Professional Documents

Culture Documents

Soldering

Uploaded by

Socorro PerezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soldering

Uploaded by

Socorro PerezCopyright:

Available Formats

Lesson Plan

Course Title: Electronics Session Title: Soldering & Circuit Fabrication Lesson Duration: 2 Weeks [Lesson length is subjective and will vary from instructor to instructor] Performance Objective: Upon completion of this assignment, the student will be able to demonstrate an understanding of soldering concepts by correctly performing the procedures outlined on the lab activity sheets and by scoring 85 percent on the unit test.

Specific Objectives: After completion of this unit, the student should be able to: Define terms associated with soldering and circuit fabrication with their definitions Describe soldering procedures Identify characteristics of a good solder connection Match types of poor solder connections with their causes Name type of soldered connections for degrees of mechanical security required prior to soldering Demonstrate the ability to perform a good solder connection: Preparation TEKS Correlations: This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. Electronics: 130.368 (c)(4)(A)(B)(C)(D)(E)(F)(G) ...master relevant safety tests; ...follow safety guidelines as described in various manuals, instructions, and regulations; ...identify and classify hazardous materials and wastes according to Occupational Safety and Health Administration regulations and industry standards; ...dispose of hazardous materials and wastes appropriately; ...perform maintenance on selected tools, equipment, and machines; ...handle and store tools and materials correctly; ...describe the results of negligent or improper maintenance.

Interdisciplinary Correlations: Mathematical Models with Applications: 111.36(c)(1)(A) uses a variety of strategies and approaches to solve both routine and non-routine problemsincluding compare and analyze various methods for solving a real-life

Copyright Texas Education Agency, 2012. All rights reserved.

1

problem; English: 110.42(b)(6) - Reading/word identification/vocabulary development 110.42(b)(6)(A)(B) ...expand vocabulary through wide reading, listening, and discussing; ...rely on context to determine meanings of words and phrases such as figurative language, idioms, multiple meaning of words, and technical vocabulary;

Instructor/Trainer References: 1. Buchla, David & Floyd, Thomas, The Science of Electronics DC/AC , Pearson Education Inc. Chapter 4, 2005 2. Floyd, Thomas L. Principles of Electric Circuits: Electron Flow Version Macmillian Publishing Co., Don Mills, Ontario 1993 ISBN 0-02-338501-4 3. Robertson, L. Paul Basics Electronics 1 Mid-American Vocational Curriculum Consortium, Inc. 1980 4. Electronic WORKBENCH, MultiSIM 8, www.electronicworkbench.org, 2005

Instructional Aids: 1. Soldering Power Point Presentation 2. Soldering Power Point Presentation Slides 3. Soldering Power Point Presentation Handouts 4. Soldering Power Point Presentation Notes Pages 5. Soldering Lab Activity Sheet #1 Handout- Strip and Tin Wires for Soldered Connection 6. Soldering Lab Activity Sheet #2 Handout Solder Wires to Turret Terminals, then Desolder Wires 7. Soldering Lab Activity Sheet #3 Handout- Solder Wires to Terminal Strip 8. Soldering Lab Activity Sheets #4 Handout Repair a Printed Circuit Board by Replacing Resistors and Correcting Open or Broken Lands 9. Soldering Lab Activity Sheets #5 Handout Splice Wires Together by means of Soldering and Crimping (flat cable) 10. Soldering Lab Activity Sheet #6 Handout- Connect Ends of Flexible Printed Wiring (flat cable) 11. Soldering and Circuit Fabrication Unit Exam 12. Soldering and Circuit Fabrication Unit Exam- Key

Materials Needed: 1. Soldering iron with rheostat control 2. Solder wick 3. Solder (60/40) 4. Paper 5. Pencils 6. Soldering tools 7. Wire 8. Printed circuit boards

Copyright Texas Education Agency, 2012. All rights reserved.

2

9. Wire strippers 10. Long nose pliers 11. Solder flux

Equipment Needed: A. Equipment needed for technology applied version only: i. Software (Microsoft Office) ii. Whiteboard iii. Breadboards and leads iv. Power supplies v. Multimeters vi. PC or Mac vii. Calculator B. Equipment needed for both hands-on and technology versions: i. Projection system to play PowerPoint presentation or ii. Optional CD or version loaded onto student desktops for individual instruction and reference.

