Professional Documents

Culture Documents

Table of Contents Print2

Uploaded by

Shankar GCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table of Contents Print2

Uploaded by

Shankar GCopyright:

Available Formats

DESIGN AND FABRICATION OF ASSEMBLY FIXTURE

(FOR A PETROL BRACKET WITH ALIGNMENT)

A PROJECT REPORT Submitted by

P.DINESHKUMAR N.C.PRASAD M.SATHESH KUMAR G. SHANKAR

090111105013 090111105038 090111105053 090111105057

In partial fulfillment for the award of the degree Of

BACHELOR OF ENGINEERING

IN MECHANICAL ENGINEERING Dr. N.G.P INSTITUTE OF TECHNOLOGY, COIMBATORE

ANNA UNIVERSITY: CHENNAI 600 025

APRIL 2013

ANNA UNIVERSITY: CHENNAI 600 025

BONAFIDE CERTIFICATE

Certified that this project report DESIGN AND FABRICATION OF ASSEMBLY FIXTURE is the FOR A PETROL work of BRACKET WITH

ALIGNMENT

Bonafide

P.DINESHKUMAR,

N.C.PRASAD, M.SATHESH KUMAR, G.SHANKAR who carried out the project work under my supervision.

SIGNATURE

SIGNATURE

Dr.C.Selvaraj

HEAD OF THE DEPARTMENT

Mr.V.Sivaraman

SUPERVISOR

Associate Professor

Dept. of Mechanical Engineering Dr.N.G.P Institute of Technology Coimbatore- 48. Dept. of Mechanical Engineering Dr.N.G.P Institute of Technology Coimbatore- 48.

Submitted during the university examination held on April 2013

------------------------------------Internal Examiner

---------------------------------------External Examiner

ACKNOWLEDGEMENT

We express our deepest gratitude to Our Management for providing us with an environment to complete our project successfully. We are very grateful to our Principal Dr.V.Porkumaran and Dr.S. Dhandapani, Advisor for their valuable guidance and blessings. We would like to thank our Head of the Department Dr.C.Selvaraj for his unwavering support during the entire course of this Major project work and who modeled us both technically and morally for achieving greater success in this major project work. We thank our Project coordinator Prof.V.M.Manivasagam., department of mechanical engineering for his help and innovative ideas in making this project a successful one. We express our sincere thanks to our internal guide Mr.V.Sivaraman., Associate professsor for his constant encouragement and support throughout our course, especially for the useful suggestions given during the course of the project period and being instrumental in the completion of our project with his complete guidance. We also thank Sakthi Auto Component Limited and our external guide Mr.K.G.mohanasundaram.,senior manager-quality assurance for their help and innovative ideas in making this project a successful one. Finally, we take this opportunity to extend our deep appreciation to our family and friends, for all that they meant to us during the crucial times of the completion of our project.

COMPANY PROFILE:

Sakthi Auto Component Limited, established in the year 1983 was founded by Dr.Mahalingam. They are the major supplier of critical components to passenger car manufacturers. The components are Steering knuckles, Brake drums, Brake discs, Hubs, Brake calipers, Brackets, Carriers, Differential cases and Manifolds etc. Presently the supplies of these components are made to MarutiUdyog Ltd., Hyundai India Auto Ltd., Ford, Honda, Volkswagen, Volvo, etc., the quantum of exports per month ranges between 250 MT to 500 MT. It is likely to go up to 1000 MT in near future. Sakthi Auto Component Limited has been awarded the industrial safety awards for three consecutive years. It has also been recognized by MarutiUdyog Limited as a First class critical Component Vendor.

ABSTRACT: Fixtures are the work holding devices, to reduce the cost of manufacture in mass production. The main aim of our project is to design and fabricate an assembly fixture for a petrol bracket without error committed for stud assembly. During the assembly of stud in petrol bracket there is a chance of human error leads to improper screwing of stud which results in loss of time and rejection of component. Thus, we have designed an assembly fixture which eliminates the chance of human error during assembly. Fixtures are mainly designed to save production time and also to ensure the dimensional accuracy and also to facilitate quick and interchangeable assembly during mass production.

