Professional Documents

Culture Documents

00 Saip 73

Uploaded by

Selvakpm06Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

00 Saip 73

Uploaded by

Selvakpm06Copyright:

Available Formats

Inspection Procedure

00-SAIP-73 Inspection Manning Determination Guidelines Document Responsibility: Inspection Department 26 October 2005

Saudi Aramco DeskTop Standards

Table of Contents

1 2 3 4 5 6 7 8

Scope............................................................. 2 Definitions...................................................... 2 Responsibilities.............................................. 3 Instructions..................................................... 3 Methodology................................................... 4 Other Factors Affecting Manpower Determination....................... 6 Datasheet Population..................................... 6 Calculation Module........................................ 8

Attachment I Data Entry/Output Form............... 9

Previous Issue: New

Next Planned Update: 1 November 2010 Page 1 of 9

Primary contact: Nasser M. Balhareth on 874-5018

CopyrightSaudi Aramco 2009. All rights reserved.

Document Responsibility: Inspection Department Issue Date: 26 October 2005 Next Planned Update: 1 November 2010

00-SAIP-73 Inspection Manning Determination Guidelines

Scope This Saudi Aramco Inspection Procedure (SAIP) provides guidelines for estimating the optimum manning levels of the plant inspection units (PIUs). This procedure can be used by either the Inspection Department when conducting the plant inspection unit assessment or the plant inspection units when assessing their manpower needs. It provides a consistent measure for level of manning in PIUs.

Definitions Inspection Unit Time (IUT): A unit of time required to conduct a single thorough inspection on the largest plant equipment in a facility. For this module, a power boiler is the largest plant equipment, and the unit of time equals three hours. Total Calendar Man-Hours (TCMH): The calendar year man-hours based on a 40hrs/week work schedule per person. The TCMH used for calculations in this module is 2080 Mhrs/year. Non Work-Available Calendar Man-Hours (NWACMH): The time lost on vacations (176 Mhrs/yr) medical appointments (32 Mhrs/yr), occasional absence (40 Mhrs/yr), training (80 Mhrs/yr), rescheduled days-off (80 Mhrs/yr), Ramadan (40 Mhrs/yr), breaks (260 Mhrs @ 1 hrs/day). The NWACMH used for calculations in this module is 708 Mhrs/year.

Commentary Note: The Non Work-Available Calendar Man-Hours (NWACMH) is based on input from practicing inspection personnel. The model makes some approximations such as that all manpower is Aramcons and Muslims which reduces their work-available man-hours.

Work-Available Calendar Man-Hours (WACMH): The total calendar man-hours (TCMH) minus the Non Work-Available Calendar Man-Hours (NWACMH). This is equal to 1372 man-hours. Effective Man-Hours (EMH): The Man-Hours that can be dedicated for inspection related activities. The effective Man-Hours are a function of the direct inspection experience level and the Work-Available Calendar Man-Hours. Required Man-Hours (RMH): The calculated inspection eman-hours required by a given inspection unit to provide the needed inspection coverage for routine and T&I related activities by each inspection group. Facility Condition Factor (FCF): A correction factor to get the optimum manning level within an inspection unit. The FCF is a function of the average plants age, the unit average direct inspection experience level and the facility's use of a management of change program. Approved Unit Full Jobs: These are approved budget slots for the unit in the department's organization structure. These correspond to specific job codes in a job ladder of a job family. The approved full jobs are used for analytical purposes only in

Page 2 of 9

CopyrightSaudi Aramco 2009. All rights reserved.

Document Responsibility: Inspection Department Issue Date: 26 October 2005 Next Planned Update: 1 November 2010

00-SAIP-73 Inspection Manning Determination Guidelines

comparison to the optimum manpower and the existing manpower. They are not used in the calculations. Grade Code Group (GC): A Grouping of Grade Codes (GC7-8, 9-10, 11-12, 13) within an inspection discipline or work group (PE&W, Elec., Civil, etc.) within an inspection unit. This grouping is used to simplify the breakdown of inspectors within a discipline or a group for ease of calculation of the average experience level and manhours per discipline or group. 3 Responsibilities 3.1 It is the responsibility of the operating organization management to ensure that their plant inspection units (PIUs) are sufficiently manned with qualified manpower to: 3.1.1 Provide adequate inspection coverage to all plant areas and support facilities within their responsibility as defined in SAEP-20 and SAEP-309 respectively. Establish, maintain, administer and optimize other inspection and corrosion control programs such as relief valves administration and OSI, etc. Ensure that inspection programs are properly and efficiently administered. This should include a corrosion control / cathodic protection engineer, and a full or part time dedicated training coordinator (based on PIU size) to ensure that development, training and certification needs of inspection personnel are properly addressed. Conduct self assessments of the various inspection programs to maximize the return from such programs.