Learner Preparation: Read chapter on soldering and circuit fabrication in textbook Complete lab activities Student watches Soldering and Circuit Fabrication PowerPoint and takes notes on material Introduction Introduction (LSI Quadrant I): SAY: Soldering of wire and components is a necessary art in the field of electronics. Many problems in the circuitry can be traced back to a poor soldering job and poor workmanship. ASK: Can solder replace the strength of a welded joint? SAY: Not likely, but soldering is not meant to strengthen the joint. It provides protection from oxidation and connectivity between metals at a joint. Today, we will study the art of soldering and circuit fabrication. Outline Outline (LSI Quadrant II): Information: I. Terms and Definitions II. Soldering tools and materials and their uses III. Cleaning before and after soldering IV. Stripping and Tinning V. Soldering Procedure VI. Characteristics of a good solder connection VII. Types of poor solder connections and causes VIII. Types of soldered connections Instructor Notes:

PPT Slides 3-4 PPT Slides 5-8 PPT Slide 9 PPT Slides 10-12 PPT Slides 13-15 PPT Slides 16-17 PPT Slides 18-19 PPT Slides 20-22

Copyright Texas Education Agency, 2012. All rights reserved.

3

Teacher Demonstrations: I. Strip and tin wire II. Solder to a terminal III. Solder a poor connection and show why Application Guided Practice (LSI Quadrant III): The students will observe, ask questions, and analyze the demonstration to be presented by the instructor. The instructor will use materials as listed in the lab activities to instruct how to read, measure with and record data needed.

Independent Practice (LSI Quadrant III): The student will then check-out on these activities and try to replicate the lab activities. Then the student will answer the discussion question at the end of each lab and turn sheets in for evaluation Summary Review (LSI Quadrants I and IV): Review the students data sheets to evaluate if individual or small group activity is best for the condition for learning. Evaluation Informal Assessment (LSI Quadrant III): The instructor will monitor each person or small group as they individually work to complete the assignments. If re-teach is needed on any information or procedure, all those involved will stop and participate in the re-teach.

Formal Assessment (LSI Quadrant III, IV): The student will be assessed by the accuracy of the completed assignments. The instructor will divide the final assessment into two parts; one being a formal exam and the other being a soldering test of a series of exercises using the solder, soldering irons, printed circuit boards and assorted wires to repair accurately and correctly. For the formal exam, use the Exam and Exam Key. Extension Extension/Enrichment (LSI Quadrant IV): The use of the soldering and circuit fabrication to correctly repair wires, printed circuit boards, terminals and lands becomes a vital part of the technical repair skills needed in the world of work. Thinking through a problem to arrive at the answer and the persistency to work past their

Copyright Texas Education Agency, 2012. All rights reserved.

4

frustrations tempers their character. There are points in the lab experience where the student takes some part in leadership skills. Leading or following creates a sense of accomplishment that adds to the character of those students involved. Cognitive and leadership skills or development go hand and hand in solving lifes road blocks.

Copyright Texas Education Agency, 2012. All rights reserved.

5

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Lab Activity Sheet # 1- Strip and Tin Wires for Soldered Connections I. Materials required A. Soldering iron B. 60/40 rosin core solder (18 gauge) C. Soldering iron holder D. Mechanical wire strippers E. 10 feet of 22-gauge stranded wire F. Acid brush G. Wire stripper H. Heat sink II. Procedure A. Wrap a strand of solder around the soldering iron tip three times before heating the soldering iron B. Plug soldering iron into AC outlet C. As soon as the tip is hot, tin the iron tip or notice that the solder has melted, remove excess solder with a clean moist rag or moist sponge D. Cut wire into 8-inch lengths E. Using mechanical wire strippers, strip about one inch of insulation from each end of each wire length F. Clean stripped wire ends with isopropyl alcohol and clean cloth G. Gently twist wire ends in direction of strand twist so that strands do not separate H. Place heat sink on stranded wire end as close as possible to end of wire insulation

Copyright Texas Education Agency, 2012. All rights reserved.

6

Name: ____________________________________ Class: ________ Date ___/___/___

I.

Place wire end on heated iron tip and apply solder until solder freely flows among all wire strands; remove wire and solder

J. Remove heat sink K. Clean tinned wire using isopropyl alcohol and acid brush L. Check that excessive solder has not been applied (outline of all strands should be visible through the solder) and that wire insulation shows no evidence of burning or wicking M. Repeat tinning operation until all wire ends have been tinned N. Turn off soldering iron and return all materials and supplies to their storage area ( NOTE: Do not return the soldering iron to storage until after it has cooled down)

Copyright Texas Education Agency, 2012. All rights reserved.