TABLE OF CONTENTS CHAPTER.NO TITLE PAGE NO

I II III 1.

ABSTRACT . (v) LIST OF FIGURES (viii) LIST OF TABLES... INTRODUCTION... 1.1. INTRODUCTION... 1.2. INTRODUCTION TO COMPONENT (PETROL BRACKET) 1.2.1. Drive shaft ...... 1.3. INTRODUCTION TO WORK HOLDING DEVICES 1.3.1 Jigs and Fixtures- Introduction.. 1.4. INTRODUCTION TO LOCATING AND CLAMPING DEVICES 1.4.1 PRINCIPLE OF LOCATION ... 1.4.1.1. Principle of Pin Location 1.4.1.2. Principle of Mutually Perpendicular Planes . 1.4.1.3 Principle of Extreme ... 1.4.2. LOCATING METHODS AND DEVICES .... 16 14 15 11 11 14 5 7 2 4 (x) 1 1

1.4.3. PINS AND BUTTON LOCATORS ... 1.4.3.1 Locating Pins . 1.4.3.2 Conical Locating Pins .... 1.4.3.3 Cylindrical Locating Pins .. 1.4.4. CLAMPING INTRODUCTION 1.4.4.1. Clamping device .. 1.4.4.1.1. Bridge Clamp . 1.5. INTRODUCTIONS TO SENSORS . 1.5.1. PROXIMITY SENSOR ... 1.5.2 PROXIMITY LIMIT SWITCH 2. METHODOLOGY . 2.1. WORKING 2.2. DESIGN OF ASSEMBLY FIXTURE.. 2.3. FIXTURE MANUFACTURING PROCESS 2.4. COST ESTIMATION .. 2.5. COMPARISON OF EXISTING FIXTURE AND NEW DESIGNED FIXTURE... 2.6. ADVANTAGES.

16 17 17 17 18 21 21 23 24 25 26 26 28 48 51

52 54

3.

CONCLUSION

...

55 56

REFERENCES ...

LIST OF FIGURES FIG NO 1.1 1.2 1.3 1.4 1.5 DESCRIPTION PAGE NO 2 10 12 12

PETROL BRACKET... A SIMPLE DESIGN OF JIG AND FIXTURE WORKPIECE IN SPACE ............... WORKPIECE LOCATED IN A FIXED BODY PRINCIPLE OF MUTUALLY PERPENDICULAR PLANES ....

15 17 19 20 21

1.6 1.7 1.8 1.9 3.1(A)

LOCATING PINS .. METHOD OF CLAMPING ... POSITION OF CLAMP BRIDGE CLAMP 3D-BOTTOM BASE PLATE WITH SENSOR STAND ....................

28

3.1 (B)

2D-BOTTOMS BASE PLATES WITH SENSOR STAND ....................... 29

3.2(A)

3D-BOTTOM BASE PLATE WITH LIMIT SWITCH 30

3.2 (B)

3D-BOTTOM BASE PLATES WITH LIMIT SWITCH 31

3.3(A) 3.3(B) 3.4(A) 3.4(B) 3.5(A) 3.5(B) 3.6(A) 3.6(B) 3.7(A) 3.7(B) 3.8(A) 3.8(B) 3.9(A) 3.9(B) 3.10(A) 3.10(B) 3.11

3D-TOP BASE PLATE .. 2D-TOP BASE PLATE . 3D-SENSOR STAND 2D-SENSOR STAND . 3D-PLUNGER 2D-PLUNGER ... 3D-SPACER 2D-SPACER 3D-SENSOR PIN ... 2D-SENSOR PIN 3D-SLIDING CLAMP 2D-SLIDING CLAMP 3D-ANGULAR BLOCK 2D-ANGULAR BLOCK . 3D-FINAL ASSEMBLY OF A FIXTURE . 2D-FINAL ASSEMBLY OF A FIXTURE PICTORIAL REPRESENTATION OF EXISTING FIXTURE AND NEW DESIGNED FIXTURE

