Professional Documents

Culture Documents

Avanti Vs Starship

Uploaded by

aeroengineer1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Avanti Vs Starship

Uploaded by

aeroengineer1Copyright:

Available Formats

Resource: Aviation Convention News; Vol. 17, No. 12; Midland Park, NJ; November 1, 1985.

Staff Report

When the curtain rose on the Dallas

NBAA gathering two years ago, it

revealed a glimpse of the future. The

unveiling of the Gates-Piaggio

GP-180-as it was then named-and

the Beech Starship charged the at-

mosphere and electrified the annual

meeting.

It is now some 26 months later and

another NBAA Convention has come

and gone. Visitors to the full-scale

mockups on the exhibit floor at New

Orleans were no longer gawking in

wonder and awe. They were asking

hard questions about delivery dates and

financing packages, flight test

schedules and equipment options. In-

exorably, the present is catching up

with the wave of the future.

Beech has opened its new

500,000-sq-fi Starship production

facility and is well on the way to com-

pleting six full-size Starship airframes,

three for flight testing and certification

trials and three for static and fatigue

testing. The wing was mated to the first

100-percent-scale Starship prototype

during NBAA Convention week in late

September, and that airplane is ex-

pected to fly early next year.

In the meantime, the proof-of-

concept (POC) 85-percent scale Star-

ship, which tantalized the Oallas

gathering with its " .. .is that a bird, a

plane ... '' flash dance, has now logged

in excess of 500 hr aloft, during which

it has not only proved its concept, but

made its shape-of-things-to-come no

longer appear radical.

While Beech is " winding up" pro-

duction of its first fuU-size Starship

prototype, Gates and Piaggio are mov-

ing steadfastly ahead with their co-

project. The two companies- which

are attempting to cooperatively design,

develop, and produce an airplane not

only between two continents, but be-

tween two cultures separated by

languages and measuring systems-are

expecting the first flight of their Avanti

in April 1986.

The forward fuselage of the first fly-

ing prototype Avanti is due out of Lear-

jet's Wichita plant this month for ship-

ment to Italy, where it wiJJ be mated

to the Piaggio-built wing and Sikorsky-

fabricated tail-cone/empennage. FAA

type certification is anticipated in the

spring of 1987, following a year-long

flight test program.

By the end of this year, Gates will

have sunk $24 million into the Avanti;

Piaggio, which conceived the design,

significantly more. Through their joint

venture, the two companies hope to

s hare t.he airplane's considerable

development risk.

Putting It Together

Beech has engineered a light, self-

supporting structure akin to an eggshell

in concept. Laminated sandwiches con-

sisting of inner and outer composite

skins bonded to Nomex honeycomb

cores are molded into desired shapes

for parts or components which are then

generally self-supporting without the

aid of frames and stringers. A fuselage,

for example, can be simply a shell with

fore and aft bulkheads but no internal

structure. Deriving much of its strength

from unidirectional skin laminates, the

Starship's main wing consists of less

than 20 parts, only a few of which are

. ribs.

Five of the Starship production pro-

totypes currently under construction

have airframes laid up of graphite and

Nomex laminates. while a sixth-

actually flfSt on the schedule to fly next

year-has been fined with a fuselage

wound of 900 miles of graphite fila-

ment impregnated with epoxy resin.

Baked in an autoclave over a removable-

mandril, the fllament-wound fuselage,

like the space shuttle booster casings

that inspired it , is extremely light and

rigid. Beech wants to study both types

of construction before making a pro-

duction decision.

Seeing Beech's huge new multi-

million-dollar autoclave, which

dominates the new Starship production

facilicy at Wichita and looks like a sec-

tion cut from the hull of a Trident sub-

ml!rine, one can't help but think that

Beech and parent company Raytheon

might be covering their bets on the

Stars.hip's success by developing an in-

house capability to subcontract its com-

posite fabrication capabilities to other

companies inside and outside of avia-

8tECH STARSHIP

HU.H SPEED

Fli&HT

LOW SPEED FU6NT

FlAPS DOWN

SKE:TCtf

.lz IS ~ ~ E A T E . t 'tHAN /

1

-VARIABLE SWEPT C.ANARP

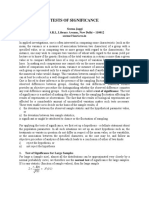

STARSHIP: HANDLING THE PITCH

Many canard-equipped airplanes omit flaps because they would

run out of elevator trying to counteract the pitching moment generated

when flaps are deployed.

Starship's designers cleverly avoid the problem by allowing the

airplane's forward canard surface to pivot forward and backward.

This "variable sweep" is movable in flight. As shown, it is swept back

at higher speeds, resulting in a shorter moment arm (distance

between e.g. and center of lift of canard). At low speeds, with flaps

down, the canard is straight (no sweep) and the moment arm is

longer, allowing the elevators (on the canard) to exert greater force

to cope with the downward pitch caused by the lowered flaps.

(Sketches by Ron Neal, Gates Learjet.)

tion. After all, that's what Sikorsky

did, and the Stratford, Conn. helicopter

manufacturer is currently poised to

harvest an expected boom in composite

construction with a dedicated subcon-

tracting operation in Alabama.

ironically, Sikorsky will subcontract to

Gates-Piaggio for construction of all

the composite subassemblies for the

Avanti.