7

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Lab Activity Sheet # 2- Solder Wires to Turret Terminals then De-solder Wires I. Materials required A. Variac, for controlling soldering iron temperature (optional) B. Soldering iron C. Vise, for holding the terminal board during soldering D. Heat sink E. Wire strippers F. Long nose or needle nose pliers

G. Rosin-core solder (22 gauge) H. Isopropyl alcohol I. Acid brush J. Bakelite board with two turret terminals mounted on it approximately four inches apart L. Two 8-inch lengths of 22-gauge stranded wire, stripped and tinned in accordance with Lab activity #1 II. Procedure A. Secure bakelite board in vise so that terminals are accessible for soldering B. Wrap a piece of solder around tip of soldering iron three or four times, then plug in soldering iron

Copyright Texas Education Agency, 2012. All rights reserved.

8

Name: ____________________________________ Class: ________ Date ___/___/___

C. Using pliers, form end of one wire around lower guide slot of one turret terminal as shown in Figure 1

(NOTE: Figure 1 shows the wire wrapped 180 around the turret terminal. If desired, the wire may be wrapped 360 around the terminal to make it more secure mechanical connection prior to soldering. However, this may require stripping and tinning a longer length of the wire end.) D. Attach heat sink to wire insulation as close as possible to wire and without interfering with soldering operation E. Using soldering iron and rosin-core solder, solder wire to terminal F. Remove heat sink G. Clean soldered connection with isopropyl alcohol and clean cloth or acid brush H. Check that soldered connection is correct ____ correct ____needs work I. Solder opposite end of wire to lower guide slot of second terminal in same manner (steps C through H) _____ correct _____ needs work

J. Solder second length of wire to upper guide slots of terminals in same manner (steps C through H) (a) ____ correct ____ needs work (b) ____ correct ____ needs work K. De-solder all connections as follows; A. Apply hot iron tip to terminal to melt solder, and pry wire off terminal B. While still applying hot iron tip, remove solder with a brush or solder sucker C. Clean de-soldered terminal with isopropyl alcohol and clean cloth L. Return materials and tools to the storage area. (Cool off iron before storage)

Copyright Texas Education Agency, 2012. All rights reserved.

9

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Lab Activity Sheet # 3- Solder Wires to a Terminal Strip I. Materials required A. Soldering iron B. Vise, for holding the terminal strip during soldering C. Heat sink D. Chain or needle-nose pliers E. F. G. H. I. J. Rosin-core solder (22 gauge) Isopropyl alcohol Pencil eraser Acid brush Mounting strip with five or more terminals Five 8-inch lengths of 22-gauge stranded wire, stripped and tinned in accordance with Lab Activity #1

II.

Procedure A. Clean terminals of oxides by means of pencil eraser, and of dirt and grease by means of isopropyl alcohol and clean cloth B. Secure terminal strip in vise C. Wrap a piece of solder around the tip of a cool tip three or four times, then plug in soldering iron D. Using pliers, mechanically attach tinned wire to first terminal; make sure and of insulation is approximately 1/16-inch from soldered connection (NOTE: It may be necessary to cut off excess wire so that the distance between the insulation and the connection is correct.) E. Attach heat sink to wire F. Solder wire to terminal

Copyright Texas Education Agency, 2012. All rights reserved.

10

Name: ____________________________________ Class: ________ Date ___/___/___

G. Remove heat sink H. Clean soldered terminal by means of isopropyl alcohol and acid brush I. Check that soldered connection is correct and that insulation is not burned

J. Repeat steps D through I for the other four connections, being careful not to touch adjacent wires with the hot iron K. Return the materials and tools to the proper storage area (cool soldering iron before storing)

L. With the magnet still under the center of the flat piece of glass, sprinkle iron filings on top of the glass M. Observe the lines of flux indicated by the iron filings N. Make a sketch of the pattern formed by the filings

NOTE: Answer the following questions and hand in for a grade.: 1. Does the compass indicate that there is a force surrounding your magnet? 2. Do the compass indications show the direction of the flux lines? Explain why your compass indicates the flow.

Copyright Texas Education Agency, 2012. All rights reserved.

11

Name: ____________________________________ Class: ________ Date ___/___/___

3. Do the iron filings concentrate at the poles? 4. Why are the lines of flux spread out when not in the vicinity of the poles? Give two reasons. 5. Do the lines of flux cross each other? 6. Give at least three other characteristics of magnetic fields that are illustrated by the position of the iron filings.

O. Return the materials to their storage area

Copyright Texas Education Agency, 2012. All rights reserved.

