Professional Documents

Culture Documents

System Overview: Problems Solved

Uploaded by

Mas Bagaz NoviantoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System Overview: Problems Solved

Uploaded by

Mas Bagaz NoviantoCopyright:

Available Formats

System Overview

The Hunting Clear-Run Advanced Tubular System sets a new benchmark in Oilfield best practice, offering a high value alternative to traditional dope-based OCTG processes. Clear-Run delivers greatly improved Operational, Commercial and Safety performance and completely removes key negative Environmental aspects of established industry practice.

In full Commercial application, Clear-Run has delivered improved Rig-Time efficiency through the removal of tubular preparation time and the achievement of benchmark safe make-up speed and connection integrity levels. A Pipe Dope is not required at any point in the manufacture, storage or running of OCTG deployed using the Clear-Run system. Corrosion inhibition and anti-galling properties are integral Clear-Run features and there is no requirement for connection cleaning and preparation on the outward or inward journey, to and from the Well Site. Key components of the Hunting Clear-Run system

Problems Solved

From the very first exploration wells through to the increasingly complex and environmentally sensitive programmes undertaken in the Oil & Gas industry of today, 'Oilfield Tubulars' have been handled using a process with the following inherent problem areas;

are recyclable/bio-degradable, adding to the overall reduction in environmental impact achieved by the removal of Dope from the entire process.

Run

START

Monitor Performance

Contamination of the Well Bore and Formation with Pipe Dope Fouling of Down Hole Equipment with Pipe Dope Costly Onshore and Offshore Thread Cleaning and Preparation Frequent Incidence of Connection Galling 'Dirty', Unsafe Workspaces Shop/Yard/Rig In-Storage Connection Corrosion High Residual Environmental Impact

Zero Dope Clean, Safe Workspace

Source Requirements

s

Non-Galling Fast Make-up

Re tu rn

Zero Preparation

Ri g

To Well Site Prepare as Clear-Run

Zero Cleaning Zero Inspection Zero Dope Storage Call-Off

The Hunting Clear-Run Advanced Tubular System removes or reduces all these negative aspects, yielding direct savings in Cost and Time and greatly reducing the Environmental impact of OCTG operations.

Zero Storage Compound

Hunting Clear-Run Advanced Tubular System

P01 - System Overview - The Hunting Clear-Run Advanced Tubular System

The Clear-Run Advanced Tubular System covers the entire OCTG Life Cycle from Mill to Well, through Return and Re-Use in a single integrated process. Features and benefits of Clear-Run at key points in this life cycle include;

At the Mill / Machine Shop

Under the Clear-Run system, the need for pipe Dope during connection make-up is removed, creating significantly cleaner, safer workspaces. The ClearPlate component of the Advanced Tubular System provides anti galling properties to all ClearRun OCTG from this point in the process.

corrosion resistant and ready for offshore running without the need for further cleaning and preparation. Clear-Cap protectors are then used to flag the tubulars as Clear-Run ready and enable quick visual condition check of threads in the Yard and at the Rig Site. Tubulars returning from the Rig Site require no routine cleaning and corrosion protection treatment prior to re-storage.

In the Pipe Yard

Immediately prior to storage, the Clear-Glide component of the Advanced Tubular System is applied to connection threads making all Clear-Run joints

At the Rig Site

Zero cleaning, zero preparation, zero Dope just remove the Clear-Cap protectors and run in hole.

System Components

A significant technological advance in OCTG anti-gall treatment, this component of the ClearRun system has been developed by Hunting in collaboration with our coatings technology partner company, MP (Eastern).

In addition to the service elements of material sourcing, connection machining and logistics, the Hunting Clear-Run Advanced Tubular System has three proprietary product components;

High performance friction reduction and corrosion resistance without Dope, enabling faster, cleaner make-up of tubulars at the Well Site. Transparent and biodegrable characteristics facilitate detailed thread inspection without cleaning. Clear-Glide was developed by Hunting in collaboration with our technology partner, R.S. Clare.