In many ways the more conservative

more on page 144

Comparison

continued from page 142

of the two, the Gates-Piaggio A vanti relies on a

structure that is 60-percent alwninum and 40-per-

cent composite media. The airplane's fuselage

and main wingbox are fabricated of aluminum

in the conventional manner, but with a new twist

introduced to general aviation airplanes by Gates.

The fuselage is built " from the outside in, " that

is, formed skin pieces are held to contour in a

massive "vacuum chuck" (a fiberglass female

mold drilled with vacuum holes) and frames are

attached to the skin, allowing tolerances to be

built "to the inside and not the outside." Accord-

ing to Gates Learjet general operations manager

Ronald Neal, "The result is a completed article

with close tolerances and extremely high quali-

ty.''

Composites, laid up of Kevlar, graphite, and

Nomex by Sikorsky, constitute the remainder of

the airframe, amounting to about 10 percent of

the aircraft's empty weight. These subassemblies

include the main wing control surfaces, forward

wing and nose structure, empennage, and engine

nacelles. Explaining the Avanti's mixed-media

construction, Neal confided that "neither Piag-

gio nor Learjet had the resources to do a lot of

research in composites. What we're doing is us-

ing proven technology within our _resources and

capabilities . I think we'll see airliners well into

the Twenty-frrst Century made of alwninum. The

damage characteristics of aluminum structures are

well understood. Not so for composites. How

many people out there know how to repair

composites?

"We can also build the airplane cheaper this

way," Neal continued, "and you have to

remember that the customer ultimately pays for

R&D. Lightning protection is another factor. We

understand how to protect an aluminum airplane

from lightning. Then there's maintainability and

interchangeability of parts. If a metal part doesn' t

fit, you can alter it, but you can't do that with

a composite part. You have to have the highest

quality tooling to avoid that problem with com-

posites.' '

Two Ways To Skin Craft

The Starship and A vanti offer an interesting

comparison in design philosophies, or the diverse

paths that two creative engineering groups can

choose to accomplish the same objective. The

airplanes' novel shapes also testify. to the com-

promises that engineers must accommodate in

achieving certain design goals. Phrased as a ques-

tion, the challenge facing Beech and Piaggio

engineers when they sat down to delineate their

next-generation airplanes was: "How can we best

design an eight- to ten- passenger, FAR-23 tur-

boprop that can cruise at the same altitudes and

speeds as the slower jets and fly at least 2,500

Midland Park, N.J. Nov. 1, 1985

nmi carrying four passengers in an ex-

tremely quiet stand-up cabin?" Or in

Beech's case, " ... a cabin as Large as

or larger than the King Air 200?"

The FAR 23 stipulation was an im-

portant COllsideration, since the more

stringent provisions of FAR 25 (re-

quired of jets and large transports)

would significantly increase certifica-

tion costs as well as complicate

operating procedures. But going with

FAR 23 also meant that gross weight

had to be kept under 12,500 lb, the

low-end threshold for FAR 25. In order

to accommodate their large cabins,

these would be big airframes, so keep-

ing weight down was going to be

critical. Hence, more than a little at-

tention would be given to structure and

construction media.

According to Gates Learjct's Neal,

the design group at Rinaldo Piaggio

started with the cabin it wanted and

engineered an airplane around it. "Us-

ing the P:l 66 [an earlier twin turboprop

pusher produced by Piaggio] as a

baseline,'' he reported, ''they quickly

realized that to optimize interior

volume, they had to move the wing

carry-through structure out of the

cabin.

Three Lifting Surfaces

" This presented a dilemma at first,

since they also wanted a fast airplane,

and, in terms of minimizing in-

terference drag [at the critical

wing/fuselage juncture], a mid-wing

configuration is best to create an end-

plate effect with the side of the

fuselage,'' Neal explained. ''So to get

the end-plate effect while keeping the

spar out of the cabin, they placed the

wing behind the aft pressure bulkhead

and thereby arrived at another dilem-

ma, which was how to maintain

balance and e.g. without having a

tail cone a mile long. ''

Piaggio's solution was the so-called

''three-lifting-surface concept.' ' Incor-

porating both a forward wing "to

balance out the cabin,. and a small aft-

mounted horizontal stabilizer/elevator

for pitch control, the arrangement per-

mitted a relatively short tailcone.

Although Piaggio could have gone to

a pure canard configuration, as Beech

did, Neal claimed the three-surface

concept offered the best compromise

between canard and conventional plan-

forms. Added Learjet's new senior v-p

of marketing Donald 0 'Mara, ''After

the Wright brothers, most designers

abandoned the canard, probably for

stability reasons. They realized that a

conventional t ailpl ane provided

superior static stability. ''

Not a true canard, the Avanti's for-

ward lifting surface works in conjunc-

tion with the conventional horizontal

stabilizer to trim the airplane over a

broad range of flight and e.g. condi-

tions. lt is not used for pitch control

and, in fact, is mounted to the fuselage

at a fixed angle of incidence.

Neal explained that "the pure

canard, by definition, has a much

larger e.g. travel range, thereby mak-

ing balance a major consideration.