12

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Lab Activity Sheet # 4- Repair a Printed Circuit Board by replacing Resistors and Correcting Open or Broken Lands I. Materials required A. Variac, to control soldering iron temperature B. Vise or clamp C. Soldering iron D. Solder sucker E. F. G. H. I. J. Nail clippers Isopropyl alcohol 60/40 rosin-core solder (22 gauge) Eraser Acid brush Chain nose pliers

K. Component lead cleaner L. Printed circuit board with two damaged resistors, an open connecting path, and a broken or removed land M. Two replacement resistors II. Procedure A. Wrap a piece of solder around the cold soldering iron tip then plug soldering iron into outlet and adjust voltage to 90-95 volts (for 30-watt iron) B. Removed damaged component by clipping components leads C. Turn board over

Copyright Texas Education Agency, 2012. All rights reserved.

13

Name: ____________________________________ Class: ________ Date ___/___/___

D. Remove remaining lengths of component leads by heating solder and lifting leads off board by means of chain nose pliers; remove melted solder by means of solder sucker E. Remove grease and rosin from connections by means of isopropyl alcohol and acid brush F. Remove oxides from the land by means of the eraser G. Clean oxides from replacement component leads by means of component lead cleaner H. Measure distance between component land connections and bend component leads at right angles so that the leads will insert into the land eyelets I. Insert component leads into land holes so that component lies on upper surface of board

J. While holding component in place, turn board over and either clinch, swage, or clip component leads as shown in Figure 1

(NOTE: Clinching provides the best mechanical connection. The leads are swaged or clipped when space limitations prevent clinching. If the leads are to be clipped, it may be best to postpone the clipping operation until after the connections have been soldered.) K. Install board in clamp or vise L. Attach heat sink to component lead at each end of the component

Copyright Texas Education Agency, 2012. All rights reserved.

14

Name: ____________________________________ Class: ________ Date ___/___/___

M.

Solder component lead to land at each connection as shown in Figure 1

N. Replace second resistor by cutting off damaged resistor as before, but soldering new resistor to old component leads as shown in Figure 2

O. Repair open in printed wiring by soldering a conductor bridge across the open using one of the techniques shown in Figure 3

Copyright Texas Education Agency, 2012. All rights reserved.

15

Name: ____________________________________ Class: ________ Date ___/___/___

P. Repair removed or lifted land as shown in Figure 4

Q. Check all soldered connections for proper configuration R. Check that no solder has been spilled to cause possible shorts with adjacent connections or wiring S. Clean all soldered connections with isopropyl alcohol and acid brush

Copyright Texas Education Agency, 2012. All rights reserved.

16

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Lab Activity Sheet # 5- Splice Wires together by means of Soldering and Crimping (flat cable) I. Materials required A. Soldering iron B. Crimping tool C. 18 inches of #26 stranded wire D. 24 inches of #20 wire E. F. G. II. One splice lug for #20 wire Two inches of shrink tubing for #26 wire Electrical tape

Procedure A. Cut the #26 wire into three equal lengths B. Strip, clean, and tin one end of each length C. Cut the #20 wire into four equal lengths D. Strip, clean, and tin one end of each length E. Trim tinned ends of all wires to -inch length

Copyright Texas Education Agency, 2012. All rights reserved.

17

Name: ____________________________________ Class: ________ Date ___/___/___

F. Splice tinned ends of one #20 wire and one #26 wire (Figure1)

G. Install shrink tubing on one length of #26 wire H. Splice tinned ends of two lengths of #26 wire (including the one with the tubing) (Figure 2)

Copyright Texas Education Agency, 2012. All rights reserved.

18

Name: ____________________________________ Class: ________ Date ___/___/___

I.

Shrink the tubing by passing the hot soldering iron back and forth across the length of the tubing, WITHOUT TOUCHING THE TUBING

J. Continue applying heat until tubing fits snugly over the splice K. Insert tinned ends of two lengths of #20 wire in opposite ends of crimping lug (Figure 3); make sure strands of both wires are visible in slot at center of lug L. Using crimping tool, crimp both ends of lug

M. Check that crimp is correct (Figure 3) N. Return all unused materials to their proper storage area

Copyright Texas Education Agency, 2012. All rights reserved.