3.1.2

3.1.3

3.1.4 3.2

PIU supervisors are responsible for anticipating and providing manpower forecasts in their departments' business plans to offset manpower attrition due to retirement, Chronic Medical Condition (CMC) cases and transfers.

Instructions 4.1 The data required for manpower determination includes but not limited to: 4.1.1 4.1.2 The various inspection programs administered by an inspection unit, The frequency of T&Is in relation to the number of static plant equipment, The facility remoteness from inspection offices, The level of direct inspection experience of each grade code (GC) group within an inspection discipline in a PIU,

4.1.3 The number of issued versus open work sheets, 4.1.4 4.1.5

Page 3 of 9

CopyrightSaudi Aramco 2009. All rights reserved.

Document Responsibility: Inspection Department Issue Date: 26 October 2005 Next Planned Update: 1 November 2010

00-SAIP-73 Inspection Manning Determination Guidelines

4.1.6 4.1.7 4.1.8 4.2

The average facility age and whether the facility has a documented and effective management of change procedure, The frequency and extent of on-stream inspection programs inclusive of special surveys, The contribution of the unit's personnel to non-core inspection activities such as special projects, and support to other organizations.

The module estimates the manpower needs for each discipline (i.e., mechanical, electrical, civil, etc.) and indicates whether there is a deficiency or excess in manpower. Facilities that conduct their T&I's on the bases of total facility shutdown at fixed intervals (5, 7 or 10 years) should not include man-hours needed for the purpose of the T&Is in the overall manpower calculations. For optimum manning, such facilities should not be manned for an activity that takes place once every 5 or 7 years. Instead, these facilities should rely on manpower support during T&I from other plants, contractors or Inspection Department. Facilities which frequently have a number of 5, 7 or 10-year T&I's that occur within any calendar year should include man-hours needed, particularly if a three 8-hour, or two 12hour shift system is used to provide coverage on a 24-hour basis. Upon filling the excel spreadsheet with the required data, the excel program estimates the variance between the Work Available Man-Hours and the Required Man-Hours and converts the variance into manpower figures.

4.3

4.4

Methodology 5.1 The module is designed to estimate the man-hours needed to provide inspection coverage on day-to-day activities and during major shutdowns and T&I's per calendar year and compare it to the Work Available Man-Hours (WAMH) per inspection group. The variance is converted to excess or additional manpower per each inspection group and the optimum unit overall manning level exclusive of the unit supervisor is determined accordingly. The module utilizes an experience-based estimate of the amount of time it takes an inspector to conduct a single thorough inspection on the largest piece of equipment in the facility and the number of inspections conducted on the same equipment for the same purpose. For this exercise, a power boiler is considered the largest piece of equipment in Saudi Aramco facilities that requires an average of three hours for a single comprehensive inspection on all of its components. It is also estimated that during T&Is and routine worksheet related inspections, an inspector will need to conduct at least two thorough inspections and three follow-up inspections. To account for the difference in the size of equipment and the extent of the required inspections, each inspection activity / equipment type is assigned a

Page 4 of 9

5.2

5.3

CopyrightSaudi Aramco 2009. All rights reserved.