Everything you put in the airplane

tends to make the e.g. move a long

distance. In addition, you must be very

careful in tailoring the control con-

figuration of the main and forward

wings. Pitch control is extremely

critical. To provide us better control

over balance and pitch, we retained the

[aft-mounted] horizontal stabilizer and

Aviation Convention News

elevator; but by optimizing the forward

surface, we could keep the aft surfaces

fairly small. "

Neal claimed that another advantage

of the three-surface arrangement is

superior distribution of trim drag. ''In

a conventional aircraft, trim drag is the

drag associated with the tail in trim-

ming the airplane-the more load on

the tail, the greater the drag. In the

A vanti, the forward surface is design-

ed to reduce downloading on the tail

at cruise. By redistributing trim drag,

we minimize the total drag of the

airplane." (See sketches.)

What The Flap Is About

Pitch stability of the pure canard is

further aggravated, Neal continued,

when flaps are incorporated in the main

wing. "When you lower the flaps, the

center of pressure moves aft and more

lift is generated by the main wing.

Unless the forward surface can com-

pensate for the additional l ift generated

by the main wing flaps, the tendency

is for the aircraft to pitch down, or

become nose heavy." Piaggio solved

this problem by simply adding flaps to

the forward wing. Area of the forward-

surface flaps was calculated to balance

the lift produced by the main wing

flaps. The two sets of devices arc in-

terconnected by an electromechanical

linkage and deployed simultaneously

by a single cockpit control.

In keeping with the Starship's radical

image, Beech adopted a correspond-

ingly unique solution to the flap

pitching-moment problem, designing a

variable-geometry canard surface. Like

the wings of some tactical aircraft, such

as the Grumman F-14 fighter and

Rockwell B-1 bomber, the two sides of

145

the Starship's canard can be swept fore

and aft relative to the longitudinal axis

of the airplane. In the Starship, of

course, the movable canard is intercon-

nected with the main wing flaps so that

when the flaps are extended, the left

and right sides of the canard, pivoted

at their fuselage mounting point, swing

forward.

With the flaps in the retracted posi-

tion, the canard surfaces are swept

back, providing a more favorable drag

configuration for high-speed cruise

flight. Angle of sweep varies from

minus four degrees forward to plus 30

degrees aft. "By sweeping the canard

forward," Neal observed, ''its center

of lift also moves forward, providing

a longer moment arm, thereby balanc-

ing the additional lift produced by

lowering the flaps on the main wing.''

(See sketch.)

Accordi ng to Beech' s executive v-p

of engineering, Chester Rembleske, the

Wichita manufacturer settled on a

canard configuration for the Starship

because "it was the only way we could

get the performance and people accom-

modation we wanted with currently

available engines while remaining

under 12,500 pounds. We simply

couldn't grow the King Air any more

to provide additional speed, range, or

more on next page

146

cominued from preceding page

cabin space Without busti ng the twelve-

five [FAR 23] limit. "

As Piaggio used the P. 166 as a

departure point, Beech's baseline

airplane was the King Air 200. (When

Beech began to consider ideas for its

next-generation airplane, the Dash 300

King Air had yet to be launched. Sup-

porting Rembleske's comments above,

Beech was forced to boost the King

Air's gross weight above 12,500 lb in

order to extract more performance

from the airplane.) Beginning in the

early 1970s, Beech investigated many

configurations-including one with

twin engines mounted inside the

fuselage driving a single pusher prop

a Ia Lear Fan- before settling on a

canard, or " tandem-wing,"

arrangement.

The reasons were s imilar to Piag-

gio's: to get the wing behind the cabin

and the engines as far to the rear as

possible to reduce vibration and interior

noise. Unlike the A vanti, however, the

Starship eliminated the conventional

empennage, incorporating rudders in

large winglets, dubbed "tipsails," on

the ends of the main wing. It was

believed that a conventional vertical

stabilizer mounted on the fuselage

would serve as a "sounding board,"

transmitting excessive noise and vibra-

tion into the cabin.

Pitch control was shared by elevons

on the main wing and an elevator on

the canard surface. A small ventral tin

and rudder driven by an automatic yaw

damper was added to the bottom of the

tailcone to promote directional stabili-

ty in the event of .m engine failure.

" The canard planfonn gave us ad-

vantages no other configuration

could," Rembleske pointed out. A few

of these included "favorable empty- to

gross- weight capabilities and net wet-

ted area for a given comfort envelope

n.e . cabin size] ... an extremely wide

operational e.g. range ... superior

visibility from both the cabin and

cockpit. .. a deeper cabin with more

headroom than the King Air' s . .. and

good stall characteristics."

According to Rembleske, Beech

designed the Starship so ''the whole

airplane doesn' t stall, just the canard;

then the nose drops, returning flying

speed so that the main wing never

stalls." Posited Learjet's Neal : "With

a pure canard airplane, you have to be

very sure that, in a stall, the front sur-

face stalls first, otherwise the airplane

will go 'over on its back. "

To assist it in tailoring the canard

configuration to its needs, Beech

retained consulting engineer Burt Rutan

of Mojave, Calif. , considered one of

the country's leading authorities on the

behavior of tandem-wing airplanes.