19

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Lab Activity Sheet # 6- Connect Ends of Flexible Printed Wiring (flat cable) I. Materials required A. Soldering iron B. 60/40 rosin-core solder C. Thermal wire stripper D. Length of flexible printed wiring (flat cable) E. F. II. 5-pin male connector Printed circuit board with five adjacent printed conductors

Procedure A. Strip insulation from one end of cable as follows (Figure 1 and 2)

1. Scribe line on printed wiring -inch back from straight end 2. Place printed wiring on flat heat-resistant surface and hold wiring in place with heel of one hand 3. Connect thermal stripper in power source

Copyright Texas Education Agency, 2012. All rights reserved.

20

Name: ____________________________________ Class: ________ Date ___/___/___

4. When stripper is not enough to melt insulation, melt and peel insulation from cable by pulling stripper from scribe line toward end of wiring as shown in Figure 2 (CAUTION: If a power supply is being used to provide power to the stripper, the stripper should be turned off periodically. Thermal wire strippers high current, and prolonged high current, and prolonged high current may damage the power supply.) 5. Turn wire over and strip opposite side in same manner, turn off stripper B. Clean and tin stripped conductors of flexible wiring and conductors of printed circuit board to which they will be connected C. Lap-solder conductors of flexible wiring to conductors of the printed circuit board as shown in Figure 3

D. Clean and tin pins of male connector, and eyelets at opposite end of flexible printed wiring

Copyright Texas Education Agency, 2012. All rights reserved.

21

Name: ____________________________________ Class: ________ Date ___/___/___

E. Insert pins of male connector in eyelets of flexible wiring as shown in Figure 4

F. Solder pins to flat cable eyelets as shown

Copyright Texas Education Agency, 2012. All rights reserved.

22

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Unit Exam

Match the terms with their correct definitions. 1. Oxides a. The ability of molten solder to flow over and fuse completely with the metal surfaces to which it is applied b. Removing insulation from electrical conductors c. Films and impurities which form on the surface of metals when exposed to air or water and which, if not cleared off, will prevent a good bond between the surfaces and solder d. A material obtained from pine trees which is used during soldering to help ensure a good bond between the solder and the metal surfaces

2. Rosin 3. Wetting

4. Stripping

Match the terms with their correct definitions. 5. Tinning a. Applying mechanical pressure to compress a sleevetype or cup-type electrical terminal to ensure a good electrical connection between the sleeve and the conducting wire it contains b. Printed wiring attached to the surface of a printed circuit board c. A liquid or solid which when heated cleans and protects surfaces to be soldered d. The application of a small amount of solder to surfaces to be soldered to help ensure good wetting during soldering

6. Flux

7. Crimping

8. Land

Copyright Texas Education Agency, 2012. All rights reserved.

23

Name: ____________________________________ Class: ________ Date ___/___/___

Match the terms with their correct definitions 9. Solder sucker a. For making a strong mechanical connection to certain sleeve-type terminals b. For soldering many connections in close spaces

10. Component lead Cleaner 11. Thermal wire stripper

c. For removing melted solder from a terminal to be resoldered d. For removing wire insulation by heating and melting the material; prevents removing wire strands, but cannot be used on insulation that will not melt, such as glass braid or asbestos e. For removing oxides and other films from component leads

12. Resistance soldering Unit

13. Crimping tool

Match the soldering tools and material with their correct definitions 14. Soldering iron, 100 watt 15. Typewriter eraser 16. Soldering Vise 17. Diagonal cutting pliers 18. Solder a. For removing oxides and other films from terminals to be soldered b. For cutting conductors c. For making electrical connections d. For soldering large electrical connections e. For clamping and holding a printed circuit board or other component during soldering or other repair operations

Copyright Texas Education Agency, 2012. All rights reserved.

24

Name: ____________________________________ Class: ________ Date ___/___/___

Match the soldering tools and materials with their correct definitions 19. Isopropyl alcohol a. For ensuring a good electrical connection by cleaning and wetting all surfaces during soldering; not required if the solder contains a rosin core b. For drawing heat from soldered connection to prevent damage to components c. For removing oil, grease, and flux from conductors and terminals both before and after soldering d. For supporting a hot soldering iron when not in use e. For cutting and pulling insulation from ends of conductors

20. Mechanical wire Strippers 21. Heat sink

22. Flux

23. Soldering iron stand

24. Select the false statement about wire stripping and tinning. a. To remove oil, grease, and dirt, wipe with isopropyl alcohol and clean cloth b. To remove old solder, heat with a soldering iron and wick away, or suck up by means of a solder sucker c. Use a typewriter eraser to clean oxides from terminals d. To remove rosin flux, wipe or brush with glycerine water 25. Select the true statement about wire stripping and tinning. a. One slot in the wire strippers is used for all size wires b. Care must be taken not to remove wire strands when stripping c. Tinning applies only to the stripped wire, not to the soldering iron tip d. After tinning, the wire strands should not be visible through the solder 26. Which of the following is a true statement about soldering procedures? a. Movement of the wire while the solder solidifies will cause no harm b. It is not necessary to clean surfaces prior to soldering c. Strip and tin wires to be soldered d. A small 35-watt soldering pencil should be used for all electrical soldered connections

Copyright Texas Education Agency, 2012. All rights reserved.