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

52

LIST OF TABLES TABLE NO DESCRIPTION PAGE NO

2.1 2.2

COST ESTIMATION... . 51 COMPARISION OF EXISTING FIXTURE AND NEW DESIGNED FIXTURE 53

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Link Springer ComDocument1 pageLink Springer ComShankar GNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Diploma TitleDocument17 pagesDiploma TitleChandra SekarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Diploma Title FinalDocument17 pagesDiploma Title FinalShankar GNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Assessment FormatDocument20 pagesAssessment FormatShankar GNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- General Concepts of Earthquake Resistance DesignDocument10 pagesGeneral Concepts of Earthquake Resistance DesignPratik SolankiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Bolt Load Analysis / Robotic Arm Simulation Engineering Methods, IncDocument8 pagesBolt Load Analysis / Robotic Arm Simulation Engineering Methods, IncKabil RajNo ratings yet

- New Production Molding System Takes Shape With ACE Team, Eaton ProductsDocument2 pagesNew Production Molding System Takes Shape With ACE Team, Eaton ProductsShankar GNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Leaf SpringsDocument7 pagesLeaf SpringsShankar GNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Types of Stuffing Boxes: Standard Purging TypeDocument1 pageTypes of Stuffing Boxes: Standard Purging TypeShankar GNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Crop - ViiiDocument13 pagesCrop - Viiivivek_theeasywaysNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Comparative Analysis For Link Cross-Section of Manipulator ArmsDocument24 pagesComparative Analysis For Link Cross-Section of Manipulator ArmsKabil RajNo ratings yet

- Doc122 86 PDFDocument5 pagesDoc122 86 PDFShankar GNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A125 PDFDocument5 pagesA125 PDFShankar GNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Flexxaire Engine Temperature Control System Ax1000 Fan SeriesDocument11 pagesFlexxaire Engine Temperature Control System Ax1000 Fan SeriesShankar GNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- CraneDocument44 pagesCraneEka KurobaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A125 PDFDocument5 pagesA125 PDFShankar GNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Nano MaterialDocument8 pagesNano MaterialShankar GNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Ecway Technologies: Automatic Pneumatic Clutch and Braking System SynopsisDocument5 pagesEcway Technologies: Automatic Pneumatic Clutch and Braking System SynopsisShankar GNo ratings yet

- Recycling Used Oil Using Acetic AcidDocument27 pagesRecycling Used Oil Using Acetic Acidcumpio425428No ratings yet

- Conveyor Belt PDFDocument30 pagesConveyor Belt PDFShankar GNo ratings yet

- UnderstandingyourresultsPEGJ00462007added PDFDocument16 pagesUnderstandingyourresultsPEGJ00462007added PDFShankar GNo ratings yet

- Recycling Used Oil Using Acetic AcidDocument27 pagesRecycling Used Oil Using Acetic Acidcumpio425428No ratings yet

- Part11 VHJGKJGPDFDocument1 pagePart11 VHJGKJGPDFuismechprojectNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- HwcompatDocument331 pagesHwcompatvikram1092No ratings yet

- Thermal and Refregeration Based Projects PDFDocument3 pagesThermal and Refregeration Based Projects PDFShankar GNo ratings yet

- Project Edited 222 (Final)Document68 pagesProject Edited 222 (Final)Shankar GNo ratings yet

- Multi Agri Cutter - AbstractDocument4 pagesMulti Agri Cutter - AbstractShankar G75% (4)

- Pneumatic Bearing PullerDocument4 pagesPneumatic Bearing PullerShankar G50% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- IitkDocument8 pagesIitkBejai Alexander MathewNo ratings yet

- Brosjyre Upcoming Projects PDFDocument15 pagesBrosjyre Upcoming Projects PDFDiego García VaqueroNo ratings yet

- Suspension Systems: Meeknet - Co.uk/e64Document40 pagesSuspension Systems: Meeknet - Co.uk/e64Veres PalNo ratings yet

- Ответы к Тестам CD 0053 HazmatDocument3 pagesОтветы к Тестам CD 0053 HazmatChesterJeorgeDizonNo ratings yet

- CDBG Public Notice (5/24/12)Document1 pageCDBG Public Notice (5/24/12)monroecountybeaconNo ratings yet

