Professional Documents

Culture Documents

Hfo Msds Shell

Uploaded by

Liam MoylanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hfo Msds Shell

Uploaded by

Liam MoylanCopyright:

Available Formats

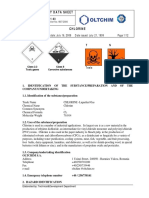

Heavy Fuel Oil

Safety Data Sheet

Heavy Fuel Oil

1. IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND COMPANY/UNDERTAKING

Product Type/Use Other Names Fuel for use in off-road diesel engines, boilers, furnaces and other combustion equipment. Name Fuel Oil Blend Component, Marine Fuel Oil 360, Marine Fuel Oil 25, Marine Fuel Oil 180, Marine, Marine Fuel Oil 180 FIJI, Inland Fuel Oil 180, Fuel Oil Tahiti, Fuel Oil TA, Fuel Oil 571. Telephone Numbers Emergency Tel. 1800 651 818 Telephone/Fax Number Tel: 03 9666 5444 Fax: 03 8823 4800

Supplier Shell Company of Australia Ltd. Level 2, 8 Redfern Road, Hawthorn East, Victoria 3123 (ABN 46 004 610 459) AUSTRALIA

2. COMPOSITION/INFORMATION ON INGREDIENTS Preparation Description Streams obtained from distillation and cracking processes and containing a mixture of saturated, aromatic and olefinic hydrocarbons with carbon numbers predominantly in the C9 to C50 range. Contains cracked components in which polycyclic aromatic compounds, mainly 3-ring but some 4 to 6 ring species, are present. Contains sulphur, oxygen, nitrogen compounds, vanadium and other metals at >10 ppm w/w. Hydrogen sulphide may be present both in the liquid and the vapour. Composition is complex and varies with the source of the crude oil.

Name Fuel oil, residual Hydrogen sulphide CAS 68476-33-5 7783-06-4 EINECS 270-675-6 231-977-3 Proportion 99-100 % 0-0.09 % Hazard T F+, T+, N R Phrase R45, R66, R52/53 R12, R26, R50

Other Information Heavy Fuel Oils are blends of residual fuels and distillate streams which always require heating before use. See Section 16 'Other Information' for full text of each relevant Risk Phrase. 3. HAZARDS IDENTIFICATION Hazards Identification HAZARDOUS SUBSTANCE. NON-DANGEROUS GOODS. Hazard classification according to the criteria of NOHSC.

Version No. 1.1 9/05/2006

Page 1 of 9

Heavy Fuel Oil

Dangerous goods classification according to the Australia Dangerous Goods Code. Human Health Hazards Fuel oil may cause cancer. Product classified as a Category 2 carcinogen. Hydrogen sulphide may accumulate in the head space of containers.The vapour phase in tanks and vessels should be regarded as a hazardous space. Hydrogen sulphide is very toxic by inhalation and may cause respiratory paralysis and death. This product is normally used as a hot liquid and contact may cause burns. Repeated exposure may cause skin dryness or cracking. Safety Hazards Not classified as flammable, but will burn. Therefore it should be treated as a potentially flammable liquid. Flammable vapours may be present even at temperatures below the flash point. May ignite on surfaces at temperatures above auto-ignition temperature. Environmental Hazards Harmful to aquatic organisms. May cause long term adverse effects in the aquatic environment. 4. FIRST AID MEASURES Symptoms and Effects Not expected to give rise to an acute hazard under normal conditions of use. Exposure to hydrogen sulphide, at concentrations above the recommended occupational exposure standard, may cause headache, dizziness, irritation of the eyes, upper respiratory tract, mouth and digestive tract, convulsions, respiratory paralysis, unconsciousness and even death. Unconsciousness as a result of exposure to hydrogen sulphide may occur extremely rapidly and without other symptoms. Contact with hot product may cause skin burns, including to the underlying skin. Owing to its high viscosity this product does not normally constitute an ingestion hazard. Ingestion will only occur in grossly abnormal circumstances. If ingested may lead to irritation of the mouth, irritation of the throat, irritation of the digestive tract, and vomiting. Inhalation Remove to fresh air. If breathing but unconscious, place in the recovery position. If breathing has stopped, apply artificial respiration. If heartbeat absent, give external cardiac compression. Monitor breathing and pulse. Seek urgent medical advice. Skin Wash skin with water using soap if available. Contaminated clothing must be removed as soon as possible. It must be laundered before reuse. When using high pressure equipment, injection of product under the skin can occur. If high pressure injuries occur, the casualty should be sent immediately to a hospital. Do not wait for symptoms to develop. Eye Flush eye with copious quantities of water. If persistent irritation occurs, obtain medical attention. Ingestion DO NOT INDUCE VOMITING. Protect airway if vomiting begins. Give nothing by mouth. If breathing but unconscious, place in recovery position. If breathing has stopped, apply artificial respiration. OBTAIN MEDICAL ATTENTION IMMEDIATELY. Advice to Doctor No specific treatment indicated. Treat with supportive measures as appropriate to the patient's condition. High pressure injection injuries require prompt surgical intervention and possibly steroid therapy, to minimise tissue damage and loss of function.