When Beech and Rutan completed their

initial renderings of the Starship, the

aircraft bore an uncanny resemblance

to Rutan's popular VariEze kit plane,

prompting one wag to dub the big tur-

boprop the " HugeEze. "

Beech then cqmmissioned Scaled

Composites, of which Rutan was one

of the principals, to build the

85-percent-scale development pro-

totype which Rembleske termed "a big

wind-tunnel test model. " During the

testing program, the scaled Starship has

flown as high as 42,250 ft and in ex-

cess of 400 mph, "demonstrating ex-

cellent asymmetrical stability

throughout its speed range. "[In July,

Beech announced that it Juu1 purchased

Scaled Composites from Rutan and his

associates and had appointed him a

Beech vice-president and member of the

Beech board of directors. -Ed.}

The POC Starship allowed Beech to

refine the design before committing

itself to building a more expensive full-

scale airplane. Constructed mostly of

foam and fiberglass in the manner of

Rutan' s kit planes, the POC easily ac-

cepted modifications. Most notable of

these are small fences positioned on the

top of the main wing between the flaps

and elcvons and six smaJI projections

termed "vortilons" attached to the

underside of the wing leading edge,

three to a side, in front of the.elevons.

Rembleske said the vortilons ''smooth

. out spanwise flow over the wing and

raise the angle of attack at which the

wing stalls."

In addition to Beech's test pilots, the

POC airplane has been flown by FAA

representatives and a selection of cor-

porate aviators (most with King Air ex-

perience) to gauge pilot reaction, which

Rembleske claims has been "extremely

favorable. '' Even though the final Star-

ship design has been frozen, Beech

continues to use the 85-percent aircraft,

most recently to test installation of the

new Dash 67 version of the Pratt &

Whitney of Canada PT6A gas turbines

which will power the full-size Starship.

In the 12,500-Jb production Starship,

the Dash 67s will be flat-rated at 1,000

shp. each and will drive four-blade

posher props specially developed for

the airplane by Hartzell. Called "jet-

fans'' by . Beech, the props have

relatively high disk loading. The

powerplants are encased in slim

nacelles mounted close tothe fuselage

(to minimize differential thrust in

single-engine operations) on the top

surface of the main wing. The nacelles

are positioned so that prop disks fall

almost completely aft of the fuselage.

The A vanti will also use a pair of

PWC PT6As; however, because the

multinational entry's gross weight is

projected to fall 2, 700 lb less than that

of the Starship, the smaller Dash 66

version of the engine (flat-rated at 800

shp) has been chosen to provide motive

power. Hartzell also is fabricating

props for the A vanti, which will feature

four -scimitar-shaped blades of com-

posite construction. While the A van-

ti 's gas turbines are, likewis.c, mounted

atop the aft wing close-in to the

fuselage, like the Starship's, the

nacelles are carefully sculpted to incor-

porate a subtle area-rule effect to

minimize drag. " In designing them, "

Neal said, "we had to consider the

prop flow field, wing juncture, and the

fact that in the position where they're

mounted, the fuselage is beginning to

pull away [taper to the tail].''

Both aircraft employ high-aspect

main' wings; however, each is quite dif-

ferent in planform. The Gates-

Piaggio's all-aluminum example

features a straight leading edge, a

tapered trailing edge, and spans 45.4

ft. According to Neal, it is based on

''an advanced airfoil optimized for high

speeds and laminar flow.' ' Designed

for Piaggio by aeronautical engineers

at Ohio State University ,. the airfoil

reportedly is derived ''from NASA

studies." At 62.96lb/sq ft, the Avan-

ti's wing loading is fairly high; Neal

cited wing toading for the King Air 300

as 46.2 and .the Cessna Citation II as

41 .2. The wing is "simple, easy to

build, " he said, "with machinedparts,

front and rear spars, upper and lower

skins, and sheet-metal ribs."

Starship's wing, with an average

24-deg aft sweep, is contoured into

thick, strake-like sections at the root,

lending it almost a .. cranked-arrow"

appearance. Most of the airplane' s

3,400 lb of fuel resides within the

massive root sections. The wing.spans

54 ft between its 8.5-ft-high tipsails,

which are canted slightly inward. Ac-

cording to sources at Beech, the wing

consists of five different airfoils and is

equipped with Fowler-type flaps which

significantly increase its area when ex-

tended, and a Hporous titanium leading

edge'' (also incorporated on the canard

surface) to accommodate -the.aircraft's

glycol anti-icing system.

The-hearts of the airplanes-literally,

their raison d'etre- are t ~ i r cabins,

both of which are expansiv.e by tur-

boprop standards. Beech likes to com-

pare the Starship's passenger compart-

ment tothat of the HS 125 business j et.

Five feet 6' in. wide, 5 ft 5.5 in. high,

and a whopping 16 ft long (not in-

cluding the cockpit), it is a foot wider,

9 in. taller, and more than 3 ft longer

than that of the baseline King Air. The

cabin contains fore and .aft baggage

compartments, both accessible in

flight, with a combined capacity of 55

cu ft. Configured with individual chairs

and a side-facingcouch, the cabin can

seat up to eight passengers. With a dif-

ferential of 8.4 psi, the pressurization

system will maintain an 8,000-ft in-

terior at the Starship's maximum

altitude of 41 ,000 ft.