Document Responsibility: Inspection Department Issue Date: 26 October 2005 Next Planned Update: 1 November 2010

00-SAIP-73 Inspection Manning Determination Guidelines

weight factor to determine the percentage of Inspection Unit Time (IUT) spent during a single inspection. (i.e.: 1 for a power boiler, 0.8 for a tall trayed column, 0.7 for a sphere, 0.6 for a pressure vessel, etc.) 5.4 The required man-hours for all inspection activities is determined in a similar fashion with the exception of activities requiring single inspections where the amount is multiplied by a pre-determined quantity (number) of inspection time required for such activities. For example, to determine the Man-Hours required for conducting inspection on relief valves (RVs) by a dedicated RV administrator, the total number of RVs is divided by their T&I interval to obtain the annual number and the result is multiplied by 0.333 (20 minutes / RV) plus the result of the total number of RVs divided by 2 multiplied by 0.167 (10 minutes / RV) if the administrator is also conducting the external inspection of the RVs as well. Otherwise, the result of the external RVs inspection is added to the mechanical inspection required man-hours for the plant equipment / welding inspectors. As a rule of thumb, for determining the man-hours required for a certain type of equipment or activity, the number of equipment or activity is divided by its frequency of inspection (T&I cycle) to get the annual figure, then the number is multiplied by its assigned inspection unit time weight factor, the number of inspections required, and the predetermined inspection unit time of 3 hours. 5.5 The other side of the calculation is based on the effective man-hours (EMH) concept. The direct inspection experience level of inspection personnel and the Work Available Calendar Man-Hours (WACMH) are the two variables governing this calculation. For example, junior inspectors spend more time on handling a certain inspection activity and on training assignments than senior inspectors. Hence, their EMH is considered lower than their WACMH. Field supervisors and senior inspectors, on the other hand, should have mastered their inspection tasks and should have completed most of their training needs which makes their EMH closer to their WACMH. 5.6 To determine the EMH of the various inspection personnel, the WACMH for inspectors in an inspection group is multiplied by the average of direct inspection experience for a grade code group (GC 7-8, 9-10, 11-12, 13) within an inspection group (PE&W, Elec., Civil, etc.). The calculated EMH for the inspection group is then compared to the RMH of the group and the result indicates whether additional man-hours are needed or excess man-hours are available. 6 Other Factors Affecting Manpower Determination 6.1 Manpower determination is affected by the remoteness of facilities covered by a given inspection unit, and the condition of the facilities under inspection in

Page 5 of 9

CopyrightSaudi Aramco 2009. All rights reserved.

Document Responsibility: Inspection Department Issue Date: 26 October 2005 Next Planned Update: 1 November 2010

00-SAIP-73 Inspection Manning Determination Guidelines

terms of their age and whether the facility has an effective management of change procedure. The overall experience level within an inspection unit also affects the calculation. 6.2 For PIU's covering remote facilities to offset the time spent on travel, one (1) hour of travel time per 50 km or a constant eight hours for flying is multiplied with the group's share of the open and closed worksheets and the result added to the Required Man-Hours (RMH) for each group. Round trips as well as the number of inspections spent on open and closed worksheets are considered in the calculation. The overtime spent on non-T&I / major shutdown related activates will be directly added to each group's RMH based on the ratio of the group's RMH, exclusive of over time and travel time, to the Total Unit RMHs. A Facility Condition Factor (FCF) has also been introduced to account for the facility age, operating practices, inspection expertise, and whether the facility is implementing a written and effective Management of Change (MOC) procedure. This factor is multiplied with the variance in manpower for each inspection group to get the optimum manpower level required for that inspection group.

6.3

6.4

Datasheet Population The performance of the calculation module is dependant on the accurate population of its data sheet. To ensure that the sheet is user friendly, directive comments are posted in all data fields. The datasheet is divided into eleven main fields each containing several sub-fields. A brief description of the main fields is provided below: 1. Operating Information: This field includes plant data such as facility age, and whether the facility has an effective management of change. The facility age is an arithmetic average of the age of all plants within the facility. Information in this field coupled with the calculated inspection Unit experience level is essential for determining the Facility Condition Factor (FCF) required for calculating the optimum manning level. Manpower: This field includes a break down of available manpower by discipline, grade code, and average years of direct inspection experience. Individuals such as training coordinators, draftsmen, clerks as well as permanently or temporally assigned engineers who are not directly involved in providing direct inspection coverage or the administration of other inspection or corrosion control programs are not included in this module. Equipment: This field provides an account for all static plant equipment subject to T&I. For ease of calculations, the equipment are broken down to four T&I cycle groups (12~24, 36~48, 60~84, & 120 months). In calculating the required Man-Hours, the average T&I cycle is used (i.e.: 1.5, 3.5, 6 and10 years). Each equipment type is assigned a weight factor related to its size and the inspection time it takes.