Version No. 1.1 9/05/2006

Page 2 of 9

Heavy Fuel Oil

5. FIRE FIGHTING MEASURES Specific Hazards Hazardous combustion products may include hydrogen sulphide, carbon monoxide, oxides of nitrogen, oxides of sulphur and unburnt hydrocarbons. Flammable vapours may be present even at temperatures below the flash point. The vapour is heavier than air, spreads along the ground and distant ignition is possible. Sinks in fresh water, floats on sea water and may be reignited on surface water. Extinguishing Media Foam, fine water spray and dry chemical powder. Carbon dioxide, Clean Agents (e.g. Inergen, Argonite etc.), sand or earth may be used for small fires only. Unsuitable Extinguishing Media Do not use water in a jet. Protective Equipment Proper protective equipment must be worn, this should include breathing apparatus when approaching a fire in a confined space. Other Information Keep adjacent drums and tanks cool by spraying with water from a safe location. If possible remove them from the danger zone. If adequate cooling cannot be achieved, the area needs to be evacuated, and further fire fighting and cooling attempts should be carried out from a safe location. 6. ACCIDENTAL RELEASE MEASURES Personal Precautions Remove all possible sources of ignition in the surrounding area. May ignite on surfaces at temperatures above auto-ignition temperature. Evacuate all personnel. Do not breathe fumes, vapour. Avoid contact with skin, eyes, clothing. Ventilate contaminated area thoroughly. Wear chemical resistant knee length safety boots and PVC jacket and trousers. Wear safety glasses or full face shield if splashes are likely to occur. Environmental Precautions Prevent from spreading or entering into drains and surface waters (e.g. lakes, ponds, ditches, rivers and streams) by using sand, earth, or other appropriate non-combustible barriers. Inform local authorities if impacts cannot be prevented. Clean-up Methods - Small Spillages To minimize soil and groundwater contamination, absorb liquid with sand, earth or other recommended sorbant material, which is commercially available. Sweep up and remove to a suitable, clearly marked container for disposal in accordance with local regulations. Do not disperse using water. Clean-up Methods - Large Spillages Prevent from spreading by making a barrier with sand, earth or other containment material. Reclaim liquid directly or in an absorbent. Dispose of as for small spills. Maritime Spillages Maritime spillages should be dealt with using a Shipboard Oil Pollution Emergency Plan (SOPEP), as required by MARPOL Annex 1 Regulation 26. Other Information Local authorities should be advised if significant spillages cannot be contained. If contamination of sites occurs remediation may require specialist advice. Observe all relevant local regulations.