25

Name: ____________________________________ Class: ________ Date ___/___/___

27. Which of the following is a false statement about soldering procedures? a. The following is the correct soldering procedure: Apply hot tip to terminal and wire, and apply solder to iron tip so that it will flow down onto the connection b. After the solder has cooled, the connection should be cleaned with isopropyl alcohol c. The heat sensitivity of components is an important factor to consider when choosing a soldering iron d. If mechanical connection is not possible, make sure component to be soldered is held stationary in vise or clamp to prevent movement during soldering 28. Which of the following is a true statement about the characteristics of good solder connection? a. Dull appearance b. Damaged insulation c. Solder spills d. No burnt areas on insulation 29. Which of the following is a false statement about the characteristics of good solder connection? a. Silvery, shiny appearance to solder surface b. Small pits or holes in solder surface c. Good wetting of solder to surface d. Solder completely covers connection, but contour of connection is still visible Match the types of poor solder connections with their causes 30. Burnt insulation 31. Dewetted solder joint 32. Excessive solder 33. Solder short 34. Insufficient solder a. too much solder applied b. Excessive heat or careless with iron c. Excessive solder or carelessness d. Too little solder applied e. Insufficient cleaning or insufficient use of flux

Copyright Texas Education Agency, 2012. All rights reserved.

26

Name: ____________________________________ Class: ________ Date ___/___/___

Match the types of poor solder connections with their causes 35. Disturbed joint a. Excessive heat applied, excessive iron application time, or lack of heat sink b. Insufficient heat c. Connection moved before solder solidified d. Excessive rosin or insufficient heat

36. Insulation damage 37. Rosin solder joint 38. Cold solder joint

39. A wire-to hole connection is what type of soldered connection? a. Butt connection b. Lap connection c. Partial mechanical connection prior to soldering d. Full mechanical connection prior to soldering 40. A wire-to flat connection could not be what type of soldered connection? a. Butt connection b. Lap connection c. Partial mechanical connection prior to soldering d. Full mechanical connection prior to soldering

Copyright Texas Education Agency, 2012. All rights reserved.

27

Name: ____________________________________ Class: ________ Date ___/___/___

Basic Electronics- DC Soldering and Circuit Fabrication Unit Exam KEY

Match the terms with their correct definitions. 1. Oxides c. a. The ability of molten solder to flow over and fuse completely with the metal surfaces to which it is applied b. Removing insulation from electrical conductors c. Films and impurities which form on the surface of metals when exposed to air or water and which, if not cleared off, will prevent a good bond between the surfaces and solder d. A material obtained from pine trees which is used during soldering to help ensure a good bond between the solder and the metal surfaces

2. Rosin 3. Wetting

d. a.

4. Stripping

b.

Match the terms with their correct definitions. 5. Tinning d. a. Applying mechanical pressure to compress a sleevetype or cup-type electrical terminal to ensure a good electrical connection between the sleeve and the conducting wire it contains b. Printed wiring attached to the surface of a printed circuit board c. A liquid or solid which when heated cleans and protects surfaces to be soldered d. The application of a small amount of solder to surfaces to be soldered to help ensure good wetting during soldering

6. Flux

c.

7. Crimping

a.

8. Land

b.

Copyright Texas Education Agency, 2012. All rights reserved.

28

Name: ____________________________________ Class: ________ Date ___/___/___

Match the terms with their correct definitions 9. Solder sucker c. a. For making a strong mechanical connection to certain sleeve-type terminals b. For soldering many connections in close spaces

10. Component lead Cleaner

e.

11. Thermal wire stripper d.

c. For removing melted solder from a terminal to be resoldered d. For removing wire insulation by heating and melting the material; prevents removing wire strands, but cannot be used on insulation that will not melt, such as glass braid or asbestos e. For removing oxides and other films from component leads

12. Resistance soldering Unit

b.

13. Crimping tool

a.

