Professional Documents

Culture Documents

B767 Air Conditioning

Uploaded by

Gustavo Avila RodriguezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B767 Air Conditioning

Uploaded by

Gustavo Avila RodriguezCopyright:

Available Formats

Smartcockpit.

com

BOEING 767 SYSTEMS REVIEW

Page 1

AIR CONDITIONING

1. GENERAL

Air conditioning is achieved by 2 identical PACKS, each of which controlled by a PACK CONTROL SELECTOR. Positioning the selector to AUTO or STBY sends an open signal to the PACK VALVE. Conditioned air from the packs flows into a common manifold where it mixes with air from 2 RECIRCULATION FANS. The mixed air is then ducted into the temperature controlled compartments of the airplane.

2. PACKS

Pack switch on AUTO : temperature control is automatic

Pack switch on STBY : - N set pack for constant MODERATE temperature - C set pack for COLD operation* - W outlet temperature controlled by RAM AIR flowing across the heat exchangers* (* from 18C to 30C). HIGH FLOW when : ground operation when APU or GND air supplies the system in flight when : - 1 PACK OFF or - 1 RECIRC. FAN U/S or OFF using WING A/I and only 1 Bleed. one engine INOP FLAPS not in UP position aft cargo compartment ARMED switch pushed

HIGH FLOW inhibited when

L/R PACK INOP : - Automatic control fault Pack temperature valves freeze in the last controlled position. Pack cannot be reset and must be operated in STBY. INOP light + EICAS message go out when the Pack selector is rotated to PACK a STBY position. OFF - Overheat (internal or air leaving the pack) Pack automatically set and locked to max cooling. After cooling, the Pack can be reset for automatic or standby operation by pushing the PACK RESET switch INOP light go out when the Pack selector and the Pack returns to the Selected control at reset. PACK OFF : - Pack valve closed due to : - pack shut down - selector OFF - loss of bleed air - overheat ONE reset, then set MANUAL (amber) INOP

3. PACK VALVE

The PACK VALVE is a flow control valve and requires air pressure to open. When open, the valve controls air flow to a scheduled rate based on airplane altitude.

Copyright Smartcockpit.com Ludovic ANDRE / version 00

Smartcockpit.com

BOEING 767 SYSTEMS REVIEW

Page 2

4. RECIRCULATION FAN

Left & Right Recirculation Fans draw air which has been exhausted from the cockpit & passengers cabin through filters and returns the air to the mix manifold. There it mixes with conditioned air from the packs and is distributed again to the cabin. Purpose of recirculating cabin air is to maintain the desired level of passenger cabin ventilation while minimizing the use of bleed air. Recirculation Fans may be turned OFF several minutes to refresh the air in the cabin.

ON

- ON : Recirculation fan signalled ON - INOP (amber) : Recirculation fan switch is OFF or the fan has failed + EICAS msg.

INOP

5. TEMPERATURE CONTROL

The airplane is divided into 4 compartments for temperature control : - the flight deck - the FWD 1/3 cabin - mid-cabin - aft cabin Temperature controller signals the pack to produce air for the compartment requiring the coolest Trim air system then adjust the others (with air from downstream the pack valve) TRIM AIR

ON

OFF INOP

- ON : Trim air regulating valve signalled open - OFF (amber) : trim air switch is OFF + EICAS msg + 4 compartments INOP lights ON Packs then provide air for a 24C cabin temperature

(amber)

- Duct temperature overheat - Fault in the associated compartment temperature control system - Associated Passenger Compartment temperature Control OFF - Trim air OFF

Setting the compartment selector to OFF, closes the respective Trim air & temperature is then controlled by the coolest compartment

6. CREW HEAT

Additional electrical heater for each pilot usable IN FLIGHT only (side window & rudder pedal areas)