Version No. 1.1 9/05/2006

Page 3 of 9

Heavy Fuel Oil

7. HANDLING AND STORAGE Handling When using do not eat, drink or smoke. Only use in well-ventilated areas. Take precautionary measures against static discharges. Ensure all equipment is properly earthed. If using pressurised equipment, take extra care to avoid injection under the skin. Use local exhaust ventilation if there is risk of inhalation of vapours, mists or aerosols. Avoid prolonged or repeated contact with skin. When handling product in drums, safety footwear should be worn and proper handling equipment should be used. Prevent spillages. Cloth, paper and other materials that are used to absorb spills present a fire hazard. Avoid their accumulation by disposing of them safely and immediately. In addition to any specific recommendations given for controls of risks to health, safety and the environment, an assessment of risks must be made to help determine controls appropriate to local circumstances. Storage This product must never be stored in buildings occupied by people. Tanks should be provided with a heating facility. Ensure heating coils are always covered with product (minimum 15 cm). Fuels coming into contact with hot, exposed heating coils, could result in the rapid generation of a flammable atmosphere. Keep in a bunded area with a sealed (low permeability) floor, to provide containment against spillage. Seek specialist advice for the design, construction and operation of bulk storage facilities. Storage Temperatures 40C Minimum. Product Transfer Electrostatic charges may be generated during pumping. Ensure electrical continuity by bonding all equipment. Wait 2 minutes after tank filling (for tanks such as those on road tanker vehicles) before opening hatches or manholes. Wait 30 minutes after tank filling (for large storage tanks) before opening hatches or manholes. Tank Cleaning Cleaning, inspection and maintenance of storage tanks is a specialist operation that requires the implementation of strict procedures and precautions. These include issuing of work permits, gas-freeing of tanks, using a manned harness, lifelines, and wearing air-supplied breathing apparatus. Prior to entry and whilst cleaning is underway, the atmosphere within the tank must be monitored using an oxygen meter and explosimeter. In addition, appropriate electrochemical sensors or colorimetric tubes must be used to check for the presence of hydrogen sulphide. Recommended Materials For containers or container linings, use mild steel or stainless steel. Aluminium may also be used for applications where it does not present an unnecessary fire hazard. Examples of suitable materials are: high density polyethylene (HDPE), polypropylene (PP), and Viton (FKM), which have been specifically tested for compatibility with this product. For container linings, use amine-adduct cured epoxy paint. For seals and gaskets use: graphite, PTFE, Viton A, Viton B. Unsuitable Materials Synthetic materials such as plastics and fibreglass may be unsuitable for containers or container linings depending on the material specification and intended use. Examples of materials to avoid are: natural rubber (NR), nitrile rubber (NBR), ethylene propylene rubber (EPDM), polymethyl methacrylate (PMMA), polystyrene, polyvinyl chloride (PVC), polyisobutylene. However, some may be suitable for glove materials. Other Information Ensure that all local and international regulations regarding handling and storage facilities are followed. 8. EXPOSURE CONTROLS, PERSONAL PROTECTION

Exposure Limits

Version No. 1.1 9/05/2006

Page 4 of 9

Heavy Fuel Oil

Substance Hydrogen sulphide

Regulations NOHSC:1003 NOHSC:1003 NOHSC:1003 NOHSC:1003

Exposure Duration TWA TWA STEL STEL

Exposure Limit 10 14 15 21

Units ppm mg/m3 ppm mg/m3

Notes

NOHSC:1003

Adopted National Exposure Standards for Atmospheric Contaminants in the Occupational Environment [NOHSC:1003(1995)] - 3rd Edition

Exposure Controls The level of personal protection and the types of controls necessary will vary depending on exposure conditions. Select controls based on a risk assessment of local circumstances. Use sealed systems as far as possible. Use local, intrinsically safe, exhaust ventilation if there is a risk of inhalation of vapours, mists, or aerosols. Provide eye washes and showers for emergency use. Respiratory Protection Care should be taken to keep exposures below applicable occupational exposure limits. If this cannot be achieved, use of a respirator fitted with an organic vapour cartridge combined with a particulate pre-filter should be considered. Where air-filtering respirators are unsuitable (e.g. where airborne concentrations are high, there is a confined space or a risk of oxygen deficiency) use appropriate positive pressure breathing apparatus. Hand Protection When handling heated product wear heat resistant gloves. Select gloves tested to a relevant standard (e.g. Europe EN374, US F739). When prolonged or frequent repeated contact occurs, Nitrile, Neoprene or PVC gloves may be suitable. (Breakthrough time of > 240 minutes). Breakthrough times for gloves vary depending on, e.g. chemical resistance, material thickness, frequency and duration of contact. Selection should also take into account other usage requirements, e.g. dexterity, heat resistance, other chemical substances handled. Always seek advice from glove suppliers. Contaminated gloves should be replaced. Personal hygiene is a key element of effective hand care. Gloves must only be worn on clean hands. After using gloves, hands should be washed and dried thoroughly. Application of a non-perfumed moisturizer is recommended. Eye Protection Wear safety glasses or full face shield if splashes are likely to occur. Body Protection Minimise all forms of skin contact. In the event of risk from splashing wear e.g. Nitrile, PVC, or neoprene rubber apron. Wear safety shoes or boots which are chemical and petroleum distillate resistant. Environmental Exposure Controls Minimise release to the environment. An environmental assessment must be made to ensure compliance with local environmental legislation. Exposure Measurement Methods Monitoring of the concentration of substances in the breathing zone of workers or in the general workplace may be required to confirm compliance with an Occupational Exposure Limit and adequacy of exposure controls. For some substances biological monitoring may also be appropriate. Information on suitable methods is available on request. 9. PHYSICAL AND CHEMICAL PROPERTIES

Colour Physical State Odour pH Value Vapour Pressure Initial Boiling Point Dark brown/black. Viscous liquid. Characteristic. Data not available. <0.1 kPa at 40C. circa 150C.