Page 6 of 9

2.

3.

CopyrightSaudi Aramco 2009. All rights reserved.

Document Responsibility: Inspection Department Issue Date: 26 October 2005 Next Planned Update: 1 November 2010

00-SAIP-73 Inspection Manning Determination Guidelines

4.

Inspection Programs: All data related to inspection programs such as external inspection, OSI, electrical, civil as well as corrosion control programs related data are provided under this field. Comments are provided at each program section explaining how the data is used for the different inspection groups and the time it takes to complete each inspection activity. Design Review Packages: All engineering design packages that undergo inspection review are broken down in this field. Comments are provided at this section explaining how the data is used for the different inspection groups and the time it takes to complete packages review. Approved Unit Full Jobs: The approved unit full jobs are listed under this field for analytical purposes upon comparison of the optimum manpower to the existing manpower. Worksheets / Year: The number of issued and closed worksheets in a calendar year is specified in this field. For the purpose of calculation, worksheets are assigned a weight factor of 0.5 of a 3 hours inspection unit times. The discipline inspector will on the average dedicate three inspection unit times per worksheet. Corrosion Control Programs: All corrosion control programs are included under this field. Comments are provided at each section explaining how the data is used and the time it takes to complete them. Project Support: This field is dedicated for the manpower support to projects provided by the plant inspection unit. Comments are provided at this section for utilization of the man-hours spent on project support with respect to each inspection group. Average Total Overtime / Year: The overtime spent by all inspection personnel including contractors is entered in this field to indicate the over utilization of the unit personnel. The overtime hours is added to the group needed man-hours based on the ratio of the group required man-hours to the overall unit required manhours. Paid and un-paid overtime shall be considered to give a more accurate reflection of man-hours associated with performing inspection activities.

5.

6.

7.

8.

9.

10.

11.

Travel Distance: This field is provided for inspection units that provide inspection coverage to areas not within one fence such as the case for producing and distribution facilities. The travel time is a function of the number of open and closed worksheets multiplied by the number of inspections conducted at a ratio of 1hr/50km. For flights, a constant eight hours is multiplied instead of the ratio. In both cases the round trip is also considered. The resulting value is shared by the different inspection groups based on their share of the issued worksheets.

Calculation Module

Page 7 of 9

CopyrightSaudi Aramco 2009. All rights reserved.

Document Responsibility: Inspection Department Issue Date: 26 October 2005 Next Planned Update: 1 November 2010

00-SAIP-73 Inspection Manning Determination Guidelines

The attached Data Entry form is used for collecting the required data for performing the manning calculations. The latest calculation program can be downloaded from the Inspection Department website.

Revision Summary New Saudi Aramco Inspection Procedure.

26 October 2005

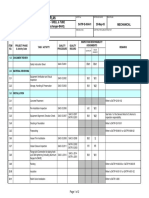

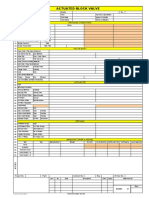

Attachment I. Data Entry/Output Form for Recommended Manning Calculation Module for Plant Inspecti

Inspection Unit Information (1) Operating Example

M.O.C Used

Date Prepared

% over Design Capacity

5

Facility Age (yrs)

No

Current

Required

OSI / NDT Related

5 Manpower

7-8 9-10 11-12

32

13

(2)

Discipline

Recommended Manning Levels PE / W Inspection 0.4 Civil Insp. Electrical Insp. 1.18 R/V Insp. OSI/NDT Insp. 1.7 Corr. Control 8.49 Unit Avg. Expereince Level Total (3) Equipment

Avg.

(4) 0.6 0.4 0.5

years

Ins

Type

OSI TM

27.9

Nippl

PE&W Insp.