Copyright Smartcockpit.com Ludovic ANDRE / version 00

Smartcockpit.com

BOEING 767 SYSTEMS REVIEW

Page 3

AIR CONDITIONING

Copyright Smartcockpit.com Ludovic ANDRE / version 00

Smartcockpit.com

BOEING 767 SYSTEMS REVIEW

Page 4

CABIN TEMPERATURE CONTROL

Copyright Smartcockpit.com Ludovic ANDRE / version 00

Smartcockpit.com

BOEING 767 SYSTEMS REVIEW

Page 5

LEFT PACK LOGIC

Copyright Smartcockpit.com Ludovic ANDRE / version 00

You might also like

- B767 Equipment CoolingDocument3 pagesB767 Equipment CoolingGustavo Avila Rodriguez0% (1)

- B767 Cargo HeatDocument3 pagesB767 Cargo HeatMiracle Boy Paras100% (1)

- Airbus Flight Control Laws: The Reconfiguration LawsFrom EverandAirbus Flight Control Laws: The Reconfiguration LawsRating: 4.5 out of 5 stars4.5/5 (16)

- B767 BrakesDocument6 pagesB767 BrakesGustavo Avila RodriguezNo ratings yet

- B767 Anti Ice and RainDocument3 pagesB767 Anti Ice and RainGustavo Avila RodriguezNo ratings yet

- B767 PneumaticsDocument6 pagesB767 PneumaticsGustavo Avila Rodriguez100% (5)

- B767 ApuDocument4 pagesB767 ApuGustavo Avila RodriguezNo ratings yet

- B767 Flight ControlsDocument9 pagesB767 Flight ControlsVishnu AnilkumarNo ratings yet

- B767 FuelDocument3 pagesB767 FuelGustavo Avila RodriguezNo ratings yet

- B767 PressurizationDocument3 pagesB767 PressurizationGustavo Avila RodriguezNo ratings yet

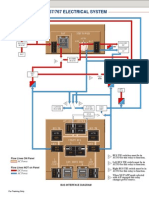

- B767 ElectricalDocument7 pagesB767 ElectricalGustavo Avila Rodriguez83% (6)

- 767 PrintDocument0 pages767 PrintLuis Felipe Belô100% (3)

- B767 WarningsDocument2 pagesB767 WarningsGustavo Avila RodriguezNo ratings yet

- B767 AutoflightDocument4 pagesB767 AutoflightGustavo Avila RodriguezNo ratings yet

- B767 PowerplantDocument15 pagesB767 PowerplantGustavo Avila Rodriguez100% (2)

- B767 300FDocument2 pagesB767 300FNadeem100% (1)

- B767 Electrical SystemsDocument11 pagesB767 Electrical SystemsRC Agulay100% (1)

- B767 HydraulicsDocument9 pagesB767 HydraulicsNabeel Arshad100% (2)

- Boeing 767 300 AntihielosDocument8 pagesBoeing 767 300 AntihielosKoldo Navarro100% (1)

- B767 Electrical SystemDocument1 pageB767 Electrical Systemjebd69No ratings yet

- 757 Schematics Layout 1Document25 pages757 Schematics Layout 1hariharanjack100% (7)

- Boeing 767 300 Landing GearDocument15 pagesBoeing 767 300 Landing GearWorawat Wongratanamajcha100% (2)

- B767 ATA 32 Student BookDocument89 pagesB767 ATA 32 Student BookElijah Paul Merto100% (4)

- 757-767 Study GuideDocument110 pages757-767 Study GuidePhilip Jackson100% (1)

- 757-767 Study GuideDocument176 pages757-767 Study GuideThanhoa Vo100% (1)

- B767 200-300 - Airplane GeneralDocument98 pagesB767 200-300 - Airplane GeneralTarik Benzineb100% (20)

- B767 200-300 BOOK 22 301 - Autoflight - IntroductionDocument32 pagesB767 200-300 BOOK 22 301 - Autoflight - IntroductionTarik Benzineb100% (4)

- B767 - Fuel SystemDocument41 pagesB767 - Fuel SystemTarik Benzineb100% (7)

- 757-767 Study GuideDocument155 pages757-767 Study Guideaske7sp8055100% (3)

- Boeing 757-767 Study Guide SummaryDocument134 pagesBoeing 757-767 Study Guide SummaryEldonP100% (2)