While a yard shor.ter than t he Star-

ship's cabin, the AvantFs passenger

compartment is 6 in. wider and 3.5 in.

higher. Gates-Piaggio likes to boast that

the A vanti' s cabin ''offers more height

than the Falcon 200 and more width

than the Citation ill.'' Its 42-cu-ft aft

baggage compartment can be loaded

through an exterior. hatch and is also

.accessible in flight. The cabin can be

configured to accommodate up to seven

passengers in lounge-type chairs. With

a pressure differential of 9:0 psi, the

A vanti can carry a sea-1evel cabin to

24,000 ft, or maintain. slightly over

7,000 ft inside at its max cruise altitude

of 41,000 ft.

Both airptanes will be certified for

single-pilot operation (meaning an ex-

tra passenger can be carried in the

copilot's seat, fuel load permitting).

The Gates-Piaggio panel will combine

both electronic flight instruments

(EFIS) and electromechanical gauges.

"We're not going heavy into EFIS, "

Neal said, ''because it costs money and

adds weight. ''

In keeping with its futuristic image,

the Starship will offer an optional ''all-

glass'' flight deck in which all in-

strumentation, except standby gauges,

will be electronic, including airspeed

indicators, altimeters, and engine in-

. struments. Incorporating no less than

14 cathode-ray tubes (CRTs), the

highly integrated digital array, in-

cluding a flight management system

and electronic tuning heads, has been

subcontracted to Collins which

showcased a mockup of the panel at the

NBAA Convention.

I ''All engine instrumentation will be

combined in a single CRT which also

adds an advisory capability for warn-

ings, '' Rembleske said. Called an

Engine Indication and Crew Advisory

System .(EICAS) "it's a step ahead of

the system Boeing uses in its new-

generation {757 and 767] airliners,'' he

said. Because the panel integrates

. many functions with fewer indicators,

Rembleske claims it cuts down on

1 weight and volume by "reducing the

1 number of..black boxes.''

I While Beech and Gates- ex-

ecutives have been relatively tight:-

l lipped about each projects un-

147

til recently, the simmering marketing

confrontation has begun to draw them

out. To Neal's observation that

' ' technical risk is much higher on the

Starship, '' Rembleske answered, ' ' I

don' t know what he's talking about.

We know what our airplane will do; we

know its performance capabilities. It's

probably been tested more before en-

try into production than any airplane

ever developed. That's why w.e built

the 85-percent-scale model. We know

what we've got, and they still have to

fly their airplane.''

Concerning comments by Neal and

O' Mara about stability and pitch con-

trol of the pure canard configuration,

Rembleske argued, "We're shooting to

meet the same stability standards re-

quired for a. conventional aircraft. If

anything, we hope . to exceed the

margins established by the FAA for

. stability and control. You can come up

with any opinion, depending upon

which side you're on.

''All of our assumptions have been

proven out in flight testing of the

85-percent airplane. We've flown it in

all sorts of configurations-one flap ex-

tended and the other retracted, one side

of the canard cranked forward and the

other aft, andso on-and, basically, the

airplane was completely flyable, . safe,

and controllable. Pitch control has not

been a problem any more with the

-more on page 150

canard than it would be with a conventional

airplane. We went through the same steps in

tailoring the aircraft that we would have followed

with a conventional one.''

Defending the Avanti's mostly aluminum con-

struction, Neal said, ''It gives us better control

over quality and weight and borrows heavily on

our twenty years of building all-metal aircraft.

Composites will make gradual inroads, but our

studies indicate that you don't achieve the weight

savings you started out to get, and they're more

expensive to produce. The materials cost more-

considerably more-and they' re labor-intensive

to work with.

"Also, you need more floor space to fabricate

composites because the molds have to be horizon-

tal; you can't pour plastic uphill. There must be

a reason why Boeing isn't designing all-composite

airliners. I admire Beech for what it's doing, but

I think it's a costly process." O'Mara wasn't so

kind: ''I think the only reason Beech is doing it

is to get a smooth finish on its airplane, which

we're going to achieve anyway with aluminum."

Countered Rembleske, "I think our experience

has indicated otherwise. We are getting weight

savings, and if you use proper design, you can

make composites work for you in a weight-

savings sense. Obviously, you' re going to have

-to establish design and manufacturing procedures

to keep costs under control, too.'' One of the

reasons why Beech chose to build the Starship

from graphite epoxy, Rembleske confided, was

because ''we wanted to maintain laminar flow

over as much of the airframe as we could through

clean airfoils and a smooth, rigid skin that can

retain its shape up to limit loads. You can't do

that with aluminum because it sags between ribs

and frames under loading.''

In terms of performance, Gates-Piaggio claims

a significant advantage over the Starship in speed.

''Superior aerodynamics'' and considerably

lighter gross weight, they say, will allow the

A vanti to achieve a maximum speed of 400 kt,

nearly 50 kt faster than the Starship's projected

max velocity of 352 kt. ''Anything above 370 will

clean up all the turboprops and butt right up

against the side of the Citation [I and II],'' Lear-

jet's O'Mara bragged. So there would be no hard

feelings in the debate with Beech, he added,

''Building an airplane is a series of compromises.

What we're talking about is how the two of us

have chosen our compromises.''