PE&W Avg. Experience

2 2 3 6 2 6 1 5 1 5 2 4

2 8 2 10 1 9 5 10 1 10

2 10 13

3 15 1 15 1 15 1 14

9.0 8.8

Type Columns

T&I Frequency (months)

12-24

Inject Dead

36-48

60 - 84

120

CUI lo

9 26 1 17 3 0 46 0 0 1 0 0 1108 0

13

0 5 0 0 0 0 32 0 0 0 0 0 93 0

(7) 14

0 208 4 0 0 17 143 190 0 0 65 0 63 0

Issued

18 277 35 0 0 0 15 35 0 0 0 0 0 0

Closed

Specia

Elec. Avg. Experience

Civil Inspectors

Civil Avg. Experience

Ext. Insp. Elec. Insp. Civil Insp. Corrosion Control Programs (8)

Elec.Inspectors

6.0 Vessels 11.0 Drums 4.0 Tanks 10.0 Boilers 7.0 Htr./Frn./Flr. 9.7 Spheres 2.0 7.5 3.0

Exch./Cond. Fin Fans Rd Crossing

Pipin

Relief

Plant

OSI/NDT Tech.

OSI Avg. Experience

Subs

Supp

RV Inspectors

RV Avg. Experience

Plant

CC.& CP Insp.

CC& CPAvg. Experience

1 9 1 6 46

8

Misce Supp

6.5

CC.& CP Engr.

CC&CP Avg. Experience

(5) Design Pkgs/

yr.

Corro. Mech Elec.

Civil

2 7 3

46

9

46

10

6.5 Loadg Fclty. 1.0 U/G H.C pip. 6.0 Supt. Faclty OSI R. Valves Misc. 2

Grade Codes

Probe

Coupo

Pot. S Trans

(6) Approved Unit Full Jobs (9) Project Support

Worksheets/ yr

5

Civil

7

GC9

11 3

12

Anode

7

Discipline P&E/Welding Corrosion

0

GC9

0

GC10

264

GC11+ (10)

243

Total Over Time/ yr.

Others

Discipline Electrical

GC10 GC11+

Ro

1 1

1 1

Note: All Cells in White Should be filled as appropriate

Page 8 of 9

CopyrightSaudi Aramco 2009. All rights reserved.

You might also like

- SAEP-31 Corporate Equipment DataDocument5 pagesSAEP-31 Corporate Equipment DataHabib ShinwariNo ratings yet

- Saep 31Document5 pagesSaep 31Anonymous 4IpmN7OnNo ratings yet

- Inspection ProcedureDocument10 pagesInspection ProcedureErin JohnsonNo ratings yet

- Inspection Procedure for Determining Retirement Thickness of PipingDocument6 pagesInspection Procedure for Determining Retirement Thickness of Pipingmalika_00No ratings yet

- 00 Saip 71Document19 pages00 Saip 71balajiNo ratings yet

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- Offshore hook-up and commissioning work proceduresDocument5 pagesOffshore hook-up and commissioning work proceduresanjangandak2932No ratings yet

- GIS 18-020 Welding of Subsea Equipment - Control Tubing: Group Instruction For SupplyDocument9 pagesGIS 18-020 Welding of Subsea Equipment - Control Tubing: Group Instruction For Supplypushloop1243No ratings yet

- Inspection Procedure: Saudi Aramco Desktop StandardsDocument90 pagesInspection Procedure: Saudi Aramco Desktop Standardssheikmoin100% (1)

- Loc ProcessDocument76 pagesLoc Processuserscribd2011No ratings yet

- 1 What Is Functional Safety, SIF, SISDocument17 pages1 What Is Functional Safety, SIF, SISAlice LinNo ratings yet

- 1044 Plant Inspection Career Poster March 2015 PDFDocument1 page1044 Plant Inspection Career Poster March 2015 PDFHoque Anamul100% (1)

- Saes A 007 PDFDocument29 pagesSaes A 007 PDFsindalisindiNo ratings yet

- Saep 20 PDFDocument25 pagesSaep 20 PDFbrecht1980100% (1)

- Active Doc ListDocument360 pagesActive Doc ListLeo NunnikhovenNo ratings yet

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Document20 pagesAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimNo ratings yet

