,3,5mmDocument3 pagesMS Plate 2,3,5mmRahul Krishnan RNo ratings yet

- EVCO O RingeDocument24 pagesEVCO O RingeteresamcabralNo ratings yet

- Watin, Kevin Rey I. BSCE 4A. Foundation and Retaining Wall. Combined Rectangular Footing PDFDocument7 pagesWatin, Kevin Rey I. BSCE 4A. Foundation and Retaining Wall. Combined Rectangular Footing PDFPrescila QuietaNo ratings yet

- Non Metallic MaterialsDocument16 pagesNon Metallic MaterialsthisisjineshNo ratings yet

- T.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User ManualDocument16 pagesT.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User Manualtailieuxaydung2019No ratings yet

- Fisher 99 Instruction ManualDocument24 pagesFisher 99 Instruction ManualJosé de Jesús MartinezNo ratings yet

- CS2 H2S SO2 analyzer sample line calculationDocument4 pagesCS2 H2S SO2 analyzer sample line calculationKevin PratyatamaNo ratings yet

- Giacomini Test Drain Valve FM UlDocument2 pagesGiacomini Test Drain Valve FM UlPassionate_to_LearnNo ratings yet

- Steel Reviewer 1.1 Steel ConstructionDocument4 pagesSteel Reviewer 1.1 Steel ConstructionCharmie Cabeltera CuelloNo ratings yet

- Depita, Velarde, Rondina, Malagamba, Solana: Homemade Aircon Made of Foam Box and Plastic BottlesDocument7 pagesDepita, Velarde, Rondina, Malagamba, Solana: Homemade Aircon Made of Foam Box and Plastic BottlesJacie TupasNo ratings yet

- KMT - GLOBE - Manual (Ver0.2) - Eng - 16-2026 (2016.08.16)Document21 pagesKMT - GLOBE - Manual (Ver0.2) - Eng - 16-2026 (2016.08.16)Ozi Fawzi100% (1)

- Mil STD 2175aDocument34 pagesMil STD 2175aYasser Hammad MohamedNo ratings yet