Match the soldering tools and material with their correct definitions 14. Soldering iron, 100 watt 15. Typewriter eraser 16. Soldering Vise d. a. For removing oxides and other films from terminals to be soldered b. For cutting conductors c. For making electrical connections d. For soldering large electrical connections e. For clamping and holding a printed circuit board or other component during soldering or other repair operations

a. e.

17. Diagonal cutting pliers b. 18. Solder c.

Copyright Texas Education Agency, 2012. All rights reserved.

29

Name: ____________________________________ Class: ________ Date ___/___/___

Match the soldering tools and materials with their correct definitions 19. Isopropyl alcohol c. a. For ensuring a good electrical connection by cleaning and wetting all surfaces during soldering; not required if the solder contains a rosin core b. For drawing heat from soldered connection to prevent damage to components c. For removing oil, grease, and flux from conductors and terminals both before and after soldering d. For supporting a hot soldering iron when not in use e. For cutting and pulling insulation from ends of conductors

20. Mechanical wire Strippers 21. Heat sink

e.

b.

22. Flux

a.

23. Soldering iron stand

d.

24. Select the false statement about wire stripping and tinning. a. To remove oil, grease, and dirt, wipe with isopropyl alcohol and clean cloth b. To remove old solder, heat with a soldering iron and wick away, or suck up by means of a solder sucker c. Use a typewriter eraser to clean oxides from terminals d. To remove rosin flux, wipe or brush with glycerine water 25. Select the true statement about wire stripping and tinning. a. One slot in the wire strippers is used for all size wires b. Care must be taken not to remove wire strands when stripping c. Tinning applies only to the stripped wire, not to the soldering iron tip d. After tinning, the wire strands should not be visible through the solder 26. Which of the following is a true statement about soldering procedures? a. Movement of the wire while the solder solidifies will cause no harm b. It is not necessary to clean surfaces prior to soldering c. Strip and tin wires to be soldered d. A small 35-watt soldering pencil should be used for all electrical soldered connections

Copyright Texas Education Agency, 2012. All rights reserved.

30

Name: ____________________________________ Class: ________ Date ___/___/___

27. Which of the following is a false statement about soldering procedures? a. The following is the correct soldering procedure: Apply hot tip to terminal and wire, and apply solder to iron tip so that it will flow down onto the connection b. After the solder has cooled, the connection should be cleaned with isopropyl alcohol c. The heat sensitivity of components is an important factor to consider when choosing a soldering iron d. If mechanical connection is not possible, make sure component to be soldered is held stationary in vise or clamp to prevent movement during soldering 28. Which of the following is a true statement about the characteristics of good solder connection? a. Dull appearance b. Damaged insulation c. Solder spills d. No burnt areas on insulation 29. Which of the following is a false statement about the characteristics of good solder connection? a. Silvery, shiny appearance to solder surface b. Small pits or holes in solder surface c. Good wetting of solder to surface d. Solder completely covers connection, but contour of connection is still visible Match the types of poor solder connections with their causes 30. Burnt insulation b. a. too much solder applied b. Excessive heat or careless with iron c. Excessive solder or carelessness d. Too little solder applied e. Insufficient cleaning or insufficient use of flux

31. Dewetted solder joint e. 32. Excessive solder 33. Solder short 34. Insufficient solder a. c. d.

Copyright Texas Education Agency, 2012. All rights reserved.

31

Name: ____________________________________ Class: ________ Date ___/___/___

Match the types of poor solder connections with their causes 35. Disturbed joint c. a. Excessive heat applied, excessive iron application time, or lack of heat sink b. Insufficient heat c. Connection moved before solder solidified d. Excessive rosin or insufficient heat

36. Insulation damage 37. Rosin solder joint 38. Cold solder joint

a. d. b.

39. A wire-to hole connection is what type of soldered connection? a. Butt connection b. Lap connection c. Partial mechanical connection prior to soldering d. Full mechanical connection prior to soldering 40. A wire-to flat connection could not be what type of soldered connection? a. Butt connection b. Lap connection c. Partial mechanical connection prior to soldering d. Full mechanical connection prior to soldering

Copyright Texas Education Agency, 2012. All rights reserved.