- 767 Training Manual - Lauda Air (1999)Document339 pages767 Training Manual - Lauda Air (1999)Javier100% (6)

- B767 ATA 26 Student BookDocument133 pagesB767 ATA 26 Student BookElijah Paul Merto100% (4)

- B777 Landing Gear Systems OverviewDocument17 pagesB777 Landing Gear Systems Overviewdnana_rian100% (1)

- EPR Vs N1Document9 pagesEPR Vs N1Xana Amaral100% (1)

- Study Note 767sDocument39 pagesStudy Note 767sGurdevBaines100% (4)

- B767 Hydraulic System Training ManualDocument37 pagesB767 Hydraulic System Training ManualTarik Benzineb100% (6)

- B767 ATA 25 Student BookDocument21 pagesB767 ATA 25 Student BookElijah Paul Merto100% (1)

- Pneumatics: Training Manual B767-3S2F Ata 36-00Document55 pagesPneumatics: Training Manual B767-3S2F Ata 36-00luisao9escobarNo ratings yet

- B767 Flightdeck and AvionicsDocument142 pagesB767 Flightdeck and Avionicsoscar89% (19)

- B767 ATA 38 Student BookDocument11 pagesB767 ATA 38 Student BookElijah Paul Merto100% (2)

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- Flight Lessons 1: Basic Flight: How Eddie Learned the Meaning of it AllFrom EverandFlight Lessons 1: Basic Flight: How Eddie Learned the Meaning of it AllNo ratings yet

- Fly the Wing: A flight training handbook for transport category airplanesFrom EverandFly the Wing: A flight training handbook for transport category airplanesRating: 4 out of 5 stars4/5 (1)

- Instrument Rating Airman Certification Standards - Airplane: FAA-S-ACS-8B, for Airplane Single- and Multi-Engine Land and SeaFrom EverandInstrument Rating Airman Certification Standards - Airplane: FAA-S-ACS-8B, for Airplane Single- and Multi-Engine Land and SeaRating: 1 out of 5 stars1/5 (1)

- Lesson Plans to Train Like You Fly: A flight instructor's reference for scenario-based trainingFrom EverandLesson Plans to Train Like You Fly: A flight instructor's reference for scenario-based trainingNo ratings yet

- Bleed Air Systems ExplainedDocument10 pagesBleed Air Systems ExplainedAhmed RefNo ratings yet

- Introduction To Air Conditioning SystemDocument5 pagesIntroduction To Air Conditioning Systemaiganym.malikovaNo ratings yet

- Air ConditioningDocument16 pagesAir ConditioningPUNEETNo ratings yet

- 2.air SystemsDocument14 pages2.air Systemsshameem aktharNo ratings yet

- PneumaticsPneumatics, Air Conditioning, & PressurizationDocument9 pagesPneumaticsPneumatics, Air Conditioning, & PressurizationAnastasios Pavlou100% (3)

- ATA 21 AirCon Day 2Document10 pagesATA 21 AirCon Day 2Muhammed YaseenNo ratings yet

- Dash8 200 300 Air Cond and PressDocument19 pagesDash8 200 300 Air Cond and PressখালিদহাসানNo ratings yet

- Chapter-21 MCQDocument12 pagesChapter-21 MCQajaydce05No ratings yet

- خلاصه ارباس ٣٢٠Document23 pagesخلاصه ارباس ٣٢٠Reza MaserratNo ratings yet

- Cl605-Air Conditioning and PressDocument25 pagesCl605-Air Conditioning and PressMax MellmingerNo ratings yet

- B737-800 Air ConditioningDocument7 pagesB737-800 Air ConditioningReynaldoNo ratings yet

- Air Conditioning: 3.1. Cockpit and CabinDocument4 pagesAir Conditioning: 3.1. Cockpit and CabinWIN MINNo ratings yet

- Static Aircraft .MDL MakerDocument21 pagesStatic Aircraft .MDL MakerGustavo Avila RodriguezNo ratings yet