- 00 Saip 80 PDFDocument90 pages00 Saip 80 PDFsaghir hassanNo ratings yet

- 031Document5 pages031Mohamad ShafeyNo ratings yet

- Sabp P 012 PDFDocument8 pagesSabp P 012 PDFfaisalqrNo ratings yet

- 00 Saip 80Document75 pages00 Saip 80heidarNo ratings yet

- Sabp A 033B PDFDocument11 pagesSabp A 033B PDFINSTECH ConsultingNo ratings yet

- 01 Saip 04Document17 pages01 Saip 04munnaNo ratings yet

- New Heat ExchangerDocument12 pagesNew Heat ExchangerMosaddekNo ratings yet

- Saudi-Arabian-Engineering-Standardssaes-J-001 PDFDocument11 pagesSaudi-Arabian-Engineering-Standardssaes-J-001 PDFsalasineNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Saep 325Document43 pagesSaep 325AbdullahNo ratings yet

- Saep 1144Document23 pagesSaep 1144Amit shahNo ratings yet

- 5-Mechanical Integrity Program-021317 508Document12 pages5-Mechanical Integrity Program-021317 508sarifinNo ratings yet

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Document2 pages1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNo ratings yet

- Sabp A 049 PDFDocument10 pagesSabp A 049 PDFWalid Megahed100% (1)

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Topside Inspection Procedure for Pressure VesselDocument54 pagesTopside Inspection Procedure for Pressure VesselIksan Adityo Mulyo100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- Saes y 301Document10 pagesSaes y 301kartik_harwani4387No ratings yet

- Integrity Verification of Safety Critical ElementsDocument1 pageIntegrity Verification of Safety Critical ElementsAnonymous 1XHScfCINo ratings yet

- 32 Saip 11Document9 pages32 Saip 11malika_00No ratings yet

- SATR-J-6913 Rev 0 PDFDocument6 pagesSATR-J-6913 Rev 0 PDFAdel KlkNo ratings yet

- Saep 318Document28 pagesSaep 318brecht1980No ratings yet

- GS EP EXP 407 05 Appendix3 Escape GenericPerformanceStandardsDocument181 pagesGS EP EXP 407 05 Appendix3 Escape GenericPerformanceStandardsAzeemNo ratings yet

- Ahmed QatargasDocument26 pagesAhmed QatargastotpityiNo ratings yet

- 34 Samss 611Document8 pages34 Samss 611naruto256No ratings yet

- Saep 125Document9 pagesSaep 125brecht1980No ratings yet

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Document15 pagesSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- Dokumen - Tips Saep-1135pdfDocument12 pagesDokumen - Tips Saep-1135pdfArsalan HaiderNo ratings yet

- Saep 303Document59 pagesSaep 303Demac SaudNo ratings yet

- Comment Resolution Sheet 19009 Welding DossierDocument1 pageComment Resolution Sheet 19009 Welding DossierDheeraj E MohananNo ratings yet

- 23 Samss 020Document44 pages23 Samss 020Cherukunnon Jubu100% (1)

- Saep 20Document33 pagesSaep 20Daniel MeanaNo ratings yet

- ES.0.08.0002 Rev.B - Engineering Data Request Form PDFDocument1 pageES.0.08.0002 Rev.B - Engineering Data Request Form PDFSaravanan VaradarajanNo ratings yet

- Saep 1630Document10 pagesSaep 1630faisalqr100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument14 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- Inspection Procedure: 00-SAIP-71 31 January 2005 Plant Inspection Index Document Responsibility: Inspection DepartmentDocument21 pagesInspection Procedure: 00-SAIP-71 31 January 2005 Plant Inspection Index Document Responsibility: Inspection Departmentaamirtec301No ratings yet

- Inspection Technical Procedure I-115 STR STL Welding InspectionDocument20 pagesInspection Technical Procedure I-115 STR STL Welding InspectionELongLeeNo ratings yet

- Calculation PoF and CoFDocument10 pagesCalculation PoF and CoFHamidNo ratings yet

- Sabp A 001Document20 pagesSabp A 001Shahid Basha Syed100% (2)

- Updating MLC e f3 - Module 1Document72 pagesUpdating MLC e f3 - Module 1LoverMind CabaronNo ratings yet

- Saep 309Document22 pagesSaep 309brecht1980No ratings yet

- Sabp G 008Document78 pagesSabp G 008Mahesh Kumar100% (1)