JFEBEAR - A connection for todays Oil and Gas Industry A new breed of premium thread connection that was designed to exceed API class 1 requirements for Compression and Torque, Bending and External Pressure. JFEBEAR ClearRun has successfully completed a connection load test programme based on ISO13679.

www.huntingclearrun.com

P01 rev1 - System Overview - The Hunting Clear-Run Advanced Tubular System

You might also like

- Clear Run Technical OverviewDocument2 pagesClear Run Technical OverviewKaveh BahiraeeNo ratings yet

- Cleanwell System Technology: Completion SolutionsDocument8 pagesCleanwell System Technology: Completion SolutionslaaliautoNo ratings yet

- Furnace Tube Pipeline PiggingDocument8 pagesFurnace Tube Pipeline PiggingPervez0% (1)

- Altair Product and Filter System UpdateDocument51 pagesAltair Product and Filter System UpdateabelsgNo ratings yet

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Document9 pagesThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationNo ratings yet

- WLX Wide Belt: Clean, Safe Conveying, Advanced PerformanceDocument12 pagesWLX Wide Belt: Clean, Safe Conveying, Advanced PerformanceOthello ErejeNo ratings yet

- Engineering 2012 02Document58 pagesEngineering 2012 02triuneenergyNo ratings yet

- Modular PSA Nitrogen Generator BrochureDocument6 pagesModular PSA Nitrogen Generator Brochureluise40No ratings yet

- Whitepaper Process Development in Cleanroom ConditionsDocument8 pagesWhitepaper Process Development in Cleanroom ConditionsCIVILNo ratings yet

- RigDeluge Product Pack Rev 0Document22 pagesRigDeluge Product Pack Rev 0aimanNo ratings yet

- Grundfos WWTPDocument34 pagesGrundfos WWTPNguyen Phuc PhamNo ratings yet

- A Wholly Owned Subsidiary Of: 456 Creamery Way Exton PA 19341 USADocument23 pagesA Wholly Owned Subsidiary Of: 456 Creamery Way Exton PA 19341 USAForum PompieriiNo ratings yet

- Madule 5Document17 pagesMadule 5Aditya ranjan BubunNo ratings yet

- Chemengmagaugust 2014Document76 pagesChemengmagaugust 2014makwana1No ratings yet

- February 2012Document60 pagesFebruary 2012noxer_dmNo ratings yet

- ValvTechnologies 01 - Zero Leakage Valve Solution PDFDocument20 pagesValvTechnologies 01 - Zero Leakage Valve Solution PDFNanangdp48No ratings yet

- Schlumberger Compact Well TSTDocument12 pagesSchlumberger Compact Well TSTAsyraf M ZamanNo ratings yet

- PROCESS AND PIPELINE SERVICES OVERVIEWDocument16 pagesPROCESS AND PIPELINE SERVICES OVERVIEWMohamed HassanNo ratings yet

- CO2 Blast CleaningDocument30 pagesCO2 Blast CleaningkangsungjinNo ratings yet

- CaseStudy EagleBurgmann SeccoLip-for-roller-dryers EN 23-05Document2 pagesCaseStudy EagleBurgmann SeccoLip-for-roller-dryers EN 23-05edavidNo ratings yet

- August 2016 - InternationalDocument88 pagesAugust 2016 - InternationalLeonardo GarroNo ratings yet

- Profil Perusahaan PT. Frata Bayutama Prima PDFDocument20 pagesProfil Perusahaan PT. Frata Bayutama Prima PDFSuhairi AnasNo ratings yet

- ZH Plus ZH 355-900 ZH 630-1600 Leaflet en LR InekoDocument20 pagesZH Plus ZH 355-900 ZH 630-1600 Leaflet en LR InekoAlbert Paco GoytiaNo ratings yet

- CheIng - June 2010 PDFDocument68 pagesCheIng - June 2010 PDFErvin WatzlawekNo ratings yet

- Filtro de AireDocument2 pagesFiltro de AireAndres Uzzi GuzmanNo ratings yet

- Caterpillar Filter ไส้กรอง กรองลม กรองน้ำมันDocument19 pagesCaterpillar Filter ไส้กรอง กรองลม กรองน้ำมันParinpa KetarNo ratings yet

- Catalogo Control ContaminantesDocument132 pagesCatalogo Control ContaminantesJose Jaramillo50% (2)

- Norris Pro-Rod Coiled RodDocument8 pagesNorris Pro-Rod Coiled RodMohamed GhareebNo ratings yet

- Efficiency Improvement and Trouble-Shooting: Separation SystemsDocument8 pagesEfficiency Improvement and Trouble-Shooting: Separation SystemsAlberto darianNo ratings yet

- 11 - SupaSep LGPDocument8 pages11 - SupaSep LGPDylan DooleyNo ratings yet

- Completions Company. Baker Oil ToolsDocument32 pagesCompletions Company. Baker Oil ToolsHamid Reza BabaeiNo ratings yet

- Pda Technical Report 48 Moist Heat Sterilizer SystemsDocument70 pagesPda Technical Report 48 Moist Heat Sterilizer Systemsmkmncs457475% (4)