Version No. 1.1 9/05/2006

Page 5 of 9

Heavy Fuel Oil

Final Boiling Point Solubility in Water Density Flash Point Flammable Limits - Upper Flammable Limits - Lower Auto-Ignition Temperature Kinematic Viscosity Vapour Density (Air=1) Partition co-efficient, n-octanol/water Other Information

Cannot be determined (>600C). Negligible. <1010 kg/m3 at 15C. >62C (Method: PMCC (B)). 5%(V/V) maximum. 0.5%(V/V) minimum. >250C. <700 mm2/s at 50C. >5 at 15C. log Pow 3 to 6. The above properties are generic. There may be parameters for which National Specifications apply.

10. STABILITY AND REACTIVITY Stability Stable under normal use conditions. Conditions to Avoid Heat, flames and sparks. Materials to Avoid Strong oxidizing agents e.g. chlorates and ammonium nitrate. Hazardous Decomposition Products Hazardous decomposition products are not expected to form during normal storage. 11. TOXICOLOGICAL INFORMATION Basis for Assessment Fuels are typically made from blending several refinery streams. Toxicological studies have been carried out on a variety of hydrocarbon blends and streams but not those containing additives. Information given is based on a knowledge of available data on the hydrocarbon blends and on a knowledge of the constituents. Acute Toxicity - Oral LD50 > 5000 mg/kg. Acute Toxicity - Dermal LD50 > 2000 mg/kg. Acute Toxicity - Inhalation Data not available. Eye Irritation Slightly irritating. Skin Irritation Slightly irritating. Respiratory Irritation Expected to be slightly irritating. Skin Sensitisation Not a skin sensitizer. Carcinogenicity Dermal application to mice causes skin tumours. Mutagenicity In-vitro mutagenicity studies show that mutagenic activity is related to 4-6 ring polycyclic aromatic content.

Version No. 1.1 9/05/2006

Page 6 of 9

Heavy Fuel Oil

Reproductive Toxicity Causes slight foetotoxicity in rats at doses which are maternally toxic. Human Effects Prolonged/repeated contact may cause defatting of the skin which can lead to dermatitis and may make the skin more susceptible to irritation and penetration by other materials. Under conditions of poor personal hygiene, excessive exposure may lead to irritation, oil acne and foliculitis and development of warty growths which may subsequently become malignant. Other Information High pressure injection of product into the skin may lead to local necrosis if the product is not surgically removed. 12. ECOLOGICAL INFORMATION Basis for Assessment Fuels are typically made from blending several refinery streams. Ecotoxicological studies have been carried out on a variety of hydrocarbon blends and streams but not those containing additives. Information given is based on a knowledge of the components and the ecotoxicology of similar products. Mobility Sinks in fresh water, but will float on seawater. Contains volatile components. Partly evaporates from water or soil surfaces, but a significant proportion will remain after one day. If it enters soil, it will adsorb to soil particles and will not be mobile. Large volumes may penetrate soil and could contaminate groundwater. Persistence / Degradability Major components are inherently biodegradable. Persists under anaerobic conditions. The volatile components oxidise rapidly by photochemical reactions in air. Bioaccumulation Contains components which may have the potential to bioaccumulate. May cause tainting of fish and shellfish. Ecotoxicity Poorly soluble mixture. Product is classified as harmful to aquatic organisms, LL/EL50 10-100 mg/l. (LL/EL50 expressed as the nominal amount of product required to prepare aqueous test extract). May cause physical fouling of aquatic organisms. 13. DISPOSAL CONSIDERATIONS Waste Disposal Waste arising from a spillage or tank cleaning should be disposed of in accordance with prevailing regulations, preferably to a recognised collector or contractor. The competence of the collector or contractor to deal satisfactorily with this type of product should be established beforehand. Do not dispose into the environment, in drains or in water courses. Do not dispose of tank water bottoms by allowing them to drain into the ground. This will result in soil and groundwater contamination. Product Disposal As for waste disposal. Container Disposal Recycle or dispose of in accordance with the legislation in force with a recognised collector or contractor. Do not pollute the soil, water or environment with the waste product.

Version No. 1.1 9/05/2006

Page 7 of 9

Heavy Fuel Oil

14. TRANSPORT INFORMATION Transport Information Not dangerous for transport under ADG, IMO and IATA/ICAO regulations. ADG UN Class None Allocated ADG Packing Group None Allocated ADG Hazchem Code None Allocated IMDG Hazard Class None Allocated IMDG Packing Group None Allocated Other Information Packed goods are not a marine pollutant under IMDG. MARPOL rules apply for bulk shipments by sea. 15. REGULATORY INFORMATION

EC Symbols EC Risk Phrase T R45 May cause cancer. R52/53 Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment. R66 Repeated exposure may cause skin dryness and cracking. S45 In case of accident or if you feel unwell seek medical advice immediately S53 Avoid exposure - obtain special instructions before use. S61 Avoid release to the environment. Refer to special instructions/safety data sheet.