- Production System IsDocument6 pagesProduction System IsAnjali AgrawalNo ratings yet

- 2004 Generator Testing - Background & Calculation of Commissioning ChargesDocument11 pages2004 Generator Testing - Background & Calculation of Commissioning ChargesHemanth MalakalapalliNo ratings yet

- Welding Insp. Tech. WorkBook2Document3 pagesWelding Insp. Tech. WorkBook2Selvakpm06No ratings yet

- Sabp A 015Document58 pagesSabp A 015sethu1091100% (5)

- Welding Insp. Tech. WorkBook PDFDocument77 pagesWelding Insp. Tech. WorkBook PDFSelvakpm06No ratings yet

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- Sa 2635Document24 pagesSa 2635Selvakpm06No ratings yet

- Visual Inspection - AWS & BS PDFDocument22 pagesVisual Inspection - AWS & BS PDFSelvakpm06No ratings yet

- Military Standard Mil-Std-130m PDFDocument45 pagesMilitary Standard Mil-Std-130m PDFSelvakpm06No ratings yet

- Fabrication Tolerances 51G14r1Document7 pagesFabrication Tolerances 51G14r1Selvakpm06100% (1)

- Steel StandardsDocument247 pagesSteel Standardsczemen67% (3)

- Iso 8502 3 PDFDocument15 pagesIso 8502 3 PDFFernandoi83% (6)

- 32 Samss 005 PDFDocument33 pages32 Samss 005 PDFRajan SteeveNo ratings yet

- Coded MarkDocument2 pagesCoded MarkSelvakpm06No ratings yet

- 9795 1 PDFDocument15 pages9795 1 PDFSushil DhunganaNo ratings yet

- Pip Stf05530 GratingDocument6 pagesPip Stf05530 GratingSelvakpm06No ratings yet

- STF 05530Document13 pagesSTF 05530aby_abraham5005No ratings yet

- Leakage Test by Feeler Gauge - FSA-HIPD-801-10Document3 pagesLeakage Test by Feeler Gauge - FSA-HIPD-801-10Selvakpm06No ratings yet

- Irsm Vs Astm A242Document1 pageIrsm Vs Astm A242Selvakpm06No ratings yet

- TriMarkCatalog PDFDocument50 pagesTriMarkCatalog PDFSelvakpm06No ratings yet

- BrochureWeldability EN PDFDocument39 pagesBrochureWeldability EN PDFAl0611981No ratings yet

- Saep 1142Document7 pagesSaep 1142Selvakpm06No ratings yet

- Handbooksa8000 FDocument7 pagesHandbooksa8000 FSelvakpm06No ratings yet

- Psychrometric chart: grains and pounds of moisture per dry airDocument2 pagesPsychrometric chart: grains and pounds of moisture per dry airSelvakpm06No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSelvakpm06No ratings yet

- General purpose ball valves specificationDocument3 pagesGeneral purpose ball valves specificationSelvakpm06No ratings yet

- Code Ref.Document155 pagesCode Ref.Selvakpm06No ratings yet

- 09 Samss 069 PDFDocument10 pages09 Samss 069 PDFSelvakpm06100% (1)

- Military Standard Mil-Std-130m PDFDocument45 pagesMilitary Standard Mil-Std-130m PDFSelvakpm06No ratings yet

- Painting Procedure (Ap110550-M023-B, Rev.d)Document18 pagesPainting Procedure (Ap110550-M023-B, Rev.d)Selvakpm06No ratings yet

- IMOA Shop Sheet 1087 PDFDocument2 pagesIMOA Shop Sheet 1087 PDFSelvakpm06No ratings yet

- NeboshDocument117 pagesNeboshmuruganNo ratings yet

- The Performing Style of Alexander Scriabin by Anatole LeikinDocument6 pagesThe Performing Style of Alexander Scriabin by Anatole LeikinRobert MorrisNo ratings yet

- D000-EL-701 Rev 4Document19 pagesD000-EL-701 Rev 4Sardar PerdawoodNo ratings yet

- DSS2060D Actuated Block Valve DatasheetDocument1 pageDSS2060D Actuated Block Valve Datasheetkrishna kumarNo ratings yet