- The Lie Behind The Lie DetectorDocument220 pagesThe Lie Behind The Lie DetectorAntiPolygraph.org95% (22)

- Catalogo 2018 Articulos JeppesenDocument40 pagesCatalogo 2018 Articulos JeppesenGustavo Avila RodriguezNo ratings yet

- SPP Fuel Commercial Air TranspDocument6 pagesSPP Fuel Commercial Air TranspGustavo Avila RodriguezNo ratings yet

- POH Cessna Skymaster-337Document63 pagesPOH Cessna Skymaster-337Gustavo Avila Rodriguez100% (2)

- Wherearemyaircraft DocumentationDocument48 pagesWherearemyaircraft DocumentationGustavo Avila RodriguezNo ratings yet

- Camerapositionx DocumentationDocument30 pagesCamerapositionx DocumentationGustavo Avila RodriguezNo ratings yet

- Sizing ChartDocument2 pagesSizing ChartGustavo Avila RodriguezNo ratings yet

- 2016 Propper Industrial CatalogDocument7 pages2016 Propper Industrial CatalogGustavo Avila RodriguezNo ratings yet

- Powerful Stereo & PA Amplifiers and Professional Speaker SystemsDocument26 pagesPowerful Stereo & PA Amplifiers and Professional Speaker SystemsGustavo Avila RodriguezNo ratings yet

- SPP Fuel Commercial Air TranspDocument6 pagesSPP Fuel Commercial Air TranspGustavo Avila RodriguezNo ratings yet

- Isa PDFDocument7 pagesIsa PDFairsorNo ratings yet

- Kodiak AimDocument630 pagesKodiak AimGustavo Avila Rodriguez100% (1)

- T 37 - Afman11 249Document194 pagesT 37 - Afman11 249Gustavo Avila RodriguezNo ratings yet

- Special Forces Handbook - ST 31-180Document49 pagesSpecial Forces Handbook - ST 31-180Mistermisfit100% (1)

- R-44 Poh PDFDocument222 pagesR-44 Poh PDFGustavo Avila RodriguezNo ratings yet

- AI Boat Traffic for Dummies GuideDocument6 pagesAI Boat Traffic for Dummies GuideGustavo Avila RodriguezNo ratings yet

- Army - fm21 60 - Visual SignalsDocument72 pagesArmy - fm21 60 - Visual SignalsMeowmix100% (11)

- PMDG 737NGX Introduction PDFDocument134 pagesPMDG 737NGX Introduction PDFuniao2016No ratings yet

- Cessna 172p 1982 Poh PDFDocument357 pagesCessna 172p 1982 Poh PDFClarence PieterszNo ratings yet

- B767 ChecklistDocument4 pagesB767 ChecklistGustavo Avila Rodriguez100% (1)

- Army - fm23 10 - Sniper TrainingDocument329 pagesArmy - fm23 10 - Sniper TrainingMeowmix100% (7)

- Cessna Grand Caravan Speeds and ChecklistsDocument18 pagesCessna Grand Caravan Speeds and ChecklistsCristian SaenzNo ratings yet

- B767 WarningsDocument2 pagesB767 WarningsGustavo Avila RodriguezNo ratings yet

- VFR Flight Planner Dax PDFDocument2 pagesVFR Flight Planner Dax PDFGustavo Avila RodriguezNo ratings yet

- B767 PressurizationDocument3 pagesB767 PressurizationGustavo Avila RodriguezNo ratings yet

- Marine Corps Common Skills Handbook 1ADocument226 pagesMarine Corps Common Skills Handbook 1AemilyabuttNo ratings yet

- B767 PowerplantDocument15 pagesB767 PowerplantGustavo Avila Rodriguez100% (2)

- Adl 2035Document8 pagesAdl 2035yoshiofazNo ratings yet

- ZTL ZJXDocument6 pagesZTL ZJX1239088No ratings yet

- Citycraft: at Airbus A320-232Document8 pagesCitycraft: at Airbus A320-232David Knapp100% (2)