Both manufacturers claim their airplanes will

have ''transcontinental range.'' Gates-Piaggio

lists Avanti's range at 320 kt and 41,000 ft with

four passengers and NBAA IFR reserves as 2, 100

nmi. Although we're getting into apples and

oranges here, Beech cites ''range with max fuel,''

economy cruise of 272 kt at 41,000 ft, and 45-min

(VFR) reserves as 2,687 nmi, but does not men-

tion the number of passengers conveyed.

Maximum twin-engine rates of climb at sea

level of the Avanti and Starship are predicted as,

respectively, 3,650 and 3,250 fpm. With one

engine out, ROC falls off to 1,250 and 1,180 fpm.

Standard-day sea-level takeoff over a 50-ft

obstacle will require 2,413 fi for the Avanti,

2,400 ft for the Starship. With maximum fuel

aboard, the Avanti's payload is limited to 810 lb,

the Starship's to 915 lb.

This is all very impressive for airplanes

motivated through the sky by propellers-until

one comes to price tags. The Starship may very

well turn out to be 40 percent more fuel efficient

than a jet, as its developers claim, but purchasers

will pay dearly to own this kind of performance.

Or to put it another way, you could buy a lot of

fuel to fly a trusty and conventional King Air,

Conquest, or even a used Lear 25 around for a

long time for the difference in price.

Beech is quoting the equipped price of a Star-

ship for 1987 delivery (certification is expected

in late 1986) as $3.3 million. Gates-Piaggio feels

it has another advantage over Starship with its

equipped price for Avanti of $2.7 million.

Although quoted in 1983 dollars, O'Mara said

the partnership's ''target is to stay in that range.

It has to be competitive.''

For comparison, the 1985 price of a Citation

II is about $2.2 million, while that of the recent-

ly introduced Citation S/II is just under $3

million. At the NBAA Convention, Cessna an-

nounced an early-model Citation 500 "reman"

program that would recycle and upgrade old 500s

into Citation I configurations and sell them for

$1.5 million. Prior to Gates' 17 -percent price cut,

also declared at NBAA, a 1985 Lear 35A was

going out the door for around $3.9 million. A

King Air 300 currently claims something in the

neighborhood of $2.6 million.

'' Starship will move closer to the jets in terms

of price but not necessarily performance, '' Ron

Neal said. " We see our market as current King

Air operators and our competition as the Cita-

tion I and II. Those were our original goals and

they haven't changed."

Chet Rembleske said Beech would also appeal

"to current King Air owners" with the Starship,

but identified his competition as ''any of the $3-

to $4-million airplanes, including the small jets.''

How would Starship fare against A vanti? "I can't

answer that because I don't know what their

airplane will do,' ' said the Beech engineering

chief who retired last month.

While Gates-Piaggio had written no firm

orders for A vantis by mid-August, Rembleske

said Beech has been accepting $100,000

deposits for Starships for some time, though

he defended the actual number of orders

collected as ''proprietary.'' If a Starship

customer agrees to buy a new King Air as an

interim aircraft, Rembleske commented, Beech

will waive the $100,000 deposit for a delivery

position.

While the A vanti and Starship have the look

of the future-and there' s no denying that looks

sell-the trick of moving a turboprop through the

sky at 350 kt at 41,000 ft has already been per-

formed. Piper's Cheyenne 400LS has been put-

ting its block times up against the up-and-coming

competition in its quest to win friends and in-

fluence people.

The new technology represented by A vanti and

Starship allows these airplanes to combine their

350-kt and higher cruise speeds with the walk-

around room of much larger aircraft. By break-

ing with past methodologies, their designers hope

to eliminate the compromises business airplane

buyers have had to make in the past.

You might also like

- Considerations About Winglet DesignDocument10 pagesConsiderations About Winglet DesignBrian Xistos100% (1)

- Northrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandNorthrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 5 out of 5 stars5/5 (2)

- Comparing the Cozy IV and Long EZ Scratch Built PlanesDocument4 pagesComparing the Cozy IV and Long EZ Scratch Built PlanesAbdul Adavuruku Okinobanyi100% (2)

- Zenith expands with new STOL CH 750 Light Sport gap fillerDocument7 pagesZenith expands with new STOL CH 750 Light Sport gap fillerfintineanu_narcisNo ratings yet

- How Propellers Work: Understanding Propeller DesignDocument92 pagesHow Propellers Work: Understanding Propeller DesignAnonymous 6sSHozW2ZF100% (1)

- HANG GLIDER RANGE AND GUIDE TO ORDERINGDocument20 pagesHANG GLIDER RANGE AND GUIDE TO ORDERINGJanardhan S IyerNo ratings yet

- Pega Stol Wing Kit Wing Stress AnalysisDocument39 pagesPega Stol Wing Kit Wing Stress AnalysislaerciofilhoNo ratings yet

- Anatomy of A Stol AircraftDocument8 pagesAnatomy of A Stol AircraftMaiconNo ratings yet

- Tuffy - PlansDocument1 pageTuffy - PlansRajib PalNo ratings yet

- STOL CH 75 Light Sport Utility AirplaneDocument2 pagesSTOL CH 75 Light Sport Utility AirplanemacshilNo ratings yet