- Neurodiagnostic TechnologyDocument3 pagesNeurodiagnostic TechnologyJeyarajasekar TtrNo ratings yet

- Smart Selangor Briefing and Invitation to Express InterestDocument30 pagesSmart Selangor Briefing and Invitation to Express InterestKUSATEX AZMI0% (1)

- Non-isometric centrifugal fan blades reduce noiseDocument5 pagesNon-isometric centrifugal fan blades reduce noiseVitthal KhandagaleNo ratings yet

- Design and analyze a non-inverting op-amp circuit with gain of 10Document7 pagesDesign and analyze a non-inverting op-amp circuit with gain of 10Mandeep KaloniaNo ratings yet

- IPC-7351A & PCBL Land Pattern Naming ConventionDocument6 pagesIPC-7351A & PCBL Land Pattern Naming ConventionSri ramNo ratings yet

- OpenSees Geotechnical Analysis Workshop 2017Document70 pagesOpenSees Geotechnical Analysis Workshop 2017Tariq MahmoodNo ratings yet

- Annotated BibliographyDocument2 pagesAnnotated BibliographyWinston QuilatonNo ratings yet

- Major ICT and manufacturing companies in EthiopiaDocument3 pagesMajor ICT and manufacturing companies in EthiopiafiraolNo ratings yet

- Mphasis - JD - 2021 PassoutsDocument1 pageMphasis - JD - 2021 PassoutsMohamed aslamNo ratings yet

- Dilg Joincircular 2018814 - 80736aa36cDocument10 pagesDilg Joincircular 2018814 - 80736aa36clexay.mangadosiervoNo ratings yet

- Sand Slinger MC Pneumatic 2016 VeltechDocument47 pagesSand Slinger MC Pneumatic 2016 VeltechChockalingam AthilingamNo ratings yet

- Muh Eng 50hzDocument8 pagesMuh Eng 50hzaleks canjugaNo ratings yet

- Mini Project-Process ControlDocument22 pagesMini Project-Process ControlthenmolhiNo ratings yet

- Fiber Reinforced Plastics & Laminates GuideDocument32 pagesFiber Reinforced Plastics & Laminates GuideMercyJatindroNo ratings yet

- Hydrogen EngineDocument4 pagesHydrogen EnginerajmehaNo ratings yet

- 00250621DVSH00011 Exde02 34Document34 pages00250621DVSH00011 Exde02 34manish318No ratings yet

- Lobbying Vacations For CongressDocument54 pagesLobbying Vacations For CongressBigMamaTEANo ratings yet

- Section 06 - Hole CleaningDocument81 pagesSection 06 - Hole CleaningRicardo Villar100% (2)

- Consistent Engineering Units in FEADocument6 pagesConsistent Engineering Units in FEAAntonis AlexiadisNo ratings yet

- Versidrain 150: Green RoofDocument2 pagesVersidrain 150: Green RoofMichael Tiu TorresNo ratings yet

- Oleh - Fadli Satrio Fadjri - Prof. Dr. Ing. Ir. Rudi Rubiandini R.SDocument3 pagesOleh - Fadli Satrio Fadjri - Prof. Dr. Ing. Ir. Rudi Rubiandini R.SGusti PanuntunNo ratings yet

- Abb FFWD 3 16 V 8 PDFDocument36 pagesAbb FFWD 3 16 V 8 PDFAnonymous N13JdnNo ratings yet

- Manual Solis-RSD-1G - V1.0 9 0621 - 27 V6Document9 pagesManual Solis-RSD-1G - V1.0 9 0621 - 27 V6Long ComtechNo ratings yet

- Advanced S DOS Programming Microsoft Programmers PDF 9ededd7e1Document2 pagesAdvanced S DOS Programming Microsoft Programmers PDF 9ededd7e1Ojas Telwane100% (1)

- Squid InvaderDocument14 pagesSquid InvaderMikhail Roy Dela CruzNo ratings yet

- MCT Mkvie OmDocument4 pagesMCT Mkvie Omnabil160874No ratings yet

- Ubd WonderDocument13 pagesUbd Wonderapi-422461005100% (1)