- Manage Aircraft TransferDocument120 pagesManage Aircraft TransferVu Nguyen TuanNo ratings yet

- ATA Chapters OverviewDocument1 pageATA Chapters OverviewJewel Christian PuseNo ratings yet

- Crowood - McDonnell-Douglas F-15 EagleDocument103 pagesCrowood - McDonnell-Douglas F-15 Eaglemagyaralba100% (23)

- Boeing Commercial Aircraft - Design Groups/Codes (FAA & ICAO)Document1 pageBoeing Commercial Aircraft - Design Groups/Codes (FAA & ICAO)Vero SalinasNo ratings yet

- Compilation of Papers Presented To Meeting On Space Vehicle Landing and Recovery Research and TechnologyDocument269 pagesCompilation of Papers Presented To Meeting On Space Vehicle Landing and Recovery Research and TechnologyBob AndrepontNo ratings yet

- B737 Load SheetDocument2 pagesB737 Load Sheetkanavkashyap85% (13)

- AE 452 Aeronautical Engineering Design II: Air LoadsDocument20 pagesAE 452 Aeronautical Engineering Design II: Air LoadsfrancescaNo ratings yet

- Diamond D42 TermsDocument3 pagesDiamond D42 TermsbillyNo ratings yet

- ERJ V2 Operations ManualDocument80 pagesERJ V2 Operations ManualJavier100% (2)

- Gurney FlapDocument29 pagesGurney FlapTitter BuckNo ratings yet

- Air Crash Investigation - QANTASDocument16 pagesAir Crash Investigation - QANTASKabilan SiranjiviNo ratings yet

- CAA 2101 Aircraft LogbookDocument98 pagesCAA 2101 Aircraft LogbookOsm For ChristNo ratings yet

- RL2011 02eDocument48 pagesRL2011 02eHeiriNo ratings yet

- IntroDocument27 pagesIntrobigfoottedNo ratings yet

- Emergency RATs Presentation PDFDocument35 pagesEmergency RATs Presentation PDFAero ChampNo ratings yet

- MSN 0700 Repair and Dent Status DEC-2018Document63 pagesMSN 0700 Repair and Dent Status DEC-2018Anonymous OEmUQuNo ratings yet

- Listas de Chequeo 737-200Document3 pagesListas de Chequeo 737-200Johan MartinezNo ratings yet

- Diploma of AviationDocument2 pagesDiploma of AviationSimone Mercer-HugginsNo ratings yet

- Chief Greenwood BioDocument2 pagesChief Greenwood Bioapi-248722668No ratings yet

- Aircraft cabin configurations and classificationsDocument10 pagesAircraft cabin configurations and classificationsLouise Gabrielle JolocNo ratings yet

- A46NM Rev37Document48 pagesA46NM Rev37juangui182No ratings yet

- FutureLofoten Process Book2030: Lofoten Airport As A Regional Growth GeneratorDocument228 pagesFutureLofoten Process Book2030: Lofoten Airport As A Regional Growth GeneratormortceliNo ratings yet

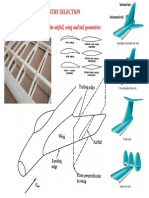

- Aircraft Design: Airfoil and Geometry SelectionDocument94 pagesAircraft Design: Airfoil and Geometry SelectionYak100% (10)

- MML - VLM - 2014 02 06 16 10 04Document51 pagesMML - VLM - 2014 02 06 16 10 04Pedro RochaNo ratings yet

- Civil Helicopter Market Forecast 2015-2025 150430081835 Conversion Gate01Document11 pagesCivil Helicopter Market Forecast 2015-2025 150430081835 Conversion Gate01TuckctNo ratings yet

- Travelport ViewTrip Itinerary - DetailedDocument2 pagesTravelport ViewTrip Itinerary - DetailedNarkco BaptistaNo ratings yet

- EASA Part FCL MILITARY ACCREDITATION AEROPLANE FLOWCHART 1Document1 pageEASA Part FCL MILITARY ACCREDITATION AEROPLANE FLOWCHART 1DIMYPSILANTISNo ratings yet