- SPinfo 1 PDFDocument127 pagesSPinfo 1 PDFSteven PollardNo ratings yet

- Taildragger Tales: My Late-Blooming Romance with a Piper Cub and Her Younger SistersFrom EverandTaildragger Tales: My Late-Blooming Romance with a Piper Cub and Her Younger SistersRating: 2 out of 5 stars2/5 (1)

- Background On Aircraft AerodynamicsDocument8 pagesBackground On Aircraft AerodynamicsAbdelrahman NassifNo ratings yet

- Aeropro EuroFOX Flight Test ReviewDocument6 pagesAeropro EuroFOX Flight Test ReviewMashrekin HossainNo ratings yet

- No Visible Horizon: Surviving the World's Most Dangerous SportFrom EverandNo Visible Horizon: Surviving the World's Most Dangerous SportRating: 4 out of 5 stars4/5 (6)

- Propeller Design Workshop Part IDocument92 pagesPropeller Design Workshop Part IJasoos ParrierNo ratings yet

- Homebuilt Aircraft Library SectionsDocument4 pagesHomebuilt Aircraft Library SectionsChukkaNo ratings yet

- Aircraft Designator Codes DecodedDocument80 pagesAircraft Designator Codes Decodedxiaopeng1No ratings yet

- Poster GyrocopterDocument1 pagePoster GyrocopterIPdaIndiNo ratings yet

- Aero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFDocument6 pagesAero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFGana tp100% (1)

- Inverse Pressure Gradient Matching Lowers Wing Interference DragDocument7 pagesInverse Pressure Gradient Matching Lowers Wing Interference DragredxusNo ratings yet

- Weight & Balance TechniquesDocument4 pagesWeight & Balance TechniquesAEROWORKERNo ratings yet

- Spitfire Ultralight SpecificationsDocument3 pagesSpitfire Ultralight SpecificationsKamini DudetNo ratings yet

- Lancair Legacy ChecklistDocument7 pagesLancair Legacy ChecklistSara JamesNo ratings yet

- Wing Installation Instructions Step 1Document12 pagesWing Installation Instructions Step 1NZHHNo ratings yet

- The Propeller Under The Bed: A Personal History of Homebuilt AircraftDocument29 pagesThe Propeller Under The Bed: A Personal History of Homebuilt AircraftUniversity of Washington PressNo ratings yet

- Analysis of Vertical Take Off Landing Aircraft Using CFD IJERTV3IS090267Document15 pagesAnalysis of Vertical Take Off Landing Aircraft Using CFD IJERTV3IS090267Prasanna NaikNo ratings yet

- Dean WilsonDocument7 pagesDean WilsonMB-RP100% (1)

- 701 Material ListDocument1 page701 Material ListIdris100% (1)

- Manual Magic Laser Operators ManualDocument16 pagesManual Magic Laser Operators ManualtrojanburroNo ratings yet

- 0007-P180 PTG Sec 7Document3 pages0007-P180 PTG Sec 7dwsims100% (1)

- Chapter 01 IntroductionDocument46 pagesChapter 01 IntroductionMark Evan Salutin100% (1)

- Design Build and Assess Composite Hub Bar For Gyroplane Application GYRATEDocument30 pagesDesign Build and Assess Composite Hub Bar For Gyroplane Application GYRATEvictorNo ratings yet

- Estimation of Wing Loading and Thrust LoadingDocument23 pagesEstimation of Wing Loading and Thrust LoadingAnonymous OFTUeE6No ratings yet

- (UAV) - Building A Composite AircraftDocument5 pages(UAV) - Building A Composite AircraftVany BraunNo ratings yet

- Ar2007043 1 PDFDocument142 pagesAr2007043 1 PDFAhmed Belber100% (1)

- Understanding Performance Flight Testing: Kitplanes and Production AircraftFrom EverandUnderstanding Performance Flight Testing: Kitplanes and Production AircraftRating: 5 out of 5 stars5/5 (1)

- July 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1Document7 pagesJuly 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1rte678No ratings yet

- A Photo History of Experimental VSTOL Aircraft and Their ContributionsDocument7 pagesA Photo History of Experimental VSTOL Aircraft and Their ContributionstofahadazizNo ratings yet

- How to Reduce Parasite Drag and Increase Your Aircraft's SpeedDocument5 pagesHow to Reduce Parasite Drag and Increase Your Aircraft's SpeedYvessNo ratings yet

- Gyro Plane PDFDocument10 pagesGyro Plane PDFHasanUSLUM100% (1)

- Minimizing Fuselage DragDocument7 pagesMinimizing Fuselage DragYvess100% (1)

- RC Amphibious Aircraft Report - Construction, Calculation & Project ManagementDocument107 pagesRC Amphibious Aircraft Report - Construction, Calculation & Project ManagementKazi Faisal100% (1)

- Design principles for small aircraftDocument34 pagesDesign principles for small aircraftMarion Nori MarallagNo ratings yet

- Harry Riblett AirfoilsDocument10 pagesHarry Riblett AirfoilsMaurizioNo ratings yet

- Aerotowing Gliders: A Guide to Towing Gliders, with an Emphasis on SafetyFrom EverandAerotowing Gliders: A Guide to Towing Gliders, with an Emphasis on SafetyNo ratings yet