EC Safety Phrase

AICS (Australia) All components listed. National Legislation National Code of Practice for the Preparation of Material Safety Data Sheets [NOHSC:2011] List of Designated Hazardous Substances [NOHSC:10005]. Approved Criteria for Classifying Hazardous Substances [NOHSC:1008]. Adopted National Exposure Standards for Atmospheric Contaminants in the Occupational Environment [NOHSC:1003]. Australian Dangerous Goods Code. Standard Uniform Scheduling of Drugs and Poisons. Hazard Category Carcinogenic (Category 2), Dangerous for the environment Packaging & Labelling Contains fuel oil, residual. 16. OTHER INFORMATION Revisions Highlighted No amendments made to information.

Version No. 1.1 9/05/2006

Page 8 of 9

Heavy Fuel Oil

SDS Distribution This document contains important information to ensure the safe storage, handling and use of this product. The information in this document should be brought to the attention of the person in your organisation responsible for advising on safety matters. References For detailed advice on Personal Protective equipment, refer to the following Australian Standards :HB 9 (Handbook 9) Manual of industrial personal protection. AS/NZS 1337 Eye protectors for industrial applications. AS/NZS 1715 Selection, use and maintenance of respiratory protective devices. AS/NZS 1716 Respiratory protective devices. Poisons Schedule NS. Restrictions This product must not be used in applications other than those recommended without first seeking the advice of the supplier. Restricted to professional users only. List of R Phrases in Section 2 R12 Extremely Flammable. R26 Very toxic by inhalation. R45 May cause cancer. R50 Very toxic to aquatic organisms. R66 Repeated exposure may cause skin dryness and cracking. R52/53 Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment. Technical Contact Numbers (03) 9666 5444. Further Information This information is based on our current knowledge and is intended to describe the product for the purposes of health, safety and environmental requirements only. It does not constitute a guarantee for any specific property of the product. ... End Of SDS ...

Version No. 1.1 9/05/2006

Page 9 of 9

You might also like

- Construction Readiness Review for Shell ProjectDocument91 pagesConstruction Readiness Review for Shell ProjectRyan Dizon50% (2)

- NITROGEN 93% OXYGEN 7% GAS WARNINGDocument1 pageNITROGEN 93% OXYGEN 7% GAS WARNINGtariqueNo ratings yet

- Weld-On 3 MsdsDocument2 pagesWeld-On 3 MsdsSergio SanchezNo ratings yet

- Heat Transfer in Fire Tube Boiler Software SumulationDocument7 pagesHeat Transfer in Fire Tube Boiler Software SumulationLiam Moylan50% (2)

- WHRB (HRSG) Performance CalculationsDocument9 pagesWHRB (HRSG) Performance CalculationsLiam MoylanNo ratings yet

- Straight Bill of Lading Short Form 2Document1 pageStraight Bill of Lading Short Form 2Mochamad Firdaus SaladinNo ratings yet

- DNV Paper - Fire On Ro-Ro Decks - tcm4-166317Document11 pagesDNV Paper - Fire On Ro-Ro Decks - tcm4-166317chwinboss85No ratings yet

- CorrVerter MSDS PDFDocument6 pagesCorrVerter MSDS PDFJose Alberto Uribe MinierNo ratings yet

- Msds - Hfo Heavy Fuel OilDocument9 pagesMsds - Hfo Heavy Fuel OilKrishnan RajappanNo ratings yet

- MSDS PetrolDocument6 pagesMSDS PetrolridgellNo ratings yet

- MSDS Natural Gas Condensate - SweetDocument10 pagesMSDS Natural Gas Condensate - SweetMuhammad Naufal Nazhib KhanNo ratings yet

- Tellus s2 M 46 MsdsDocument8 pagesTellus s2 M 46 MsdslindanoraNo ratings yet

- MARPOL ANNEX 4 Explained: How to Prevent Pollution from Sewage at SeaDocument10 pagesMARPOL ANNEX 4 Explained: How to Prevent Pollution from Sewage at SeaORLANDONo ratings yet

- Marine Fuels Safety Data Sheet SummaryDocument33 pagesMarine Fuels Safety Data Sheet Summaryscribd_alphaNo ratings yet

- HWMDocument41 pagesHWMJessica Laine TumbagaNo ratings yet

- Pentane Msds Praxair p6229Document8 pagesPentane Msds Praxair p6229Michael SchreiberNo ratings yet