- Main CatalogueDocument10 pagesMain CatalogueMohamed SalahNo ratings yet

- Delbag Filter System MultiAir Eco 2000-MWFDocument12 pagesDelbag Filter System MultiAir Eco 2000-MWFnileshNo ratings yet

- RAF Baghouse Filter MikropulDocument4 pagesRAF Baghouse Filter MikropulCharik JainNo ratings yet

- EcoPower Brochure PDFDocument4 pagesEcoPower Brochure PDFAlejandroNo ratings yet

- Cryogas - Profile - 2011 PDFDocument26 pagesCryogas - Profile - 2011 PDFRey LieNo ratings yet

- Packaged Air Separation PlantsDocument12 pagesPackaged Air Separation PlantsSrinivas VemulapalliNo ratings yet

- Oil-Free Rotary Screw Compressors: ZR 300-750 & ZR 400-900 VSDDocument16 pagesOil-Free Rotary Screw Compressors: ZR 300-750 & ZR 400-900 VSDElsa Dewi100% (1)

- Economic N2 Removal Hydrocarbon EngineeringDocument8 pagesEconomic N2 Removal Hydrocarbon EngineeringSergio JavierNo ratings yet

- Cleansource - Cleansolv HF EP Technical BulletinDocument1 pageCleansource - Cleansolv HF EP Technical BulletinPrimitivo GonzálezNo ratings yet

- Recirculating Biotower: High Performance CompactDocument4 pagesRecirculating Biotower: High Performance CompactfatamorgganaNo ratings yet

- SHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationDocument42 pagesSHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationOliver JimmyNo ratings yet

- GEA Wiegand Distillation Technology GuideDocument16 pagesGEA Wiegand Distillation Technology GuideNurul AniraNo ratings yet

- Leaflet ZR300-900 - LR - InekoDocument16 pagesLeaflet ZR300-900 - LR - Inekojharold22No ratings yet

- The Inertial Filters Manufactured by Barclay Engineering Are SelfDocument2 pagesThe Inertial Filters Manufactured by Barclay Engineering Are SelfArt JamesNo ratings yet

- TITAN 250 - Solar Turbines - Caterpillar b250pg PDFDocument8 pagesTITAN 250 - Solar Turbines - Caterpillar b250pg PDFNhat Tran100% (1)

- Chemical Engineering June 2013Document66 pagesChemical Engineering June 2013Riki MandolNo ratings yet

- Solution: Your Application.... ... OurDocument6 pagesSolution: Your Application.... ... OurSuresh Kumar MittapalliNo ratings yet

- Diva Envitec Contufilt-MDocument6 pagesDiva Envitec Contufilt-MThe Sur StudioNo ratings yet

- Water Treatment Water Disinfection ProMinent Product Catalogue Volume 4 PDFDocument120 pagesWater Treatment Water Disinfection ProMinent Product Catalogue Volume 4 PDFCesario GoncalvesNo ratings yet

- CR Asia Insert Fin Fan Optimisation Services 0221Document4 pagesCR Asia Insert Fin Fan Optimisation Services 0221Juliyanto STNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Meeting Week 4Document14 pagesMeeting Week 4Mas Bagaz NoviantoNo ratings yet

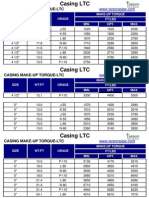

- Gauging Procedure Buttress Casing PipeDocument1 pageGauging Procedure Buttress Casing PipeMas Bagaz NoviantoNo ratings yet

- Pipe and Connection IdentificationDocument7 pagesPipe and Connection Identificationbalusandeep20No ratings yet

- SN The SimsDocument7 pagesSN The SimsMas Bagaz NoviantoNo ratings yet

- Local HolicDocument1 pageLocal HolicMas Bagaz NoviantoNo ratings yet

- Make Up Torque LTC Trpon PipeDocument17 pagesMake Up Torque LTC Trpon Pipeboytofan1No ratings yet

- Vallourec en Acquisitions in North America PresentationDocument23 pagesVallourec en Acquisitions in North America PresentationMas Bagaz NoviantoNo ratings yet

- SR NSCC 2013 08Document17 pagesSR NSCC 2013 08Mas Bagaz NoviantoNo ratings yet

- Grant Prideco USA OCTG Tubular ProductsDocument2 pagesGrant Prideco USA OCTG Tubular ProductsMas Bagaz NoviantoNo ratings yet

- Whats The DifferenceDocument5 pagesWhats The DifferenceMas Bagaz NoviantoNo ratings yet

- Jfetiger BrochureDocument8 pagesJfetiger BrochureMas Bagaz NoviantoNo ratings yet