- BS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFDocument13 pagesBS EN 12697 Part 36 2003 - Determination of The Thickness of A Bituminous Pavement PDFjerin sam kurianNo ratings yet

- Cdi 4 Lesson 15Document32 pagesCdi 4 Lesson 15Jemmuel MedinaNo ratings yet

- 2D Cuboid+Point+Polygon Linking Annotation DocumentDocument45 pages2D Cuboid+Point+Polygon Linking Annotation DocumentVitas Vitaly67% (3)

- Reduce WBV Exposure from Heavy EquipmentDocument1 pageReduce WBV Exposure from Heavy EquipmentAaquil RaziNo ratings yet

- Evaluation of Performance of Maruti Suzuki India LTD PDFDocument10 pagesEvaluation of Performance of Maruti Suzuki India LTD PDFHomi_nathNo ratings yet

- King Standard Detail DrawingDocument64 pagesKing Standard Detail DrawingTimNo ratings yet

- Vocab FilesDocument3 pagesVocab FilesKhánhSocksNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 6 Earthworks 4Document34 pagesChapter 6 Earthworks 4Tewodros Abate100% (1)

- Manuals Scooty Zest 110Document68 pagesManuals Scooty Zest 110Sagar Yadav100% (1)

- PRINCIPLES OF INFRASTRUCTUREDocument47 pagesPRINCIPLES OF INFRASTRUCTUREJosephine CepedaNo ratings yet

- MMMMMMMDocument606 pagesMMMMMMMAnn JamisolaminNo ratings yet

- AP Building Rules-2012 13 04 2012Document69 pagesAP Building Rules-2012 13 04 2012Saikiran SunnyNo ratings yet

- 1.final MC Assignment Group IIDocument64 pages1.final MC Assignment Group IISolomon TesfayeNo ratings yet

- Specialty Mix 5 - Cold In-Place Recycling JKR/SPJ/2008Document34 pagesSpecialty Mix 5 - Cold In-Place Recycling JKR/SPJ/2008NajimieItachiIINo ratings yet

- KeNHA PORTAL - Dashboard PDFDocument2 pagesKeNHA PORTAL - Dashboard PDFPhoebe NyamariNo ratings yet

- For Upload Transportation LawDocument31 pagesFor Upload Transportation LawGissy GaudielNo ratings yet

- Curriculamvitae Atul Kumar Mishra: Personal DetailsDocument3 pagesCurriculamvitae Atul Kumar Mishra: Personal DetailsAtul Kumar MishraNo ratings yet

- Lawsuit For Crash Near Lyons Township High SchoolDocument3 pagesLawsuit For Crash Near Lyons Township High SchoolDavid GiulianiNo ratings yet

- Basti Bikash Mapdanda 2072Document17 pagesBasti Bikash Mapdanda 2072Aayush Koirala100% (1)

- Civil Engineering 1st PreBoard Exam RefresherDocument12 pagesCivil Engineering 1st PreBoard Exam RefresherFely Joy RelatoresNo ratings yet

- Bridge Design Standards For Roads & Highways DepartmentDocument14 pagesBridge Design Standards For Roads & Highways Department00152No ratings yet

- Government of Andhra Pradesh: Panchayatraj Engineering DepartmentDocument12 pagesGovernment of Andhra Pradesh: Panchayatraj Engineering DepartmentD.V.Srinivasa RaoNo ratings yet

- Chassis: by Naveen KDocument56 pagesChassis: by Naveen KNaveen KandasamyNo ratings yet

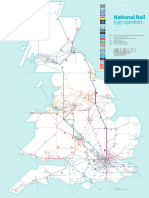

- Train Map UKDocument1 pageTrain Map UKRussellNo ratings yet

- Case Study P6Document3 pagesCase Study P6shaniakateogalesNo ratings yet

- Cynwyd Heritage Trail MasterplanDocument99 pagesCynwyd Heritage Trail MasterplandsrmanayunkNo ratings yet

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumFrom EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumRating: 3 out of 5 stars3/5 (12)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideFrom EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideRating: 5 out of 5 stars5/5 (2)

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (54)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyFrom EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyRating: 4 out of 5 stars4/5 (51)