- Li Report AdamDocument31 pagesLi Report Adammuhammad ilyasNo ratings yet

- Natural Gas Condensate MSDSDocument15 pagesNatural Gas Condensate MSDSHafiz AkhtarNo ratings yet

- Shoreline Cleanup Methods GuideDocument3 pagesShoreline Cleanup Methods GuideTdukeresolveNo ratings yet

- Health Safety AwarenessDocument186 pagesHealth Safety AwarenessHarthwell Capistrano100% (1)

- Assignment 1Document9 pagesAssignment 1TejasNo ratings yet

- MSDS Disel FuelDocument12 pagesMSDS Disel FuelMatthew Pham-EvansNo ratings yet

- TGM Comman Hazardous Waste Treatment 010910 NKDocument279 pagesTGM Comman Hazardous Waste Treatment 010910 NKNidhi PopliNo ratings yet

- Module 5 - Pathways, Fates, and Disposition of Hazardous Waste ReleasesDocument38 pagesModule 5 - Pathways, Fates, and Disposition of Hazardous Waste ReleasesJatskinesisNo ratings yet

- TankWash ProductsDocument67 pagesTankWash ProductsRahmat RiskiNo ratings yet

- OCTFDocument30 pagesOCTFVidhyaNo ratings yet

- Gas Freeing Safety ProceduresDocument3 pagesGas Freeing Safety ProceduresSamarinerSingh100% (1)

- Spill Prevention and ControlDocument20 pagesSpill Prevention and ControlZaid MubeenNo ratings yet

- Bulletin 76 AFQRJOS Issue28 April 2015 PDFDocument7 pagesBulletin 76 AFQRJOS Issue28 April 2015 PDFKeith Kelewou100% (1)

- Acute Exposure Guideline Level (AEGL)Document31 pagesAcute Exposure Guideline Level (AEGL)chem_taNo ratings yet

- Global Regulatory BodiesDocument42 pagesGlobal Regulatory BodiesMelwyn XavierNo ratings yet

- 213-35916 The Marine Equipment Directive Guidance For Manufacturers PDFDocument24 pages213-35916 The Marine Equipment Directive Guidance For Manufacturers PDFDang Thanh TuanNo ratings yet

- 4 Steps To Spill Response: Prevention: The Best SolutionDocument4 pages4 Steps To Spill Response: Prevention: The Best SolutionJuan Carlos Guerrero RNo ratings yet

- Coshh Risk Assessment: Substance InformationDocument7 pagesCoshh Risk Assessment: Substance Informationnumair khanNo ratings yet

- MSDS PIB - More 300Mw PDFDocument5 pagesMSDS PIB - More 300Mw PDFshinta sariNo ratings yet

- 200802261708480.flammable and Combustible LiquidsDocument38 pages200802261708480.flammable and Combustible LiquidsFouad Badri100% (1)

- Hazmat Regulations DotDocument30 pagesHazmat Regulations DotMark Evan SalutinNo ratings yet

- Guide FoundriesDocument13 pagesGuide Foundriesnadaf2No ratings yet

- Cargo Change Over ChecklistDocument2 pagesCargo Change Over ChecklistRajat K. ChauhanNo ratings yet

- KR Technical Information For Safe Return To Port System Design of Passenger Ships - (No.2015-ETC-04) PDFDocument60 pagesKR Technical Information For Safe Return To Port System Design of Passenger Ships - (No.2015-ETC-04) PDFKowalski KrzysztofNo ratings yet

- Slagen Refinery Harbor Procedure (Exxon Mobil)Document28 pagesSlagen Refinery Harbor Procedure (Exxon Mobil)kanakarao1No ratings yet

- UN Pipelines 2014Document24 pagesUN Pipelines 2014omissam2No ratings yet

- HazardsDocument17 pagesHazardsNavin DipaliNo ratings yet

- Oil SpillsDocument1 pageOil SpillstheotherschoolofeconomicsNo ratings yet

- 7 - Environmental AuditDocument16 pages7 - Environmental Auditsuna13No ratings yet

- Chemical Accident PreventionDocument190 pagesChemical Accident PreventionDaisyNo ratings yet

- Safe Storage Handling LPG Gas PDFDocument1 pageSafe Storage Handling LPG Gas PDFAnonymous dSFbLxc9100% (1)

- Hach - Chlorine (Free - Total) Test Kit, Model CN-66, Color Disc, 0.1-3.5 MG - L, 100 TestsDocument1 pageHach - Chlorine (Free - Total) Test Kit, Model CN-66, Color Disc, 0.1-3.5 MG - L, 100 Testsyudhaari0206No ratings yet