- Vintage Airplane - Dec 2004Document36 pagesVintage Airplane - Dec 2004Aviation/Space History LibraryNo ratings yet

- Super King Air 300Document11 pagesSuper King Air 300aeroengineer1100% (1)

- Atr 42Document2 pagesAtr 42aeroengineer1No ratings yet

- Dash 8 and SF-340Document3 pagesDash 8 and SF-340aeroengineer1No ratings yet

- Learjet 20th AnniversaryDocument6 pagesLearjet 20th Anniversaryaeroengineer1No ratings yet

- IAI Astra Business JetDocument11 pagesIAI Astra Business Jetaeroengineer1100% (1)

- Gates Piaggio GP 180Document2 pagesGates Piaggio GP 180aeroengineer1100% (1)

- Beechcraft StarshipDocument4 pagesBeechcraft Starshipaeroengineer1No ratings yet

- CASA Nurtanio CN 235Document5 pagesCASA Nurtanio CN 235aeroengineer1100% (1)

- Dornier 228Document5 pagesDornier 228aeroengineer1No ratings yet

- AircraftDocument45 pagesAircraftaeroengineer1No ratings yet

- Climb Performance of A Turbojet AircraftDocument5 pagesClimb Performance of A Turbojet Aircraftaeroengineer1No ratings yet

- EASA Part 66 Aerodynamics QuestionsDocument39 pagesEASA Part 66 Aerodynamics Questionsaeroengineer195% (19)

- Module11 Aerodynamics SubjectsDocument2 pagesModule11 Aerodynamics Subjectsaeroengineer1No ratings yet

- Module 8 SubjectsDocument2 pagesModule 8 Subjectsaeroengineer1No ratings yet

- Best Mesl StudoDocument15 pagesBest Mesl StudoJoenielNo ratings yet

- Adb Wind ConeDocument4 pagesAdb Wind ConeSulistyo WidodoNo ratings yet

- Calculating Molar MassDocument5 pagesCalculating Molar MassTracy LingNo ratings yet

- E 74 - 06 - For Force Measuring InstrumentsDocument12 pagesE 74 - 06 - For Force Measuring InstrumentsSarvesh MishraNo ratings yet

- Kuliah 1 - Konservasi GeologiDocument5 pagesKuliah 1 - Konservasi GeologiFerdianNo ratings yet

- Lab Report 1Document8 pagesLab Report 1Hammad SattiNo ratings yet

- Wiley Wesleyan UniversityDocument36 pagesWiley Wesleyan UniversityBirunda SilvaNo ratings yet

- CSE (With SPL)Document65 pagesCSE (With SPL)parthasarathycseNo ratings yet

- The Field: Health Services InformationDocument34 pagesThe Field: Health Services InformationRyan Michael Oducado100% (4)

- Brochure Troysperse+CD1+Brochure+ (TB0112)Document8 pagesBrochure Troysperse+CD1+Brochure+ (TB0112)mario3312No ratings yet

- Pnas 1703856114Document5 pagesPnas 1703856114pi. capricorniNo ratings yet

- Understanding Logistics and Supply Chain Management ConceptsDocument12 pagesUnderstanding Logistics and Supply Chain Management Conceptsarfat kabraNo ratings yet

- Teodorico M. Collano, JR.: ENRM 223 StudentDocument5 pagesTeodorico M. Collano, JR.: ENRM 223 StudentJepoyCollanoNo ratings yet

- CHB1 Assignmen5Document2 pagesCHB1 Assignmen5anhspidermenNo ratings yet

- RB450G Trouble ShootingDocument9 pagesRB450G Trouble Shootingjocimar1000No ratings yet

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 pagesManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- Vega Plus 69Document3 pagesVega Plus 69yashNo ratings yet

- SO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BDocument15 pagesSO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BATMMOBILISNo ratings yet

- Campbell Soup Case-StudyDocument3 pagesCampbell Soup Case-StudyraghudeepaNo ratings yet

- Mayan Calendar End Date Sparks Doomsday SpeculationDocument16 pagesMayan Calendar End Date Sparks Doomsday SpeculationElfen RoxanneNo ratings yet

- 31 Legacy of Ancient Greece (Contributions)Document10 pages31 Legacy of Ancient Greece (Contributions)LyreNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaNurha ZizahNo ratings yet

- Amber ToolsDocument309 pagesAmber ToolshkmydreamsNo ratings yet

- G String v5 User ManualDocument53 pagesG String v5 User ManualFarid MawardiNo ratings yet

- 5 Tests of Significance SeemaDocument8 pages5 Tests of Significance SeemaFinance dmsrdeNo ratings yet

- Y06209 November 2015Document28 pagesY06209 November 2015Fredy CoyagoNo ratings yet

- CommunicationDocument5 pagesCommunicationRyan TomeldenNo ratings yet

- University Reserch Worksheet PDFDocument7 pagesUniversity Reserch Worksheet PDFapi-410567922No ratings yet

- Language Culture and ThoughtDocument24 pagesLanguage Culture and ThoughtLý Hiển NhiênNo ratings yet

- Super-Critical BoilerDocument32 pagesSuper-Critical BoilerAshvani Shukla100% (2)