- Boracay Rehabilitation Project Restores Island's BeautyDocument7 pagesBoracay Rehabilitation Project Restores Island's BeautyDanielle Diaz100% (1)

- EO 77 Virginia Leading by Example To Reduce Plastic Pollution and Solid WasteDocument4 pagesEO 77 Virginia Leading by Example To Reduce Plastic Pollution and Solid WasteFauquier NowNo ratings yet

- 15 Major Current Environmental ProblemsDocument7 pages15 Major Current Environmental ProblemsErwin BucasasNo ratings yet

- Reflection The Planet Earth Is A Gift From GodDocument2 pagesReflection The Planet Earth Is A Gift From GodPrince JosephNo ratings yet

- Explore SACON, India's Leading Ornithology Research CenterDocument33 pagesExplore SACON, India's Leading Ornithology Research Centerram kumarNo ratings yet

- (Đề thi có 04 trang) Thời gian làm bài: 60 phút không kể thời gian phát đềDocument5 pages(Đề thi có 04 trang) Thời gian làm bài: 60 phút không kể thời gian phát đềPhi VyNo ratings yet

- L1, Introduction To Hospital EngDocument32 pagesL1, Introduction To Hospital Engabyalew birhanuNo ratings yet

- RCC Pipe Market Survey and Manufacturing ProcessDocument12 pagesRCC Pipe Market Survey and Manufacturing Processsamruddhi mNo ratings yet

- Sustainable Development Is To Make A World A Better Place For Everyone Now Without Destroying The Possibilities For The Next Generations.Document3 pagesSustainable Development Is To Make A World A Better Place For Everyone Now Without Destroying The Possibilities For The Next Generations.rico molNo ratings yet

- 2nd Avinash Kumar 7june19Document11 pages2nd Avinash Kumar 7june19Anshuman SinghNo ratings yet

- Evidence 7 Writing Make A Summary AboutTechnical Topics in EnglishDocument6 pagesEvidence 7 Writing Make A Summary AboutTechnical Topics in EnglishGiovanny Monar Buitrago50% (2)

- Tongji University, ChinaDocument12 pagesTongji University, ChinaOctavio Manuel Ibacache VelasquezNo ratings yet

- Environmental AuditingDocument27 pagesEnvironmental Auditinghitman agent 47No ratings yet

- Banksia CaneiDocument7 pagesBanksia CaneiGurkan UzunNo ratings yet

- Smart City Bangalore: Maithray Bhavana - Vi YearDocument13 pagesSmart City Bangalore: Maithray Bhavana - Vi YearMaithrayNo ratings yet

- Found Words: Direction: Write Below All The Words You SeeDocument2 pagesFound Words: Direction: Write Below All The Words You SeeHailla GuiralNo ratings yet

- Kentucky River DevelopmentDocument233 pagesKentucky River DevelopmentsolarbobkyNo ratings yet

- Scope and Limitation of The StudyDocument3 pagesScope and Limitation of The StudyDalvik CleadNo ratings yet

- Ocean Circulation Lab Report: ProblemDocument4 pagesOcean Circulation Lab Report: Problemno thankyou0% (1)

- TopographyDocument22 pagesTopographyAksharaNo ratings yet

- Robert Staimer-ManDocument44 pagesRobert Staimer-ManPaulo PereiraNo ratings yet

- Water Supply System - Module 1Document49 pagesWater Supply System - Module 1Harshita MittalNo ratings yet

- UniRam HCNL Product SheetDocument2 pagesUniRam HCNL Product SheetDiego GómezNo ratings yet

- 8-Draft Chapter 3 - Adopted Methodology - 02!10!16Document20 pages8-Draft Chapter 3 - Adopted Methodology - 02!10!16KISHOR KOTKARNo ratings yet

- Customer Journey Roadmap DFDocument3 pagesCustomer Journey Roadmap DFDzaky FajratamaNo ratings yet

- Resources Guide 2022 HSSC II Commercial GeographyDocument7 pagesResources Guide 2022 HSSC II Commercial GeographyIMAN'S CREATIONNo ratings yet

- Water Resource EngineeringDocument12 pagesWater Resource EngineeringAshtrydNo ratings yet

- Position PaperDocument2 pagesPosition PaperJelly Ann RimalosNo ratings yet

- The Seven Environmental PrinciplesDocument12 pagesThe Seven Environmental PrinciplesAngela VillamorNo ratings yet

- Periodical Test Tle 6 Industrial Arts 3rd QuarterDocument8 pagesPeriodical Test Tle 6 Industrial Arts 3rd QuarterSan Pedro Elementary SchoolNo ratings yet