- Msds Cl2Document12 pagesMsds Cl2Ganjar Tri Gita AzhariNo ratings yet

- HM 49 - API MPMS Chapter 17.9 Vessel Experience Factor (VEF) - EIDocument2 pagesHM 49 - API MPMS Chapter 17.9 Vessel Experience Factor (VEF) - EIanNo ratings yet

- Assignment On Marine Pollution: Environmental EducationDocument12 pagesAssignment On Marine Pollution: Environmental EducationJyotishmoi BoraNo ratings yet

- Prevention of Marine Litter PollutionDocument35 pagesPrevention of Marine Litter Pollutionrmb2007No ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetyelvis hidalgoNo ratings yet

- 24 6 2011 Port SecurityDocument112 pages24 6 2011 Port SecurityFiroze Zia Hussain100% (1)

- Skagway2008 Final Emissions ReportDocument60 pagesSkagway2008 Final Emissions ReportdpossNo ratings yet

- Environmental Impacts of Firefighting FoamsDocument16 pagesEnvironmental Impacts of Firefighting FoamsPiyush JainNo ratings yet

- Flag state responsibilitiesDocument2 pagesFlag state responsibilitiesMuhammad Rafi SiratNo ratings yet

- CDI-T Operating Manual Section 4.0 Terminal Inspection ProceduresDocument6 pagesCDI-T Operating Manual Section 4.0 Terminal Inspection ProceduresTh NattapongNo ratings yet

- Tallow Amine - MSDS PDFDocument4 pagesTallow Amine - MSDS PDFshreeket3953No ratings yet

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet

- Diethylene Glycol Cargo Handling SheetDocument7 pagesDiethylene Glycol Cargo Handling SheettoanvmpetrologxNo ratings yet

- Manpreet Kaur: B Tech Biotechnology - 5 SEMDocument91 pagesManpreet Kaur: B Tech Biotechnology - 5 SEMManpreet KaurNo ratings yet

- Bunkering Safety Checklist and GuidelinesDocument6 pagesBunkering Safety Checklist and GuidelinesvaaliNo ratings yet

- Diesel Msds ReportDocument0 pagesDiesel Msds ReportsahilchemNo ratings yet

- Kerosene PDFDocument9 pagesKerosene PDFishnafathonahNo ratings yet

- Data Sheet - HFO Heavy Fuel OilDocument9 pagesData Sheet - HFO Heavy Fuel OilPierluigiBusettoNo ratings yet

- OTSG Information by Innovative Steam Technologies WP0602Document22 pagesOTSG Information by Innovative Steam Technologies WP0602Liam MoylanNo ratings yet

- Marine Boilers GPESGDocument12 pagesMarine Boilers GPESGLiam MoylanNo ratings yet

- 11-Flues and ChimneysDocument97 pages11-Flues and ChimneysValiNo ratings yet

- MAC Boiler Manual (Extract)Document35 pagesMAC Boiler Manual (Extract)Liam Moylan100% (1)

- Waste Heat RecoveryDocument112 pagesWaste Heat RecoveryArmando Casas100% (1)

- Advanced Post-Combustion CO2 CaptureDocument39 pagesAdvanced Post-Combustion CO2 CaptureMuhammad Faiz Fudzaili100% (1)

- SGT-800 Gas TurbineDocument12 pagesSGT-800 Gas TurbineIee XpNo ratings yet

- SGT-800 Gas TurbineDocument12 pagesSGT-800 Gas TurbineIee XpNo ratings yet

- Emerson Throttling Valves VCTDS-00405-ENDocument8 pagesEmerson Throttling Valves VCTDS-00405-ENLiam MoylanNo ratings yet

- Asme Stress Linearization and Classification - A Discussion Based On A Case StudyDocument12 pagesAsme Stress Linearization and Classification - A Discussion Based On A Case Studysagar1503No ratings yet

- Auto Ignition of Gaseous Fuels Near A Hot SurfaceDocument15 pagesAuto Ignition of Gaseous Fuels Near A Hot SurfaceLiam MoylanNo ratings yet

- Safety Relief Valve SizingDocument9 pagesSafety Relief Valve SizingLiam MoylanNo ratings yet

- Molykote Lubrication BrochureDocument12 pagesMolykote Lubrication BrochureLiam MoylanNo ratings yet

- Spray Attemperator PDFDocument4 pagesSpray Attemperator PDFWahyu HaryNo ratings yet

- Rmodak f90Document19 pagesRmodak f90Liam MoylanNo ratings yet

- NOx Emissions Steam Boilers ArticleDocument1 pageNOx Emissions Steam Boilers ArticleLiam MoylanNo ratings yet

- ME3HE14 BoilerHeattransfer1Document46 pagesME3HE14 BoilerHeattransfer1Liam MoylanNo ratings yet