32

You might also like

- Philippine Vending Corporation: Outlet InformationDocument1 pagePhilippine Vending Corporation: Outlet InformationSocorro PerezNo ratings yet

- Resignation LetterDocument1 pageResignation LetterSocorro Perez50% (2)

- Academic Department Information Technology ProgramDocument2 pagesAcademic Department Information Technology ProgramSocorro PerezNo ratings yet

- Zamboanga City State Polytechnic College Performance Evaluation FormDocument3 pagesZamboanga City State Polytechnic College Performance Evaluation FormSocorro PerezNo ratings yet

- School Key OfficialsDocument17 pagesSchool Key OfficialsSocorro PerezNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Supporting References in Release 12 SLA PDFDocument8 pagesSupporting References in Release 12 SLA PDFsoireeNo ratings yet

- Communication and Globalization Lesson 2Document13 pagesCommunication and Globalization Lesson 2Zetrick Orate0% (1)

- Iso 20816 8 2018 en PDFDocument11 pagesIso 20816 8 2018 en PDFEdwin Bermejo75% (4)

- Facilitation TheoryDocument2 pagesFacilitation TheoryYessamin Valerie PergisNo ratings yet

- De La Salle Araneta University Grading SystemDocument2 pagesDe La Salle Araneta University Grading Systemnicolaus copernicus100% (2)

- Pilot SafetyDocument120 pagesPilot SafetyamilaNo ratings yet

- Pagan and Wiccan Quotes and GuidanceDocument8 pagesPagan and Wiccan Quotes and GuidanceStinkyBooNo ratings yet

- The Handmaid's Tale - Chapter 2.2Document1 pageThe Handmaid's Tale - Chapter 2.2amber_straussNo ratings yet

- How To Create Partner Function in SAP ABAPDocument5 pagesHow To Create Partner Function in SAP ABAPRommel SorengNo ratings yet

- Acfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptDocument1 pageAcfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptbbNo ratings yet

- Bab 3 - Soal-Soal No. 4 SD 10Document4 pagesBab 3 - Soal-Soal No. 4 SD 10Vanni LimNo ratings yet

- Report Body of IIDFC - 2Document120 pagesReport Body of IIDFC - 2Shanita AhmedNo ratings yet

- Domestic and Foreign Policy Essay: Immigration: Salt Lake Community CollegeDocument6 pagesDomestic and Foreign Policy Essay: Immigration: Salt Lake Community Collegeapi-533010636No ratings yet

- Respiratory Examination OSCE GuideDocument33 pagesRespiratory Examination OSCE GuideBasmah 7No ratings yet

- SPQRDocument8 pagesSPQRCamilo PeraltaNo ratings yet

- CN and OS Lab ManualDocument53 pagesCN and OS Lab Manualsudheer mangalampalliNo ratings yet

- ChitsongChen, Signalsandsystems Afreshlook PDFDocument345 pagesChitsongChen, Signalsandsystems Afreshlook PDFCarlos_Eduardo_2893No ratings yet

- Chapter 9 - PPT (New)Document43 pagesChapter 9 - PPT (New)Syarifah NourazlinNo ratings yet

- A Study On Investors Perception Towards Sharemarket in Sharekhan LTDDocument9 pagesA Study On Investors Perception Towards Sharemarket in Sharekhan LTDEditor IJTSRDNo ratings yet

- 10-C# Forms InteractionDocument22 pages10-C# Forms InteractionMaria Anndrea MendozaNo ratings yet

- Rita Ora - Shine Ya LightDocument4 pagesRita Ora - Shine Ya LightkatparaNo ratings yet

- Reported SpeechDocument2 pagesReported SpeechmayerlyNo ratings yet

- PSYC1111 Ogden Psychology of Health and IllnessDocument108 pagesPSYC1111 Ogden Psychology of Health and IllnessAleNo ratings yet

- Capgras SyndromeDocument4 pagesCapgras Syndromeapi-459379591No ratings yet

- Unidad 12 (libro-PowerPoint)Document5 pagesUnidad 12 (libro-PowerPoint)Franklin Suarez.HNo ratings yet

- Birds (Aves) Are A Group Of: WingsDocument1 pageBirds (Aves) Are A Group Of: WingsGabriel Angelo AbrauNo ratings yet

- Biosphere Noo Sphere Infosphere Epistemo PDFDocument18 pagesBiosphere Noo Sphere Infosphere Epistemo PDFGeorge PetreNo ratings yet

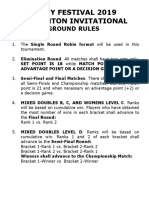

- Ground Rules 2019Document3 pagesGround Rules 2019Jeremiah Miko LepasanaNo ratings yet

- TypeFinderReport ENFPDocument10 pagesTypeFinderReport ENFPBassant AdelNo ratings yet

- Coronally Advanced Flap With Connective Tissue GraDocument13 pagesCoronally Advanced Flap With Connective Tissue GrasutriNo ratings yet