- Keppel Golar FLNG ConversionDocument2 pagesKeppel Golar FLNG ConversionLiam MoylanNo ratings yet

- Fuels and Combustion OverviewDocument28 pagesFuels and Combustion OverviewDrupad PatelNo ratings yet

- General Overview Boilers and FlowDocument22 pagesGeneral Overview Boilers and FlowLiam MoylanNo ratings yet

- Firetube Boilers & Accessories CatalogDocument93 pagesFiretube Boilers & Accessories Catalogriza_azhariNo ratings yet

- Aarding Company ProfileDocument15 pagesAarding Company ProfileLiam MoylanNo ratings yet

- Tva HRSG PresentationDocument43 pagesTva HRSG PresentationLiam MoylanNo ratings yet

- Kubota Def 2 - 2.5 GaDocument13 pagesKubota Def 2 - 2.5 GaMichelleAdanteMorongNo ratings yet

- Marine Orders - Part 32 - Cargo Handling EquipmentDocument121 pagesMarine Orders - Part 32 - Cargo Handling EquipmentGiorgos Laourdekis100% (1)

- 3DT177Document11 pages3DT177dalton2004No ratings yet

- ZeTo Rules Violation Consequence Management GuidelineDocument23 pagesZeTo Rules Violation Consequence Management Guidelinemin thant100% (2)

- Repsol LONG LIFE 5W30 - TRADUCIDODocument9 pagesRepsol LONG LIFE 5W30 - TRADUCIDORoberth FernandezNo ratings yet

- DMFDocument11 pagesDMFKeerthana SNo ratings yet

- 15 W - 40 Premium Performance Motor OilDocument15 pages15 W - 40 Premium Performance Motor OilJuan David Benitez MonroyNo ratings yet

- Krafft Antisieze 907Document6 pagesKrafft Antisieze 907Imran MustafaNo ratings yet

- AGM-Handbook, Part 2, Edition 8, June 2013 PDFDocument49 pagesAGM-Handbook, Part 2, Edition 8, June 2013 PDFsistemsem30No ratings yet

- Carbopol 940 Polymer (SDS)Document12 pagesCarbopol 940 Polymer (SDS)virgilia sorianoNo ratings yet

- CAA Guide to Shipping Dangerous Goods by AirDocument20 pagesCAA Guide to Shipping Dangerous Goods by AirrodgerlutaloNo ratings yet

- MSDS MX - 99 Geranium PDFDocument4 pagesMSDS MX - 99 Geranium PDFrenitaNo ratings yet

- Sika Grout 215Document9 pagesSika Grout 215Sri EkoNo ratings yet

- IATA DG Presentation Rudy ReyesDocument35 pagesIATA DG Presentation Rudy ReyesPortCallsNo ratings yet

- Battery Safety and Environmental Concerns TranscriptDocument13 pagesBattery Safety and Environmental Concerns TranscriptAbhijeet Kumar SinghNo ratings yet

- Safety Data Sheet: 3M General Purpose Cleaner Disinfectant P2Document10 pagesSafety Data Sheet: 3M General Purpose Cleaner Disinfectant P2FjdjdNo ratings yet

- Prostar Anti Spatter Spray PDFDocument6 pagesProstar Anti Spatter Spray PDFPubcrawlNo ratings yet

- Lithium Battery Manual: Approvals Contributing Author(s) DateDocument49 pagesLithium Battery Manual: Approvals Contributing Author(s) DateRefisal BonnetNo ratings yet

- Urea Hydrogen PeroxideDocument12 pagesUrea Hydrogen PeroxideaficoNo ratings yet

- MSDS RetinolDocument11 pagesMSDS RetinolPhilip PuaNo ratings yet

- Sip002 - Guidance On General Cargo - Issue 1Document28 pagesSip002 - Guidance On General Cargo - Issue 1Alonso Olaya RuizNo ratings yet

- SDC Occupant Handbook October 2019Document39 pagesSDC Occupant Handbook October 2019Ian FinchNo ratings yet

- Mouse monoclonal OC4-30 to Osteocalcin SDSDocument6 pagesMouse monoclonal OC4-30 to Osteocalcin SDSIna MarsomNo ratings yet

- Section 1. Identification: Safety Data SheetDocument13 pagesSection 1. Identification: Safety Data SheetMohammad Imtiaz AliNo ratings yet

- MSDS CuSO4 1,0 MDocument7 pagesMSDS CuSO4 1,0 MMuh. Ma'arifNo ratings yet

- Appendix H Environmental Protection PlanDocument15 pagesAppendix H Environmental Protection PlanEneyo VictorNo ratings yet